Removing carbon deposits and soot

Important! Before starting cleaning procedures, it is necessary to turn off the gas and water supplies. To tidy up that part of the gas water heater that is responsible for the gas supply, it is recommended to call gas workers

Because this is a rather complicated procedure that requires disassembling all elements and parts of the equipment

To put in order the part of the gas water heater that is responsible for the gas supply, it is recommended to call gas workers. Because this is a rather complicated procedure that requires disassembling all elements and parts of the equipment.

If you still start doing all the work yourself, you need to completely remove the gas unit from the device. Then you need to open the water and loosen the nut that secures the pipe and the water unit: everything that is in the heat exchanger will flow out through the tap (it should be left open).

After this, the remaining nuts are loosened and the assembly is removed. If something interferes with the free removal of the heat exchanger, you need to disassemble these parts as well.

Advice! To ensure that all fasteners can be loosened easily, you need to use an aerosol product, the most popular of which is WD40. It can be purchased at any hardware or construction store.

When dismantling the unit, you need to cover the burner nozzles so that soot does not fall into them.

After this, you can put the heat exchanger in a basin or bathtub and clean it with detergents and a brush.

It is then thoroughly dried and the entire structure is put back together.

Those people who do not dare to undertake such a complex procedure at home can also do something on their own:

- Clean the holes through which the gas is supplied

- Clean soot from the radiator using a brush

- Check for leaks

- Improve the operation of the chimney

The holes are cleaned using copper or aluminum wire. It needs to be pushed inside the jets and soot and carbon deposits removed.

After this, you need to check for gas leaks. To do this, you need to prepare a soap solution and apply it to all joints. When gas is supplied, bubbles begin to appear. If this happens, you need to immediately turn off the gas and call the gas workers.

In some cases, poor traction may be the cause of unit malfunctions. To find out, you need to check for traction using a match or a lit candle. If the ventilation duct is not functioning, it will need to be thoroughly cleaned.

How to know when it’s time to clean your gas water heater

Cleaning the gas water heater is necessary if:

- The speaker does not turn on or turns off after working for a while. At the same time, it is known for sure that gas and water enter the column.

- The column's thermal protection sensors are constantly triggered. The scale layer has a porous structure and has heat-insulating properties, which interferes with normal cooling of the column.

- The efficiency of the column has noticeably decreased: during normal operation of the burner, the water heats up much less.

- Weak pressure at the outlet of the column with normal pressure at the inlet. Water cannot get through channels blocked by scale.

Cleaning the water intake unit

The water receiving unit is installed at the inlet of the water supply system of the column, has a mesh filter to prevent clogging of the heat exchanger tubes with large particles of rust and sediment, as well as a membrane for automatic gas supply when the water tap is turned on.

- We remove the water intake unit from the column body.

- After unscrewing the connecting screws, we open the case.

- We clean the filter and rinse it with strong water pressure.

- Checking the membrane. The membrane must be flat; if the membrane has a pronounced concavity, it means that it has exhausted its service life and must be replaced. You can replace the “native” membrane of the old speaker with a modern silicone one, which has a much longer service life.

- We close the cover of the water intake unit, tighten the screws and tighten the diametrically opposed pairs of screws one by one. This ensures uniform membrane tension.

Cleaning the heat exchanger

- Disconnect the water inlet and outlet tubes into the heat exchanger. If the heat exchanger is not cleaned regularly, the fastening nuts may become clogged with scale, preventing their removal. In this case, we recommend using a special liquid, VD-40, which can be purchased at any auto store. It is necessary to drip liquid into the joints of the nuts using an oil can. You can also use “Silit” for scale. After 15-30 minutes, the nuts can be unscrewed. If that doesn't work, try tapping the nut from all sides.

- After disconnecting the heat exchanger, use a funnel to pour descaling agent into it. A solution of 100 g of citric acid per 0.5 liter of hot water is perfect for such a remedy. You can also clean the heat exchanger with nine percent table vinegar diluted with water in a ratio of one to three. But using hydrochloric acid is not recommended, as it can react with the metal from which the heat exchanger is made, which will only worsen the situation. Leave the solution inside the heat exchanger overnight.

- Drain the solution thoroughly. If you do not remove the scale that has come off the walls, it can clog the heat exchanger tubes, so we wash the heat exchanger with a strong stream of tap water. For this purpose, tubes of the appropriate diameter can be adapted.

- We put the washed heat exchanger in place, tighten the fastening nuts, having previously changed the sealing gaskets.

Removing soot and deposits

Unlike the plumbing part, you cannot disassemble the gas part of the water heater yourself; this should only be done by a specialist from the city gas service. The only thing we can do to eliminate soot is to remove carbon deposits from the burner jets.

- The jets are cleaned with thin copper wire.

- The soot is swept away with a metal brush.

- It is advisable to immediately check the column for gas leaks. To do this, you need to prepare a soap solution, which is applied to all joints of gas pipes and units. A gas leak will be indicated by the formation of characteristic bubbles at the junction. If we find a leak, turn off the gas and call 104.

