How to properly replace the heating element in a boiler

The part is replaced when it breaks due to lack of regular cleaning of the boiler.

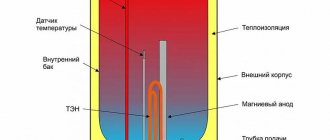

The need to replace the heating element arises when it malfunctions. When it stops heating the water, the electrical protection device is triggered. The average service life is 4 years. Then it fails due to increased water hardness. This event can be delayed if you perform annual boiler maintenance: clean the heating element and magnesium anode from scale. This operation will increase the duration of operation and improve the quality of water and the rate of its heating. Before purchasing a new element, you should check the condition of the old heating element using a test lamp or multimeter. In the first case, a simple electrical circuit is assembled, including a lamp and a heater. If the light is on, it is not the problem. In the second case, the resistance is measured with a special device. A zero value indicates a heater malfunction.

The designs of different boiler models have minor differences, but the principle of replacing heating elements in a water heater is the same for all types of devices.

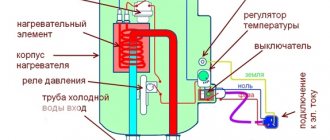

To begin with, turn off the water supply and drain the remaining liquid from the boiler. The water heater must be de-energized by unplugging the plug from the socket. At the bottom of the boiler there is a cover that is attached with screws. You need to unscrew them with a screwdriver and the cover will come off. For safety reasons, before you start replacing the heating element in the boiler, you need to check the presence of voltage at the terminals, for example, using an indicator screwdriver. Then disconnect the wires and unscrew the nuts holding the heater in place. Replace the heating element on the water heater, first checking that the contacts are dry. If an anode is installed in the boiler, replace it as well. Check the seal for leaks and screw the lid into place. After these manipulations, you need to fill the boiler with cold water and bleed the air from it by opening the hot water tap. Only now can you turn it on to the network.

What is good about soapstone technology?

Soapstone is a naturally occurring mineral obtained from unprocessed talc ore. The mineral is known for its healing and even magical properties, but most of all the creators of the technology were interested in the phenomenal ability of steatite to retain heat. For example, if you immerse this mineral in hot water for a few minutes, it will remain warm for about an hour.

People also knew about this property for a long time, and therefore used the mineral in the manufacture of stoves and thermal insulation coatings. Moreover, they took pure steatite and its mixtures with other elements.

Additional benefits

- Soapstone is able to absorb excess heat, and thus protect the metal parts of the heating element and the protective flask itself from overheating. The service life of the heater is increased, and corrosion is significantly slowed down.

- The peculiar shape of the ceramic part of the steatite heating element helps to correctly use the beneficial properties of the material and thereby increase its service life.

- To replace a soapstone heating element, you do not need to drain the water from the tank.

Atlantic is so confident in the reliability of this technology that the warranty on soapstone heating elements is 3-4 years longer than on conventional dry heating elements. In addition, mandatory boiler maintenance is allowed once every 2 years. While other boiler models must be checked annually. This says a lot, because manufacturers have always been able to calculate the costs of warranty repairs.

Our website offers a wide selection of Atlantic Steatite series water heaters at attractive prices. Our specialists will also provide you with qualified advice on all additional issues. We will be glad if this information is useful to you.

Criterias of choice

When choosing a heating element for a boiler, you need to build on the characteristics of the previously installed element.

Types of devices

The material of the tank and heating element must match, so stainless steel parts are often purchased

. In addition to the type of heating element in contact with liquid, you need to take into account a lot of other parameters:

Mounting method: nut or flange. The latter can be cast or stamped. Flange mounting is typical for open-type heating elements; Possibility of installing an anode - this element is designed to protect metal surfaces from corrosion and scale, thereby increasing the overall service life of the boiler. The anode gradually “melts”, so a new one must be installed periodically. If there is a hole for the anode in the base of the heating element, then a new heater with the same hole is needed. The shape depends on the type of storage container. The heating element can be straight or bent. A heating element similar to the previously installed one is selected, taking into account not only the shape, but also the size, as well as the bending angle. Manufacturing material - the outer surface of the heating element can be made of copper or stainless steel

It is important that the material of the tank and heating element match, otherwise, due to the difference in potential, the service life of the heating element and the tank itself will be shortened. A closed-type copper heater can be located inside an enameled steel flask, in which case you don’t have to worry about creating a galvanic couple.

