A perfectly working air conditioner makes us happy in the wild heat and severe cold, either cooling or warming the air we need so much. A faulty air conditioner cannot provide us with such pleasure, both in the home and in the office, and usually in such cases, air conditioner repair is necessary.

When exactly do service professionals come to your home to solve a problem such as a broken air conditioner? There are a whole lot of options. First, they determine what kind of air conditioner is installed or not even installed by the client: split system, simple or industrial. Next, the causes of air conditioner malfunction . Many customers think that the air conditioner broke down just like that, out of the blue. I just took it and broke it. Of course, this also happens, but in most cases, any breakdown has its own cause, which is clarified during the diagnostic process, and experienced air conditioner repair technicians know all these possible causes, repair algorithms and consequences that entail the client’s attempts to use his crazy hands for the good unit and your wallet (which is not always justified).

So, what causes of air conditioner malfunction can stand in your way?

— Freon leak

This is mainly discovered when the air conditioner stops cooling the air, although it continues to turn on properly, flows little, and the radiator of the indoor unit or the nuts on the external unit freeze over. The reason for this situation may be natural wear and tear, depressurization of the freon route, as well as unsuccessful or untimely air conditioner service (independent maintenance). Which exit? – Refueling the air conditioner and full diagnostics of the air conditioner to detect any related faults.

Basic faults

Repairing wall-mounted split systems with your own hands is a difficult process, since not every person knows the operating principle and design of climate control equipment. However, indicators that allow you to determine the nature of the malfunction help restore the functionality of the devices. Equipment breakdowns occur, which can be eliminated only after contacting modern air conditioner repair shops. However, consumers often face simpler problems. They can deal with them on their own.

Air conditioner won't turn on

The cause of the malfunction may be dead batteries in the remote control or its failure. In such a situation, it is recommended to do the following:

- turn off the equipment and then turn it on again;

- the same operation is carried out with the remote control;

- change the batteries in the remote control.

If the above actions do not lead to a positive result, then it is recommended to contact companies that repair various air conditioners. Such companies employ qualified craftsmen who have the necessary tools and equipment. This will allow you to perform error-free diagnostics of the air conditioner and carry out professional repairs of the equipment.

The appearance of water

Often, water may begin to drip from the indoor unit of the air conditioner or condensation may appear on the walls of the housing. Such malfunctions occur as a result of improper operation of the device. Thus, a breakdown may occur due to the start of the cooling mode at a low ambient temperature. As a result, a plug will appear in the drainage. The channel can also become clogged with dirt that accumulates on the internal radiator and flows into the tray, from which it moves into the drain tube. To get rid of malfunctions and repair industrial or other air conditioners, you need to carry out the following operations:

- During the cold season, warm up the channel if an ice plug has not yet formed in it. The optimal heating temperature is +7 O

- If an ice plug appears, wait until it warms up, which will allow it to dissolve on its own.

- Flush the drainage with water when using a pump or compressor unit.

Important! It is impossible to operate climate control equipment with a clogged drainage system, as liquid will flow out of the air conditioner housing. This will lead to damage to the interior and the climate control unit.

Clogged filters

The problem is eliminated by cleaning the filter elements of the internal unit of the device, on which dust and lint often accumulate. The sources of their appearance are often carpets and various wool products.

Filters are removed from the equipment after opening the front panel. They are washed under running water. In this case, a brush can be used to remove stubborn dirt.

The air conditioner does not heat the air

If the device continues to cool the air in the room when switching to heating mode, then you need to pay attention to the technical condition of the 4-way valve or control circuit. After replacing the elements, refrigerant is charged and a new receiver-dryer is installed.

The air conditioner does not cool the air in summer

The cause of the malfunction may be hidden in exceeding the maximum operating temperature of the outdoor equipment unit. During installation, the outer element of the device is usually placed in the shade, which prevents it from overheating in hot weather.

The air conditioner does not produce cold in cool weather

The cause of the breakdown may be a freon leak or a capillary tube clogged with ice. To eliminate the malfunction, you need to turn off the climate control equipment and wait a maximum of 4 hours. If after this the air conditioner starts working normally, then the cause of the breakdown was water accumulated in the freon circuit. When the equipment continues to not function, then the malfunction is due to a refrigerant leak. In such a situation, the repair of duct and other air conditioners consists of restoring the functionality of the device’s radiators.

