The principle of operation of an inverter compressor in a refrigerator

That is why refrigerators began to be called inverter, since this is the principle of operation of the compressor, that is, the main power unit, which is found in any device of this type.

Their operation differs from the operation of linear compressors in that they can change the engine speed. That is, the device allows a smooth transition from one operating mode to another.

Linear compressors are started at their maximum power. Automatic shutdown occurs as soon as the refrigerator reaches the set temperature. The relay regulates operating processes that are associated with starting and stopping.

It is inherent for this element to create an accompanying sound at the moment of operation. It is very similar to a click. When the engine is running, it creates sounds and noises that can be clearly heard by others.

IMPORTANT! Please note that such compressors are also used in the manufacture of computer and medical equipment, as well as in the automotive industry and in the production of measuring instruments.

Constantly starting the engine at full power, alternating with stops, leads to the compressor overheating. And soon the refrigerator will fail. In addition, when the engine is turned on every time, this leads to an increase in the load on the electrical network. There are unnecessary energy costs. It's not economical.

IMPORTANT! The solution that can optimize the efficiency and duration of operation of cooling devices is an invention that has become an alternative to outdated devices. In this case, we are talking about inverter models.

What is the principle of operation:

- the compressor turns on;

- during operation it cools the inner chamber;

- the inverter’s action is aimed at maintaining the specified temperature in the chamber;

- With such a system, the compressor, when it temporarily slows down, does not turn off completely.

The operation of the device is smooth. In order to show the difference in the operation of linear and inverter compressors, a comparison can be made with how a car engine works. An inverter is a car moving along a perfectly flat road. And a linear compressor means moving along a dirt road. And it's uneven. It has steep ascents and descents.

If we take the improved models, then brushless, three-phase motors are used in them. They are also used in the manufacture of modern equipment. Both measuring and medical. And also in the production of modern engineering developments.

What is the essence of the work of inverter compressors? Using the control unit of the device, alternating current is converted into direct current. And then the current changes again to an alternating form. But it already has a different frequency, which is necessary in this case.

IMPORTANT! This process is called inversion, that is, it is a change. The transformation that is carried out makes it possible to adjust the output parameters of any load with great accuracy. Including the compressor.

According to those who produce such equipment, the inversion principle makes it possible to make energy costs more economical. Stable operation of the compressor, when precise output parameters are set, allows for temperature control inside refrigeration and freezer chambers with great accuracy and speed.

Design and principle of operation of an inverter refrigerator compressor

Everyone knows that the compressor is the “heart” of the refrigerator. Take it out, it will become a useless device. Therefore, it is worth knowing how this device works.

The role of the compressor is to compress freon gas into a hot liquid. This liquid passes through the condenser unit to cool it before spreading inside the refrigerator. As this hot liquid circulates inside the coils, it releases heat from the refrigerator into the environment. The freon then passes through the capillary tube and enters the evaporator. There, under the influence of low pressure, it cools down to -23, after which it enters the internal heat exchange. This lowers the temperature inside the case. As a result, the gas returns to the compressor, where the entire process is repeated.

We described the scientific work. Now let's look at the mechanical side of this process. The compressor turns on when the temperature inside the refrigerator reaches a certain threshold. It continues to operate until it cools down to the calibrated level. When this temperature is reached, the device automatically turns off. This process continues with regular switching on and off.

Whenever the compressor turns on, it causes a surge in current consumption. It also makes noise. You can hear the distinct sound of a running refrigerator not only in the kitchen, but even in neighboring rooms. This continuous switching on and off also causes wear and tear.

The operating principle described above applies to both standard and inverter compressors. However, the inverter differs in that it operates continuously, unlike the standard one.

Difference between inverter and standard technology

As mentioned, an inverter compressor works similarly to a standard device. However, engineers have made a number of improvements, therefore, thanks to inverter technology:

- The inverter compressor does not turn on or off at regular intervals. It continues to work, but at different speeds. Therefore, the refrigerator does not make any noise.

- There is no surge in current consumption because the device does not need to be constantly turned on and off. Thus, there is a saving in energy consumption.

- Also, due to continuous operation, there is less engine wear.

But the best aspect is that inverter technology saves electricity as the temperature stabilizes. Variable speed motors provide energy savings of 20% to 40%.

However, the inverter motor also has a disadvantage (if it can be called a disadvantage). Refrigerators with inverter technology are comparatively more expensive compared to standard ones. However, consumers benefit because they can save on energy consumption when they use refrigerators powered by an inverter compressor. The energy savings over the life of the refrigerator easily make up for the difference in purchase price.

Advantages and disadvantages of an inverter compressor in a refrigerator

Advantages

It is generally accepted that the advantages of an inverter compared to a standard unit include the following.

Low noise level

This is not entirely true. The quietest of the models presented in the table is standard, not inverter - Siemens KI87SAF30 with a noise level of 35 dB. Next again is the classic Bosch KIS87AF30 with a noise of 36 dB.

Among the inverters, the Samsung RB-31 FERNCSA model closest to them is noisier - 37 dB. Everyone else creates even more noise.

The noisiest model is the non-inverter Liebherr CTN 3663 with a noise level of 43 dB. (see table No. 1).