The need to clean the column can be reduced to a minimum through prevention. Longer operation of the column without failures and cleaning is facilitated by the use of filters and devices to reduce water hardness.

Cleaning the water heater from soot

Fuel burnout products cover the lower surface of the radiator fins over time, this is facilitated by:

- long-term use of the maximum flame of gas burners;

- insufficient draft in the chimney pipe due to poor exhaust;

- poor ratio of gas and oxygen in the air, contributing to its incomplete combustion;

- excessive content of impurities in the gas mixture;

- drops of condensate containing soot on the radiator plates from the chimney.

Cleaning of soot is carried out when the area of contamination is more than 30%; in most cases it is combined with the elimination of scale. It is not necessary to call a professional to remove the soot layer from the radiator plates, but in order to save money, you will have to independently remove the heat exchanger from the water heater body, which is a task of average difficulty for the average person.

When carrying out this operation, you will need the following plumbing and household tools:

- An adjustable plumbing wrench, in rare cases a gas wrench (Bacho pipe wrench), designed to work with pipe nuts.

- Set of Phillips and flat screwdrivers, chisel.

- Pliers, pliers or round nose pliers.

- Consumables - paronite gaskets, flax fiber.

There is a wide range of geysers of domestic and foreign production on the market (Vector, Bosch, Astra, Neva, Oasis, Junkers, Termet, Electrolux), with the same operating principle, they have different assembly schemes, so we will focus on the general stages of their disassembly to remove the heat exchanger:

- Turn off the water and gas supply, remove the upper protective casing and handles, disconnect the water supply pipe from the heat exchanger, pulling out the locking latches and moving it to the side.

- Do the same with the outlet pipe of the coil, unscrewing the flexible line from it, remove the coarse filters from both outlets and put them aside.

- The reverse draft sensor is removed and moved to the side, the gas burner block is unscrewed from the frame of the unit and taken out.

- The fixing plate is snapped off the column body and the brackets holding the heat exchanger are removed, the additional screws securing the coil body are unscrewed, after which it is removed out and subjected to further cleaning.

Dismantling the water heating column heat exchanger

It is easy to clean the heat exchanger from soot using the following methods:

- Place it in a plastic basin with warm water and add household dishwashing detergent to it, wipe off the oily soot deposit with a soft sponge.

- A good way to remove soot is laundry soap, grated and placed in hot water.

- When simultaneously cleaning soot and scale, a cleaning solution is poured into the inverted coil and left in this position for several hours - during this time the scale should completely dissolve in the anti-scale agent.

- Since the gas burner block is removed when the coil is dismantled, it can also be cleaned by placing it in a bowl of water and household dishwashing detergent and wiping the contaminated areas with a sponge. After cleaning, it is washed several times in warm water and dried thoroughly, otherwise water that gets into the small channels of the igniter and wicks will interfere with the passage of gas.

Cleaning the heat exchanger from soot

When to clean

There are several signs that indicate the need to clean the gas water heater.

Difficulties with arson

The main sign that the device needs cleaning is difficulty igniting the igniter. It stops igniting due to severe blockage, which impairs the flow of gas. Therefore, before igniting the device, you need to carefully inspect the igniter and check whether it is clogged with soot or other debris.

The heater starts briefly, the main burner quickly turns off

Some owners of gas heating devices experience premature shutdown of the main burner. This problem leads to poor heating of the water. Most often, it stops burning and heating the liquid due to the accumulation of debris inside the burner.

See also

TOP rating of the 30 best brands of detergents for washing dishes and cooking with your own hands

Soot is pouring out from underneath the casing

If you do not clean the column for a long time, soot will begin to spill out from under its casing. Therefore, if there are traces of soot near the device, you will have to remove the protective casing yourself and clean all contaminated parts.

Water heats up slightly at maximum power

Some people are faced with the fact that the gas water heater does not heat up the water well. In order for it to heat the liquid better, you have to set the maximum power, but sometimes even this does not help get rid of the problem. Poor water heating is associated with severe clogging of the burner, and therefore, in order to normalize the operation of the device, you will have to clean it.

Cotton in the combustion chamber

Sometimes during operation of the column in the combustion chamber you can hear a loud bang. Many people, when such extraneous noise appears, think that the device is faulty, but this is not the case. The popping noise may occur due to a clogged igniter that takes a long time to ignite.

Yellow flame

Each modern model of geysers is equipped with a special jet. This is a small hole responsible for adjusting the gas supply before igniting the igniter with the burner. After prolonged use, the hole becomes clogged with soot and other debris, resulting in a yellow wick flame.

Triggering of overheating and draft sensors

Several sensors are installed in geysers that monitor draft and heating temperature. When the device overheats and traction deteriorates, they operate and turn it off. Most often, overheating occurs due to the accumulation of soot inside the heat exchanger. The accumulation of debris leads to a narrowing of the gas-air cross-section and an increase in temperature.