The air conditioner cools the air too much

The cause of the malfunction may be a failed thermostat. In such a situation, the sensor or part of the electrical circuit usually breaks down. When this malfunction occurs, the device does not normally turn off, even when the room temperature reaches the set value.

The outdoor unit does not turn on

If such a breakdown occurs, it is necessary to pay attention to the serviceability of the control relay located in the indoor unit. The electrical circuit board of the equipment may also fail or the electric drive may break.

High-quality repairs of modern air conditioners are most often required due to a refrigerant leak. The breakdown is eliminated by soldering the copper parts of the device. Professional tools are used for this. They can be purchased in specialized stores or borrowed from craftsmen who repair refrigeration equipment. A leak detector is used to find the location of a freon leak. It is used after air has been pumped into the copper channel.

— Air conditioning compressor malfunction

You may suspect such a problem when the characteristic noise of turning on the air conditioner ceases to be heard, and just as in the previous case, the air conditioner ceases to cool your precious air. The reasons for such a disaster may be that you used it for other purposes (wrong temperature, threw it from a window) or the air conditioner was installed incorrectly (something went wrong while laying the freon line or the system was simply depressurized). The only way to get out of this situation is to replace or repair the air conditioning compressor.

Failure of the fan, compressor and air conditioner control board

What are the most common air conditioner malfunctions?

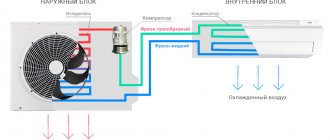

Conventionally, all breakdowns can be divided into malfunctions of refrigeration circuit components and failures in electronics or failure of electrical components of the system. Most often, users of the same split systems encounter breakdowns of the board, fan, compressor, or leakage of the heat exchanger of the outdoor unit. This is due to the fact that the main load falls on these parts, so their wear, especially if operating conditions are not observed, is inevitable.

Fan

Air conditioner impeller

What can happen to the air conditioner fan and what repairs are made in certain situations?

Some malfunctions are indicated by error codes displayed on the display panel of the indoor unit. If the fan “flies”, then most likely the system will turn on for a few seconds and then turn off again. There are several reasons:

- the fan blades are faulty;

- the fan motor is faulty;

- The fan motor capacitor is faulty.

In all three cases, the solution to the problem will be to replace the failed part.

The service worker first of all checks with a tester the resistance of the windings, which are different for different models of refrigeration machines and are given in the manuals. If the suspicion is confirmed, then proceed to repair the air conditioner fan.

Replacing the fan impeller:

- Remove the front protective grille;

- Unscrew the fan mounting nut (left-hand thread);

- Remove the impeller from the electric motor pulley;

- Place the new impeller on the pulley;

- Reassemble the parts in reverse order.

Fan motor replacement:

- The system is de-energized and the protective front grille is removed;

- Unscrew and remove the fan mounting nut (left-hand thread);

- Disconnect all electrical connections to the fan motor;

- Unscrew the motor itself from the housing and remove it;

- Put on a new spare part;

- Reassemble and secure the parts in the reverse order.

Replacing the starting capacitor of the fan motor:

- Completely de-energize the system;

- Disassemble the housing of the outdoor unit;

- Unscrew the capacitor fixing bracket;

- Disconnect all wires from it;

- Replace with a new starting capacitor;

- Reassemble and secure the parts in the reverse order.

Typically, repairing an air conditioner fan takes no more than an hour. How much such repairs cost depends on the urgency of the work, its volume, the power of the air conditioner, the amount of materials and spare parts used.

Compressor

What are the main malfunctions of the air conditioning compressor, and what repairs are carried out in this or that case?

Most often, a compressor breakdown is indicated by incorrect operation of the device, namely:

- it does not turn on at all or there is a delay in turning on for several minutes;

- it does not turn on and at the same time makes a corresponding hum;

- frequent change of start and stop cycles.

The reasons may be incorrect phase activation, a malfunction of the starting capacitor, flooding of the compressor crankcase with liquid freon, failure of the expansion valve or four-way valve. This is not a complete list of problems. But most of them do not require replacing the compressor itself. It is enough to eliminate the cause and the device functions normally.

If a phase imbalance occurs, then most likely the load in the network is distributed incorrectly. An air conditioner with a three-phase connection cannot be connected to a single-phase network and vice versa. They usually check the current in each phase with a clamp meter and redistribute the load. The electrical panel may need to be rebuilt.

