Each of us is the owner of a vehicle. During use, the paintwork applied to the car body fades, wears off, and cracks. Often, pockets of rust and corrosion can be seen on the surface of the vehicle. This is due to the fact that under the influence of an aggressive environment, the paint layer on the car body loses its aesthetics and becomes covered with chips and scratches. Sometimes the coating literally falls off. To prevent negative processes and improve the appearance, you should paint the body. The easiest way is to take the car to a professional paint shop. But the services of car painters are expensive. An alternative is to paint the car yourself. But then you can’t do without special equipment. To do this, you will need a spray gun for painting a car.

What is a spray gun

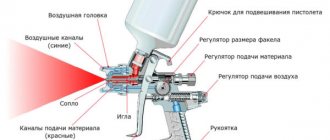

This equipment is designed for automatic painting of various (metal, wood, plastic, stone) surfaces and has universal characteristics. It is possible to adjust the operation of the tool, depending on the task. The device allows you to “evenly” apply a paint coating, forming a smooth layer, without fluff, pellets, or bristles, which are possible when working with a roller. The device consists of three main technical components:

- spray gun;

- paint storage tank;

- power supply systems for supplying the mixture.

Today, several types of equipment are produced for carrying out paint and varnish activities. The operating principle of all these units is approximately the same. In addition, using this automatic device, it is possible to apply paintwork not only to vehicle bodies. It is also used for:

- applying a decorative protective coating to a metal surface;

- spraying trees, shrubs, flowers in the country;

- treating premises against insects;

- surface priming during repair and construction operations;

- sanitary disinfection (from fungi) of rooms, workshops, apartments, private houses;

- processing of road infrastructure objects.

A pneumatic spray gun sprays any type of solution. The main thing is that individual fractions of liquid pass through the hole without problems. In this case, the viscosity of the mixture must correspond to the required technical parameters.

Diagram of the spray gun device

How many spray guns should you have?

There are units designed for applying paint, primer, and varnish. The best option would be to have three spray guns at hand. Each of the devices will perform its own “role”, spraying one or another type of liquid. This eliminates the risk of mixing varnish with primer or paint when using one device. It is possible to use one device for all types of solutions. But then you will have to additionally carry out the procedure of washing the equipment before pouring different mixtures. Next, we will tell you how to choose a spray gun for painting a car.

Please note: Painting a car with chameleon paint

Types of spray guns

A spray gun is a device designed for automatically applying various compositions to a surface. Their list is represented by paint, varnishes, and other liquid-type materials. The compositions are applied to wood, metal, plastic, and other surfaces, obtaining a thin, uniform and evenly distributed layer.

When spraying, the likelihood of drips is reduced to zero; an additional bonus is the ability of the spray gun to paint hard-to-reach areas. No brush or roller can compare with it when processing wavy walls, corners, and inaccessible places. The most obvious example is the inner surface of the battery.

Practicality in use has made the spray gun a favorite tool for specialists. It is used by painters, plasterers, car mechanics, artists, florists. The list of works performed using the device includes:

- surface treatment;

- applying drawings and patterns;

- spraying house plants and shrubs.

Miniature spray guns have even found use in cooking. In particular, confectioners readily use them when creating cakes. The product classification is represented by many models, each of which deserves a separate description. At the same time, they do not have to be a highly specialized mechanism; most spray guns are universal.

Their design is not fundamentally different, representing a trigger device equipped with a container of paint (of a different composition) and a handle. When you press the trigger, activation occurs and the composition is sprayed over the surface. The differences are determined by the characteristics of the drive, which are discussed below.

Mechanical

When choosing a spray gun for your home, pay attention to mechanical products. This is the best option for a private home. With its help, the owner will be able to perform maintenance tasks on buildings and gardens. Specifically, this includes whitewashing, painting walls, and spraying trees in the garden. The mechanical structure is expressed in the characteristics of the work, depending on the muscular strength of the operator. There is a lever and a pump.

When the lever is pressed, air enters the container, which in turn is pushed out by the pump, squeezing the paint onto the surface. Given the low power, it is important to select the compositions wisely. They should not be too thick, otherwise the nozzle will quickly clog. The advantage is autonomy. The operator does not depend on the power grid, freely moving the unit around the territory.

Pneumatic

The system includes a compressor and a receiver. When the trigger is pressed, the injected air forces material into the nozzle. Here it turns into funnel-shaped dust, applied to the surface. A characteristic feature is its finely dispersed structure. This allows you to work with materials of varying thickness.

Electric air spray guns

Here the pressure is created by a motor, under the influence of which the paint enters the nozzle. It comes out in the form of fog, evenly covering the surface. It is important that there is no need to purchase a compressor here, so the modification is suitable for all users, regardless of experience and skills. The downside is the low percentage of paint transfer.

