The autonomous heating system of a private house is becoming the predominant heating method.

This option has a lot of advantages, it removes dependence on the appetites and capabilities of resource companies and allows you to independently determine the mode of heat supply to the house.

The main component of the system is the boiler.

Practice has shown that the most efficient and economical type is a gas unit. does not require constant attention and can operate automatically.

In addition, gas boilers are available in a wall-mounted version, compact and able to fit into any interior.

On smartphones, you can scroll the table right/left ↔

| Place | Name | Price |

| TOP 5 wall-mounted single-circuit boilers | ||

| 1 | Buderus Logamax U072-18 | Find out the price |

| 2 | BAXI LUNA-3 1.310 Fi | Find out the price |

| 3 | BAXI LUNA Platinum+ 1.32 | Find out the price |

| 4 | MORA-TOP Meteor Plus PK24SK | Find out the price |

| 5 | Protherm Panther 25 KTO (2015) | Find out the price |

| TOP 5 wall-mounted double-circuit boilers | ||

| 1 | Buderus Logamax U072-12K | Find out the price |

| 2 | Navien DELUXE 13K | Find out the price |

| 3 | Vaillant turboTEC pro VUW 242/5-3 | Find out the price |

| 4 | Bosch Gaz 6000 W WBN 6000- 12 C | Find out the price |

| 5 | BAXI LUNA-3 COMFORT 240 i | Find out the price |

Single-circuit and double-circuit wall-mounted gas boilers

There are two groups of gas wall boilers:

- single-circuit . Designed only for supplying coolant to the heating circuit;

- double-circuit . They are capable of performing two functions at once - heating the coolant and preparing hot water for domestic needs.

Double-circuit boilers are distinguished by the presence of a second heat exchanger, which heats water for domestic hot water indirectly.

The hot coolant leaving the primary heat exchanger cannot be immediately directed into the heating circuit.

Its temperature is too high, so you have to add a certain amount of colder liquid from the return line. Installing a secondary heat exchanger slightly changes the operating mode of the boiler.

Since part of the thermal energy is spent on preparing hot water. The temperature of the coolant drops, so the proportion of reverse flow in the mixture decreases. This is not of fundamental importance; fuel consumption changes insignificantly.

The only drawback of dual-circuit units is considered to be heating instability and the possibility of sudden changes in DHW temperature when other plumbing fixtures are turned on.

Atmospheric gas boilers

An atmospheric boiler is a device that performs a heating function, based on the principle of maintaining the combustion process by continuously replenishing the combustion chamber with oxygen. It is in great demand for installation in private buildings as an excellent heating device with simple functional characteristics. Now there is a large selection of domestic and foreign manufacturers. The newly created boilers are equipped with advanced electronics that improve the quality of operation and use.

Characteristics of the work performed

An atmospheric gas boiler creates a natural draft in the chimney, through which air enters (this phenomenon is necessary for the operation of a gas burner), and there is also a removal of burnt products through the chimney.

Using a nozzle, the release of gas under pressure is regulated. When the gas combustion process occurs, oxygen enters the chamber, which enhances combustion. Gas containing an air admixture is delivered to the nozzles. There is complete and incomplete contact with air. There are wall-mounted and floor-mounted boilers.

Wall-mounted heating boilers

Wall-mounted models are lightweight and spacious. Possibility of removing combustion products through the wall. Therefore, it is possible to install it in any convenient place in the room. The disadvantages include direct dependence on electronics.

Floor standing atmospheric gas boilers

Equipment in this category is the most powerful, reliable and durable. But the operation of the floor heating structure is accompanied by a high noise level; during operation, regular cleaning work is required.

Advantages of atmospheric boilers

- The equipment is capable of performing its activities with great success even when low-pressure fuel is supplied;

- It is designed to withstand a sufficiently wide range of loads;

- There is no need for additional air injection to ensure combustion;

- The designs of heating boilers are quite simple;

- Long term of high-quality functioning of the work;

- Quite a reduced level of costs for replacing parts;

- Silent operation of the boiler.