Construction dust after renovation

During renovation work, a lot of construction dust is generated in an apartment or house. It can settle not only on furniture, but also on devices installed in the room. If repairs are carried out in a room with a gas water heater, a lot of dust can get into it, which will negatively affect the operation of the device. Therefore, after completing the repair work, it is necessary to clean the column from accumulated debris.

Second cleaning method

The unit must be cleaned every 6 months, but at least once a year. If there is an agreement on gas supplies, then the company’s specialists must carry out timely maintenance of gas boilers. If you want to clean the column yourself, then you must follow the following instructions:

- 1Initially, you need to close the gas; the tap is usually located under the device. Then you need to loosen the bolts that secure the casing, then unscrew them and clean everything with a needle with 4 edges. Today it is possible to buy a special brush for cleaning boilers, which is more convenient to use than a needle. The next step is to wash the burner sections in a degreaser. If the wick is clogged, it also needs to be cleaned with a needle or metal scraper. At the last stage, you need to assemble all the parts of the column in the reverse order and fill the unit with water before starting the gas.

- 2To clean the burners in the pipe through which the gas flows, you can use a stiff brush. The pipe must be cleaned with wire and rinsed with water and solvent. The upper area of the burner is cleaned with fine sandpaper.

- 3Units that are cleaned in a timely manner will last much longer. The fire will be glare-free and uniform. If it is noticeable that the column is smoking, the fire is uneven, weak or, conversely, strong, then it needs to be cleaned. An uncleaned unit is dangerous.

Classification of methods

To eliminate scale from the device, you can completely disassemble it, you can do without these measures. In the first case, the level of pollution is serious. In the second, only the radiator is cleaned.

There is another way - to clean the igniter, electrode system and water block.

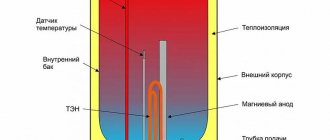

If the situation requires you to disassemble the device, it will not hurt to have an idea of the circuit diagram of its structure.

A typical drawing of such units is as follows:

If the gas water heater is thoroughly clogged, the flame of its burner will turn yellow. This is the main sign of serious blockages.

If the igniter produces a weak flame, local soot removal is required.

Soot removal

Most often, the heat exchanger has to be cleaned of soot. The best option is to remove it from the device. To do this, turn off the water and gas supply, and then open the tap closest to the water heater. Then the pipe is loosened with an open-end wrench and the nut is unscrewed a couple of turns. The contents of the device will flow out through the tap, which must be open.

When you dismantle the heat exchanger, it is better to cover the burner with a rag to prevent soot from getting on it. The lion's share of the work on cleaning the column is precisely removing the assembly. Once you remove it, you won't have any problems cleaning it. Feel free to take the device into the bathroom. Clean the parts with detergents and a stiff brush, and then dry thoroughly. After this, the device can be installed back and the unit can be reassembled, only in the reverse order. And be sure to remember to replace the O-rings on the unit with new ones. The last, most important operation is washing the unit and checking it. First you need to open the water. When the heat exchanger is full, close the tap and inspect the unit for leaks. If everything is in order and water does not leak anywhere, then you can try to start the column.

Removing soot

We wrote above where the heat exchanger is located; before starting maintenance, it is advisable to remove it from the unit, first turning off the gas and water, opening the tap for supplying hot water (the one located near the flow-through heater). Then, using a gas or open-end wrench, loosen the nut securing the tube to the water unit and unscrew it slightly (a couple of turns will be enough). The contents must be allowed to flow out through the mixer, which is left open.

Helpful advice. Before cleaning the geyser from scale, prepare a special tool and products. The most convenient way to solve the problem is to use an aerosol agent to loosen boiled threaded joints. You can ask for the WD40 product at any auto store or hardware store.

How to clean the geyser heat exchanger further:

- Unscrew a couple of union nuts and dismantle the assembly.

- Disassemble other elements and parts that prevent easy dismantling. Their number depends on the specific model and design features of the column. In some cases, it is necessary to remove the smoke exhaust diffuser, in others - the ignition group, in others - overheating and draft sensors. You may have to remove all the parts.

- Cover the burner nozzles with a cloth to prevent soot from getting into them.

- Take the heat exchanger to the bathroom, thoroughly clean it with a long-bristled brush to remove all soot, rinse and dry.

- Return the unit to its place and reassemble the unit in the reverse order described above.

Do not forget to install new seal rings at the pipe connections. Cleaning a geyser is not difficult; most of the time is spent on assembly and disassembly. Work must be carried out strictly according to the rules. If you are not sure that you will do everything as needed, call a specialist.

Helpful advice. If the installation is clogged, you have already removed the heat exchanger, it makes sense to immediately rinse and clean the gas water heater from scale. Maintenance will be more efficient and will not take much extra time.

Before starting the unit, you need to check it for leaks. To do this, open the water supply tap and wait until the heat exchanger is filled from the open mixing tap. Then the supply is closed again, and the unit is inspected to determine the degree of permeability of its connections. If there are no serious problems, the gas valve is re-opened and the apparatus is started up for testing in standard operating mode.

Use liquid for flushing and softening connections during maintenance at your discretion. Chemistry simplifies the work, but it is not necessary to use it.