For comparison: the sensitivity threshold of the human ear is 20 dB. Consequently, a person hears sounds with a level of more than 20 dB. The noise level created by a wall clock is 30 dB, a muffled conversation is estimated at 40 dB. All of the above models of units, except for the one used in the Liebherr CTN 3663, create noise that is less than a muffled conversation.

Longer service life

Typically, refrigeration equipment manufacturers do not indicate service life, limiting themselves only to the warranty period. For both of these parameters, the inverter Liebherr IKB 3660 with a two-year warranty and a service life of 10 years stands out in the above rating. The non-inverter model Liebherr SBSes 7353 has similar parameters.

Also noteworthy is the Liebherr CBN 4815 inverter unit, which comes with a two-year warranty. The service life of the device is not reported. There are also standard “two-year models” - Liebherr CTN 3663. But it is the only one among the models in this class. (see table No. 1).

Consequently, the thesis about a significant difference in the service life of inverter and non-inverter devices does not correspond to reality.

Small limits of temperature change in the refrigerator

Manufacturers do not provide data on this parameter. But after analyzing the operating principle of an inverter refrigerator, we can assume that the temperature range in its cabinet will be less than in a unit with a standard compressor.

Great freezing power

If we do not consider the exclusive Liebherr SBSes 7353 model with two non-inverter compressors and a huge total usable volume of 661 liters, then of the non-inverter models only the Samsung RL-60 GJERS is equipped with a unit that provides slightly more freezing power than the inverter GA-B489 TGRF, Samsung RB-31 FERNCSA , Liebherr IKB 3660.

But the Samsung RL-60 GJERS is not inferior in this parameter to the inverter GA B489 YEQZ and loses to the Liebherr CBN 4815 (see Table No. 1).

Therefore, the statement that high freezing power is typical for inverter devices is not true for all models.

Less energy consumption

Formally, from the point of view of energy efficiency, most of the presented models belong to the A++ category. The only exception is Liebherr SBSes 7353, which belongs to category A.

This is explained simply: the Liebherr SBSes 7353 has two compressors, which is necessary to cool the total useful volume of 661 liters. This is almost twice the volume of other models.

The annual energy consumption of inverter models is in the range of 166-257 kW. The same parameter for all non-inverter devices, except Liebherr SBSes 7353, is in the range of 204-258 kW. At first glance, these are comparable values, if you do not take into account the total usable volume of the refrigerator.

Taking this parameter into account, the leaders in energy efficiency are inverter compressors of the Liebherr IKB 3660 and Liebherr CBN 4815 models. For them, the electricity consumption W/year per 1 liter of useful volume is 417.0 and 542.2, respectively.

They are followed by the non-inverter models Liebherr SBSes 7353 and Liebherr CTN 3663, consuming 656.5 and 658 W/year per liter of useful volume, respectively. But the Liebherr SBSes 7353 has the largest usable refrigerator volume, so its energy efficiency rating is pleasantly surprising.

Oddly enough, the worst model in terms of the parameter under consideration is also an inverter - Samsung RB-31 FERNCSA (see Table No. 3).

Important! It cannot be stated unequivocally that all non-inverter models of units are less economical than inverter ones, although the latter are the leaders.

Flaws

Disadvantages of inverter refrigerators compared to standard ones:

- Higher price. This is confirmed by the data in Table No. 1. The price of inverter models is in the range of 28,502 - 78,560 thousand rubles, and non-inverter 35,650 - 66,390 thousand rubles, not counting the non-inverter exclusive Liebherr SBSes 7353 (from 220,000 thousand rubles).

- Smaller selection of products in each price category. Inverter refrigeration systems began to be produced relatively recently, so the number of manufacturers and models themselves is noticeably smaller than non-inverter ones.

According to statistics, 95% of compressors fail due to poor quality of the supply network, manifested in sudden voltage drops.

Important. There are Volt Control voltage control devices that ensure the operation of household appliances when input voltage drops in the range of up to ±25%. They are made in the form of a small block with a socket into which the protected equipment is plugged in. The unit itself plugs into a wall outlet.

Refrigerator with inverter compressor

Inverter refrigerators are units equipped with inverter compressors.

Many parameters of modern refrigerators depend on what type of compressor is used in them and how it is controlled.

These parameters include:

- noise level;

- reliability (warranty period);

- temperature stability in the refrigerator;

- price;

- energy efficiency class or amount of electricity consumed.

The rating of some popular economical refrigerator models with various compressor systems and their characteristics are given below.

Table No. 1

| Place in ranking | Model | Noise level, dB | Warranty deadline/term service, years | Type compressor (way management) | Power freezing, kg/day | Price, thousand rubles b. |

| 1 | Liebherr CBN 4815 | 38 | 2/n.s. | inverter | 16 | from 78 499 |

| 2 | LG GA B489 YEQZ | 40 | 1/n.s. | linear/inverter | 14 | from 29 378 |

| 3 | LG GA-B489 TGRF | 40 | 1/n.s. | linear/inverter | 11.6 | from 65 591 |

| 4 | Liebherr SBSes 7353 | 42 | 2/10 | standard, 2 compressors | 18 | from 220,000 |

| 5 | Bosch KIS87AF30 | 36 | 1/n.s. | standard | 7 | from 65 990 |

| 6 | Samsung RB-31 FERNCSA | 37 | 1/n.s. | inverter | 12 | from 28 602 |

| 7 | Liebherr IKB 3660 | 38 | 2/10 | inverter | 12 | from 78 560 |

| 8 | Samsung RL-60 GJERS | 40 | 1/n.s. | standard | 14 | from 70 705 |

| 9 | Siemens KI87SAF30 | 35 | 1/10 | standard | 7 | from 66 999 |

| 10 | Liebherr CTN 3663 | 43 | 2/n.s. | standard | 8 | from 35 650 |

Notes:

- N.s. - no information.