Device

The main components of a wall-mounted gas boiler are:

- gas-burner;

- primary and secondary heat exchangers;

- turbocharger fan;

- circulation pump;

- gas equipment;

- electronic control board and self-diagnosis sensor system.

The operation of all components is continuously monitored by a sensor system. If a problem occurs, they immediately issue a command to the control board, which displays the corresponding error code on the display.

In difficult situations, the boiler operation is stopped and blocked to avoid accidents.

The design of a wall-mounted gas boiler does not differ fundamentally from floor-standing models. However, the hinged installation method dictates its own conditions, limiting the weight of the units.

Because of this, the power of wall-mounted boilers is never too high, so that massive and heavy components and parts do not have to be used . There are some requirements for installation - it is necessary to ensure proximity to the outer wall so that the length of the chimney is sufficient for normal operation.

Typically, wall-mounted gas boilers are installed in kitchens, where they fit harmoniously into the interior.

Operating principle

According to the principle of operation, wall-mounted boilers are no different from floor-standing boilers. The main unit is a gas burner combined with a primary heat exchanger . It performs a basic function - heating the coolant.

Then, under the action of a circulation pump, it is discharged into a secondary heat exchanger, from where it enters a three-way valve.

There, the hot liquid mixes with some return flow to reach operating temperature. and enters the heating circuit .

The air supply to the burner is provided by a turbocharging fan. It also creates pressure that displaces flue gases from the burner to the outside. To do this, use your own coaxial type chimney (pipe within a pipe), led out through the wall.

Gas supply and regulation is provided by equipment, which includes:

- gas tap;

- gearbox;

- gas valve;

- feed units and control sensors.

The heating of the coolant, as well as the preparation of hot water, is carried out in flow mode. The hot liquid is removed, it is replaced by a colder flow, which heats up and is also discharged from the boiler into the heating circuit.

With active use of hot water, some models experience a drop in the temperature of the heating radiators.

NOTE!

There are non-volatile boilers that operate on simpler principles. They produce normal heating of the coolant, just like a gas stove does. They do not have any elements that require power supply, which makes the design more primitive, but also more reliable.

Single-circuit and double-circuit devices - what is the difference?

A single-circuit heating device differs from a double-circuit heating device only in that it is responsible only for heating the room. At the same time, a double-circuit boiler, in addition to heating, is also designed to solve issues of providing hot water supply.

Owners of single-circuit boilers solve DHW problems by installing additional equipment. Most often this is an indirect water heating boiler connected to the boiler. What is more efficient: a single-circuit boiler or a double-circuit boiler? We'll figure this out now.

The main advantage of a single-circuit boiler in conjunction with a storage heater is that water is heated to a comfortable temperature without cooling the home. Whereas, with significant water consumption in a double-circuit boiler, the circuit responsible for heating is automatically switched off, and the unit only works to heat the water.

A single-circuit gas boiler with an indirect heating boiler completely solves the issue of hot water supply without disrupting the operation of the heating system

The following factors should be considered before selecting a heater configuration:

- Heated housing area;

- Number of water intake points;

- Distance from water intake points to the boiler;

- Number of residents.

In a house with a small heated area, with economical consumption of hot water and close placement of water intake points, the optimal solution would be to install a double-circuit boiler.

If hot water is simultaneously consumed from several water intake points, the water temperature may be lower than required. In addition, with a large housing area, additional inconveniences arise. In double-circuit boilers, the priority is DHW; when hot water is consumed, the circuit responsible for heating is turned off.

But these issues are also resolved at the level of the unit design. There are double-circuit boilers that heat water in flow mode and are equipped with a built-in boiler.

The latter provide a supply of hot water of 30-60 liters, but at the same time gas consumption increases slightly. In addition, the weight of the boiler and its overall dimensions increase significantly.

A floor-standing gas boiler with a built-in indirect heating boiler provides an adequate supply of hot water

We can conclude that if the needs are met, the optimal solution would be to install a double-circuit flow-type boiler. If you want to have a sufficient supply of hot water at a comfortable temperature at any time without cooling your home, then it would be preferable to install a combination of a single-circuit boiler with an indirect heater.

