X

The use of a concrete vibrator during laying is a necessary condition for obtaining the design characteristics of the material.

Regardless of the mixing method, freshly poured concrete contains air bubbles, “excess” moisture, and heterogeneous fragments. You can give a monolith density and brand strength using different compaction methods, one of them is vibration.

Purpose

Even a solution thoroughly swirled in a stirrer cannot be 100% homogeneous. In theory, an uncured monolith is a “skeleton” of crushed stone, evenly covered with a wet cement-sand mixture. In reality, the contents of the formwork (form) include:

Helpful information:

- Concrete substitute and its advantages

- How much does a cube of concrete weigh?

- Ironing of concrete surface

- Anchors for concrete

- Plasticizer for concrete: types and applications

- DIY concrete polishing

- air bubbles;

- water unbound with cement;

- undistributed aggregate or additive particles.

The risk of stratification and airing of the mortar increases with a long time interval between mixing and installation, incorrect pouring (from a great height or in thick layers) or transportation.

Liquid and air “pockets” impair the adhesion of the crushed stone frame to the binder. Having gained strength, uncompacted concrete quickly cracks and crumbles.

To achieve uniformity when pouring into formwork, the concrete solution must be fluid (plastic). At the same time, the correct proportions of heavy concrete exclude a consistency convenient for laying. The use of a deep vibrator for pouring concrete can temporarily increase the fluidity of concrete and prevent the mixture from separating.

After the “correct” vibration compaction:

- the volume of concrete poured into the formwork is reduced by a third - due to the removal of gas and liquid sinks, compaction of sand and crushed stone;

- Cement laitance and fine sand fractions float to the top, the surface becomes smooth and glossy.

During hardening, the “vibrated” monolith reaches high density and maximum (for the design grade) strength.

Principle of operation

The main purpose of the vibrator is to transmit mechanical impulses to concrete throughout its entire volume, influencing the particles of the mixture. As a result, the viscosity of the solution decreases and it gains the ability to penetrate into small cavities, displacing air from there.

The following video clearly shows how the vibrator works:

With prolonged exposure, heavy fractions push the air in the solution to the surface and, as a result, the concrete acquires the most homogeneous structure, which increases its performance characteristics.

Vibration of the working fluid occurs from the rotation of an eccentric inside it (electromechanical and motor vibrators), due to the difference in pressure of air or liquids (pneumatic and hydraulic devices) or due to oscillations of the electromagnetic field in devices of the same name.

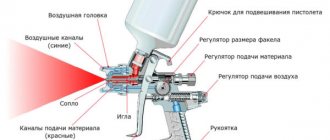

Vibrator device for concrete

More often, vibrators for deep (internal) type concrete are used on construction sites. Therefore, the design and general principle of operation should be considered using the example of a submersible model.

Main components of vibrating tools:

- drive based on an electric (usually) motor - creates torque on the rotor shaft;

- flexible shaft – transmits the rotation of the motor through the coupling to the shaft (spindle) of the vibrating tip. The flexible shaft is attached to the spindle using a thread;

- vibrating tip (mace) - a rigid body with a spindle located inside and a mechanism that converts the rotational movement of the rotor into vibrations (vibration).

A more detailed drawing of a needle vibrator for concrete is shown in the figure.

Based on the type of rotation conversion mechanism, vibrating tips are distinguished between pendulum and eccentric types.

In the first case, the runner attached to the shaft rolls inside or outside the cone (core or sleeve).

To start a tool with a “pendulum”, it is not enough to turn on the engine - you need to hit the tip on a hard surface to initiate oscillations.

Inside the tips of the second type, vibration is created by an eccentric unit, similar to a crank.

Also, the eccentric mechanism can be implemented in the form of a shaft with a load to shift the center of gravity.

The most common drive option is an electromechanical motor operating from a standard network (220 or 380 V at a frequency of 50 Hz).

High-frequency deep vibrators operate at a frequency of 200 Hz and a voltage of 42 V.