Electric plunger (airless) spray guns

Electric spray guns do not have this drawback. They are equipped with nozzles with a small cross-section, into which paint is supplied under high pressure through a hose. Almost all the material reaches the surface, increasing productivity. The downside is the uneven application; often the composition is layered on the surface.

The decisive factor is the skill of the specialist, his ability to keep up with the speed of the tool.

Rechargeable

Electric spray guns are divided into mains and battery models. In the first case there is a wire, in the second there is a powered battery. The battery version creates autonomy, but on average the operating time is 30 minutes, after which the product needs to be recharged. The cost of autonomous versions is higher, but they have less power and are heavier due to the battery. This factor must be taken into account before choosing an electric spray gun for home use.

Tool requirements

When choosing it, you should take into account several criteria on which its performance and cost level will depend. Need to know:

- how often the tool will be used. There is no need to purchase a professional device for one-time work;

- what is the build quality? This will determine how well the device functions;

- product settings. They must be suitable for the tasks performed;

- unit power;

- what are the leading brands in the market.

It will be useful to analyze user reviews on the Internet. Often, forum participants present interesting facts about these devices.

Types of paint supply

Spray systems

The operating principle of this equipment is the same. The device mixes the dye in a tank (or another solution). Compressed air under the compressor enters the device. The solution flows through another channel. The air splits the mixture coming out of the nozzle, forming a solution torch. Then the liquid medium is supplied in the form of a fine-grained jet to the car body part. Depending on the pressure force and the mixture supply scheme, the type of equipment is determined. There are the following spraying options by which these devices are classified:

- HP;

- HVLP;

- LVLP.

To choose the optimal specimen for painting, you need to have information about each of the systems. We will talk about three popular options.

Spray systems

HP system

Produces a working pressure of 3-4 atmospheres. Creates a wide torch and evenly applies paintwork to the surface. The speed of application of the mixture is high. The model is relatively inexpensive. The disadvantages of the unit include:

- low coefficient of transfer of liquid substance to the surface;

- significant air movement provokes the raising of dust in the workshop, which is undesirable;

- The system is quite old, but reliable.

After using this type of spray gun, the surface of the car is sanded. This is due to the high rate of air contamination with dust.

HVLP system

This type of equipment has been used since the 90s. twentieth century and has proven itself well. The device uses a significant volume of air, and the mixture is sprayed at low pressure - one atmosphere. Thanks to this technology, over 75% of the paintwork material is transferred to the working surface. The system has its advantages:

- creates a low level of fog in the air;

- does not raise dust in the workshop;

- shows good performance.

Pay attention to: Choosing paint in a spray can for painting a car: main problems and methods for choosing the composition

There are several disadvantages to this system. It requires a powerful compressor to operate. The coloring solution should be applied close to the surface. This makes it difficult to process hard-to-reach, remote areas. The procedure will require special skills.

LVLP system

This type of sprayer is an innovative device, and was developed to eliminate the shortcomings of the previous two types of units. The technology used makes it possible to combine low air consumption with a significant coefficient of paint coating application. The input pressure of these devices is 1.6-2 atm, and the spraying process is 0.7-1.2 atm. The efficiency of the mixture transferred to the surface is 70%. The unit distributes any liquids. Paint guns of this brand:

- do not consume a lot of air;

- have a high percentage of efficiency;

- do not raise dust;

- create minimal “fog”;

- do not respond to power surges;

- show an excellent percentage of spray paint.

This type of equipment has few disadvantages: it creates a smaller torch than the previous two types and a low solution spraying speed. The LVLP spray gun has proven itself well during operation.

Pneumatic spray gun

A pneumatic spray gun is rightfully considered a professional tool, which is very actively used in production and service stations, but before you buy such a device, you need to understand their varieties and features.

The first thing you need to know when purchasing an air spray gun is that it requires an air compressor to function. Without a compressor, any pneumatic tool is useless. Moreover, to connect the spray gun to the compressor you need a special high-pressure hose, and sometimes additional fittings. The principle of operation of a pneumatic spray gun is as follows: through a hose, a compressor supplies compressed air under pressure into the gun; inside the gun, the air sprays the paint into small particles and releases them through a nozzle onto the surface to be painted. When choosing a pneumatic spray gun, first of all, you need to understand the spray systems that are used in pneumatic spray guns; the speed, quality and overall efficiency of using a particular spray gun depends on the choice of a particular system.

