When choosing a water heater, you need to take into account a number of important factors so that the purchased device lasts as long as possible. The weak point of any such device is metal water tank.

The main enemy of metal is not the water itself, but the impurities it contains, which form scale on the walls of the vessel when heated. An example of scale formation can be seen in an electric kettle: lime contained in the water gradually accumulates, settles on the walls and destroys them. And if the kettle can be cleaned by boiling water with citric acid or vinegar in it, then descaling a water heater is not so easy.

Scale on the walls is dangerous because it causes corrosion of the metal tank and failure of the device itself. To do this, the inside of the heater tank is coated with enamel, which protects the metal from impurities and rust. Also, in addition to enamel, manufacturers use glass ceramics. This article will tell you what the differences are, the strengths and weaknesses of each coating.

Internal coating of a water heater tank - which is better?

Currently, manufacturers offer water heaters with 3 types of internal anti-corrosion coating:

- with titanium coating;

- stainless steel;

- from glass porcelain.

They reliably protect the container from corrosion processes. In other words, the lifespan of the device depends on the internal coating of the tank.

Which tank is better to choose a water heater with? These questions are often asked by buyers. It is impossible to give an unambiguous answer to this question. After all, each of them has its own pros and cons.

Rating of storage electric water heaters

| Photo | Name | Rating | Price | |||

| TOP 4 storage electric water heaters with an enameled tank | ||||||

| #1 | Gorenje GBFU 80 SMB6 | ⭐ 98 / 100 3 - votes | ||||

| #2 | Zanussi ZWH/S 50 Smalto V | ⭐ 97 / 100 2 - votes | ||||

| #3 | Timberk SWH FEX1 80 V | ⭐ 96 / 100 1 - voice | ||||

| #4 | Electrolux EWH 50 Formax | ⭐ 94 / 100 | ||||

| TOP 4 storage electric water heaters with a stainless steel tank | ||||||

| #1 | Hyundai H-SWS1-40V-UI706 | ⭐ 97 / 100 | ||||

| #2 | Hyundai H-SWS11-80V-UI707 | ⭐ 96 / 100 | ||||

| #3 | Timberk SWH FSI1 50 V | ⭐ 94 / 100 1 - voice | ||||

| #4 | Electrolux EWH 80 Royal Flash | ⭐ 92 / 100 | ||||

Which electric boiler would you choose or recommend?

Take the survey

As mentioned above, water heaters can be selected according to different criteria. But since our article is devoted to comparing boilers with different types of heating tank, 4 models were selected precisely according to this principle.

The most common water heaters are devices with enameled tanks, and they will be considered first.

TOP 4 storage electric water heaters with an enameled tank

Electric boiler "Electrolux EWH 50 Formax"

"Electrolux EWH 50 Formax" is a model developed by a Swedish company, domestically produced. The boiler has a neat, ergonomic rectangular shape with rounded corners. The water heater is equipped with a system of independent heating elements “X-HEAT”. Each of them is closed with its own sealed flask, preventing contact with water. If one of the heating elements fails, the second continues to function, that is, the boiler does not lose its functionality.

Electric storage water heater “Electrolux EWH 50 Formax”

The device is easy to operate - for this purpose, there are two knobs on the front panel that allow you to adjust the maximum temperature and set the economical mode.

The boiler has protection against overheating and dry operation. The power cord has an RCD.

A layer of foamed polyurethane “CFC-Free” is used as thermal insulation, which allows you to keep water in a heated state for a long time.

The quality of the enamel coating of the tank will probably be indicated by the warranty period established by the manufacturer of 7 years. True, with an annual replacement of the magnesium anode.

What do users say about this model?

pros

- The heating elements are hermetically sealed with a protective flask from contact with water, which eliminates the risk of them becoming overgrown with scale and rapid failure.

- The boiler heats up quickly.

- The cost can be considered quite affordable.

- Availability of economy mode.

- The flattened shape of the body makes it easier to find a place suitable for hanging the device.

- Heating elements are easy to change.

Minuses

- Lack of a display (although the “complainant” did not really explain why this absence was inconvenient for him).

- After five years of use it began to leak. This is serious!