Rating of the best deep-seated vibrators

Now let’s look at the best deep-seated vibrators, which received the most positive customer reviews and were liked by experts for their characteristics.

| Nomination | place | Name of product | price |

| Review of the best deep-seated vibrators | 1 | Wacker Neuson IEC 38/230/5/15 | 70 000 ₽ |

| 2 | ENAR М5AFР | 49 608 ₽ | |

| 3 | RED MAYAK EPK-1300/51 (045-0261) | 13 850 ₽ | |

| 4 | Sturm! CV7120 | 16 262 ₽ | |

| 5 | Zitrek Z-1100 | 4 099 ₽ | |

| 6 | PATRIOT CV 100 | 2 860 ₽ | |

| 7 | Energomash BV-71101 | 3 810 ₽ |

Wacker Neuson IEC 38/230/5/15

Rating: 4.9

In first place is a German deep-well vibrator with a drive shaft length of 5 m and a network cable of 15 m. The size of the mace is 285 mm and it makes high-frequency vibrations up to 12,000 per minute. The vibrating tip with base weighs 11.3 kg, so it is easily immersed in the solution. The diameter of the mace is 38 mm, ensuring penetration of the impact up to 40 cm from the epicenter. Construction equipment operates on a 220 V network and consumes 420 W/h. Users in the reviews like the thick power cable of the vibrator - even if you step on it with tarpaulin boots, it will not be damaged. The rubberized button protects against electric shock if you touch it with wet hands. One third of the length of the club has a hardened metal part, which increases the strength of the equipment.

We considered the vibrator to be the best due to the thin, elongated base body. It does not need to be carried in your hands and it does not stand, like other deep-depth devices, but lies down. If the shaft length is not enough, the operator can easily pull the base itself by the hose without going to the device. This increases ease of use and saves time when working on a large site.

Advantages

- long shaft 5 m;

- high level of strength;

- good capsule tightness;

- 30% of the tip is hardened.

Flaws

- high price;

- Not sold in every city.

ENAR М5AFР

Rating: 4.8

In second place is a deep vibrator from the Spanish manufacturer Enar. The device has a club with a length of 385 mm and a diameter of 50 mm, which consumes a current of 14 A and generates 12,000 oscillations per minute. The average productivity of concrete compaction is 30 m³/h. The vibrator converts the frequency from a household socket of 50 Hz to a higher frequency of 200 Hz, which improves the effect on loose concrete. The 5 m long shaft facilitates operator mobility on the construction site. User reviews praise the reliable insulation of the power cable exit from the housing - the cable is covered with an additional rubber cuff and secured with steel clamps. All this increases safety during daily use on damp ground.

According to experts, deep vibrato is the best in terms of the strength of the drive shaft shell. It is made of a hose with a wall cross-section of 7 mm. This design prevents the shell from breaking during regular bending. If one of the workers accidentally steps on the drive, the device will not stop working from the pressure.

Advantages

- reliable insulation of the network cable exit from the housing;

- aluminium case;

- drive shaft 5 m long;

- operates at a frequency of 200 Hz.

Flaws

- the shaft is not the most flexible due to the thick shell;

- high price;

- connection to an external voltage converter is required.

RED MAYAK EPK-1300/51 (045-0261)

Rating: 4.7

This is a deep vibrator from a domestic brand, which belongs to the semi-professional class. The unit has a power of 1.3 kW and creates 3600 vibrations per minute. The mace with a length of 410 mm and a diameter of 51 mm allows you to carefully penetrate the screed to the very base. The weight of the tip is 4.5 kg and does not require recessing - the nozzle itself is immersed in the concrete. The base of the model is made on a flat, stable base, on top of which the motor and starting device are fixed. There is a handle on top for repositioning. All metal parts are powder coated to protect them from corrosion.

The product is recognized as the best in terms of the ratio of sound volume and vibration quality. Despite the oscillation frequency of 3600 vibrations/min, the device hums relatively quietly. In reviews, buyers share that this is the best option when you have to lay the foundation for a house, cottage or other buildings yourself. After a whole day of work, your ears don’t get tired and your head doesn’t hurt. It works flawlessly, and if the tip does not vibrate when turned on, users advise hitting it on the ground and everything will spin.

Advantages

- handle for transportation;

- a stable base, thanks to which the equipment does not get dirty;

- The relatively small tip diameter of 51 mm allows compacting concrete in corners.

Flaws

- the bulky body cannot be pulled up by the flexible shaft;

- you will have to rearrange the base more often due to the drive length of 3 m;

- total weight 14 kg.

