Design and principle of operation

The design of a circular saw is quite simple. The device can be manual or stationary, and combined models are also available.

Regardless of the type, the equipment consists of a saw and a base plate. The last element is made of durable steel sheets or aluminum alloys. The main purpose of a circular saw is accurate and high-quality longitudinal cutting of wood.

A circular saw

Cutting boards and bars is carried out by rotating disks, which have special casings that serve as protection against injury during the working process. The cutting part is driven by a trigger mechanism. Circular equipment allows you to process large volumes of wood.

Recommendations for working with a circular saw

Reading the instructions for the tool is not interesting, it is difficult. The manufacturers themselves are often to blame for this - they write in complex language, small font, and write things that are too obvious. As a result, buyers often rely on intuition rather than rules. Due to ignorance of basic rules, equipment fails prematurely, or even worse, the user is injured.

A circular saw is a dangerous and complex tool; you MUST read the instructions for it!

For those who cannot read the factory instructions, we have made a simple and understandable summary from several passports, at least read it...

- If you are very tired, under the influence of alcohol, or under the influence of medication, or under the influence of drugs - do not use the circular saw! Any inattention when working with a saw can result in serious injury.

- If both hands hold the saw , they will not be cut by the saw blade.

- When sawing, do not apply excessive force to the saw. Move the saw forward at a speed that allows the saw to cut without reducing blade speed. Applying excessive force to the circular saw can cause the motor to overheat and cause the saw to fail. Uneven cutting, or possible kickback from the disc.

- Place the wider part of the saw base on the part of the workpiece that has good support, not on the part that will fall after cutting. If the part being cut is short or small, it must be secured. Do not hold short parts of the workpiece with your hand.

- Do not attempt to cut workpieces with the circular saw mounted upside down. This is dangerous and can cause serious hand injuries.

- To ensure cleaner , safer cuts, set the depth of cut to such a value that only one tooth of the blade protrudes under the workpiece. Setting the proper cutting depth reduces the chance of dangerous kickbacks that could cause injury. Setting the saw to the correct depth of cut minimizes blade friction, helps remove dust between the blade teeth, allows for faster cutting without overheating, and reduces the risk of kickback.

- If the cut deviates from the intended line, do not try to force the tool back onto the cut line. This can cause the saw blade to bend and cause dangerous kickback, which can cause injury. Release the switch, wait for the tool to stop, and remove the tool. Re-align the tool with the new cut line and start cutting again.

- Dull saw blades increase the load on the tool. To maintain the proper speed, the operator is forced to apply increased force to the tool, thereby contributing to the misalignment of the disk in the cut. Worn saw blades may also have insufficient idle plane, increasing the risk of jamming and increased stress on the tool. A dull blade increases the load on the saw and the operator, which leads to premature failure.

- If the saw overheats , do not turn off the tool immediately; let the circular saw run at idle speed. This way, with the help of internal airflow, you will quickly cool the engine.

- Move the circular saw forward only; moving the saw is uncomfortable and increases the risk of injury.

- Clean the saw from sawdust and wood chips . Clean the disc from resins. Cleaning extends the life of the tool.

- When sawing, use personal protective equipment. Goggles – eye protection, gloves – hand protection. When processing some materials, toxic dust may be generated, for example from paint containing zinc or dust from certain types of wood (oak). Use a respirator.

You can choose circular saws here

Classification of types and sizes

Circular saws are divided into two classes - household and professional. The equipment differs in power, size and diameter of the saw blade:

- Household models are small equipment weighing from 4 to 5 kilograms, which is usually used for cutting wood at home. Equipment power – no more than 1800 watts. The size of the blade in such saws is 160 – 200 millimeters.

- Professional circular saws are designed for processing large quantities of wood. They are capable of sawing beams up to 85 millimeters thick. The weight of such equipment exceeds 8 kilograms, and the diameter of the disk is 250 millimeters. Professional saws have higher power - over 1800 watts.

Household model of a circular saw

Several types of circular saws are produced:

- Standard. The model is designed for cutting wooden blocks with a density of up to 85 millimeters.