In addition, if it is necessary to increase the need for hot water, the boiler can always be replaced with a larger capacity boiler. As a result, the price of such a combination will be higher than the cost of a double-circuit boiler, but the issue of hot water supply and heating will be reliably resolved.

Kinds

There are different structural types of wall-mounted gas boilers. They are combined into groups according to certain characteristics.

By type and material of heat exchanger:

- separate . The primary heats the coolant, and the secondary prepares hot water. On cheap models they are made of stainless steel, more expensive models are equipped with copper components;

- bithermic . This is a heat exchanger whose design is close to the coaxial form (pipe in pipe). As a rule, such units are made of stainless steel. . Bithermic heat exchangers are more efficient and do not cause fluctuations in the temperature of the hot water supply, but they quickly fill with scale and are extremely difficult to clean.

By type of burners and combustion chambers:

- open (atmospheric) . Combustion air is taken directly from the room, and smoke is removed according to the principle of stove draft;

- closed (turbocharged) . Air is supplied using a special fan. It also provides excess pressure, displacing smoke into the chimney.

According to the method of transferring thermal energy:

- convection The coolant is heated normally in the burner flame;

- condensation _ This is a relatively new two-stage heating technology. First, the coolant is heated in a condensation chamber, where thermal energy from the deposition of water vapor from the flue gases is used. The liquid then enters the primary heat exchanger, where it is brought to the desired state in the usual way.

Condensing boilers are almost twice as expensive as conventional boilers. but can only work under certain conditions. In particular, the difference in temperature inside and outside the room should not exceed 20°, which is only possible in warm countries.

By type of power supply:

- volatile . Units whose many components require power supply are fans. pumps, control boards, etc.;

- non-volatile . These are boilers that operate only on a mechanical principle (like a gas stove). They can be used in remote villages that do not have a network connection.

Many models of wall-mounted gas boilers have various additional functions:

- possibility of remote control . The units have a module for Internet access and can be configured from anywhere in the world via a smartphone application;

- climate sensors . This function allows you to adjust the boiler operating mode in case of sudden changes in outside temperature;

- connecting a room thermostat . Controlling the operation of the boiler with priority to external sensors allows you to save fuel and provide more comfortable indoor conditions.

IMPORTANT!

Many functions that are available on expensive boiler models are almost never used. When purchasing, you need to decide whether it is advisable to overpay for unnecessary features. There is always the opportunity to buy exactly the boiler that will be used to its fullest extent.

Criterias of choice

When choosing a boiler, you need to take into account functions, efficiency, power, price, dimensions, heat exchanger material and the presence of safety systems. The type of device location primarily affects the cost and complexity of its installation, and only indirectly affects the technical characteristics.

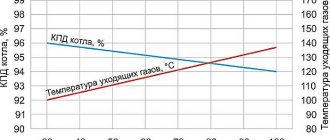

The efficiency for atmospheric boilers is in the range of 80-93%.

By power

The characteristics of a gas heater depend on the area of the heated room:

P (boiler) = UM * Pl * K, where UM is the specific power of the device (0.1 kW/m²), Pl is the area of the house, K is the correction factor of the geographic zone. For Moscow and Moscow Region this figure corresponds to 1.5, for the middle zone - 1.2-1.5, for the northern regions - 2-2.5, for the southern regions - 0.9. The resulting value is multiplied by the safety factor (1.15-1.2) and rounded up.

For example, for a house with an area of 80 m² in the city of Vladimir, the boiler should have a power of 12-15 kW.

For a more accurate calculation, you can use an online calculator. The service takes into account the following factors:

- maximum temperature difference between inside and outside the house;

- volume of heated room;

- heat loss coefficient (wall material and thickness, insulation, etc.);

- type of floors;

- type and number of windows.