Sturm! CV7120

Rating: 4.6

And here is another model from another Russian brand, which involves mobile operation. If necessary, the base can be hung on the shoulder using a belt for which there are holes. The operator loads the club with one hand and starts the rotation of the shaft with the other. The kit includes a 4 m long flexible drive, suitable for compacting concrete with a depth of up to 3 m. There are also two spare carbon brushes, and their replacement does not require disassembling the housing, which is what customers like in the reviews. The diameter of the vibrating nozzle is 38 mm, and the unit makes 3600 vibrations per minute. The drive is fixed through a threaded connection, so jerks or sharp turns by the operator will not lead to breakage.

The deep vibrator is the best in terms of price and power. More expensive analogues have an indicator of less than 1 kW, but here the equipment generates 2 kW. This allows it to be used for a longer time and protects the winding from overheating.

Advantages

- protection of the network cable from refraction;

- loop on the body for a shoulder strap;

- the converter is already built into the housing;

- possibility of disconnecting and replacing the flexible shaft.

Flaws

- it is difficult to find tips on sale;

- plastic case;

- You need to keep the start button pressed at all times.

Zitrek Z-1100

Rating: 4.5

A portable vibrator for deep immersion in mortar is assembled in the Czech Republic. Its motor has a power of 1100 W and makes 13,000 vibrations per minute. The equipment is powered from a 220 V network. The diameter of the mace is 35 mm, which is optimal for working even with reinforced concrete, where the sheathing pitch is 50 mm. The manufacturer recommends immersing the vibrating attachment every 40 cm for best results. The flexible shaft is already included and has a length of 2 m. Its armor is both elastic and reliable. The start key has a safety button, so unauthorized start is excluded. During operation, it can be fixed to relieve the load on the index finger.

Buyers and our experts agreed that this is the best internal vibrator for ease of use. The portable model weighs 7.2 kg, which is much lighter than the competitors described above in the review. The D-shaped handle makes it easier to hold it suspended for 3-5 hours and it is easier to perform immersion manipulations in concrete, since the handle serves as an additional support.

Advantages

- affordable price;

- elastic hose armor;

- there is perforation on the case for accelerated cooling;

- the drive can be replaced;

- high-quality assembly.

Flaws

- small seal diameter - 20 cm;

- short shaft 200 cm.

PATRIOT CV 100

Rating: 4.4

The American company PATRIOT with production facilities in China offers a budget vibrator CV 100 for deep immersion and compaction of cement mortar. The electrically driven unit consumes 220 V and produces 1000 W, performing 13,000 vibrations/min. The length of the flexible shaft with armor is 1 m. It can be disconnected and replaced if necessary. To work, you will need to hold the base with one hand and guide the nozzle with the other. But with a total weight of 5.5 kg, it is easier than with other portable devices. In reviews, the vibrator is most praised for its effective heat removal through a metal gearbox, which facilitates long-term operation without interruption.

This model is designed to work in confined spaces. That is why its drive has a length of 1 m, but the size of the vibrating nozzle is 45x3.5 cm. This will allow you to avoid getting tangled in hoses in a small area where walls have already been erected. Most often, such a deep vibrator is used to compact concrete floor screeds in rooms of a private house, garages and baths.

Advantages

- start button lock;

- comfortable handle;

- light weight 5.5 kg;

- 13 thousand vibrations/min.

Flaws

- short shaft 1 m;

- Not everywhere you can buy a replacement mace for this model.

Energomash BV-71101

Rating: 4.3

The review of the best vibrators for deep compaction of concrete is completed by a model from the Energomash brand. The equipment is household and is designed to improve the quality of cement screed to the stated values by performing 4000 vibrations per minute. The kit includes a 1 m flexible drive with a tip, but optionally it can be extended to 2.5 m. The vibrator power is 1 kW, and the diameter of the mace is 35 mm, making it easy to immerse between the reinforcement bars. Immediately behind the gearbox and in the end part of the case there is perforation to remove excess heat, so the household model can work for a long time without overheating. In the reviews, buyers are satisfied with the affordable price of the vibrator and the high-quality assembly, but they advise immediately disassembling and adding lubricant to the gearbox, since there is little of it there from the factory.

This is the best deep-seated vibrator in terms of lightness of the body. Together with the submersible nozzle, the weight of the equipment is 2 kg. If a builder has back problems and lifting heavy tools is contraindicated, we recommend choosing this model.

Advantages

- reliable metal gearbox;

- efficient cooling system;

- start key lock;

- The network cable is protected from refraction.