Flushing helps not only from carbon deposits, but also from dust.

How to protect against scale

There are three types of filters that will prevent scale from appearing.

Water filter for water softening

This is a small plastic tube, inside of which there is a small tube with salt crystals. When a liquid passes through such a tube, its composition changes. Thanks to this, the amount of scale on surfaces is reduced by 2-3 times.

Magnetic filter

Magnetic models have two small magnets that form a field. The water passing through such filtration structures is purified and becomes softer.

Popular homework tools

In many cases, descaling at home is quite possible. The main thing is to use the right tools.

The most common mistake is working with hydrochloric or sulfuric acids. They are characterized by a weak cleaning effect, but they leave scratches and other defects on the walls of the device.

But if you still decide, then you should know how to flush a gas water heater with hydrochloric acid?

First, dissolve this acid in distilled water. The composition should be 5-8%. Pour it into the TO and leave for 5-10 minutes. Be sure to wear protective gloves when working. And never use such acid in undiluted format for these purposes.

You should not make too strong a solution and leave the created product in the column for a long time, otherwise it will fail. Also, the composition with hydrochloric acid must be supplemented with inhibitors, especially when flushing the radiator. Without these additions, corrosion may form. After the procedure, rinse the device with a solution of water and soda.

Phosphoric acid is more effective and safer. This is a neutral product that perfectly removes scale and does not harm the metal surface of the column. The acid dissolves in water in a ratio of 1:6.

They also often clean the geyser from scale with vinegar. It is not used in pure form, but also in solution. Household acetic acid is often used. Make the composition in the following proportions: a glass of water and a teaspoon of acid. The solution is poured into the device to be cleaned and left for 10-15 minutes. Then, using a stiff brush, very carefully clean the area. The composition is drained, the column is washed with soda water.

Most often, the device is cleaned using citric acid. It dissolves in water in the ratio: 1 l - 60 g. If the contamination is complex, you can increase the proportion of acid to 100 g.

The procedure follows a similar scenario. The product is poured in for 10-15 minutes. It merges. The operation is carried out using a hard sponge. If necessary, repeat until complete cleansing.

To effectively remove scale from plate heat exchangers and coils, special cleaning agents, such as aquashield and anti-scale, are optimal.

It's time to cleanse: the first signs

You can determine that a geyser (for example, from Bosch) needs cleaning based on 4 characteristic signs:

- The device stops turning on or often goes out during operation . When there is 100% confidence that gas is supplied to the column uninterruptedly, and water flows with a stable pressure, the reason for such independent shutdowns may be an excessive amount of burning on the ignition element. The problem can only be resolved by cleaning the burner.

- The thermal protection of the device is activated . To prevent the column from overheating, the equipment is equipped with a thermal sensor. It signals an increase in temperature, warning the owner of a malfunction. If this sensor is triggered frequently, it is worth cleaning the pipes from scale. Since scale has good thermal insulation, it interferes with the normal cooling of the device.

- The productivity of the device has decreased for no apparent reason . If the water begins to heat up more slowly or the pressure level drops significantly, you need to check the heat exchanger for scale and clean out the accumulated products of the column.

So, it’s clear that the device is dirty, but how can you clean the geyser from scale and soot when such a need arises? The answers are in the following sections of the article.

Descaling procedure

To flush the heat exchanger of a conventional gas water heater, you must first find the valves that shut off the flow of gas and water to the device, and then turn them. At the same stage, it is recommended to obtain the operating instructions and refresh your memory about the device’s design, as well as the manufacturer’s recommendations. This will avoid mistakes during dismantling.

To disassemble the column, you will need the usual tools that any experienced craftsman has at his disposal:

- adjustable and pipe wrench;

- straight and Phillips screwdrivers;

- paronite gaskets;

- a hose at least half a meter long;

- a metal clamp to secure this hose.

The hose is connected to the outlet of the heat exchanger and lowered into the sink so that waste water with contaminants can be drained into the sewer. If this is not possible, you will also have to stock up on a large enough container to drain the water. The protective casing is removed from the column. Be careful not to break the control panel.

Now you need to remove the water filter, which is usually secured with a nut. The filter should then be washed and replaced. If the deposits prove to be too complex, it is recommended to use chemical cleaners to remove contaminants from the mesh. During the washing process, damage to the filter may be detected. In this case, it is better to replace it.

Now you need to disconnect the heat exchanger from the water pipes; usually in these places a regular threaded connection is used, which should simply be unscrewed. The heat exchanger is removed from its hinges and turned over. Some craftsmen advise placing it in a large enough container during cleaning so that aggressive chemicals do not leak onto the floor.

Suitable products can be used as a cleaner, for example, Antiscale. A regular 9% vinegar solution and other household compositions will also work. You can make a solution of citric acid: 100 g per liter of water.

Some have had positive experiences descaling with drinks like Pepsi-Cola or Sprite, which contain phosphoric acid. But you should not use vinegar essence for these purposes, it can corrode the walls of the pipes, and serious repairs will have to be carried out.