If liquid refrigerant fills the crankcase, then it is necessary first of all to bleed off the existing freon, evacuate the system, and then refill the circuit, since it is the lack of refrigerant that causes such problems. It may be necessary to readjust the operation of the condensing pressure regulator.

If the problem is in the operation of the four-way valve, then it is worth remembering that replacing it will not cost much less than repairing the air conditioning compressor, so first check the serviceability of the electrical circuit and whether there is enough freon in the circuit. When the problem does not disappear (warm air blows in any mode), then you can desolder this part, but this is done only if there is no need for subsequent heating.

You may need to change the oil to a better quality one or try applying power to the four-way valve for a short time. As a last resort, it is replaced.

When a complete replacement of the compressor is required, do it in the following sequence:

- Freon is collected from the system using a pressure gauge station.

- De-energize the device.

- Dismantle the external unit.

- Its body is being dismantled.

- Disconnect the tubes and electrical wires from the compressor.

- Remove the compressor from the vibration dampers.

- Install a new one on the vibration dampers.

- Fasten and solder all the tubes back.

- Connect the wires.

- Reassemble the housing and mount the unit back.

- Connect tubes and wires.

- Vacuum the circuit and refill it.

- Turn on the device for testing.

When repairing an air conditioning compressor, pipes are soldered using nitrogen.

Electronic control board

How does a control board malfunction manifest itself and how can it be eliminated?

If all the LEDs on the indoor unit are blinking and the split system does not turn on, then most likely there is a failure in the software settings of the control board. This can be eliminated by reprogramming it in the service center using codes, information about which is available only to employees of this center.

The control board could burn out during voltage surges (inverter systems are sensitive to this) or during a short circuit, so in this case it will need to be repaired - the broken microcircuits are unsoldered and new ones are soldered, the triacs are replaced with more powerful ones, and the buffer microcircuit is checked.

Manufacturers equip control boards with solid-state switches that are responsible for fan rotation, so failures in its operation may indicate a malfunction of this element. Before starting repairs, it is necessary to measure the resistance of the part. If it is closer to zero, then the broken microcircuit is soldered out.

Malfunctions of the compressor, temperature and motion sensors can also be signs of a faulty control board.

When a burnt microcircuit is visible to the naked eye, there is no need to take resistance measurements. Here they immediately begin repairing the air conditioner control board - replacing the triac.

Sometimes during installation, installers make mistakes in interconnect connections, which also leads to failure or burnout of the board. Most often, the diode bridges, transformer or voltage stabilizer burn out first. In such cases, it is more advisable to replace the failed part. It is impossible to repair the air conditioner circuit board; if it is completely burnt out, then it must be replaced.

Replacing the control board:

- Turn off the power;

- Disassemble the housing or remove the top cover of the unit;

- Remove the board from the slots by unscrewing the fixing screws and disconnecting all wires and connectors;

- Replace with a new one and assemble the block in the reverse order.

It is better to contact the service center immediately, since repairing the board of an air conditioning system is an expensive process, and if the elements of the device are handled carelessly, additional waste may arise.

Service Temporarily Unavailable

This could have happened because it was not plugged in or the batteries in the remote control were dead (and this happens). Don't write off the wear and tear of the air conditioner, since it hasn't been running for the first day? To diagnose and correct this problem, you should establish access to the power supply to the air conditioner, and the Internet or our service center technician will help you with this.

A sufficient number of reasons for air conditioner malfunctions , which may not have happened, or did not happen due to timely service of air conditioners, correct installation of the air conditioner and purchase. We advise you to follow the prescribed rules for operating the equipment, regularly maintain the unit, and you will not experience any troubles. And if something breaks, then at most there are a couple of parts that can be easily replaced and it will turn out much more profitable than if you had to buy a new air conditioner.

We recommend that you regularly carry out preventive maintenance in order to avoid sudden loss of the air conditioner, and also to extend the service life of rather expensive equipment, just remember the following rules:

When the air filters in the indoor unit are dirty

Those little meshes you might see on the front panel of your air conditioner are air filters. You might think that their main task is to filter air, but this is to protect the indoor unit, or more precisely its radiator. One of the most important methods of air conditioner prevention is to ensure that the filters are clean to prevent overheating of the radiator and unwanted breakdown.

When there is not enough freon in the air conditioner

One of the main side effects of using an air conditioner is the evaporation of refrigerant or freon. Taking into account the fact that the annual rate of freon evaporation is considered to be 5-7%, you should systematically refuel the air conditioner at a service center to avoid compressor breakdown and air conditioner repair.