The average specific power factor, taking into account losses, is 50-70 W/m² for buildings made of modern materials, 90-110 W/m² for houses with thermal insulation, built after 1990, 130-200 W/m² for old buildings without thermal insulation. isolation.

Important: for a double-circuit boiler, the design power increases by 20-25%. This part of the energy will be spent on hot water supply.

According to the material of manufacture

Most often, heat exchangers are made from cast iron, stainless alloy or steel with a corrosion-resistant coating. Boilers with a copper tank are less common.

For equivalent cost and functionality, it is better to buy a model with a heat exchanger made of copper or cast iron. It is also worth paying attention to reviews about the strength of the case.

On automation and safety

Independent protocols turn off the boiler in emergency situations, lack of draft, strong voltage drops, drop in fuel pressure, etc. The presence of a monitoring electronic unit allows you to determine the error without completely disassembling the installation.

The device's safety system consists of sensors for hydrocarbons, draft, temperature, flame, overheating and water level. The self-diagnosis function reduces the risk of unexpected shutdown of the boiler.

Most popular manufacturers

European companies are usually considered to be the most famous manufacturers of wall-mounted gas boilers.

These include:

- Vaillant;

- Buderus;

- BAXI;

- Protherm;

- MORA-TOP;

- Ariston;

- Viessman.

The list of manufacturers can be continued for a long time. It is constantly being replenished; new successful companies are entering the market offering their models of wall-mounted gas boilers.

NOTE!

Many companies are expanding and moving production to other countries. This often harms quality because there is inconsistency and inappropriate parts are used. This point should be taken into account when choosing a wall-mounted gas boiler.

How to calculate power?

Performing a full calculation of the power of a heating system is difficult and beyond the power of a person who does not have special training. However, there is an easy way to determine power.

It has been experimentally determined that heating 10 m2 of area requires 1 kW of thermal energy. This means that a 24 kW boiler is designed to heat a house of 240 m2, and a room of 150 m2 will require 15 kW of power.

Guided by this ratio, you can quickly and accurately select the right boiler . It is necessary to take into account that it is impossible to make a large reserve of power - the unit will operate abnormally, which will cause the burner to constantly turn on and off.

This mode will create conditions for rapid failure of important components and parts of the boiler.

Rating of TOP 5 wall-mounted single-circuit boilers

Among single-circuit wall-mounted boilers, the following models stand out:

Buderus Logamax U072-18

world famous concern Bosh. Experts note the high quality of the products, which is not inferior to the products of the parent company . The Buderus Logamax U072-18 boiler is a single-circuit unit with a power of 18 kW, which is suitable for heating a house of 160-180 sq. m. m.

The manufacturer warns that if the water hardness is more than 16°dGH, you will need to use softeners or special filters.

Boiler parameters:

- coolant temperature - 40-82°;

- pressure in the heating circuit (max) - 3 Bar;

- dimensions - 400/299/700 mm;

- weight - 32 kg.

The unit can be connected to an external indirect heating boiler, which will provide the home with hot water.

BAXI LUNA-3 1.310 Fi

The BAXI company is considered Italian, although the enterprises are scattered throughout Europe, and the head office is located in the Netherlands. The LUNA-3 1.310 Fi boiler is a convection unit with a power of 31 kW.

This is a solid device capable of heating a residential building or office with an area of up to 310 square meters. m. High efficiency (93.1%) ensures fuel savings and allows you to get maximum performance from the boiler.

Characteristics:

- coolant temperature - 30-85°;

- gas consumption - 3.52 m3/hour;

- pressure in the heating circuit (max) - 3 Bar;

- dimensions - 450x763x345 mm;

- weight - 40 kg.

According to the manufacturer, the boiler service life is at least 10 years with a 2-year warranty.

BAXI LUNA Platinum+ 1.32

Another representative of the Italian company is a condensing single-circuit boiler with a capacity of 34.8 kW. Its efficiency is 105.7%, which is nothing more than a clumsy marketing ploy.