Electric boiler “Timberk SWH FEX1 80 V”

The Swedish company produces electric water heaters with both enameled containers and those made of stainless steel. Therefore, having previously chosen one of these materials, you should carefully study the characteristics before purchasing a specific model. Chinese-assembled models predominantly enter the Russian market.

Electric boiler “Timberk SWH FEX1 80 V”

The model shown is with enameled tank walls. A high-quality glass-ceramic composition is used, which will not accumulate scale. The products have strong welding seams covered with a protective layer, as well as reliable thermal insulation.

The boiler has all the degrees of protection necessary for modern models.

What do consumers write?

pros

- Ergonomic shape that allows you to install the boiler both horizontally and vertically.

- Stylish case design

- Effective protection against leaks and corrosion.

- Quick heating of the collected volume of water.

- Convenient device control.

Minuses

- No negative comments were made

- Maybe a little overpriced

However, the majority believes that the price corresponds to the quality. That is, the period guaranteed by the manufacturer for the product to work according to the “full program”.

Electric boiler “Zanussi ZWH/S 50 Smalto”

Storage water heater made in Italy - “Zanussi ZWH/S 50 Smalto”. It is designed to heat 50 liters of water, which is quite enough for a family of two people. Or the heater can serve as a backup source of hot water in case of emergency shutdown of the hot water supply. The temperature range for heating water in the boiler is between 30 and 75 degrees.

Boiler "Zanussi ZWH/S 50 Smalto V". Similar models “... Smalto DL” have a digital display, and therefore are somewhat more expensive with other equal functionality.

The heating tank is covered with a layer of waterproof glass-ceramic enamel, applied using innovative electrostatic dry spray technology. And the manufacturer boldly gives an 8-year guarantee!

All necessary degrees of protection are provided, both for water and electrical parts.

Operation in economical mode is provided. Reliable thermal insulation in which the internal tank is placed allows you to maintain a high temperature for a long period, minimizing heat loss.

The model is distinguished by its installation versatility - it can be hung both vertically and horizontally.

Let's take a look at the reviews:

pros

- Compact, laconic dimensions.

- Powerful device that heats water quickly.

- Thanks to the effective insulation layer between the body and the tank, the water remains hot for a very long time.

- The presence of a display (DL models only) allows you to control the water temperature.

- Convenient device control.

Minuses

- Quite a lot of weight.

- It would not hurt to have a special separate valve for draining water.

Electric boiler “Gorenje GBFU 80 SMB6”

Gorenje is a Slovenian company founded in 1950, and today it is a very reputable European manufacturer of household appliances.

Electric storage water heater “Gorenje GBFU 80 SMB6”

The internal coating of the boilers is made of ultra-pure, high-strength glass-ceramic enamel. In addition, a magnesium protective anode is installed in the tank, which significantly extends the active service life of the device. Such protection copes well with almost any theoretically possible aggressive impurities in water. Boilers are produced with a volume of 50 to 200 liters and can be mounted horizontally or vertically on a vertical surface.

A good solution, that is, the heating element is installed in a sealed flask, so it does not come into contact with water.

Another feature that is not typical for all modern water heaters is “anti-legionella”. If the water does not heat above 65 degrees for two weeks, the device independently carries out preventive disinfection, heating the water to a temperature where pathogenic bacteria die. The development of a colony of microorganisms will be eliminated.

Users also say a lot of good things:

pros

- Fast water heating - in just one hour the water reaches the desired temperature.

- Convenient boiler control system: one button - manually setting the desired temperature, the second button - automatic operating mode.

- The insulation retains heat well, making the device economical.

- Protection is provided against both boiling and freezing.

- Knows how to “assess the situation” and independently fight Legionella.

Minuses

- There have been no negative comments yet.

TOP 4 storage electric water heaters with a stainless steel tank:

Electric boiler "Electrolux EWH 80 Royal Flash"

And again, the Swedish Electrolux is a fairly well-known brand in Russia, where it has gained a high reputation among consumers.

Electric boiler "Electrolux EWH 80 Royal Flash"

The Electrolux EWH 80 Royal Flash model has laconic shapes and an interesting design, thanks to which it will fit perfectly into the kitchen without spoiling its interior at all. And the flattened shape is a plus for placement in a tight, limited space, for example, in a bathroom.

On the front panel of the water heater body there is an electronic screen on which the set and current temperature is set.