- In the “Compressor Type” column, the term “inverter” is borrowed from the refrigerator specifications published by the manufacturer. From this information it is unclear what type of compressor is used in the device - linear or standard. What is clear is that the device uses inverter control. Likewise, the term “linear” does not give any idea about the method of controlling the unit, but only contains information about its design.

The efficiency of any device is characterized by its energy consumption class. It shows how much electricity the appliance spends to maintain the required temperature in the refrigerator chambers. The classification of devices by energy consumption is based on the energy efficiency index. This is the ratio of real consumption to estimated consumption, multiplied by 100.

The following table gives an idea of the parameters of different energy efficiency classes.

Table No. 2

| Energy class designation | Energy efficiency index | Amount of energy consumed per operating cycle | Annual consumption, kW/h |

| A+++ | until 22 | less than 22% | 125-300 |

| A++ | 22-33 | 27,5% | |

| A+ | 33-42 | 37,5% | |

| A | 42-55 | 48,5% |

If we calculate the relative electricity consumption of a device per year to cool 1 liter of useful volume, then the places in this ranking of the most economical models will be distributed differently.

Table No. 3

| Place V ranking | Model | Type compressor (way management) | Energy efficiency class | Electricity consumption, kW/year | Total useful volume, l | Electricity consumption, W/year per 1 liter of useful volume |

| 1 | Liebherr IKB 3660 | inverter | A++ | 166 | 398 | 417,0 |

| 2 | Liebherr CBN 4815 | inverter | A++ | 186 | 343 | 542,2 |

| 3 | Liebherr SBSes 7353 | standard 2 compressors | A | 434 | 661 | 656,5 |

| 4 | Liebherr CTN 3663 | standard | A++ | 204 | 310 | 658,0 |

| 5 | LG GA B489 YEQZ | linear/inverter | A++ | 237 | 360 | 658,3 |

| 6 | Samsung RL-60 GJERS | standard | A++ | 258 | 370 | 697,2 |

| 7 | LG GA-B489 TGRF | linear/inverter | A++ | 246 | 335 | 734,3 |

| 8 | Siemens KI87SAF30 | standard | A++ | 205 | 272 | 753,6 |

| 9 | Bosch KIS87AF30 | standard | A++ | 226 | 272 | 830,8 |

| 10 | Samsung RB-31 FERNCSA | inverter | A++ | 257 | 304 | 845,3 |

This is the most objective assessment of the energy efficiency of compressor systems used in refrigerators with different useful volumes.

Comparison of an inverter compressor in a refrigerator with a linear one

The more complex the design, the more unexpected the cause of failure may be. Therefore, you need to know how to check this or that node. The inverter compressor in the refrigerator is tested with a device from DAIKIN, an inverter analyzer. The task is to find what is faulty, the electronic unit (board) or the electromechanical part. Failures in the network can lead to a malfunction if protection in the form of a voltage stabilizer is not installed.

A linear compressor is much simpler than an inverter compressor. He is not afraid of voltage surges. But the irregular operation mode is accompanied by peaks in energy consumption during the startup period. In the same way, the temperature inside the chamber changes within the range of the thermostat. Such cyclicality does not benefit the products; equipment is destroyed. This means that the inverter compressor in the refrigerator is more technologically advanced in all respects, which is confirmed by measurements.

Many people ask what an inverter is and how it differs from a linear compressor in terms of the efficiency of the refrigerator. Is it worth overpaying? Budget models are equipped with standard components. In domestic use, a well-regulated refrigerator makes little noise. But frequent starts and stops not only consume 40% more energy, but also destroy the metal.

A common cause of system failure is the thermostat. This device has several components that require monitoring. The spring for closing the relay contacts has weakened, the seal of the freon tube has broken - the refrigerator is leaking. Vibrations may cause a microcrack in the circuit and freon leakage.

Repairing a linear compressor with refilling is not cheap. Therefore, if funds allow, it is better to buy a model with an inverter heart. But the device has one significant drawback. When connecting inverter compressors for refrigerators, a stabilizer must be installed in the line or a built-in Volt Control must be provided, a technology that does not allow the engine to turn on until the voltage is restored. Failure of an inverter due to changes in parameters in the network is a non-warranty case.

Refrigerator compressor test

In domestic refrigerators, low-power compressors are used, in which the starting winding is connected for a few seconds through a starting relay using a posistor or an electromagnetic relay.

Circuit with electromagnetic relay:

In this case, the current passes in series through the relay coil and the operating winding of the compressor. The starting current is always greater than the operating current, using this principle, the relay is designed so that the starting current closes the relay contacts and connects the starting winding of the compressor, which starts. In this case, the current flowing through the working winding and the relay winding decreases, the contacts open, turning off the starting winding.

The relay also includes a thermal relay that turns off power to the compressor when it overheats.