Flaws

- construction dust gets inside through large holes in the housing;

- shaft 1 m long;

- short power cord;

- the handle slips in your hands.

Types and characteristics

Vibration compaction of poured concrete is possible in three ways - immersion (c), smoothing (a) and vibrating together with the formwork (b).

Depending on the dimensions and other features of the compacted mass, three types of vibrators are used. Having a similar operating principle, different types of vibration compactors differ in design.

Deep vibrator

Also called submersible or internal concrete vibrator. Compaction occurs when the vibrating tip is immersed in the solution.

Depending on the shape, a vibrating attachment can also be called a vibrating bayonet, vibrating shovel or vibrating rod.

Based on the location of the engine, there are:

Waterproofing impregnations and additives for concrete: how to make concrete waterproof

Classic deep-well vibrators with a flexible shaft inside the hose - using the example of such a model, the design and principle of operation were considered. The drive is based on a standard electric motor - a concrete vibrator connected to a 220 Volt network. Disadvantages - the presence of unreliable links - couplings and a flexible shaft, plus a heavy engine, which (in order to prevent overheating) must be kept suspended.

High frequency vibrators (pulse). The key difference is the location of the motor and motion transducer in the tip - the vibrating head. The absence of couplings and a flexible shaft increases reliability. It was possible to “fit” the engine into the nozzle by increasing the operating frequency (hence the name). To connect the vibrator to a regular electrical outlet, you need a frequency converter (external or built-in). If there is a built-in converter, the pulse vibrator for concrete is connected to a 220 V network directly.

Due to the absence of a large motor, the vibrator is 2 times lighter than a regular one - it is sometimes called “small”. High-frequency models are equipped with a flexible hose (up to 30 m) or a rigid handle.

Industrial high-frequency models are installed on technological equipment for automated road laying or the production of reinforced concrete products.

Area vibrator

From the point of view of the method of influencing the solution, area vibrators are classified as:

- external – working without immersion;

- surface - directly in contact with the surface (as opposed to external hinged ones).

Scope of application: flat surfaces: floors, road surfaces, ceilings.

Surface vibrators for concrete consist of a housing with a motor and a working surface. Depending on the shape of the working body, there are two types of surface vibrators. The first one is vibrating slats.

The second is the actual platform models, equipped with a vibrating platform.

As the working body moves along the surface, vibration is transmitted deeper, compacting the entire laid layer of concrete.

External vibrators

They are also classified as external. Unlike surface models, external models do not come into contact with the mortar, but are hung on the formwork. Hence the second name - mounted.

The main area of application is massive structures with frequent placement of reinforcing rods.

What you need to know about deep vibrators?

So, a deep vibrator is designed to compact the concrete mixture and remove excess air bubbles from the solution. Why is this necessary? The production of concrete requires constant mixing (and it is necessary to mix it both during the construction of a multi-story building and when pouring the simplest path on a summer cottage). As a result of stirring, bubbles form in the mixture, which do not have time to disappear before hardening. The remaining air negatively affects the strength of the material, leading to cracks and additional shrinkage.

The problem is solved by using a deep vibrator: it compacts the mixture that has not yet hardened and removes air. Along with this, the use of a vibrator has a positive effect on the condition of raw concrete as a whole (it is more uniformly distributed in shape and interaction with reinforcing structures is improved).

The operating principle of the tool is as follows. The mixture has a thick consistency, and due to its density and low fluidity, air bubbles formed in the lower layers do not manage to rise to the surface. Vibration is designed to increase the plasticity of the green concrete, thereby eliminating obstacles to removing bubbles from the mixture. The mixture itself is further compacted.

By drive type

The engine is one of the main components of the vibrator.

Based on the type of drive, vibrators are distinguished:

Electromechanical.

Tied to the electrical network - single-phase (220 V) or three-phase network (380) - they have limited mobility. 220 V manual concrete vibrators do not require any special conditions, but do not provide much power. Models with a three-phase motor are more powerful, but heavier and more difficult to connect;

Compact submersible vibratory compactors are mobile - they are battery-powered (often powered from the mains is also provided). Disadvantages - limited operating time by the battery capacity and low power. Regardless of the price, compact models are intended for domestic use and do not involve processing large volumes of concrete.

Based on an internal combustion engine - gasoline or diesel.