Features and amount of heated liquid

Heating element with magnesium anode for hard water

If the water is hard, you need a heating element under the anode, which will partially eliminate the problem of scale and extend the life of the boiler. The power must correspond to the volume of the heated liquid. It is recommended to purchase a part of the same power as the failed one. The heater parameters are indicated in the technical data sheet of the device.

terms of Use

The power must match the wiring capabilities. But this applies more to the choice of a boiler rather than a heating element, since the old element is replaced with a new one of similar power. The power of the boiler as a whole also affects the heating rate of a given volume of water. If the heating element is low-power, for example 1000 W, and the capacity is 80 or even 100 liters, it will take a very long time for the water to heat up to the maximum temperature, several hours, so you need to turn on the boiler in advance. This power is optimal for small boilers, up to a maximum of 50 liters.

If you plan to consume a lot of hot water, it is recommended to buy a model with two heating elements. They heat the water faster. In economical mode, one element will work, and the second will be connected thanks to the thermostat when it is necessary to heat a new portion of cold water.

Differences between steatite heating elements and conventional dry heating elements

- Larger size. The photo clearly shows the difference between a steatite heating element and a classic dry heating element of similar power. Steatite is much larger, and the heat exchange area is accordingly increased. Thanks to this, the water heats up faster and less scale forms on the walls.

- Fixed heating element. In a conventional heating element, a copper alloy or stainless steel heater can move slightly inside a protective enamel flask, while a steatite heater fits tightly, motionlessly and evenly to the flask, which promotes high-quality heat transfer.

- Combined heating element. The stainless steel heating element is hidden in a ceramic base containing steatite. Soapstone remains warm for a long time, even after the boiler is turned off, which significantly saves energy consumption when maintaining the set temperature.

Categories of heating elements by type of contact with liquid

In a dry heating element there is no contact with water, which extends the service life of the part

A nichrome spiral is hermetically sealed inside the heating element for heating water, and the space between it and the outer walls is filled with quartz sand. The outer tube can be made of copper, carbon steel or stainless steel.

Open heating elements come into direct contact with water. Their main advantage is the high speed of heating the liquid and low cost, but there are also significant disadvantages:

- limited service life;

- rapid formation of limescale;

- high electricity consumption;

- insecurity.

Closed ones do not come into contact with water. The heating element is protected by a durable bulb. Its advantages:

- the likelihood of an electrical short circuit is reduced;

- easy to repair and maintain;

- serve for a long time - three times longer than open heating elements;

- consume significantly less electricity than open-type heating elements.

There are two important disadvantages: high price and slow water heating.

Pros and cons of dry heating elements

The main advantage can be learned from the name of the device. Its spiral does not come into direct contact with water, so it will not quickly collapse even with poor quality liquid and regular use.

A dry heating element also differs from a wet one in that it is easier to maintain. It only replaces the spiral with terminal terminals for 220 volts. The capsule itself remains in the boiler body, which allows repairs to be made without draining the water from the tank. This kind of work can be done well on your own even without proper qualifications. All you need is a high-quality tool, and step-by-step instructions can be found in the training videos.

It is not recommended to drain water from the tank unless absolutely necessary. When its body interacts with oxygen from the inside, the risk of corrosion spreading increases significantly. This may cause a leak. A small crack or hole can still be repaired, but if a large area is damaged, the boiler will have to be replaced.

Another advantage of a dry element is safety. Due to the fact that it is placed in a special capsule, there is no risk that the energized spiral will touch the conductive body and a so-called “breakthrough to the body” will appear. If a person touches a boiler with a “broken” device, he may be electrocuted.

These devices are also compact. Therefore, some manufacturers place 2 elements in the tank body at once, which speeds up the heating process.

The key disadvantage of a dry tubular electric heater is its high price. A classic tubular element can be purchased at 2 times cheaper. Also, the heater power in the capsule will always be less.

How to connect a heating element with a thermostat

Now you know how and by what parameters heaters are selected. But how is the connection made? In order to connect a heating element with a thermostat, you must select a wire with reliable insulation

We also pay attention to the cross-section - it must be such that the wire can provide adequate power to the heater and not melt. For example, for a 3 kW heater, the wire cross-section must be at least 2.5 mm. We recommend choosing cables with copper conductors for connection

Do not forget to pay attention to the presence of an RCD - it will instantly turn off the power in the event of an unexpected failure of the heating element or a short circuit. The RCD must be installed as close as possible to the heater itself

You should also ensure a reliable connection of the conductors with the contacts of the heating element (without “snot” and flimsy contacts that can spark).