Circuit with posistor:

In the diagram, the posistor is indicated by the temperature symbol t0, and the thermal relay by the number 6.

The operating principle is as follows: at room temperature, the posistor has low resistance and directly supplies voltage to the starting winding S. A current flows through it, which heats it up; when heated, the internal resistance of the posistor increases, actually turning off the starting winding a few seconds after the compressor starts. The posistor cools down only after turning off the power from the compressor and, during the subsequent switching cycle, reconnects the starting winding.

Which compressor to choose in the refrigerator

First of all, let's evaluate the manufacturers who equip refrigerators with inverter compressors. The first company to assemble an innovative refrigerator was Korean. It still owns the largest number of models using its own digital inverter compressors, Digital Inverter. Two and multi-chamber models are equipped with electronic control, a No Frost system, and some are controlled remotely. Electronics provide automatic adjustment in 7 temperature modes. Naturally, they are not cheap, but they are in demand.

The Korean company Samsung added to its innovations by inviting famous designer Jasper Morison to create refrigerators with inverters. Other well-known manufacturers use Korean or German developments. Refrigerators with inverters cost about 30% more than those with linear compressors, when comparing the same volumes and options.

It is necessary to pay attention to the new “linear” compressors with magnetic drive. They are characterized by the absence of a rotating shaft. They were also created by the company. The piston is driven by an electromagnetic field.

The equipment is designed for large-volume refrigerators. 2-3 compressors in one installation work especially efficiently. Unlike inverter models, these compressors operate cyclically. But models without a crank mechanism began to consume 20% less energy. When choosing a refrigerator with a linear compressor, the buyer first of all benefits in price.

Operating principle of an inverter compressor

When the linear compressor is operating, the device is started to its maximum. When the set cooling temperature is reached, automatic shutdown is triggered. The relay controls the process of turning off and resuming operation of the refrigerator. At the moment of switching on and off, a click is triggered. A characteristic hum indicates that the engine is running.

When the refrigerator is constantly running at full power and frequently switched off, the device becomes very hot and after a certain time fails, after which the cooling device must be replaced. Another disadvantage: high electricity consumption due to increased electrical load.

When creating the inverter motor, we took into account all the listed disadvantages. In general, the device works on the same principle, with the exception of a few differences. When the inverter refrigerator cools to the required temperature, the operation does not stop, but there is a gradual decrease in speed and a decrease in the speed of the refrigerant. Thus, a certain temperature level is maintained.

When the refrigerator door is opened, the number of shaft revolutions increases based on a sensor signal indicating an increase in temperature and discrepancy with the required one. Unlike a linear generator, the new generator operates more smoothly, using minimal power.

If we explain inverter operation from a technical point of view, alternating current is converted into direct current, followed by the reverse process, but at the same time the required frequency is set. Three-phase compressor motor with brushless system used in refrigerators is used in the production of automobile mechanisms, computers, medical equipment, etc.

See also -

Which two-chamber refrigerator is the best - 2017 rating

Do you need an inverter refrigerator?

So, approaching the main issue of the relevance of purchasing an inverter unit, it is necessary to summarize. By comparing the pros and cons of such a device, we can draw the main conclusions.

In terms of cost, an inverter refrigerator is outright inferior to linear models. After all, the price for such complex devices is much higher.

It is also worth noting the complexity of the design of refrigerators of this type. Thanks to this, if repairs are needed, it will be much more difficult to find a knowledgeable technician.

Another important factor is that the operation of a linear refrigerator can be dangerous due to poor wiring. In turn, poor wiring can be dangerous for the inverter unit. Thus, the price of the protective device is also added to the cost of purchasing the inverter.

However, inverter refrigerators are more durable. However, this advantage is relevant only if the electrical wiring is good and all operating rules are followed.

Possible causes of inverter compressor failure

Despite the fact that the inverter compressor model has many advantages, including a long service life, it can also fail. However, most are preventable. As already noted, there is sensitivity to voltage changes. Inexperienced owners may not take this factor into account when purchasing.

Experts recommend doing the following before purchasing a refrigerator:

- inspect the condition of the outlets;

- replace those that are faulty;

- check the condition of the wiring.

These steps will help prepare the room for the new equipment. In addition, such actions will be useful for prevention purposes.

Many manufacturers of modern household appliances take into account this specific operation of inverter compressors. Therefore, they create protection using Volt Control technology. The operating principle is based on putting the device into standby mode when surges occur. When the situation stabilizes, engine operation resumes.

Brands that produce refrigerators with an inventory compressor

In order to truly evaluate the quality, operational efficiency and other functionality, manufacturers subject refrigeration units of this type to lengthy studies. A competent assessment of all these parameters will allow the devices to be durable, safe and, importantly, achieve a high level of ergonomics.

Therefore, only companies that have sufficient conditions for testing devices can launch the production of such models of refrigerators. Today there is the following gradation of brands that produce them.

Popular models of refrigerators with inverter compressor:

- Samsung;

- LG;

- Hitachi;

- Mitsubishi;

- Sharp;

- Kaiser;

All other manufacturers who manufacture refrigeration units with this type of compressor present their own models for sale in a total amount equal to only 3% of the total market. Of course, this does not mean the low quality of products from such brands. But they may offer a lower warranty than manufacturers who have not only produced more, but also tested their electrical appliances to a high level.