The heating tank is made of high quality stainless steel, suitable for food equipment. By the way, Swedish companies are just those exceptions from the general range of European manufacturers that practice the production of stainless tanks.

The device is equipped with electromechanical control and several degrees of protection.

Additionally, the boiler is equipped with a water heating timer, an economical operating mode, an anti-scale protection system, as well as water disinfection.

Let's take a look at the reviews:

pros

- Modern design.

- Safety in operation - protection is provided for all occasions.

- Good performance of the device.

- Neat body shape.

- Reliability of the device (works for six months without turning off).

- Very high quality build.

- Possibility of horizontal or vertical stop.

- There is a water disinfection function.

- Operation can be programmed using the built-in timer

Minuses

- Quite a high cost.

- There is a need to replace the anode once a year - the manufacturer's requirements, without compliance with which the warranty will be void.

- Some users who have been using the boiler for more than a year have not been able to identify a single drawback.

Electric boiler “Timberk SWH FSI1 50 V”

The inscription “stainless” on the front panel of the case just means that the model has a stainless steel tank.

Electric boiler “Timberk SWH FSI1 50 V”

The storage water heater “Timberk SWH FSI1 50 V” is well suited for installation in both standard apartments and private houses. The device operates from the mains and is capable of supplying hot water to several points.

All necessary protective systems are provided, such as a magnesium anode, an RCD. from overheating and leaks.

The electric heater can operate at one of three selectable power levels, so you can customize the energy consumption yourself. High-quality thermal insulation prevents the body from wasting waste.

What do its owners write about the model?

pros

- Convenient body shape.

- Availability of protective shutdown for different cases.

- Quite convenient control of the device.

- The proven service life without breakdowns is already 5 years (in summer), and continues to grow...

- The water heater is quite economical to operate.

Minuses

- There are complaints about insufficient quality of assembly.

- The lack of a network cable and mounting brackets is disappointing. A penny, of course, but extra hassle.

Electric boiler "Hyundai H-SWS11-80V-UI707"

The first two lines in the ranking were occupied by models of South Korean, albeit Chinese, assembly. As already mentioned, it is Asian manufacturers who more often provide boilers with stainless steel tanks to the market.

Electric boiler "Hyundai H-SWS11-80V-UI707"

The “Hyundai H-SWS11-80V-UI707” boiler-type water heater has a white enameled outer casing with a discreet, neat design. Therefore, the device will fit perfectly into any room, especially since it can be positioned both horizontally and vertically.

The boiler has a tank capacity of 80 liters, which is quite enough for a family of three or even four people. The material of the tank is high-quality stainless steel, which can withstand the aggressive effects of water.

The water is heated within 64 minutes to a maximum possible temperature of 75 degrees.

There is nothing superfluous in the controls - the device is equipped with a thermostatic temperature setting handle, a heating and power-on indication system, thanks to which you can find out the current operating mode with one glance. All basic levels of protection are available.

pros

- Convenient tank volume, enough for all the necessary needs of a family of 4 people.

- Heats up quickly.

- By today's standards, it is quite affordable.

- The water heater is very economical to operate.

- The shape of the case is attractive and convenient for placement on the wall.

Minuses

- No display. This is the pattern, and some take it as a virtue. And for supporters of more complex control systems, there are corresponding offers from the same manufacturer and with similar other characteristics.

- There were no significant comments on operational issues.

Another model also has a high quality stainless steel tank.

Enamel and glass ceramics: advantages and disadvantages

Today, buyers give their preference to water heaters with glass porcelain coating. Such equipment is characterized by a minimal price compared to others. So, the advantages of these units:

- Profitable price.

- Preventive work to remove contaminants (sediment) on enamel coatings is easy to eliminate. To do this, just use a good detergent.

- Enamel is an inert material that is resistant to various chemicals. For example, only aggressive compounds such as hydrofluoric acid can damage the structure of glass ceramics.

Boiler with enameled tank and magnesium anode

The disadvantages of such an internal coating of the container include:

- The equipment faces the problem of good adhesion between the coating and the metal of the tank.

- Ceramic coating differs significantly in the composition of the metal from which the boiler itself is made. Often, due to constant temperature changes, materials separate from each other. But the use of glass ceramics in the production of equipment practically eliminates this drawback.