- Mini saw. A small circular device weighing up to 2 kilograms and a power of up to 800 watts. Used for cutting thin wood.

- Submersible. Equipment is used to cut holes inside the wood. The design of such a saw consists of a mechanism that promotes vertical immersion of the disc.

- Diamond. This type of equipment is designed for cutting hard materials - stone, ceramics or tiles. The working mechanism of the device consists of a diamond disk, which allows cutting to a depth of 55 millimeters.

- Rechargeable. Such a circular tool has low power and fairly compact dimensions. The device runs on a battery and is often used in the construction of wooden houses.

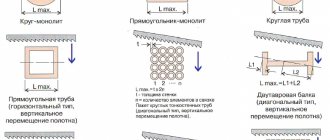

Circular saws are divided into four types depending on the depth of the blade:

- professional - from 65 to 140 millimeters;

- large - from 70 millimeters;

- medium - 55 millimeters;

- small - from 40 to 46 millimeters.

The number of teeth on the disk is of no small importance for the quality of the cut. The fewer there are, the lower the productivity of circular equipment. For large-scale processing of wood, special cutting devices with carbide tips are used.

Adjusting the Cutting Depth of a Circular Saw

Not a bad hand-held circular saw. Which circular saw to choose: tips and advice

circular saw was only found in sawmills . Today, many private craftsmen are already thinking about which model of such equipment to choose. If you also decide to acquire such a device, then it is important to consider the main characteristics, including, for example, the power source.

Purpose

Most often, saws are powered by mains electricity, but battery-powered analogues can also be found on sale. It is also important to decide under what brand the saw is produced; the most popular today are Makita, Bosch, DWT, Hitachi, but they will cost more than the Sturm, Sparky and Zenit models. If you also need a hand-held circular saw, which one to choose, you must decide before visiting the store. This equipment is designed for convenient and quick cutting of almost any soft material, namely wood, soft metal and plastic. As for wood, all products made from it can be cut, and it is permissible to move the cutting element both along and across the fibers. There is a precise adjustment of the depth of the saw # makita5008mg circular saw. All models of circular saws provide the ability to make cuts at an angle of 45 degrees.

Tips on which saw to choose: professional or household

A review of circular saws with reviews will allow you to understand which way to choose. When purchasing the device described, you need to determine what this tool is needed for. If you have to carry out construction work on a large scale, which involves cutting parquet boards and chipboards, then you should pay attention to professional models. If you do housework on rare occasions, and most of the time the equipment lies idle in the pantry, then it is advisable to buy a household circular saw.

circular saw is used for precise and fastest cutting . You can understand which one to choose from those presented in the store by reading the article. Thus, the difference between professional and household tools lies in the resource and performance of the engine. In the manufacture of one or another type of equipment, materials and parts of different quality are used. With less power, discs of less impressive diameter are used, which is why the device is able to cut material to a shallower depth. The hand-held circular saw, the selection and reviews of which are presented in this article, can be used for household use. In this case, the engine will have to be allowed to rest from time to time, the equipment will need to be turned off to cool down.

An example of using a household and professional tool

If you need a hand-held circular saw , which one to choose, you can decide by reading the recommendations below. If you use a professional model, then in 1.5 hours of continuous work you will be able to cut enough chipboard blanks to assemble 4 cabinets. If you use a regular household model, the same work will take 2 times longer. The quality will remain high, but the cost of a professional tool will be 2 times higher.

READ Repair of the Festool Ts 55 Ebq Plunge Saw Part-2 “Cleaning, Washing” (Full Version)

Choosing a professional model: Makita 5103R

Quite often during construction work a hand-held circular saw is required. It is recommended that you read the selection tips before making a purchase. The above model is a powerful saw that can be used to cut large pieces of wood and other materials. The model is designed for active use, is highly wear-resistant and is characterized by a wide range of functions that ensure safety during operation. Cutting depth, circular saw depth adjustment. How to choose a hand-held circular saw? The parameters are the decisive criterion. Below we will talk about them in more detail.