Inverter equipment can be equipped with several compressors if it has two separate refrigeration chambers with different temperatures. This design makes it easier to distribute the cold between the opening and mostly closed parts of the refrigerator.

Inverter refrigeration equipment is slowly but confidently gaining popularity among buyers. All this happens thanks to the high technical characteristics of the devices. The latest models of refrigerators, air conditioners, washing machines and other “human assistants in everyday life” with similar equipment are appearing.

Refrigerator repair in Bishkek

Converting from an inverter compressor to a conventional start-stop compressor instead of a linear or BLDC.

What if the compressor fails and the case is not covered by warranty!?

For example, the refrigerator only worked for a couple of years and such a disaster happened... ((It has already reached the point that two years for LG refrigerators is often the death of the linear inverter compressor.

What is an inverter compressor?

For example, the cost of a new inverter compressor is incommensurate with the cost of a refrigerator, or there is no place to get it, buy it, or order it. A regular motor compressor costs about 3500-5000 soms (without installation) and they are always available for sale. It would seem that in this case it would be more expedient to install a conventional motor instead of an inverter one, but here the manufacturer protected itself from this. If you install a regular compressor, then there is simply nothing to control it; it will not work there. The inverter controller immediately recognizes that there are some problems with the motor-compressor and goes into error; with an error, the refrigerator may completely turn off or work in emergency mode. The electronic control module is designed to control only an inverter compressor; it will immediately give an error and nothing will work. You only need the original compressor, or replacing or converting the control module to a version that controls a conventional compressor.

Especially for such cases, we have developed a special “fake” simulator for installing a conventional compressor, instead of an inverter one, without any major modifications to the refrigerator (there is no interference in the operating logic of the control module or its replacement).

LG:

Photo of the installed decoy on the control module. Refrigerator LG GA-B429SECZ To install it, it is advisable to clear the space and turn off the power to the integrated inverter , as well as solder the power wires and the data exchange protocol wire .

Review of the new version of the LG adapter:

SAMSUNG:

In Samsung, the inverter is installed separately from the main board. To install it, just disconnect 3 chips from the inverter and connect them to the blende. All standard wiring and connectors are used.

Inverters: 459 and 814

757 inverter samsung

404 inverter Samsung

Embraco:

Adapter for installing a conventional compressor instead of an inverter from EMBRACO (EMBRACO compressors are used on many brands of refrigerators, for example BOSCH, SIEMENS, HAIER, LIEBHERR, LERAN-Panasonic EFI120E13DGH

Just like on SAMSUNG, native connectors and wires are used.

LIEBHERR AC protocol

Decoy for the LIEBHERR refrigerator. Compressor - VESD9C, Inverter - AC protocol VES 2456 01 F 00

Its logical work consists of converting the signal output from the native control module into operation or stopping of a conventional compressor. And also an imitation of the feedback signal about the operation of the inverter compressor “feedback”, i.e. it sends a signal to the native controller “brain” that a native compressor is installed, so that it does not generate an error code about any malfunction with the compressor. A kind of deception of the native “brains”. The trick has been tested and successfully put into operation on some refrigerators. (For now only for some brands and models of refrigerators.) HITACHI, LG, SAMSUNG, SIEMENS, BOSCH, HAIER.

Examples:

Replacing the LG GA-B499ZVCZ refrigerator compressor from a linear inverter FMC088NAMA to a regular one from SECOP (made in Austria) :

Replacing inverter BLDC and linear inverter compressors on LG refrigerators BMG089NHMV, BSA075NHMV, FC102NEM, FLC102NAMA FC124NAME, FC124NBMA, FC150NAMA, FMC088NAMA, FMA102NAMA

Replacing the Hitachi R-VG470PUN3 refrigerator compressor from an inverter CL1588-DA to a regular one from SECOP (made in Austria) :

HITACHI refrigerator repair

Replacing inverter compressors on refrigerators HITACHI CL1588-DA CL1588DA WL16H10DAN CL1610-DL CL1610DL

HITACHI refrigerator repair

For all questions and to order decoys, write to whatsapp: +996550322144

Possible delivery by SDEK courier service in Russia and CIS countries

Opening hours: 9:00 to 18:00 (Sunday closed)

Contacts:

0550 322-144; 0312 894-615 (Vitaly)

Non-inverter refrigerator compressor - what happens?

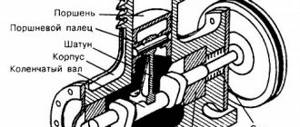

Piston compressor

The most common and popular type. Such a unit consists of one or more cylinders located vertically or horizontally. The pistons located in these cylinders carry out reciprocating movements using a connecting rod and crank mechanism.

Strengths of this compressor:

- Simple design;

- Reasonable price;

- There are no difficulties with repair or maintenance;

- The air pressure at the outlet is high;

- High wear resistance. Perfectly withstands both continuous operation and rare inclusions;

- Unpretentious in work and maintenance.

Weak sides:

- Strong vibration and noise;

- Low performance;

- Regular maintenance is required;

- Needs a filter system.

Rotary (screw) compressor

Known since the end of the 19th century. In such cooling units, the pressure difference arising due to the rotation of the rotor and the movable plate changes the rotational energy. Such compressors are installed in some models of Indesit refrigeration household appliances.

Pros:

- Significant compression ratio.