Temperature regulators are used quite widely for domestic purposes, and they regulate the temperature literally everywhere: from a common soldering iron to the microclimate in the house.

Dry and wet heating element of a water heater. What is the difference? Why is dry heating element better?

Wet heating element. This heating element has the shape of a curved spiral; a wet heating element is often made from copper, because this material conducts heat very well. It is called a wet heating element because it is in direct contact with water and has a temperature close to the temperature of water. The main advantage of a wet heating element is its low price. Thanks to this advantage, water heaters with a wet heating element are always much cheaper than their counterparts with a dry heating element.

Now let's go over the disadvantages of the Wet Heating element.

- When buying a boiler with a wet heating element, be prepared for the fact that you will have to completely drain the water when replacing the heating element if it fails.

- There is a risk of breakdown of the heating element and electric shock, although such stories have never happened in our practice.

- Well, the last drawback, which is mentioned by all manufacturers and experts. Due to constant direct contact with water, the heating element gradually becomes overgrown with scale, losing its efficiency and breaking down much more often. I would like to note that scale is formed not due to the design of the heating element, but to a greater extent due to the quality of the water that is in the pipes. Regardless of the type of heater, scale is the main enemy of the boiler and the process of fighting scale is no different for water heaters of different models: it is a simple annual cleaning and replacement of the magnetic anode, which, gradually dissolving, prevents the formation of scale on the walls of the heating element and boiler. As a rule, all manufacturers of modern boilers will refuse to provide you with a warranty if you neglect the annual maintenance of your boiler.

Dry heating element. The heater received the name “dry” due to its design, which is structurally different from the wet one. In a dry heating element, the heating element is placed in an additional tube (usually with ceramic inserts) and does not come into contact with water with its body. Since there is no direct contact with water, the temperature of such a heating element is always higher than the water temperature, but this is not a problem, because dry heating elements are designed primarily for heating air and their service life is in no way lower than that of a wet heating element. The main disadvantage is the higher price of both the boiler itself and the heating element, as a consumable.

Advantages of dry heating element.

- Thanks to the design, it is possible to quickly replace a burnt-out heating element without draining the water from the tank. It is enough to pull out the old element from the flask and, having reconnected the power, you can already use the new one.

- Also, scale has a lesser effect on the heating efficiency of a dry heating element, and most manufacturers establish long warranty periods for such boilers. But the obligation of annual maintenance - cleaning the tank and replacing the magnetic anode - still remains as a mandatory condition of the warranty. For some boilers with a dry heating element, the manufacturer increases the mandatory maintenance period by 2 years, but this is still a prerequisite.

- The risk of electric shock also remains, but it is practically negligible. After all, this requires damage to the bulb in which the heating element is located, and this can only happen in water heaters that have not been serviced for a very long time. This is all thanks to the fact that the heating element is enclosed in a special metal flask of increased strength and is made not of metal, but of ceramics - magnesium silicate (steatite).

- The “dry” heating element has smaller, more compact dimensions compared to the “wet” heating element. This allows you to use not one, but two heating elements in one boiler. In this case, the service life of the water heating device and its reliability are significantly increased. But this is more of a marketing advantage; water heaters with 2 wet heating elements have already begun to appear.

So. We looked at all the pros and cons of two types of water heaters in a boiler - dry and wet. We tried to answer the question: why is a dry heating element better and is it worth paying more for a boiler with a dry heating element. The decision is yours to make. Our opinion is that a boiler with a dry heating element has more advantages and, if you have the financial opportunity, it is better to choose this option. If the budget for purchasing a boiler is limited, do not worry that you bought a much worse option. Often, boilers with wet heating elements show amazing longevity and, at the same time, for more modest money.

For convenience, we present the pros and cons of dry and wet heating elements in the table. This will help you make the right decision

| № | Advantages and disadvantages | Dry heating element | Wet heating element |

| 1 | Warranty period and, conditionally!, service life of the water heater. | Typically higher | Typically below |

| 2 | Need for annual maintenance | There are different options | Necessarily |

| 3 | Easy annual maintenance | Need to drain water | Need to drain water |

| 4 | Easy to replace heating element | NO need to drain water | Need to drain water |

| 5 | The cost of the boiler and heating element | Typically higher | Typically below |

| 6 | Risk of electric shock | Minimum | Eat |

| 7 | Efficiency in case of scale formation | Better | Worse |

| 8 | Models of water heaters with two heating elements | Eat | No |

On the website of the Heat store, you can select a water heater not only by certain characteristics, but also by size. If there is a limitation in the installation location, indicate the maximum permissible height, width or depth of the boiler and choose only among the models that suit you.