A preheating stage has been added to the design of the unit, which allows reducing the intensity of the burner and saving fuel. However, the physical possibility of condensation with the release of heat is possible only under certain and rather narrow conditions, which are impossible in Russia.

Unit parameters:

- coolant temperature - 25-80°;

- gas consumption - 3.49 m3/hour;

- pressure in the heating circuit (max) - 3 Bar;

- dimensions - 450x760x345 mm;

- weight - 37.5 kg.

The price of the BAXI LUNA Platinum+ 1.32 condensing boiler averages 76-80 thousand rubles.

Considering the uselessness of an additional heating stage in most regions of Russia, the need for such a purchase should be carefully weighed.

MORA-TOP Meteor Plus PK24SK

A product from Czech manufacturers with a power of 23.7 kW. This is the optimal value for a room with an area of 220-240 square meters. m., which corresponds to the size of most cottages .

It is a single-circuit gas wall-mounted atmospheric type boiler. Requires connection to a common stove-type chimney.

Its characteristics:

- coolant temperature - 30-80°;

- gas consumption - 2.6 m3/hour;

- pressure in the heating circuit (max) - 3 Bar;

- dimensions - 400x750x380 mm;

- weight - 27.5 kg.

Users note the high performance and reliability of the unit, stability of operation.

Protherm Panther 25 KTO (2015)

The Protherm brand is the brainchild of the Vaillant Group, and was created specifically for the production of inexpensive, high-quality gas boilers. Initially, the products were aimed at the market of Russia and the CIS countries.

The Protherm Panther 25 KTO (2015) boiler has a power of 25 kW, which is suitable for heating 250 sq.m. It features low fuel consumption and stable, trouble-free operation.

Main characteristics:

- coolant temperature - 30-85°;

- gas consumption - 2.8 m3/hour;

- pressure in the heating circuit (max) - 3 Bar;

- dimensions - 440x800x338 mm;

- weight - 41 kg.

When connecting an external boiler, it becomes possible to provide the room with hot water, which makes the unit a fully functional device.

Types of boilers

It’s worth starting with a brief analysis of the main types of boilers in order to understand the system of their operation and the appropriateness of installation in a particular home.

Floor and wall types of equipment

The floor structure is distinguished by its high weight - up to 100 kg. Its installation requires a lot of space, and installation is labor-intensive, complex and expensive. Most floor-standing atmospheric boilers do not heat water to be supplied to mixers. During operation, the floor-standing unit makes a lot of noise, and the chimney requires regular cleaning.

Positive sides:

- high power;

- durability;

- lack of electronics.

Wall heaters are smaller in size and weight (up to 50 kg). Such boilers are predominantly double-circuit. The model is easier to install and does not take up much space. The boiler can be placed anywhere in the room. Wall-mounted atmospheric boilers are single-circuit and double-circuit.

Both floor-mounted and wall-mounted boilers are produced to serve one or two circuits. However, if space allows, it is better to take two: a floor-mounted single-circuit one for heating and a column for preparing hot water

Disadvantage: a wall-mounted boiler depends on electronics. If something burns out, you will lose hot water and heating. Boilers are installed mainly in small apartments and houses.

Single-circuit and double-circuit

Single-circuit and double-circuit boilers differ in the tasks they can perform. So, for example, a double-circuit boiler (following the name) performs two tasks: it heats the room and heats water to be supplied to the mixer.

The single-circuit one performs only one standard function - heating.

A double-circuit boiler, in addition to its standard function, makes it possible to obtain hot water for various needs, but it cannot be called a full-fledged “boiler”. The fact is that the pressure of water that passes through the unit must be very strong for the system to work. Therefore, such a boiler needs to be installed near the bathroom and kitchen.

We recommend: Soapstone stoves: features, principle of operation, do-it-yourself lining

A single-circuit boiler does not give you the additional function of a boiler, however, it costs several times less. The operating system of such a unit is simple, which means that if it breaks down it will be easier to repair. In addition to a single-circuit boiler, you can install an indirect heating boiler, which can operate on various fuels (gas, electricity, solid fuel), be floor-mounted or wall-mounted.