- The composition of bulk enamel may include coloring pigments. The latter often contain arsenic and lead - substances harmful to the body. But it should be remembered that devices manufactured over the last 20 years with a glass-ceramic tank do not have such a drawback.

- Ceramics is a fairly fragile material. Sudden shocks can lead to destruction of the coating. But this indicator is not important for permanently installed water heaters.

Interesting! Enamel and glass porcelain are particularly sensitive to temperature changes. This often causes the formation of microcracks on the surface.

To avoid this, some users use equipment by setting its maximum water heating temperature to 600C. But experienced experts recommend increasing the water heating temperature to maximum at least once a month to prevent the development of harmful bacteria inside the container.

The manufacturer's warranty for water heaters with enamel coating is 1 year.

Stainless steel: advantages and disadvantages

Water heaters with an internal stainless steel coating belong to the category of expensive equipment. In principle, this affects their service life.

Stainless steel water heater

The advantages of boilers with this coating include:

- The coating is resistant to various shocks and damage compared to the above-mentioned model.

- Such water heaters are not afraid of temperature changes. If the equipment suddenly overheats due to the lack of liquid in it, it will not suffer. You will only need to replace the heating element and other parts that may fail due to high temperature.

- The service life of such boilers is longer than the models described above.

- The warranty period for containers with this coating varies from 7 to 10 years.

Disadvantages include:

- Stainless steel is characterized by its resistance to corrosion. But if a simple welding method was used, in this place the composition of the metal differs from the main one. The use of outdated technologies in the manufacture of equipment can cause oxidation on the seams. In addition, it should be remembered that all chemical reactions occur much faster at elevated temperatures.

- Many people remember the toxicity of iron, which comes into direct contact with water. But only divalent iron can have a negative impact on human health. Such a connection practically cannot be formed when steel comes into contact with water. In addition, examinations with ultra-precise instruments and methods did not show the presence of this element in large containers, except that the water itself could be its source.

- The price of equipment for heating water with a stainless steel coating significantly exceeds the cost of the models described above.

Plasma welding is used in the manufacture of a water heater tank

Requirements for water heater tanks

One of the most important criteria by which consumers choose a water heater is its service life. As a rule, the scales tip in one direction or another depending on the material and wall thickness of the internal tank, as well as the name of the manufacturer.

Of these three components when choosing, one is superfluous, namely the thickness of the metal sheet from which the container is made. Let's try to figure out why.

Plasma welding is used for welding water heater tanks

As a rule, in the manufacture of tanks, sheet metal with a thickness of 1.75mm to 3mm is used. Thicker sheets are used for shells and bottoms in floor-standing models. Of course, as the volume of the boiler increases, the thickness of the walls of its tank also increases, which is calculated only on the basis of the need for its mechanical strength, but not in any way for the purpose of protection against corrosion. In the aggressive environment in which the internal tank is located, even fairly thick metal will not withstand more than 3-4 years, so the type of protective coating of the tank has a much greater influence on the service life.

When wondering what is better - stainless steel or enamel, we must not forget about another equally important factor - the quality of the welds.

The EN12897:2006 standard requires the tank to withstand at least 20,000 operating cycles at 50% operating pressure or 100,000 cycles at 30% operating pressure.

Control samples from any batch of tanks are subjected to this test after applying a protective coating.

The image of the manufacturer, undoubtedly, also affects the quality and service life of products, since world-famous companies have been on the water heater market for decades and have the ability to use the most advanced technologies in production. Their laboratories do not stop developing new protective compounds for a single day, and the coatings themselves are a trade secret and are protected by patents. Small manufacturers do not have such capabilities, so their products most often have a shorter service life, but they are also cheaper.

Titanium coated water heaters: advantages and disadvantages

Boilers with internal titanium coating are quite rare. They belong to a small class of devices. This lightweight and chemically resistant metal is applied electrostatically. As a result, the protective layer is highly resistant to corrosion processes and increases the strength of the equipment.

Due to the high adhesion and strength of the metal, the water heater can operate at high temperatures. This eliminates the risk of damage or peeling of the protective coating.

The weak point of the titanium coating is the welded joints. Corrosion often appears in these areas. And the cost of such equipment is quite high.