The vibrators do not depend on the electrical network and have a power of up to 4 kW - this is enough for vibration processing of large-volume concrete masses. Disadvantages - large dimensions and weight, difficulty of maintenance.

There are portable models of gasoline vibrators for concrete. They are mobile - the engine fits in a backpack. However, they are more expensive than stationary ones, and the power usually does not exceed 2 kW.

Pneumatic.

The oscillatory force is created by supplying a stream of compressed air from the compressor. Pneumatic vibrators are used in industrial conditions - they have a long service life, are explosion- and electrically safe, do not require complex maintenance, and can operate in humid and dusty conditions. The main area of application is the production of reinforced concrete products.

Based on power, we can conditionally distinguish vibrators:

- household - up to 2 kW. These are stationary or more convenient (and expensive) portable models - working with them does not require special knowledge and experience;

- professional – up to 4 kW. Heavy and, as a rule, stationary models, the maintenance of which requires special skills. Such vibrators are used for laying concrete in multi-story and industrial construction, and in the production of reinforced concrete.

Watering concrete after pouring: proper care

Advantages and disadvantages of use

Despite the simplicity of the device, a more effective way to compact concrete mixtures and remove air particles from them has not yet been found. The previously used concrete bayonet method cannot be compared to the vibration effect on the solution.

The advantages of the latter are as follows:

- Speed of work. The time spent on bayoneting is many times greater than when using vibrators. If the pin can influence a maximum of the surrounding 5 centimeters of concrete area, then the vibrator's mace transmits the frequency effect to at least three times the area.

- Quality. When bayoneted, the pin slightly pushes the concrete around itself, due to which the latter can be squeezed out into hard-to-reach areas. The technology did not provide for complete filling of voids, and removing air was often an impossible task. The vibrator shakes the concrete, causing heavy particles to fall down, which solves both problems.

- Labor intensity. The metal pins used for bayonet are heavy, which increases the difficulty of processing concrete. In addition to the fact that the mass of the vibrator is no higher than that of a hand drill, it does not need to be driven into concrete with force - the work can be entrusted to a person without special physical conditions.

- Simplicity of design - allows you to convert a standard drill or hammer drill into a vibrator.

There are significantly fewer disadvantages:

- The price of the devices still exceeds the cost of scrap for bayoneting.

- To operate or recharge batteries, the vibrator must be connected to an electrical network: 42, 220 or 380 volts. Some devices can be powered by internal combustion engines that require gasoline.

- There is a risk of “overdoing it” - in this case, the heavier cement particles may sink to the bottom.

Whether this is a sufficient price for the benefits obtained must be decided on a case-by-case basis, but usually the quality outweighs the savings.

By shaft speed

The shaft rotation frequency coincides with the vibration frequency of the nozzle - the number of vibrations per minute.

The vibration frequency can be specified in vibrations/min (vpm) or in Hertz (Hz). The values are related by the following ratio: 1 Hz = 1 vpm/60.

Based on this parameter, vibrators can be divided into:

- low frequency. The shaft rotates at speeds up to 3500 rpm. Low frequencies are capable of moving larger aggregate particles. Such vibrators are suitable for heavy, non-plastic concrete with a “skeleton” of crushed stone or gravel of large fractions;

- mid-frequency. The rotation speed falls in the range from 3500 to 9000 rpm. These are universal models - if configured correctly, they are used for compacting solutions with fillers of different sizes, including the “running” grades M200–M300;

- high frequency. Frequency – from 10,000 to 20,000 rpm. Such vibrating tools have a narrow specialization - fine-grained concrete. For heavy concrete, high frequency compaction may not be effective.

Oscillations are characterized by two quantities – frequency and amplitude. The amplitude of vibrations is directly proportional to the weight of the tool. As the frequency increases, the weight, as a rule, decreases - low-frequency models produce greater amplitude.

In theory, a high vibration frequency implies greater efficiency, regardless of the fractional composition of the mixture. In practice, the result also depends on the amplitude of the oscillations. High-frequency vibration of heavy concrete at low amplitude will only intensify delamination.

Vibrators differ in the size of the working parts:

- submersible - the length of the flexible shaft (from 50 cm to 30 m) and the diameter of the mace (25–140 mm);

- vibration slats – slats length – from 150 to 500 cm (for telescopic slats);

- platform - length (450–620 mm) and width (320–480 mm) of the working surface.