When the power of the air conditioner for the room is incorrectly calculated

In order for the air conditioner to wear out as late as possible, you should very carefully calculate the power for the air conditioner you purchased, due to the fact that if the air conditioner is incorrectly configured, it will have to work with increased load. Recommendations on the correct selection of power can be provided by the service center.

When the air conditioner is not operating at the correct temperature

It is necessary to take into account when using an air conditioner that it has a certain range of permissible temperatures for safe operation, for example, the negative temperature limit is about -5 degrees. Therefore, we recommend not to ignore the requirements stated by the manufacturer, but to use a “winter start” device for non-standard situations.

View prices for services

Review of major breakdowns

Having familiarized yourself with the main faults, it will be easier to carry out repairs.

Each breakdown has different causes.

Doesn't turn on

The problem with turning on the air conditioner is the most common. This may be due to normal wear and tear or internal failure.

Electrical part

When the equipment is turned on, the sensor sends a corresponding signal. A breakdown of the electrical part prevents the sensor from working correctly.

Control panel or receiving module

The air conditioner is controlled using the remote control. Due to malfunctions of the remote control or receiving sensor, the equipment cannot be turned on.

Protection system

Air conditioners are equipped with a protection system against improper operation. If the system breaks down, the air conditioner will not start.

Wear of parts

Long-term use leads to wear of components. As a result of normal wear and tear, startup failures occur.

Shutdown after short-term operation

Spontaneous shutdown indicates a breakdown. The problem may be due to violation of operating rules and internal malfunctions.

Room temperature

Air conditioners with automatic control function can turn off independently. This occurs when the room is sufficiently cooled.

See also

Rules for do-it-yourself installation of slopes from sandwich panels and how to finish them

Dry mode

In dehumidification mode, cooling occurs so that the heat exchanger of the indoor unit reaches the lowest temperature. When this mode is turned on, the fan operates at minimum speed.

Compressor overheating

Due to overheating, the air conditioner may turn off spontaneously. It will be possible to start the equipment only after the compressor has cooled down.

Control board failure

A board malfunction disrupts communication between the external and internal units. Most often, a board replacement is required to solve the problem.

Protection relay fault

The protective relay fails when the contacts stick or the winding breaks. If there is a malfunction, the air conditioner will not be able to operate properly.

Eliminating leaks in the indoor unit

Condensation forms in the outdoor unit when the air conditioner operates. Due to the breakdown, some of the water begins to leak.

Installation of drainage system

The air conditioner is equipped with a drain to remove accumulated liquid. Improper installation of the system leads to leakage.

Mechanical damage to the housing

Liquid can also leak through cracks in the housing. Minor defects can be eliminated using waterproof glue.

Unpleasant smell

When using air conditioner, a strong odor often occurs. Depending on the specifics of the smell, you can understand the problem.

Gorely

A burning smell is often caused by burnt-out wiring. If you smell the smell, you need to turn off the air conditioner and call a specialist.

Plastic

As a rule, the smell of plastic occurs in cheap equipment. High-quality equipment is made from safe material without a pronounced odor.

Dampness and mold

The presence of bacteria inside the unit causes a musty smell. To eliminate the smell, you need to treat the body from the inside.

Wrong sounds

Based on the sounds produced, you can determine the cause of incorrect operation. The presence of extraneous noise is often associated with internal failure.

Uneven noise

Partial clogging of the filter or passage hole creates uneven noise. In this case, equipment cleaning is required.

Clack

During the first time after startup, clattering is normal. The sound is associated with changes in housing temperature and expansion or contraction of parts.

Gurgling

The cause of gurgling may be damage to the drainage structure.

The presence of a defect leads to noise when draining liquid.

Squish

By analogy with the previous problem, squelching occurs when water is not drained properly. Damage to the housing is also often the cause.

Ineffective work

In some situations, the air conditioner does not work efficiently. To get the most out of it, you need to eliminate the cause of the problem.

Clogged filters

The accumulation of dust and dirt on the filter does not allow air to pass freely. Cleaning the filter helps correct the situation.

Dust getting into the impeller

Dust on the impeller slows down its operation. As a result, the air conditioner cools the air worse.

Heat exchanger clogged

The role of the heat exchanger is to convert heat into cold air. Clogging reduces cooling efficiency.