The heat exchanger is turned over and the cleaner is poured into it using a rubber bulb or a large syringe. Usually you need at least 500 ml of the substance, but no more than a liter. After this, vinegar or citric acid is left inside for about a quarter of an hour. When using industrial cleaners, it is recommended to follow the instructions.

At the end of cleaning, the solution is drained and the pipes are washed to remove accumulated dirt. To do this, the inlet of the heat exchanger is again connected to the water supply, and a container is placed at the outlet to collect dirty water. Flushing is carried out until a clean stream appears. If there is serious contamination, a one-time cleaning procedure may not be enough; it will have to be repeated again, using a fresh portion of the cleaner.

Upon completion of work, it is necessary to reassemble the column in the reverse order. The heat exchanger is connected to the water supply. In this case, the threaded connections should be sealed and treated with graphite lubricant. All gaskets present at the installation sites must be immediately replaced with new ones.

Now you need to replace the washed coarse filter, put the casing on the device and again supply gas and water to the column by unscrewing the corresponding valves. All that remains is to perform a test run of water to make sure that the column is working properly.

Methods and means of cleaning

The instructions must describe in detail the rules for cleaning the components of the device, deviating from which can be life-threatening. If, during the process of descaling or burning, damage to one of the elements of the device occurs and a gas leak occurs, you must immediately contact the emergency gas service.

Before proceeding with the procedures for cleaning the column, it is necessary to block access to gas and water

If, after weighing all the pros and cons, you have decided to clean the device yourself, we suggest that you familiarize yourself with industrial preparations and folk remedies that will allow you to effectively get rid of contaminants.

In the video below you can see in more detail how to flush a water heater radiator using citric acid:

Before starting work, be sure to turn off the gas and water supplies.

You can clean it with your own hands:

- burner for soot and soot;

- internal parts from dust;

- anti-scale heat exchanger;

- water pipes.

Basic cleaning products:

| Problem | Folk recipe | Industrial product |

| Scale in the heat exchanger | An aqueous solution of citric acid (100 g of substance per 0.5 l of hot water) | Calgon, "Antinscale" |

| Carbon deposits on the heat exchanger | A solution of table vinegar and warm water (1:3) | 7-10% hydrochloric acid solution |

| Dust on internal parts | Warm soap solution | Regular household vacuum cleaner |

Descaling

You can remove scale using chemicals, following the manufacturer's recommendations, as well as folk remedies.

If the second option is chosen, you must adhere to the following procedure:

- disconnect the device from gas and water;

- disconnect the heat exchanger, remove it from the wall, drain the water;

- using a bulb or syringe, pour a cleaning agent (soda or vinegar solution) into the heat exchanger pipes;

- then we immerse the entire part in a deep basin with the same mixture and leave it for several hours.

After the contaminants have been completely removed, the heat exchanger is connected back and the column is started. The water pressure will finally clean the inner surface of the pipes, making them perfectly clean.

The heat exchanger is an important part of the water heating device, which ensures the transfer of heat from the burned gas to water

The heat exchanger can be cleaned without dismantling. To do this, remove the front panel and disconnect the device from the water supply hose. After that, the cleaning solution is poured into the pipes through the inlet. The device is left in this form for 2-3 hours, after which the liquid is drained and everything is returned to its place.

Removing soot and soot

You can clean the surface of parts from soot without disassembling the column in just a few minutes. To do this, you must adhere to the following procedure:

- turn off the gas and remove the front part of the housing;

- wipe the internal parts with a damp cloth or vacuum;

- put the column back together.

From the video below you will learn how to quickly and effectively clean soot from burners:

Cleaning the injectors

If the column begins to burn weakly, most likely the nozzle is clogged. You can find it on the gas manifold near the pressure sensor. For cleaning, use a thin wire or a stiff brush.

After the work is completed, it is necessary to check the column and eliminate the possibility of gas leakage. To do this, lubricate the burner with soapy water and make sure there are no bubbles.

Cleaning the water intake unit

In addition to the water heating part, any geyser is equipped with a water intake unit, the main task of which is to prevent large solid particles from entering the heat exchanger. Over time, the mesh filter and membrane, which is responsible for the automatic supply of gas when the water is turned on, become contaminated.

To clean the water inlet, you must:

- remove it from the column body;

- rinse the filter under running cold water;

- inspect the membrane for bends and bulges (if there are defects, the membrane must be replaced with a new one).

After examination and washing, all parts are installed in place, and the water inlet is closed with a lid.

Cleaning the heat exchanger without dismantling

There is also a way to clean the heat exchanger without completely dismantling it. To do this, you must first remove the casing from the device and disconnect the water supply pipe from the heat exchanger. The inlet copper tube of the coil should be slightly shifted to make it easier to work with.

A hose is put on the outlet pipe. Then you need to open the tap and drain a little water, about a liter, to free the coil from liquid. If it is possible to clarify the capacity of the heat exchanger in the technical data sheet, then it is recommended to drain exactly the same amount of water or a little more from the system.