It works as follows: a central heating system is connected to the boiler (in a small circle); A flask with water is installed inside the unit, through which a coil passes. Hot water passing through the coil heats the water inside the boiler, and it can be used for personal purposes. When the heating is turned off, the taps at the inlet and outlet of the central heating pipes are closed, and the water in the boiler is heated using gas, electricity or solid fuel.

For more information on the structure and difference between single-circuit and double-circuit boilers, watch the video

Rating of TOP 5 wall-mounted double-circuit boilers

Of the huge number of double-circuit wall-mounted boilers, the following should be highlighted:

Buderus Logamax U072-12K

Wall-mounted double-circuit unit, created specifically for work in Russian conditions. Capable of efficiently heating a room of 100-120 square meters. m., and also provide hot water for a family of 3-4 people.

According to the manufacturer, the boiler can withstand voltage surges from 165 to 240 V, although practice does not confirm this. The unit is equipped with a pre-mix burner, which can be adjusted to a specific heating mode.

Main characteristics:

- coolant temperature - 40-82°;

- DHW temperature - 40-60°;

- pressure in the heating circuit (max) - 3 Bar;

- pressure in the DHW line (max) - 10 Bar;

- dimensions - 400/299/700 mm;

- weight - 29 kg.

The boiler is easy to install and quickly configured, as it is sold already prepared for operation.

Navien DELUXE 13K

The Korean company Navien positions itself as a manufacturer of high-quality and inexpensive heating equipment.

The DELUXE 13K boiler with a power of 13 kW is capable of heating an area of up to 130 square meters. m., which is suitable for a small house or apartment . The model is characterized by low gas consumption, which is not typical for dual-circuit devices.

Characteristics:

- temperature in the heating circuit - 40-80°;

- DHW temperature - 30-60°;

- pressure in the heating circuit (max) - 3 Bar;

- pressure in the DHW line (max) - 8 Bar;

- dimensions - 440x695x265 mm;

- weight - 28 kg.

Korean boilers are criticized due to their high noise level, but their low price and reliability more than compensate for this drawback.

Vaillant turboTEC pro VUW 242/5-3

There is no need to introduce Vaillant - one of the leading manufacturers of heating equipment is known to everyone. The Vaillant turboTEC pro VUW 242/5-3 boiler with a power of 24 kW is designed for medium-sized private homes or offices - up to 240 sq.m.

Its capabilities:

- temperature in the heating circuit - 30-85°;

- DHW temperature - 35-65°;

- pressure in the heating circuit (max) - 3 Bar;

- pressure in the DHW line (max) - 10 Bar;

- dimensions - 440x800x338 mm;

- weight - 40 kg.

Vaillant products are rightfully considered one of the benchmarks for quality and durability. Experts and ordinary users note the reliability and stability of the operation of these boilers.

Bosch Gaz 6000 W WBN 6000- 12 C

Double-circuit gas boiler of convection type. With a power of 12 kW, it is capable of heating a room up to 120 sq.m., which is suitable for an apartment, office or small house.

Boiler parameters:

- temperature in the heating circuit - 40-82°;

- DHW temperature - 35-60°;

- pressure in the heating circuit (max) - 3 Bar;

- pressure in the DHW line (max) - 10 Bar;

- dimensions - 400x700x299 mm;

- weight - 32 kg.

The Bosch company is widely known all over the world, but recently there has been a noticeable decline in the quality and reliability of its products.

This is due to the scattered nature of production, inconsistency of parameters and quality of parts, and other organizational reasons.

BAXI LUNA-3 COMFORT 240 i

The brainchild of Italian engineers, the BAXI LUNA-3 COMFORT 240 i boiler has a power of 25 kW. This is suitable for heating rooms up to 250 sq.m.

The copper heat exchanger allows for maximum operating efficiency. The boiler efficiency is 92.9%, which is a very high figure for double-circuit models.