Freon leak

Without refrigerant, the air conditioner cannot operate. If there is a freon leak, you will need to make up for the shortage.

Adaptation to severe frosts

Some air conditioner models are unable to operate at very low outside temperatures. Forced activation may cause damage.

Incorrect power selection

To quickly cool the room, you need to select the appropriate mode. An incorrect choice may result in the required temperature being slow to reach.

Icing of the outdoor unit

Covering the external unit with ice interferes with the functioning of the device. In winter, it is worth knocking off the icy crust.

Sample equipment decommissioning certificate

Equipment write-off act is a document that is drawn up by several persons and confirms the fact that the equipment has been written off.

All organizations are faced with the need to write off old equipment. Computers, office equipment and other property must be disposed of according to a write-off report. Correct write-off requires an expert opinion on the condition of the equipment, which contains an assessment confirming the impossibility of further use. A specially created commission or an invited expert organization draws up a technical inspection report, on the basis of which it is possible to write off fixed assets from the balance sheet and dispose of them.

Property tax has to be paid for equipment that has not been written off but is out of order or obsolete. You can write off fixed assets gradually - through depreciation, but there is a shorter way - drawing up an equipment write-off act. It is recommended to write off material assets that:

- cannot be used because they have become unusable;

- do not exist based on inventory results;

— morally outdated;

- extremely worn out;

- damaged when repair is impossible or economically unfeasible.

Every year, the head of the organization must issue an order appointing a commission to write off fixed assets.

DIY air conditioner hose repair

Due to a violation of the seal in the hoses and main pipes, the car air conditioner does not work properly. This is the most common breakdown in a car's cooling system.

The pipes in question are located at the bottom of the car. Due to their location, they are affected by external mechanical influences, which leads to various damages and the car’s air conditioning stops working correctly. The most reasonable solution to this problem is to replace the device hose.

There is a version that the reduction in the service life of the hose and tubes is due to their contact with dirt and high humidity. In addition, debris on the road and vibration in the area of the wheel arches provoke cracks, so it’s worth considering and replacing the lines with metal ones, as they are more durable. Although, even such a resistant material as metal has its drawback - tubes made from it are susceptible to corrosion and are not resistant to temperature changes.

Hose repair

Replacing a hose is far from cheap, so it's worth knowing how to do it yourself.

If the rubber hose is not significantly damaged, you can solve this problem with a patch. The patch is made using specialized tools and substances; its damage is significant, then the hose must be replaced with a new one.

If you decide to replace the hose yourself, follow the description below:

- First, you need to choose a hose that is suitable in size.

- After this, crimping cylinders are hung on it.

- Finally, it is placed on the teeth and crimped with cylinders.

To avoid such problems, it is important to regularly carry out repairs and maintenance of the car’s climate system; if the breakdown is not repaired in time, the malfunction may develop into a larger problem.

Video describing in detail the repair of air conditioning hoses:

General rules and recommendations for the maintenance of climate control equipment

Maintenance of climate control equipment is carried out to maintain the normal operation of the devices and eliminate problems that arise during operation.

Recommended maintenance frequency:

- once every six months - for apartment air conditioners, the filters of the internal module of which are cleaned by the owner himself every month;

- once every 3 months - for office air conditioners;

- every month - for air conditioners installed in other premises;

- at the beginning of the season and at its end - for climate control equipment operating in the “cold only” mode.

Causes of breakdowns and their prevention

The causes of air conditioner breakdowns are varied, and in order to eliminate any malfunctions in the operation of the equipment, you need to follow all operating rules and carry out timely maintenance of the device.

Preventive measures:

- The minimum frequency for preventive inspections is once a year. It is better to do this before the start of the warm season.

- Timely refilling of the air conditioner with freon.

- Cleaning filters and internal parts of the device (performed by a specialist).

Repair of climate control equipment is best left to professionals. The intervention of an inexperienced user can provoke new breakdowns, requiring even greater costs or complete replacement of climate control equipment.

After purchasing an air conditioner, be sure to read the user manual and follow all manufacturer recommendations.

Activities carried out as part of the service of climate control equipment

Internal module:

- cleaning the filter;

- cleaning the front panel;

- cleaning and treating the fan with antibacterial agents;

- cleaning and treating the evaporative heat exchanger with antibacterial agents;

- cleaning, treating the drainage system with antibacterial agents, checking the conductivity and functioning of the drainage system;

- checking electrical wiring.