To clean the column using this method, it is better to take Antiscale powder, which is diluted with hot water before use. It doesn’t hurt to take care to protect your skin and eyes from accidental exposure to the composition, since it contains hydrochloric acid.

Now you need to insert a funnel into the inlet pipe and pour Antiscale into the heat exchanger. It should be remembered that when pouring quickly, a reaction may begin inside, which will lead to the ejection of the dangerous solution in the opposite direction. Therefore, you need to pour the composition in small portions and in a thin stream.

The heat exchanger filled with solution should be left for about two hours. To speed up the cleaning process, you can turn on the igniter (it is not necessary to turn off the gas for this cleaning method). When the process is over, you should open the tap and drain the water with the sludge dissolved in it from the column.

If a lot of contaminants come out and the jet shows good pressure, cleaning can be considered satisfactory. If not, you need to carry out the procedure again, but when using Antiscale, such a need usually does not arise.

This cleaning method is recommended to be carried out using just such a cleaner. The use of vinegar or citric acid in this case can have a bad effect on the condition of the aluminum gearbox.

Removing scale from the heat exchanger

Scale is a very common problem with any water heating equipment. It is formed as a result of the interaction of salts contained in water with high temperatures. Accordingly, its main concentration falls on those elements that are simultaneously in contact with both heat and liquid. In this case, it is a heat exchanger.

Scale has a rather negative effect on equipment. At a minimum, it clogs the tubes, reducing their capacity. Because of this, the water circulates worse, and even heats up poorly in the process.

You can determine whether there is a problem even before you disassemble the column and look inside the heat exchanger. Symptoms may include:

- hot water from the mixer runs much worse than cold water;

- the gas in the water heater goes out almost immediately after ignition;

- the column does not turn on;

- The water began to heat up worse than before.

Fortunately, you can deal with scale yourself, and it will not require any major costs. All you need is some time, a large basin, a hose, citric acid and warm water. Just in case, also stock up on a rag—some liquid may spill onto the floor during the process.

- Prepare a cleaning solution. To do this, 100 grams of citric acid must be diluted in 1 liter of warm water. If there is a lot of scale, then it is better to use more radical means. Household chemical stores sell various chemical compounds designed specifically to remove such deposits. Of course, this will cost more than citric acid, but this product also works more effectively. If both options are not suitable for you for some reason, you can try a not too concentrated solution of vinegar - you should use the table variety for it, not the essence. In extreme cases, a soda like Coca-Cola or Sprite can pass for a cleaning agent. They contain orthophosphoric acid, which plays the role of a solvent. But use this method at your own peril and risk, since, to put it mildly, it is not recommended.

- Place the heat exchanger in a large basin. Pour the prepared solution into the tubes until they are completely filled. To make it more convenient, use a rubber enema bulb or something similar.

- If you used vinegar or lemon solution for cleaning, then the heat exchanger should lie in a flooded state for 15 minutes. If you used store-bought chemicals, the soaking time is indicated on the package.

- After the soaking has taken effect, it is necessary to drain the solution and rinse the heat exchanger. For this you will need a hose. Lower one end of it into the nearest sink, and attach the other to the heat exchanger, which must be connected to the cold water supply pipe. Then open the shut-off valve on it. A stream of water will wash away all the solution, draining through the hose into the sink. Do the flushing for a longer period of time so that all the aggressive composition leaves the walls of the heat exchanger. Otherwise, exposure to substances will continue, which may lead to damage to the metal.

After washing, perform a visual inspection of the heat exchanger tubes. If the walls are clean, great, you can assemble the column to its original state. If there is some scale left in the tubes, then repeat the procedure from the very beginning.

Preventing scale formation

It is obvious that scale primarily forms in the heat exchanger

It is important to warn her - if the radiator becomes clogged, this will lead to damage to the device

Water hardness depends on the region. In the northern regions it is less, but towards the south it gradually increases

Residents of regions with hard water should pay attention to softeners. They are installed at the entrance of pipes to a house or apartment.

This is useful not only for the column, but in general for devices that have a heating element.

If the water situation is not so severe, then such radical measures are not required. It is enough to install special filters.

You can flush the system with formic or phosphoric acid. With this treatment, a properly prepared solution is very important: for 1 mm of scale there is 1% acid. However, the total concentration should not exceed 10%! Stronger solutions may damage surfaces.

The nature of geyser pollution

This technique is a simultaneous representative of two types of household appliances (water and gas). Consequently, problems can arise in two directions at once.

- Due to hard water, the salts it contains can settle on the walls of the pipes leading to the column in the form of scale. Clogging “contributes” to the uneven distribution of water, up to the complete cessation of its flow.

- The gas part of the unit accumulates the final product - soot. Carbon deposits also form here. Soot will lead to a decrease in normal draft. The problem can be called advanced when soot flakes begin to fall out from under the steel frame of the device.

Preventing scale formation

Hard water is not the only cause of scale build-up inside heat exchanger tubes. For its appearance, you need not only the salts contained in the water, but also a high heating temperature. The hotter the gas burns, the more intense the solid deposit inside the device. Temperatures of 80 degrees or higher are considered critical.