- The absence of elements subject to high loads and regular injection of oil into the steam chamber ensure reliability and durability.

- Performance can be adjusted by changing the speed at which the rotors rotate.

- It has little vibration and therefore does not require a solid foundation.

- Relatively low noise level, so the refrigerator can be installed in any room

- Small dimensions of the unit itself.

Minuses:

- Efficiency of changing the state of freon within the system. The constant speed of rotation of the shafts causes different compression forces.

Inverter compressor

It works without interruptions, unlike linear. After the first switch-on, the cooling system lowers the temperature in the chambers to the specified level, then the compressor, using only the necessary power, maintains the conditions necessary to preserve food. Samsung refrigerators are equipped with such units.

Advantages:

- With rare exceptions, the compressor does not use maximum power in its operation, therefore, compared to other cooling systems, electricity is consumed more economically.

- Due to their constant operation, such units do not emit loud sounds that usually accompany the startup process of a traditional compressor.

- Inverter compressors are more durable due to the absence of the need to experience increased loads during constant starts and stops.

- At first glance, refrigerators equipped with a compressor of this category are more expensive than household appliances with a traditional cooling system. But the high level of energy savings, long service life, and wear resistance make the purchase more profitable.

Flaws:

- The complexity of the device and production technology make the cost of the finished compressor higher in comparison with simpler types of cooling devices.

- A voltage drop in the home electrical network can damage the inverter compressor. To avoid such a situation, before purchasing a household appliance with such equipment, it is advisable to check the quality of the wiring and, if necessary, replace weak areas or secure the installation site of the refrigeration unit.

Linear compressor

The operation of such a unit is carried out in three stages: switching on, cooling, switching off. The temperature in the refrigerator chamber is monitored by a sensor; as soon as it exceeds a preset level, the compressor starts. By lowering the temperature as soon as possible, it switches off again. This cycle repeats as long as the refrigerator is connected to the mains. The reciprocating movement of the piston in the cylinder occurs due to the influence of electromagnetic forces, due to which energy losses are reduced and the service life is increased. The energy consumption of such compressors is 40% lower compared to traditional units. Some Electrolux refrigerators are equipped with such units.

Pros:

- Increased durability and reliability due to fewer moving parts.

- The compressor control system helps to minimize temperature deviations in the refrigeration chamber from those set by the owner and improve control over the range of temperature fluctuations.

- The design and operating system of the compressor allows for economical energy consumption.

- The stability of conditions inside the refrigeration chamber due to the continuous operation of the cooling system helps to cool products in the shortest possible time and preserve all useful properties.

- A refrigerator equipped with a linear compressor operates relatively quietly, thanks to the smooth start and stop system of the cooling unit.

Minuses:

- Each switching on and off of the cooling unit is accompanied by characteristic clicks.

- When starting up, the compressor experiences maximum load and increases energy consumption.

Dynamic compressor

They are divided into two classes according to the type of fans: axial and centrifugal.

The first use the fact that the compression of the refrigerant occurs subsequent to a change in its speed between the rotor blades and the guide device. In this case, the refrigerant moves in the direction of the rotor axis.

In the second type, a vacuum occurs on the supply side, gas is supplied to the impeller blades. When it rotates, the coolant is thrown away, under the influence of centrifugal force, to the outer radius. At the exit from the wheel, the gas is directed to the diffuser, where its speed drops and the pressure increases.

They are classified according to the following criteria:

- According to final pressure. The pressure created by the gas flow.

- By the number of compression stages. Single-stage and multi-stage.

- By type of drive. Turbine or electric.

Dynamic compressors are characterized by a simple design, durability, and ease of use. The device has small dimensions and weight. The main disadvantage is the low efficiency, which is especially evident at low productivity and high pumping pressures. In such a design it is impossible to obtain a high compression ratio, and therefore create high pressure.

Scroll compressor

The design of this unit includes two spirals - movable and fixed, with the help of which injection is carried out. The fixed one is fixed on the body, and the movable one is fixed on the eccentric. Their profile is carefully selected and form chambers through which gas moves.

As a rule, scroll compressors are used to work with oil-free gases. Their design features make it possible to obtain certain advantages over similar equipment:

- the motor operates under less loaded conditions;

- when the refrigerant passes through the housing, intense heat is removed;

- gas is supplied evenly;

- high reliability;

- silent operation.

The active implementation of these machines is hampered by a number of disadvantages:

- complexity of manufacturing;

- low productivity.

Scroll compressors are constantly being improved, which makes it possible to promote high-quality samples on the market that can compete with analogues of other types.

Turbochargers

Equipment of this type includes high-performance centrifugal compressors. Turbocompressors are used in the production of industrial refrigeration using powerful equipment. They have 2-3 sections with 3-7 steps. Intermediate cooling and stepwise throttling are carried out through pipes located between the sections.

The performance of the unit is regulated by the input control device. In this case, productivity can vary in the range of 100-50% of the nominal value.

Turbochargers operate at high speeds. Therefore, the drive uses a reduction gear.

Hermetic, semi-hermetic and open type compressor

The design of a hermetic compressor means that it is placed in the same housing as the engine. In this case, cooling is carried out due to the passage of refrigerant. These machines are characterized by their efficiency, compact size and versatility. The power of this equipment does not exceed 35 kW.