External module:

- cleaning the condenser heat exchanger;

- cleaning the module body;

- cleaning the ventilation mechanism;

- cleaning and checking the drainage system;

- checking electrical wiring.

Checking the functionality and additional parameters of the system:

- checking the supercharger pressure and air suction force, evaporation temperature, condensation of the air flow and subcooling of the charged refrigerant;

- refilling freon fluid (if necessary);

- checking the functioning of the remote control.

The application for maintenance (in the list of documents - Appendix No. 1) is sent by fax (ext. 9) or scanned.

Departure of specialists to carry out maintenance of climate control equipment is carried out within two days from the moment the application is processed by our specialists.

All activities within the framework of service maintenance of split systems and air conditioners are regulated and carried out in accordance with the Technological Map for the maintenance of split systems (multi-split systems) of air conditioning (in the documents - Appendix No. 2). Completion of the tasks assigned to the specialists is confirmed by the client’s signature on the work completion certificate.

The warranty for service work performed depends on the frequency of maintenance (6, 3 or 1 month).

Clogging of filters and air exchangers of modules with dust, fluff and other debris does not qualify for warranty coverage.

If specialists are falsely called during the warranty period, an equipment defect report is drawn up (in the documents - Appendix No. 3). A false call is considered to be a call to specialists to repair devices whose performance has decreased due to clogging of air exchangers with household waste, violations of equipment operation rules, and similar reasons.

Condensate leak

According to technology, condensate should drain from the indoor unit through the drainage system. If this does not happen, then it will flow directly into the room.

The reason why an air conditioner leaks is due to the drainage system. For example, it is clogged or frozen on the side of the outdoor unit.

In the first case, the solution is to turn off the power to the system, wait 15 minutes, remove the plastic tube and clean it yourself (by blowing or using a thin wire), then you need to completely dry the tube and secure it in its original place.

The second situation occurs if the device operated at sub-zero temperatures, and drainage heating is not provided by the manufacturer.

In summer, the condensate container is often overfilled, which is why the liquid is not recycled. And the result: instead of water dripping outside, the air conditioner drips inside the room. Therefore, you need to drain the liquid from the container more often.

If it leaks at the joints of the parts, then you need to tighten the nuts more firmly (but not overtighten), and apply sealant to the joints themselves.

It may be that the drainage system hose was not installed correctly, was pulled up and the water was flowing back into the indoor unit. Then the hose needs to be lowered at the optimal slope so that the water flows outward and not inward. By the way, an incorrect slope of the hose also leads to outside air being blown into the air conditioner. And this contributes to an annoying hum in the room, especially when there is a strong wind outside.

Fault prevention

In order not to encounter most possible malfunctions of climate control equipment, it is enough to diagnose and clean it once or twice a year. These manipulations will help prevent the formation of dust and dirt on the working elements of the system. After all, it is the clogging of air conditioner parts that is often the main cause of malfunctions in the operation of equipment.

On a note! The decrease in efficiency of the system occurs gradually and imperceptibly. When a certain level of contamination is reached, the unit fails.

If malfunctions do occur, regardless of the reason, be it incorrect operation of the equipment or natural wear and tear of parts, you need to think several times before trying to fix the problem yourself. Firstly, in most cases this requires professional equipment, and secondly, the system components must be handled carefully and delicately, since any awkward movement will not only invalidate all repair efforts, but will also lead to the need to purchase a new air conditioner.

Thus, it is best to entrust the installation of climate control equipment, its maintenance and repair to specialists . Self-installation and saving on professional installation may lead to malfunctions and additional hassle throughout the entire period of operation.

And in the event of problems with the operation of the split system, which is under warranty, the service center specialists will draw up an appropriate conclusion and provide the owner of the equipment with a special certificate of work performed (one sample should be kept by the user and the service department). And if the defect is confirmed, the air conditioner is confiscated for write-off. A new unit is installed in its place absolutely free of charge.

Summarizing the above, it should be noted that large manufacturers of climate control equipment, such as Samsung, Midea, Carrier, Daikin, LG and others, who produce air conditioners not only for homes, but also for cars, have their own service centers and are ready to provide their professional employees for service and repair of equipment of our brands. And what and how the user can do on his own - in the material “do-it-yourself air conditioner repair.”

write-off of fixed assets, if depreciation has not yet ended, postings and documents, example

The write-off of an asset is not always associated with the end of its useful life. The reason for deregistration of a non-current asset may be a breakdown, malfunction, or defect that does not allow further operation of the equipment with the required output.