Boiler with two-layer titanium enamel

Types of interior coatings

At the moment, there are two types of coating: glass porcelain with enamel and stainless steel. The first varieties are somewhat cheaper. But this does not indicate that steel, if more expensive, is better. Each option has its own characteristics that you need to understand.

Glass porcelain coated with enamel

When water heaters first began to appear, their insides were covered with ordinary enamel. It was also used for steel and cast iron bathtubs and sinks. However, during operation, a serious drawback was identified - cyclic temperature loads caused rapid cracking of the enamel.

Important! The steel on the inside of the tank could not resist electrochemical corrosion, which led to equipment failure. Even plastic coatings had a service life of no more than 3-4 years.

Having analyzed the situation, manufacturers identified what the service life of the enamel depends on - the protective enamel layer had a completely different thermal expansion value when compared with the values of the temperature coefficients inherent in steel. To equalize the performance, the protective composition was modified - titanium powder was added.

As a result, the enamel “turned” into another material called glass porcelain. Such a tank for new water heaters quickly became popular due to its increased strength, elasticity and resistance to temperature deformation. The porcelain glass coating keeps water in a clean and fresh state longer, since scale forms on the walls of the device less often.

Water heaters coated with glass ceramics are made as follows: a steel sheet is taken, from which a container is made by welding. Next, its inner surface is covered with glass porcelain and fired at temperatures up to +900 degrees Celsius.

As for glass porcelain itself, it is a substance in powder form. It can be applied to the walls of the tank in different ways, which will affect the service life of the device. Newbie manufacturers use the liquid method - the powder is mixed with liquid substances, then it is sprayed onto a tank, which is left to dry, and then sent to a kiln for firing.

Important! World-famous companies use another method - dry, which is electrostatic spraying. Particles with a charge “stick” better to the surface of the tank, and evenly. Liquid enameling, in turn, causes the enamel to flow down the tank, causing the coating in the upper part to be thinner. But the upper area of the water heater is most susceptible to corrosion, because an aggressive environment is formed due to the air gap.

When deciding which tank coating is best for a modern storage water heater, do not forget about new protective technologies. Not so long ago, silver began to be added to glass porcelain, which makes it possible to saturate water with ions of this metal. As a result, the likelihood of bacteria forming in such tanks is reduced, and they require preventive cleaning much less often.

To understand which tank is better in a water heater, it is necessary to highlight the advantages and disadvantages of each coating. Glass porcelain units are characterized by the following advantages:

- affordable price;

- ease of preventive maintenance. To remove sediment, just use a good detergent;

- enamel is a material inert to many chemicals. To damage the glass-ceramic structure, you will need a really aggressive composition, for example, hydrofluoric acid.

This internal coating also has disadvantages:

- ceramics and the boiler itself differ in composition. Constant temperature changes can lead to delamination of materials. However, glass ceramics practically eliminates this point;

- Coloring pigments are often added to bulk enamel. The latter contained arsenic and lead - substances dangerous to humans. This only applies to devices that were manufactured more than 20 years ago;

- fragility of ceramics. If the indirect water heater is “shaken”, this will lead to damage to the coating.

Important! Enamel and glass porcelain are sensitive to temperature changes, which causes microcracks to form on them.

Steel

To better understand which water heater to choose – enamel or stainless steel, you need to consider the features of steel products. It includes non-magnetic stainless steel. And thanks to chromium, a dense protective film is formed on the metal surface, which prevents corrosion from developing. In purely steel or cast iron products, this film is not strong enough, which is why the metal can crack.

In theory, stainless steel does not corrode. Therefore, such tanks do not require additional enamel coating, just like a magnesium anode. But to make a water heater, welding is necessary, which disrupts the structure of the metal in the processing areas. As a result, intergranular corrosion appears. To eliminate this point, new welding technologies have been developed.

The price of stainless steel is 30-100% more than an enameled tank. Such containers are more durable; they do not require replacing the magnesium anode. When wondering which water heater is better - stainless steel or enamel, you need to consider the conditions under which it will be used. In Russia, the quality of cold water is far from ideal, so stainless steel is more in demand as a coating.

Tips for using porcelain glass water heaters

Such water heaters are considered the most common. Unfortunately, not everyone can afford to purchase expensive equipment. But with proper operation, you can achieve uninterrupted operation of the equipment over a long period.