Buy a water heater

Advantages of dry heating elements

If you compare a dry design with a submersible one, the first one will have a lot of advantages:

- no scale;

- compact dimensions;

- ease of maintenance;

- excellent performance;

- long service life;

- no air pockets.

The main problem with all water heaters is scale.

The reason for the formation of this layer is poor quality water and the fact that the surface of the heater comes into contact with the liquid. Harder water causes scale to form much faster, and the lime layer is thicker and denser. Because of this phenomenon, the heating rate is significantly reduced, and the service life of even the most expensive water heater is noticeably reduced. The dry structure is reliably protected from such troubles, since there is no contact with water, which means scale cannot form.

Since most developers allocate catastrophically little space to the toilet and bathroom, the second important criterion for choosing a boiler is its size. The dry heating element has quite miniature dimensions in comparison with its “wet” relative. Since the size of the water heater itself is significantly reduced, it is not unreasonable for the manufacturer to install two or even three heating elements, which allows the consumer, if desired, to heat the water in just a few minutes. Moreover, the consumer is not afraid of interruptions in the operation of one of the heaters, since he can always use the remaining ones.

High performance and easy maintenance

Since scale does not form on a dry element, the speed of obtaining hot water increases significantly.

The water heater does not spend a large amount of energy to fulfill its direct responsibility, which puts a dry heating element a step higher in comparison with a wet one. Another important feature of the tubular element is the ease of repair. Despite the fact that such an element is durable, it can still fail. In order to repair the device, you do not need to completely dismantle the tank. You just need to unscrew the protection and remove the element. After inspection and repair, the heating element is put back. According to a similar scheme, the tank is cleaned of scale every six months. In this case, the heating element is not affected, and only the inner wall of the tank is cleaned.

Water heater durability

Due to the fact that the heating element itself does not come into contact with water and is not covered with scale, its service life can last for 5-6 years, while a submersible heating element will have to be changed every 2 years.

With current prices for components, this advantage allows you to save a lot of money, even though a water heater with a dry heating element costs an order of magnitude more. Manufacturers also made sure that the boiler does not turn on if there is no water in it at the moment. Dry start protection is installed in absolutely all water heaters with a dry element. This function allows the unit not to burn out and last longer.

If you still need to repair the element, the variability of such a water heater will be a pleasant surprise. Tubular heating elements differ little from each other, so finding the right part will not be difficult.

Comments:

Danil

It seems to me that “wet” heating elements are only possible in our country. I visited the Siemens plant in Austria. Just in the climate equipment production department. So their principle has long been such that the heating elements do not come into contact with the active liquid.

Igor

Previously, there was a water heater with a “wet” heating element - during its service I changed the heating element itself 2 times. After 7 years the tank leaked and I threw it away. Now I installed it dry and the difference is obvious. There have been no replacements for 3 years, and the price of dry is much less (I looked at it just for fun)

Vasiliy

You begin to understand the difference exactly when you change the dry heating element. The procedure takes 5-7 minutes depending on the place from which the arms grow. You don’t need to remove it from the wall or drain the water - you don’t need to do any of this. So dry heating element rules

Rudolf

All this is great, but what happens to the pipe, can it itself by any chance become corroded? If not, why not?

Sidor Kovpak

What nonsense. As we already got tired of advertising the usual marketing trick called “dry heating element”. 1. To begin with, a boiler with a dry heating element costs 1.5-2 times more than usual. 2. Replacing a heating element is, in principle, a rare phenomenon and just one can burn out. 3. To extend its service life, any boiler must be cleaned once a year from debris/scale and change the magnesium anode, it is he who is responsible for whether the tank leaks or not, and not heating element, so you still have to disassemble any tank. 4. As the practice of my sales of household appliances for 12 years shows: “dry and wet” tanks last the same number of years. I would understand if the life of a tank with a “dry” heating element was 30% longer, but no. SO WHY PAY MORE. Buy the cheapest tank 5-7 thousand rubles. Once a year they cleaned and replaced the anode. It leaked after five years and was thrown away. And it’s not too bad. Let me note: the only returnable boilers I have lying around in my warehouse are gorenje ones with dry heating elements. They died during the factory warranty stage. Don’t be fooled by sellers’ persuasion, don’t overpay, their job is to sell at a higher price. Yes, and pile on top of another scam Paid additional service..