Semi-hermetic compressors are used when high power is required using compact equipment. Their power reaches 350 kW. In most cases these are piston and screw models. The compressor and electric motor are placed in a collapsible housing, which greatly facilitates repair and maintenance of the equipment. The modes are regulated by closing part of the valves that work for suction. The advantages of such machines include compactness with high power, as well as maintainability.

Open type compressorThe main design feature of the open type compressor is the external motor, which makes it bulky. Despite this, the unit has a number of advantages and is used to produce industrial refrigeration. The mechanical part of the compressor is driven by a shaft that extends beyond its limits and therefore requires a reliable seal. The rotation speed of the compressor and the engine are the same or higher (if a belt drive is used and the pulley diameter is selected).

The advantages of open type compressors include:

- starting can be done at idle, which allows you to unload the engine;

- high reliability;

- ease of repair and maintenance;

- adjustment of operation is very convenient due to the use of inverters.

Smart compressor in the refrigerator

The smart compressor in Haier refrigerators is advanced technology, energy consumption class A+, low noise level, high reliability, 12-year warranty.

An innovative multilayer thermal insulation filler created on the basis of nanotechnology. It is able to maintain temperature for a long time and thereby save energy.

In the back wall of Haier refrigerators there is a carbon filter that eliminates unpleasant odors from the refrigerator compartment.

Other types of compressors

- Oil-free. As the name suggests, the unit does not require oil to operate. They are usually installed in refrigeration units.

- Electrogasdynamic. In this design, the required pressure is obtained due to the appearance of space charges of particles in the electric field.

- Volume. In such devices, the compression effect is produced using a mechanical device driven by an engine (electric motor). The efficiency of this type of equipment is much higher than that of screw units. Widely used before the advent of inexpensive rotary devices.

Like any device, compressors have their own lifespan and require periodic maintenance.

Inverter tester - Air conditioner spare parts

Device for testing the power stage of the inverter

User manual

To ensure safe and correct use of the device, please read these operating instructions carefully before starting operation.

The Inverter Power Stage Tester is a tool that assists in identifying and troubleshooting problems during compressor operation. When connecting the device to the outdoor unit of the Mitsubishi Electric air conditioner, a malfunction of the power board and the compressor drive power module is detected. You can use this tool to detect inverter faults such as compressor overcurrent protection. 1. Safety Precautions

Caution: High voltage (compressor clamps and terminals).

High temperature (resistors). High Voltage Warning: Compressor clamps and terminals are under high voltage. Before using the inverter tester, turn off the power and wait at least 5 minutes until it is completely discharged. Do not touch the device with wet hands. Do not connect the power line (L1/L2/L3/N) to the device. Do not use the inverter tester for more than 10 minutes continuously to avoid overheating of the instrument. Do not make any changes to the test device. Do not remove the protective cover from the tester. The tester resistors become very hot. Failure to do so 2. Installing the tester may result in burns.

2.1. Components Check the components shown in Figure 2-1 below. 2.2 How to connect the inverter tester 2.2.1 Precautions before connecting the tester

2.2.2 Connecting the test device Test device for checking the power stage of the inverter Power board and high voltage power module.

For safety reasons, carefully follow the maintenance manual for the outdoor unit you are working with. • When connecting the device, turn off the power supply.

Failure to do so may result in electric shock. • Before turning off the device, wait until it is completely discharged. Failure to do so may result in electric shock. • To fully discharge, turn off the power and wait at least 5 minutes. Capacitors on the power board are under high voltage. Turning off the power supply alone does not provide a complete discharge. Be sure to wait 5 minutes. 2.2.2 Connecting the test device 1) Turn off the power supply. 2) Wait at least 5 minutes for the power board to completely discharge. 3) Before connecting the tester, check the voltage at the compressor terminals (U, V, W) or the compressor connection terminals (U, V, W) of the power board with a tester (not included) to ensure complete discharge. 4) Connect the test device. The connection method depends on the type of compressor terminals. 4-1) TAB Type Terminals Disconnect the compressor wiring from the compressor and the clamps at each terminal. To prevent short circuits between phases, insulate the terminals with insulating tape.

4-2) Screw Type Terminals Disconnect the compressor wiring from the compressor and the clamps at each terminal. To prevent short circuits between phases, insulate the terminals with insulating tape.

4-3) Cluster type terminals (Three-wire connector) Disconnect the wiring on the connection terminal side from the tester connector. Cluster type terminals use the connector to connect the compressor wiring and power board. Disconnect the compressor wiring from the connectors and connect the compressor wiring to the inverter tester connectors.

2.3.

Troubleshooting 2.3.1 Precautions before troubleshooting Never touch the terminals. High voltage terminals. Failure to do so may result in electric shock. Never touch terminals with wet hands. Failure to do so may result in electric shock. Do not use the inverter tester for more than 10 minutes continuously to avoid excessive heating of the tester resistors. 2.3.2 How to determine the fault 1) Disconnect the compressor wiring and measure the resistance to check for short circuit or ground fault. • Measure the resistance between the compressor terminals (UV, VW, UW) to check for short circuit. If a short circuit is detected, replace the compressor. Be sure to troubleshoot the inverter. (Be sure to check the status of the inverter outputs.) • Measure the resistance between the compressor terminals and the ground terminals (U-ground, V-ground, W-ground). If a short circuit is detected, it is a ground fault. In this case, replace the compressor. Be sure to check the inverter troubleshooting. 2) Check the status of the inverter outputs using a test device. 3) Connect the power supply. 4) Run the air conditioner in warm or cold mode. Note.