Model specifications

One of the most important parameters is power, which in this case is 2100 W. The cutting depth is 100 millimeters, and the rotation speed is equivalent to 3800 rpm. The size of the circle used is 270×30 millimeters, the weight of the device is 9.4 kilograms. For more convenient work, there is a soft start function, which ensures accurate cutting. Safety is guaranteed by instant engine stopping thanks to the electronic brake.

Circular saws: angle and depth adjustment

All tools will tell you how to adjust the angle and depth

on

bosch and sparky saws

https://youtu.be/obdq-ywWV7g

Setting the cutting depth on a plunge-cut saw Makita SP6000

My first video editing experience.

The equipment is equipped with a durable and reliable cast aluminum support base. The operator will not face the problem of the disk getting stuck, since the device has a riving knife. Safety when operating such tools is paramount; in this case, it is ensured by protection against accidental starting, which is made possible thanks to a switch with a fuse.

Choosing a household saw: Einhell RT-CS 190/1

The main features are the ergonomic handle, thanks to which even a beginner can handle the tool. This is also why the saw is most convenient to use when solving everyday problems. The master can easily replace the saw blade thanks to the key and spindle lock. There is no need to purchase an additional key, as it is included in the kit. You can work with the equipment at home, as it has a low noise and vibration level.

This reliable and inexpensive circular saw has a dust extraction device with a special adapter that connects to the vacuum cleaner. With this functionality you can keep your workplace clean. The gears of the gearbox are made of a material of increased hardness and strength, which is wear-resistant and has a long service life.

READ Saws for Trimming Tall Trees

The manufacturer has made sure that the work is made easier, which is also possible thanks to the practical cable clamp. Among other things, it prevents cable damage and curling. The size of the disc is 190×30 millimeters, the number of teeth is 24. At an angle of 90 degrees, the operator will be able to go deeper into the material by 66 millimeters, as for 45 degrees, the cutting depth will be equivalent to 48 millimeters.

Recommendations for choosing a model depending on engine power

Quite often, in the process of repair or construction work, a hand-held circular saw is needed. Also, the cost of a circular saw will be - adjustment - adjustment of the cutting depth. You will decide which one to choose after reading this article. The consumer must also take into account the fact that the tool may have a motor of different power. With higher motor parameters, the equipment will be able to cut high-density materials and products in a short time. The operator will not experience any difficulties when cutting. The powerful engine is not afraid of even knots in wood. But low-power circular saws have a significant advantage, which is expressed in their low weight. Thanks to this, the tool can be transported from place to place. Thus, models whose power is 2000 watts or less will weigh approximately 7 kilograms. Features of the Dnipro-m DPE-1800 circular saw. Adjustment of cutting angle and depth of cut. If the saw has a power of 1200 watts, then the weight will be reduced to 4 kilograms. Do you need a hand-held circular saw for everyday tasks? Which one to choose? Price. an important factor when purchasing. For private use, models with a power of 1000 to 1200 watts are excellent. If the tool is not used professionally, then the power reserve will remain unclaimed. The cost of the product will depend on this parameter; the difference in price can reach 100 percent or more.

Model selection by price: Skil 5740 LA

This equipment, whose power is 700 watts, is characterized by 4300 revolutions per minute. The cost of the tool is 3,700 rubles, the mounting diameter is 16 millimeters, the cutting depth is 40 millimeters. If you need to make a straight, neat cut in a tree of any species, then you can use this model. Despite its modest characteristics, this equipment has other impressive advantages, including: ergonomic design, comfortable handle, compactness and low weight - 2.4 kilograms. To prevent accidental startup, the tool uses a power button lock. Increased stability is guaranteed by a large wide metal support. There is a special compartment for storing the key.

READ Idle Does Not Work On Saw Calm

Reviews of the Dewalt DW366 model

If you need a hand-held circular saw, which one to choose, reviews will help you understand. Among the popular models, we can highlight the above-mentioned one, for which you will have to pay 9,200 rubles. The price is due to the high power, which is 1800 watts, as well as the impressive cutting depth of 60 millimeters. The seat diameter is equivalent to 16 millimeters, the maximum speed reaches 5000 per minute. This saw is a professional device and is designed for cutting wood to a depth of 60 millimeters.