Dasha

Don’t build your theories here - I’ll tell you without advertising, from personal experience - a wet heating element is absolute crap: A water heater for 10,000 rubles. bought it (yay, it’s cheap, and it heats well!), after a year it started to heat poorly, started leaking, and began to give an electric shock from the water... replacement of heating elements 3500 RUR. with pick-up to the service (thought it would be under warranty - no idea). Another half a year later, the same story, they changed it themselves - for 3800 (2 heating elements, 2 anodes). The first time the service did not supply anodes, so replacement was cheaper and more useless. You can imagine what a “pleasure” it is to shoot 100 hp. the tank, even if it’s empty, and then hang it back up. Or pleasure - you turn on the water, and the water/bath/faucet gives you an electric shock. And hot water becomes expensive, however! That’s what I concluded for myself: we need such joy.

Igor

From all the comments said, I still don’t understand. Who’s lying. Vasya Senya. Citizen “H” is negatively opposed to dry heating water heaters. And it is obvious that everyone is already using dry heating water heaters. so who will tell me the truth about water heaters????

Andrey

It’s like buying a Zhiguli - they’re easy to repair and the parts are cheaper, but a Toyota just lasts a very long time without repairs. I have an Ariston Shuttle 80L, it has a 7-year warranty, and it lasts even longer, so if it breaks, I’ll just replace it with a new, similar one.

Victor

16 years with a “wet” Ariston 80 l. Every year I boil the removed heating element in citric acid and mechanically descale the magnesium anode. I don’t understand how to descale (the world hasn’t yet figured out how to avoid it) the water heating surface in a “dry structure” without draining the water. During the season I get about 1.5 liters of it. Thanks to Sidor Kovpak for his sober assessment of this innovation, I will be careful in my choice.

Marianne

We have catastrophically hard water. A private house and tanks are constantly working, so on one floor the Italian BAXI has been working for more than 13 years, the heating elements have been changed several times, and on the other, about 4 water heaters have been changed, the heating elements have been changed countless times. Maybe it matters that BAXI is horizontal?

zheka

I have a 50 liter Ariston water heater with a titanium coating on the tank, I clean the tank every year for 8 years, this year traces of corrosion appeared on the tank, I change the anode every year, the higher the water temperature, the faster the anode is consumed, the higher the corrosion, it’s ten times copper in all that time. I didn’t let you down, I just changed the thermostat, I’m thinking about getting a stainless steel tank next so that I don’t have to worry about leaking the tank, the heating element and the anode are consumables, I don’t worry about them, the water is very hard, I drain the bucket in a year, I’m thinking of installing an ion exchange filter to soften the water, for heating and Installed the washing machine, the result is no scale, softer water, fewer problems with the boiler, turn around 15 years of experience

Sergey

The stainless steel tank lasts a long time. The heating elements were wet, I changed them 5 times in 4 years. I installed them dry and it lasted for 3 years.

Mark

I have a home-made boiler produced by a local emergency company, it has been in service for 12 years, I cleaned it once a year ago because... The thermostat began to act up. That's all.

Sergey

“Dry” heating element, I understand, but scale does not form on top of the tube in which it is installed! scale I have a wet heating element, an 80-liter tank, I clean it once a year, change the anode, work for 30 minutes with draining the water. The boiler has been working for 6 years, without problems. I haven’t changed anything except the anode!

Sergey

Zheka, as an end user, it doesn’t matter to you what kind of steel the tank is made of (stainless steel or just enamel-coated steel). If you don’t take care of the anode, then your stainless steel or ordinary steel coated with enamel will leak equally quickly, because... a stainless steel tank at the weld seam has a weak point, and steel coated with enamel, under the influence of constantly changing temperature, the enamel cracks and access to the steel appears. Look on the Internet how stainless steel corrodes. There is also an opinion that if you haven’t taken care of the anode, the heating element will be the next one to be eaten up by corrosion, and only then it will come to the tank. But only if your heating element is wet, if it is dry, then after the anode the salts are taken immediately to the tank