Compressor selection

When selecting this technical unit, you should take into account what type of spray gun it is. We remind you that there are electric and pneumatic. The second model is considered preferable in terms of performance indicators. Each type of equipment (HP, HVLP, LVLP) has its own characteristics. Based on them, the compressor is selected. HP units require 4 atm for manipulation, while the spray gun incurs noticeable losses during operation (which is why they are gradually going out of use). A compressor is required that is not very productive (100-300 l/min.) with an indicator of 6 atm. AURORA BREEZE-8, KOLNER KAC 24 L are suitable. Devices designed according to the HVLP type require 2-3 atmospheres for spraying. When choosing a compressor for this type of device, we pay attention to technical products with a capacity of 360 l/min, and from 1.5 to 4 atm. The following types of equipment have proven excellent: QUATTRO ELEMENTI 248-504 KM 50-380, FUBAG VDC 400/50 CM3, GARAGE PK 50.MKV370/2.2. LVLP is a technologically advanced instrument, operating in the range from 0.7 to 1.5 atm. A compressor with a capacity of 150-300 l/min is required. The output indicators must be at least 2 atm. We recommend purchasing: QUATTRO ELEMENTI SENZA-24, ZUBR ZKP-190-24-1.5.

Compressor AURORA BREEZE-8

Compressor QUATTRO ELEMENTI KM 50-380

Compressor BISON ZKP-190-24-1.5 Pay attention to: How and with what to paint plastic in the car interior

Selection options

When purchasing, the specific parameters of the spray gun are taken into account, determining its operating speed and functional properties.

Gun type

Spray guns are divided into 3 subsections:

- High pressure model marked HP. They are distinguished by their low cost, but a relatively low rate of paint transfer to the surface. Specific figures are 30-50%. The budget format predetermines the purchase of modifications by individuals and companies. They do a good job of work that does not require specialist qualifications;

- The high-volume, low-pressure model is designated HVLP. Here the transfer percentage reaches 65%, excluding paint overuse. Therefore, spray guns are popular among painters, as well as in auto repair shops. A powerful compressor becomes a prerequisite for use. In addition, products require clean air;

- Low volume, low pressure version with LVLP marking. The most economical option of all pneumatic models. Almost all the material reaches the surface - 80%. Due to this, the cost of the product is higher, but it quickly pays for itself. These are the models that professionals prefer to use.

Power (for electric models)

The average power of network modifications is about 200 W. Their network analogues provide 350 - 700 W. These parameters allow you to cope with any job, be it a painted wall or a fence.

Pressure

When talking about pressure, we always pay attention to the type of spray gun, since in all cases the indicators are different, for example:

- mechanical units have a pressure of 0.4-0.6 MPa;

- pneumatic option. It all depends on the labeling. HP pressure is 1.5 - 2 atm, in HVLP this figure is about 1 atm;

- electric models. Pressure reaches 400 – 530 bar

Attachments (tanks, nozzles)

Some components are removable. During operation, they can be changed, increasing the versatility of the spray gun. The material for painting is poured into a container, the volume of which is determined by the scale of the work. If they are minor and associated with occasional use, painting furniture and crafts, a 300-600 ml tank is suitable. When the work involves painting large objects (houses, garages, fences), it is better to choose 800-1000 ml containers.

The larger the tank, the more your hand gets tired, but the bonus is the speed of application of the material. You don’t need to constantly add paint while taking time away from your work.

Performance

The parameter is determined based on paint consumption per minute. The higher the indicator, the higher the operating speed. For example, if the flow rate is 1 liter/min, painting a surface of 100 m2 will take about 20 minutes.

Maximum viscosity

The accompanying instructions for the spray guns indicate the viscosity of the material acceptable for use. If it exceeds the value, the composition must be diluted, making it more liquid. The problem can also be solved by replacing the nozzle.

Nozzle diameter (nozzle)

The higher the nozzle diameter, the thicker the solution can be. Depending on the material, a spray gun of the following diameter is used:

- 1.3-1.7 mm. Varnish, enamels, liquid paints;

- 1.8 mm and above. Putty, thick compounds.

It is optimal to opt for products with replaceable nozzles.

Material, volume and shape of the paint tank

Liquid compounds are located in containers called a tank. They can be located at the bottom, top or side of the spray gun. Here the choice determines the nature of the surface to be painted. If these are walls and other vertical objects, then it is better to use models with a lower tank location. Modifications where it is located at the top are great if you need to treat the floor and ceiling.

Availability of adjustments

In modern modifications, the parameters can be adjusted. This will help you choose the right spray gun for painting a car or decorative surface treatment. Adjustable power and pressure ensure fine work.

How to choose a nozzle

This part of the atomizer plays an important role. The fact is that it has a certain size, and paint is directed through it and a needle is attached to it, which sprays the working mixture. Depending on the viscosity and physical composition of the substance used, the nozzle diameter is selected:

- Local painting and metallic color mixture -1.2.

- Water-soluble paints, as well as bases – 1.3-1.6.

- Varnish and acrylic – 1.4 -1.6.

- Primer – 1.6-2.2.

- Liquid putty – 2.5-3.0.

To begin with, you can buy a device with a nozzle with parameters 1.4. This diameter allows for different types of work. But it will also be possible to apply paint and primer, including those with the addition of solvents.

Attention! On the market you can find models with a set of replaceable nozzles and needles, and a varied range of diameters. They are universal and suitable for any event.

Replacement nozzle for spray gun