- You should give preference to models with a magnesium anode. Its presence greatly reduces the activity of oxidative processes, which negatively affect the performance of equipment.

- It is necessary to periodically replace the magnesium anode.

- A coarse filter must be installed at the water inlet. Grains of sand and other particles that get inside the boiler can damage the surface from the inside when heated.

- Try not to overheat the tank. For domestic needs, water at a temperature of 50-600C is sufficient.

Preventive inspections and cleaning will extend the life of your device

- The water heater must be cleaned 2 times a year. This procedure will significantly extend the life of your device. At the same time, plaque is removed from the walls and bottom of the container, the heating element is cleaned of scale, the wear of the magnesium anode is checked and then replaced if necessary.

In stores today there are various devices for heating water. They differ from each other not only in functionality, but also in the internal coating of the tank: stainless steel, glass ceramics, titanium coating. Each of them has its own advantages and disadvantages. But regardless of the model you choose, you should remember that proper care is the key to long-term operation of the device.

Properties of materials

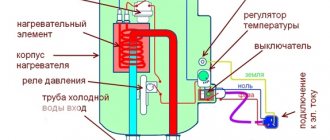

Electric storage water heaters consist of external and internal tanks. The latter experiences heavy loads and is subject to the aggressive effects of dissolved oxygen and electrochemical corrosion. Residual active chlorine leads to intergranular destruction of the metal.

Water purification systems produced from Tyumen not only reduce the amount of aggressive chlorine, but also prevent the formation of scale on the inner surface of the heater.

Stainless steel

Chromium is used as an alloying element in stainless steel. A thin film of insoluble oxides forms on the surface of the sheet, which provides corrosion resistance to stainless steel. In this case, the base metal should not have internal stresses and crystalline defects. They occur during calcination (welding) and deformation of the steel sheet during the manufacture of the tank. Structural changes occur in weld seams, which lead to corrosion.

Such defects are dangerous because, despite its normal appearance, the stainless steel becomes brittle and a leak may occur in the boiler due to loads (increased pressure). To reduce the likelihood of corrosion of the weld and heating element, some manufacturers install magnesium anodes. In this case, instead of the base metal, electrochemical processes occur in the tread material.

Manufacturing of water heaters from stainless steel.

Over time, the anode is completely used up. To replace it, you will need to dismantle and disassemble the heater. Not everyone can do such work on their own, and hiring specialists will require additional costs.

Some companies use stainless steel of dubious quality, which not only has poor anti-corrosion properties, but can also be hazardous to health.

Enameled coating

To prevent oxidation of the material, the inner surface of the tank is covered with enamel. This prevents rusting and increases the life of the product. However, enamel and metal have different coefficients of linear expansion when heated. Therefore, microcracks appear on the surface of the protective coating. During the operation of the heater, they develop and become centers of corrosion.

Manufacturers introduce a titanium additive into the enamel, which increases the ductility of the protective layer. This makes it possible to increase the service life of the heater to 5-7 years, which is not much different from models with a tank made of stainless materials. Enameled boilers are the most common.

To protect the body from corrosion, protective anodes must be installed in enamel-coated containers. Their operating time depends on the quality of the water. Therefore, it is recommended to install filter systems, for example, Tyumen.

The inside of the water heater is covered with enamel.

Such heaters can be used in heating systems of country houses. The use of purified water increases the service life of the heater elements, however, these devices require periodic inspection of the internal cavity and replacement of the anode.

Useful tips to help increase the service life of inexpensive boilers

Not everyone can afford to buy an expensive water heater. Don’t get upset in advance - if you use the equipment correctly, it will last for decades. A number of rules have been developed for inexpensive devices:

- It’s good if the design has a magnesium anode. Thanks to it, oxidative processes will not occur so often. The element needs periodic replacement;

- A coarse filter is installed at the water inlet. If debris gets into the container, even in the form of small grains of sand, it can ruin the coating;

- The tank must not be overheated. For domestic purposes, the optimal temperature ranges from +50 to +60 degrees Celsius;

- It is recommended to clean the boiler twice a year. The walls and bottom are cleaned of plaque, the heating element is cleaned of scale. At first glance, this is a cumbersome procedure, but it will extend the life of water heating equipment.

These are simple but effective tips that you should follow.