Obviously, such high heating is not needed for domestic use. For a shower, 40-42 degrees is enough; for washing even the dirtiest dishes, 45 degrees is enough. An automatic washing machine will heat the water up to 95 degrees, if necessary, but the gas water heater does not participate in this process in any way.

Therefore, if hot water constantly has to be diluted with cold water, it is worth reviewing the settings of the geyser for heating temperature. Some amateur craftsmen drill out the igniter of a gas water heater. This is done in order to increase the heating rate of the water flow.

In older models, this modification eliminates the need to light up and adjust the device every time you turn it on. Finally, a drilled igniter is needed to ensure that the gas ignites even with very low water flow pressure.

In this case, a very dangerous situation can arise when a small amount of water in the heat exchanger boils and goes into gaseous form. As a result, the pressure in the heat exchanger will increase sharply and it will simply burst.

Of course, gas workers consider such intervention dangerous, and manufacturers refuse to fulfill warranty obligations for devices with such modifications. To improve the pressure in the system, you can select and install a conventional circulation or booster pump. And the quality of the water supply will improve, and the devices will not be damaged.

Operating principle of instantaneous water heater

A gas water heater is a relatively simple device for heating water. On top there is a heat exchanger connected to the water supply system. Underneath there is a burner, which is connected to a gas pipe.

In all modern models, burner ignition is automated; only very old or faulty models are ignited manually. It is better to repair the latter so as not to risk the health of your family and the integrity of your property.

The design is hidden by a protective casing, on the front panel of which the control unit is usually located. It regulates the maximum temperature of water heating, the amount of gas and other indicators of the operation of the device. On top there is a hood and a chimney pipe through which combustion products are removed.

When the water is turned on in the house, the burner automatically turns on and the gas heats the water to the required temperature. Auto-ignition is configured in such a way that the column turns on only when the water pressure in the system is sufficiently high. Another important indicator is the presence of good traction.

Before starting work on cleaning a household geyser, you need to get acquainted with the structure of the device in order to disassemble it correctly

The process of heating water is accompanied by the precipitation of hard sediment, which gradually accumulates inside the heat exchanger. The tubes become clogged with deposits, as a result the quality of heating deteriorates and the operation of the instantaneous water heater becomes insufficiently efficient.

Regular cleaning of the column will help avoid such problems. In addition to scale, other contaminants can accumulate inside the device, it all depends on the quality of the water.

A household geyser is not particularly complicated: water moves through the heat exchanger pipe, it is heated by a burner, and the ignition is turned on automatically

The following signs indicate that it is time to clean the column:

- the pressure from a hot water tap is much weaker than the stream from a cold tap;

- the pressure is good, but almost immediately after switching on the column goes out;

- the device stopped turning on altogether, regardless of the pressure;

- there is insufficient heating of the flow compared to the previous state;

- The water heats up to the desired temperature, but too slowly.

Some malfunctions can also be observed when the shut-off valve, which is installed at the entrance to the dispenser, breaks down. It doesn’t hurt to check it first, and only then start cleaning.

How to know when it’s time to clean your gas water heater

Cleaning the gas water heater is necessary if:

- The speaker does not turn on or turns off after working for a while. At the same time, it is known for sure that gas and water enter the column.

- The column's thermal protection sensors are constantly triggered. The scale layer has a porous structure and has heat-insulating properties, which interferes with normal cooling of the column.

- The efficiency of the column has noticeably decreased: during normal operation of the burner, the water heats up much less.

- Weak pressure at the outlet of the column with normal pressure at the inlet. Water cannot get through channels blocked by scale.

Cleaning the water intake unit

The water receiving unit is installed at the inlet of the water supply system of the column, has a mesh filter to prevent clogging of the heat exchanger tubes with large particles of rust and sediment, as well as a membrane for automatic gas supply when the water tap is turned on.

- We remove the water intake unit from the column body.

- After unscrewing the connecting screws, we open the case.

- We clean the filter and rinse it with strong water pressure.

- Checking the membrane. The membrane must be flat; if the membrane has a pronounced concavity, it means that it has exhausted its service life and must be replaced. You can replace the “native” membrane of the old speaker with a modern silicone one, which has a much longer service life.

- We close the cover of the water intake unit, tighten the screws and tighten the diametrically opposed pairs of screws one by one. This ensures uniform membrane tension.

Cleaning the heat exchanger

- Disconnect the water inlet and outlet tubes into the heat exchanger. If the heat exchanger is not cleaned regularly, the fastening nuts may become clogged with scale, preventing their removal. In this case, we recommend using a special liquid, VD-40, which can be purchased at any auto store. It is necessary to drip liquid into the joints of the nuts using an oil can. You can also use “Silit” for scale. After 15-30 minutes, the nuts can be unscrewed. If that doesn't work, try tapping the nut from all sides.