When the air conditioner is turned on, the output status is not displayed correctly.

Depending on the outdoor unit model, the abnormal state of the compressor output may be detected by the compressor protection control. Therefore, troubleshooting does not end at this stage. Rice. 2-10 Example of compressor protection control indication. (Do not complete troubleshooting at this stage.) Note 2:

We recommend turning on the test mode, as this mode of operation is independent of the target and room temperature, which makes it easier to identify faults.

5) Check the status of the six LED indicators on the inverter tester. 5-1) The inverter output is normal when all six indicators light up evenly. Therefore, check for faults in the compressor and refrigerant circuit. Rice. 2-10 LED indication when inverter output is normal. Note 3:

In the following cases, even when all six indicators are lit evenly, an increase in current may be detected when wiring is connected to the compressor. Check the power board, control board and wiring settings. • Compressor test error (The output of the control board is normal, but the protection is triggered when the compressor current is exceeded). • Incorrect model installation on the control board (for models that use switches on the control board to install the model). • An incorrect control board is installed in the unit (if the control board is replaced during maintenance, there may also be a different firmware). • An incorrect power board is installed in the unit (if the control board is replaced during maintenance, there may also be a different firmware). • When the supply voltage is low. 5-2) The inverter output is faulty when the LEDs do not light up, light up unevenly or light up dimly. Check for any faults with the power board and the wiring between the power board and the compressor. Fig. 2-12 LED indication when V phase is broken / Fig. 2-13 Example of LED indication when the V phase of the power module is broken. 6) After completing the diagnostics, turn off the power and wait at least 5 minutes for the power supply capacitors to finish discharging. Then turn off the indicator tester.

Video: inverter compressors in household refrigerators

I recommend to read:

- Refrigerator with inverter compressor - Home appliance stores offer customers a huge range of refrigerators. This article talks about what an inverter compressor is in a refrigerator, describes...

- Linear inverter compressor in an LG refrigerator - what is it - A linear inverter compressor does not have an electric motor and can change the speed of the pump piston. This type of compressor is the quietest and most economical to date. Principle…

- Smart inverter in an LG refrigerator - what is it? An inverter compressor is also an electric motor with a pump, but only with an adjustable shaft speed. The adjustment allows you to smoothly regulate engine speed and…

- Linear compressor in a refrigerator: reliability rating by manufacturer - The main component of any refrigerator is the compressor. By design it can be rotary or piston. A linear compressor in a refrigerator is a type of piston compressor with a magnetic…

- On what principle does the compressor work in a household refrigerator - Refrigerator compressor - what is it? A compressor is a device that compresses a substance (in our case, it is a refrigerant in the form of freon), as well as its...

- Choosing a refrigerator compressor - It is important to understand which refrigerator compressor is better when purchasing new household appliances and when old ones break down. Failure of the main part is one of the most typical...

- The quietest refrigerators: review and influence of noise - The definition of “quiet refrigerator” is conditional. According to the current general technical conditions for household electric refrigerators for 1987, the permissible noise level of the compressor…

Compressor device

At the base of the refrigerator there is a black casing with oil. The compressor is suspended in it.

Many refrigerators have compressors that look the same. These are piston electric motors with a starting winding. When the engine breaks down, the refrigeration equipment does not function.

Compressor device

The compressor has three outputs for communications, one of which is common. They are located below in the form of a triangle. The device has a relay for starting the motor. This device is connected to all pins.

Modern refrigerator models have compressors connected to a separate box. It contains the electrical circuit. Let's check how the cable works. If it is ok, then you need to check the refrigerator compressor, whether it is working or not.

We check the compressor with a multimeter (tester)

We remove the compressor and disconnect the relay. This can be clearly seen in the video. It is necessary to check the integrity of the windings. To do this, separate all wires and terminals. We measure the resistance. The working device should have a resistance of 20 ohms between the left and top contacts. We close the upper right contact. Its resistance is about 15 ohms. We close the left and right contacts. The highest resistance value is 30 Ohms.

Checking the compressor with a multimeter

If the values are different, the device is faulty. For different models of refrigerators, the indicators differ, but not by more than 5 ohms.

It is necessary to check the resistance between the casing and the feed-through wires. We connect one probe of the multimeter to the fitting, and connect the other to the feed-through contacts. If the screen shows a break, then everything is fine. The appearance of resistance indicates that the motor is working.

Checking with a monometer

We measure the pressure. We connect the outlet hose to the discharge fitting and take readings. When the engine is working properly, the screen of the device should show an increasing pressure reading of 6 atmospheres or more.

Checking with a monometer

You can take an electric motor from an old refrigerator and connect the compressor directly without a relay. It is necessary to connect the windings. Be sure to follow all safety rules.

Checking the current

Using a new relay, you need to check whether current is flowing to the electric motor or not. We connect the relay to the compressor and start it. You will need a clamp tester. We clamp one network wire. The device screen should show 1.3 A, while the power of the electric motor is 140 W. At these values, the current flows properly. As the engine measurement decreases, the tester indicator should also decrease. Use a multimeter to test the relay as it breaks often.

Current test