The tool is characterized by a high level of safety and ease of operation. The first feature is provided by a casing that protects the user from chips and dust. This equipment can be used not only for professional purposes, but also on a summer cottage, as well as a construction site or in a carpentry workshop.

According to users, this good hand-held circular saw is versatile as it can be used to cut wood of different densities. Users especially like the safety, which is reflected in the reduced risk of injury. The operator can change the range from 0 to 50 degrees during operation. Users emphasize that when operating the equipment, they get an excellent overview of the cutting line, since the design is ergonomic.

Overview of the characteristics of a saw with a battery

If you prefer autonomy, then it is best to choose a battery model, but you should be prepared for less performance. Among other things, the rotation speed will also be significantly lower than in electric circular machines. Such models cope excellently with wood of small thickness and low density. As practice shows, the battery charge may be sufficient for 30-50 minutes of operation, after which the battery will need to be charged. This can cause some inconvenience, since charging sometimes takes up to 4 hours.

Overview of features of the Aeg BKS 18-0 cordless saw

You will have to pay 10,000 rubles for the model. The equipment can be used in buildings without power, which most often concerns construction sites. The rotation speed is 5000 rpm, and the diameter of the circle used is 165 millimeters. The weight of the tool is small and is equivalent to 3.2 kilograms. Another feature of a circular saw is depth adjustment, limiting the depth of cut. Features include adjustable cutting and depth . The technician will be able to quickly replace the disk. The tool is equipped with a magnesium base, a charge level indicator, and a built-in backlight. The operator will be able to connect a vacuum cleaner to keep the work area clean. During operation, you can use one or two hands at once.

Source

Types of jobs

The area of application of a circular saw depends on its size and type.

Hand circular saw

These electric saws are designed for precise straight cutting of thin wood materials. The manual circular device is small in size and is most often used for work at home.

Small-sized equipment for cutting wood is necessary for interior decoration of houses. Hand-held circular saws are often used during renovations to cut laminate flooring or wall finishing material.

Circular machine

Stationary circular saws are equipment for daily use. Such professional machines are capable of processing a large amount of wood in a day. They have quite a large weight - more than 10 kilograms and high power of up to 2500 watts.

Circular machine

Circular machines are used mainly in production for industrial purposes. The cost of such a device is quite high. Some small models of circular equipment also have the function of stationary use. They are successfully used in home workshops.

What can you do with electric circular saws?

Electric circular saws allow you to process wood and wood-based products in different ways, which depend on the type of tool chosen.

Types of work with a hand-held circular saw

The following types of work can be performed with a hand-held circular saw:

- trim multiple workpieces laid in one plane;

- trim wide boards using a rip fence that cannot be cut on a pendulum saw;

- trim boards when laying floors;

- trim the workpiece at an angle, without a guide and with its use;

- perform longitudinal sawing of the workpiece at an angle;

- align the unedged board along a pre-drawn line;

- choose a quarter in a board or timber;

- cut sheet materials using a guide rail;

- By changing the equipment, you can use a circular saw to cut metal profiled sheets;

- cut plexiglass and various types of plastic;

- Place the hand saw in the table and use it as a stationary circular saw.

Working on a circular saw

Working with a circular saw (stationary) is slightly different from working with a hand-held unit. Using a circular saw you can do the following:

- cut and trim wide workpieces, both with a straight cut and at an angle;

- perform longitudinal and transverse sawing of wooden panels;

- cutting wood-based sheet materials;

- open the board at an angle;

- sawing an unedged board.

Types of work with a miter saw

You can do the following with a miter saw:

- trim wood blanks at any angle relative to the edge;

- trim the workpiece at an angle to its face;

- a miter saw with a broach allows you to cut wider workpieces;

Operation algorithm

Hand-held and stationary circular saws have a similar operating principle. But equipment management has some differences.