- After disconnecting the heat exchanger, use a funnel to pour descaling agent into it. A solution of 100 g of citric acid per 0.5 liter of hot water is perfect for such a remedy. You can also clean the heat exchanger with nine percent table vinegar diluted with water in a ratio of one to three. But using hydrochloric acid is not recommended, as it can react with the metal from which the heat exchanger is made, which will only worsen the situation. Leave the solution inside the heat exchanger overnight.

- Drain the solution and thoroughly rinse the heat exchanger. If you do not remove the scale that has come away from the walls, it can clog the heat exchanger tubes, so we wash the heat exchanger with a strong stream of tap water. For this purpose, tubes of the appropriate diameter can be adapted.

- We put the washed heat exchanger in place, tighten the fastening nuts, having previously changed the sealing gaskets.

Why does soot appear?

Many owners of geysers are faced with the problem of soot. To get rid of such contaminants, you can contact specialists, however, carrying out this work is not difficult, so you can do everything yourself. In cases where contaminants appear in the holes of the jets, you can completely get by using a small brush or thin wire.

Traces of soot very often appear in the unit due to leaks that occur in the pipes. At this time, the release of fuel is so weak that household members are unlikely to notice its smell. To identify such violations, you need to check the pipe connection areas. To do this, take brushes and apply a soap solution with them. If the applied layer is covered with bubbles, this will indicate that it is time to call the gas service employees.

Poor water quality can also cause contamination of the geyser. Foreign elements from the liquid can accumulate and, as a result, settle on the mesh filter. This negatively affects the throughput of the unit. Those inclusions that managed to overcome the barrier in the form of a filter may begin to accumulate on the membrane part. Under such conditions, this part stops responding correctly to pressure changes.

Another common problem with gas-powered dispensers is scale. It appears due to the crystallization of salts that are present in the liquid. Here you need to take into account that the higher the temperature of the water, the sooner the salt will accumulate on important components of the equipment. In most cases, scale appears in such equipment due to the constant operation of the burner or due to heating that exceeds 50 degrees.

Signs of heat exchanger contamination

To exclude premature failure of the water heater due to the listed symptoms, it is advisable to call specialists as soon as possible to diagnose and repair the malfunction. Since the heat exchanger is contaminated on the outside with soot, and on the inside with scale and patina (copper corrosion), we will consider the signs for each individual case.

Geyser heat exchanger.

The following indicators indirectly indicate the appearance of scale in the heat exchanger of the gas water heater and water heating system:

- Water consumption from a hot water tap is significantly lower than from a cold tap. To identify the true cause of the decrease in pressure, the condition of the shut-off valves is checked, since its breakdown can lead to a similar situation.

- The appliance is set to maximum power, but the water does not reach the set temperature. Such symptoms are possible when the pressure in the gas line decreases. Therefore, before dismantling and cleaning the heat exchanger, the supply gas pressure should be examined. In the absence of a low pressure pressure gauge, you can navigate by readings on the gas stove burner. The presence of a normal flame will indicate normal pressure in the system.

- The water heater burners begin to turn on and off frequently. But, such a malfunction can also occur if the gas valve or control module is unstable.

- There is noise inside the double-circuit boiler. It is worth considering that noise in the heat exchanger also occurs due to boiling water, or breakdown and clogging of the pump turbine. Boiling of the coolant is possible due to poor contact of the temperature sensors with the pipeline.

The listed signs indirectly indicate the formation of scale in the heat exchanger of the column, so first of all you need to check the components that affect the occurrence of the above symptoms.

External contamination of the heat exchanger is determined by opening the device housing. The radiator is considered dirty if it is more than 30% covered with black deposits.

Homemade instantaneous water heater for small household needs

I will sell this homemade product or make it to order. Message me or leave a comment to discuss details. Good day everyone. This article may be useful for those who are faced with the problem of disconnection or lack of hot water. The technique will also be relevant for summer cottages, where installing purchased water heaters is not always advisable.

Necessary materials

The source of heating the water will be a gas stove. There are 2 options for how to quickly make an instantaneous water heater, but their operating principle is the same. In the first case, you will need a copper tube. In the second option - an old car radiator (it is better to give preference to a copper one, whatever is available). You will also need 2 hoses and 2 clamps.

Stages of manufacturing a water heater

If you use a copper tube as a heating element, then initially it will need to be bent in such a way as to form a spiral. You can make the coil neat and even by wrapping the tube several times around another pipe of the required diameter or something similar, as shown in the photo.

(The picture was taken from the network as an example, since my bending process was not filmed due to the fact that I preferred to make an instantaneous water heater from a car heater radiator). The main thing is that one edge of the pipe is free, otherwise it will not be possible to remove the spiral it will work out. All further steps for making an instantaneous water heater for a copper coil and radiator are the same. You need to take 2 hoses. We connect one of them to a cold water tap, and the other end to the radiator pipe of the stove (or copper tube). The second hose, respectively, to the second pipe. Heated water will flow from it. To prevent leakage, clamp the edges at the junction of the hose with the water heater element with a clamp. In my case, such actions were not required, since the whole village was quite tight. Open the cold water tap, light the fire and place the radiator (or coil) on top of the cooking stove grate.

(no votes yet)