How to choose

The main criterion is the planned scope of application:

- large deep masses - foundations, supports and columns - a deep vibrator is needed to compact concrete;

- long or flat pours of thin thickness - concrete floors or road surfaces - a surface model is needed.

External vibrators are rarely used “in everyday life”. Small reinforced paths and foundations can be vibrated using the submersible method.

In addition to the type, you must consider:

- power. It is not advisable to buy a vibrator more powerful than 2 kW for private purposes - bulky equipment will not justify the cost;

- rotation speed. For private purposes, mid-frequency models are usually optimal;

- engine's type. Electric drives lead in popularity. In the absence of electricity, a gasoline engine is suitable, and if the outlet is remote, a battery engine is suitable. To operate a pneumatic vibrator, you need a compressor that produces a stream of compressed air. The compressor pressure must correspond to the vibrator operating pressure;

- mass. Small jobs (pouring screed, paths, small foundations) can be handled by a tool weighing less than 6 kg. Heavier models weighing up to 20 kg are suitable for intensive use and compaction of massive monoliths. Such vibrators are used by small construction crews.

The weight of professional equipment starts from 16 kg, and the upper limit reaches 200 kg or more. These are expensive, powerful units for continuous operation in industrial environments.

When choosing a depth model, you also pay attention to:

Tip diameter . For unreinforced fills, you can use a mace from 100 mm. If there is reinforcement, the diameter should be from ½ to 2/3 of the distance between the rods - usually 15–50 mm. The minimum diameter of the high-frequency vibrator head is 35 mm - such models are not suitable for compaction with small reinforcement pitches;

Productivity depends on the radius of action - the larger the radius, the less often you will have to insert the tip into the solution. The radius, in turn, depends on the diameter of the tip. If the radius is not indicated in the passport, it can be determined approximately by multiplying the diameter by 4.

Flexible sleeve length . The standard range is 1–6 m; upon request, the length can be increased to 20 m. For compacting foundations or screeds, a length of 2–3 m is sufficient.

The use of an unreasonably long hose will reduce the productivity of the equipment.

DIY concrete vibrator

If the amount of work is small, buying a vibrator is not always justified - a cheap one is unreliable, and an expensive one will not pay for itself. You can make a vibrator yourself - based on a drill or hammer drill with the ability to adjust the rotation speed.

How to make concrete flowerpots that the whole family will love

From a drill

There are two ways to turn a drill into a vibrator. The first involves using a purchased vibrating mace with a “sleeve” as an attachment for a drill. Most flexible shaft models end in a hex hole and can be mounted in a drill chuck.

Now all that remains is to attach the protective cover.

This can be a metal ring (in the picture) or a rubber ring (tube). You need to drill 3-4 holes in the ring - bolts are screwed into them. To securely fasten the ring to the drill body, just tighten the bolts.

If the output of the drill and the shaft differ in shape, an adapter is made to secure the shaft in the chuck.

The second method suggests saving 1.5–2.5 thousand rubles by making a vibrating tip with a shaft yourself. The general algorithm is:

- Make a body from a piece of pipe, providing a place for attaching the bracket holding the coupling.

- Make a shaft by welding an eccentric to a metal cylinder or hollow stud.

- Select and install bearings.

- Pass a steel cable through the shaft, transmitting rotation from the drill to the tip.

- Assemble the vibrator by placing the cable in the gas hose and securing it to the drill with a bracket.

When assembling a homemade vibrator for concrete, it is important to ensure the tightness of the tip and the reliability of all connections.

From a hammer drill

You can make a vibrator for concrete with your own hands using a hammer drill. To make it you will need:

- hammer drill with a power of 1.5 kW;

- a piece of metal lance with a diameter of 8 mm or more - the length should be sufficient to immerse entirely in the thickness of the solution;

- washer - it is welded to the end of the rod. The washer can be replaced with several short rods welded to the peak at an angle of 90 degrees.

The end of the rod without a washer is adjusted to the shape for installation in the hammer drill chuck. You need to make sure that the rod is firmly fixed.

The resulting attachment for the hammer drill can be used to vibrate concrete in a vertical and horizontal position - immersing the entire peak or only the transverse rods

The hammer drill can be used without immersion:

- Place a trowel, spatula or sheet steel plate on top of the solution.

- Place the punch rod on top of the plate and use the tool in impact mode.