Unit parameters:

- temperature in the heating circuit - 30-85°;

- DHW temperature - 35-65°;

- pressure in the heating circuit (max) - 3 Bar;

- DHW line pressure (max) 8 Bar;

- dimensions - 450x763x345 mm;

- weight - 38 kg.

The boilers of the Italian company demonstrate high performance and reliability. The only drawback is considered to be the poor organization of service.

The best wall-mounted single-circuit gas boilers

High-quality space heating is the main purpose of single-circuit units. The heat exchanger heats the coolant (water, steam) circulating through the heating system in the house. Single-circuit wall-mounted gas boilers are characterized by relatively small dimensions and have good efficiency (at least 90%). Such designs are popular among owners of small spaces. We present single-circuit boilers that are among the top five best models.

Bosch Gaz 6000 W WBN 6000 24H

A wall-mounted gas boiler produced under the German brand Bosch is designed only for heating a room. During operation, the device consumes natural gas in a volume of 2.8 m3/hour. Coolant type – water. The combustion chamber is turbocharged, closed. The power of the Bosch Gaz 6000 W WBN 6000 24H unit is 24 kW, the efficiency is 93%, and the weight is 34 kg. Ignition is carried out automatically. The design of the device includes a circulation pump with a built-in deaerator and a fan. The front panel has a liquid crystal display that displays data on the operation of the boiler and error codes.

Pros:

- Compactness of the product.

- High build quality.

- Strict design.

- Ease of Management.

- Automatic control of power, draft, flame, and coolant circulation is provided.

- Frost protection.

- Safety sensors with automatic shutdown function.

- OpenThermTM operating parameters regulators.

Minuses:

- The body is made of thin metal.

- Difficulty with initial settings.

- High cost of maintenance and original spare parts.

Protherm Panther 12 KTO

The standard gas boiler is made in Slovakia. The wall-mounted device is designed to heat rooms with a total area of no more than 120 square meters. The Protherm Panther 12 KTO model can be installed in enclosed spaces without a chimney, since it independently removes combustion products forcibly. The burner is made of chromium-nickel steel.

For the convenience of users, a special liquid crystal display is placed on the unit body. Sensor indicators displaying the heating process and error codes are displayed on the screen. If necessary, the owner changes the operating parameters using the appropriate buttons. The list of device functions includes: protection against overheating, freezing, flame control, chimney draft.

Pros:

- High efficiency of the unit.

- Compactness.

- Modern design.

- Operational safety.

Minuses:

- Lack of automatic fuel supply.

Ariston Clas EVO 15 FF System

The Italian mounted gas boiler Ariston Clas EVO 15 FF System runs on liquefied or natural gas and is capable of providing heat to rooms up to 165 square meters. m. The power of the product is 16.5 kW, the efficiency coefficient is 93.6%, weight is 30 kg, dimensions are 400x770x315 mm. In one hour of operation, the boiler burns gas with a volume of 1.75 cubic meters. The heat exchanger is made of copper. The temperature range in the circuit is from +35 to +80°C. Thanks to the closed-type turbocharged combustion chamber and forced draft, the unit is suitable for rooms without a chimney.

Pros:

- Compact sizes.

- Beautiful design.

- Ignition type – automatic.

- Electronic control, LCD screen, buttons.

- There is protection against freezing and disruption of water circulation in the system.

Minuses:

- There are no cons.

Buderus Logamax plus GB172i

The wall-mounted gas boiler Buderus Logamax plus GB172i is made in an ultra-modern style. The unit is characterized by increased efficiency and efficiency. Using the Buderus EasyControl program and the installed KM200 web module, the owner can control the heating from a distance using a smartphone. The front panel is made of Buderus Titanium Glass.

Pros:

- Energy efficiency (when using the additional Logamatic RC300 control system, the boiler corresponds to class A+++).

- Stylish design.

- A harmonious combination with any interior design.

- Compactness (the boiler takes up little space).

- Convenience, ease of use.

- The body coating is scratch resistant and easy to maintain.

- Versatility (the device is ideal for installation in apartments, private houses, office buildings, etc.).

Minuses:

- High price.