Assets that have become unusable can be removed from the balance sheet. In this case, the organization must follow a certain algorithm: draw up the necessary documentation, reflect postings, dismantle, dispose of unnecessary fixed assets, and capitalize the remaining usable parts.

Reasons for writing off fixed assets if depreciation has not yet ended

If an organization decides to write off a fixed asset that has not yet been depreciated (that is, has a non-zero residual value), then the reason for this is the inexpediency of further use of the asset.

If the OS has become unusable, it is better to remove it from the balance sheet and replace it with a more modern, productive, and fast one.

As a rule, the reason for premature write-off before the end of its useful life is:

- A breakdown is one that cannot be corrected, or can be corrected at significant costs that are not economically feasible.

- Reduced productivity due to wear and tear.

- Moral obsolescence – when a model does not meet modern requirements.

In all of these cases, equipment or other fixed assets that have become unusable should be written off.

How to properly deregister an object that has not yet been depreciated?

Below is a step-by-step instruction that will tell you how to proceed in order to correctly write off an under-depreciated fixed asset that has become unusable.

Step-by-step write-off algorithm:

Step 1. Create a commission.

This group of persons is formed by order of the manager for the purpose of inspecting fixed assets to identify objects that have fallen into disrepair and are subject to write-off.

Step 2. Inventory and inspection of the OS.

During the inspection, the commission assesses the condition of existing assets, determines the degree of wear and tear, damage and makes a decision on the advisability of further use or write-off.

In carrying out their duties, the members of the commission are:

Step 3. Issuing an order.

Based on the decision of the commission members to write off an under-depreciated object that has fallen into disrepair, an order is issued.

The order indicates the reason for removal from the balance sheet, the type of property, the timing of the write-off, and the persons responsible for the process.

Step 4. Drawing up a write-off act.

It is possible to use the standard form OS-4 (for a single object), OS-4a (for road transport), OS-4b (for groups of similar objects).

Step 5. Reflection of transactions in accounting.

To make double entries for write-off operations on assets that have become unusable, a documentary justification is required. This is the act of write-off.

Step 6. Disposal of fixed assets.

Dismantling, partial or complete destruction may be carried out.

Step 7. Capitalization of components and parts remaining from dismantling.

These values are included in the warehouse as materials at market value.

Documentation of disposal of under-depreciated fixed assets

To write off a fixed asset for which the depreciation process has not completed, but which has become unusable, the following documents must be completed:

- Order on the creation of a commission for writing off fixed assets.

- Fixed asset inspection report.

- A statement of defects identified, if any.

- Conclusion and protocol of the commission on write-off.

- An order to remove a fixed asset that has become unusable from the balance sheet.

- Write-off act.

- Depending on the further fate of the decommissioned OS - an act of dismantling, an act of recycling, or destruction.

Postings in accounting

The process of deregistration of any fixed asset - depreciated or for which the depreciation period has not expired - is always accompanied by a transfer of the cost of fixed assets and accumulated depreciation charges to a separate subaccount of account 01.

Since the object has not yet been depreciated, it has a residual value, which is considered as a balance in an open subaccount on account 01. This value is written off as expenses of the organization.

Also, the organization’s expenses may include expenses for dismantling and destruction of the facility - payment for the services of third-party companies, contractors, payment of its own workers, and other related expenses.

All expenses associated with write-offs are collected on the debit of account 91. The cost of incoming parts is reflected on the credit of account 91.

If it is decided to sell the written-off object, then the sale value is also shown on the credit of account 91.

As a result, account 91 generates the financial result from writing off the operating system that has become unusable. Typically this is a loss.

The table below shows the entries made by the accountant during this procedure:

| Postings | Operation description | |

| Dt | CT | |

| 01.1 | 01.2 | The initial cost of the asset that has fallen into disrepair is transferred to a separate sub-account for write-off |

| 02 | 01.2 | Current accrued depreciation is reflected |

| 91.2 | 01.2 | The residual value of the unsuitable OS has been written off |

| 91.2 | 70, 76, 60, 69, 23 | Costs associated with write-off are reflected |

| 10 | 91.1 | Parts, components, mechanisms remaining after dismantling the OS have been capitalized |

From the month following the month of disposal, the accountant stops accruing depreciation on this asset.

The last posting for depreciation charges occurs on the first day of the month in which the object that has become unusable is disposed of.