Manual models

A circular hand saw is an effective and safe tool. But still, the use of such equipment requires compliance with certain operating rules:

- Electrical connection. When using a saw in areas remote from the power supply, an extension cord is often used. It must fully match the power of the circular tool. Before connecting it, you should check the integrity of the cable insulation. When connecting the saw to the network, you should check that the switch on the device is turned off.

- Fastening the material. Wood intended for cutting should be well fixed on a flat surface. To do this, the material is placed on a workbench and secured until it is completely stable.

- Setting the cutting depth. The required indicator is determined using a special scale on the instrument. When cutting a block, the disc should not protrude beyond the boundaries of the material, otherwise the workbench may be damaged. Therefore, it is recommended to fix the cutting depth slightly less than the required value.

- After setting all the necessary parameters, the cutting mechanism should be set in motion. Start cutting only with the disc rotating. The movement of the saw along the material should be smooth and even.

At the end of the work process, the hand-held circular tool must be disconnected from the network.

Stationary models

The use of circular machines has its own operational characteristics. To cut wood you need:

- Set the switch on the equipment to the “off” position. Only after this can you connect the cable to the electrical network.

- Raise the handle to adjust and fix the cutting height of the disk according to the dimensions of the material prepared for cutting.

- Check the position of the guide bar and saw blade. Their arrangement must be parallel to each other.

- Start the circular saw and make a longitudinal cut of the wood material. Cutting one board should be done in a single approach.

Using a stationary circular saw

After processing all the material, turn off the switch on the equipment that stops the rotation of the blade and disconnect the tool from the electrical outlet.

How to use a circular saw?

The quality of work performed with a circular saw depends, contrary to popular belief, not only on the tool itself, but largely on the type, quality of workmanship and the degree of wear of the disc.

Therefore, before starting work, you need to make sure of two things - the serviceability of all mechanisms and the compliance of the equipment used with the desired result.

Fixed components of the technological process should be securely fixed. The next stage is the correct choice of mode and installation of the appropriate user settings. In addition to the rotation speed, it is important to adjust the depth of cut, especially when using hand and combination tools, which can damage the bearing surfaces under the lumber. Now you can proceed directly to the work.

Important! It is better to saw the workpiece along the guides of the bed or sole, or, as a last resort, according to preliminary markings or a pointer beam, if provided for by the design.

To make the cut smooth and neat, the disc is immersed in the material gradually and fed forward slowly, otherwise the teeth will “gnaw” rather than cut. While performing work, you should quickly analyze all emerging difficulties and inaccuracies - this will help to quickly eliminate them, for example, by making changes to equipment settings.

Safety precautions when working with a circular saw

Working with circular saws poses three types of danger:

electric shock, injury from moving equipment, and damage from sawing by-products, which can include sawdust, chips, and even broken blade teeth.

To prevent all undesirable consequences, you should adhere to the following simple rules:

- carry out preliminary monitoring of the technical condition of equipment;

- turn on the power of the device immediately before performing work and turn it off immediately after completion;

- be sure to install protective covers and connect a system for removing sawdust and shavings;

- wear protective clothing and personal protective equipment; concentrate on work as much as possible, abandon it if you feel unwell;

- Carry out regular cleaning of tools and cleaning of the workplace.

Following these simple recommendations will protect you from mistakes and make working with a circular saw easy and safe.

Nuances of additional functions

Modern models of circular saws are safe equipment with high technical parameters. Many devices are equipped with additional functions that make the work process much easier:

- Slip clutch. This device allows you to avoid injury when the disk jams. Using a clutch, you can significantly reduce the shock when stopping the rotating mechanism.

- Smooth start. This function allows the disc to gain speed without jerking. A smooth start protects the mechanism from shocks, which has a positive effect on the service life of the engine.

- Overload protection. When the engine reaches critical indicators, the mechanism is automatically switched off.

- Supports the required disk rotation speed. When under load while cutting dense materials, power is automatically added. This function protects against a decrease in the disk speed.

- Accelerated braking. When you press the power off button on the device, the drive suddenly stops.

- Locking the start buttons. This feature prevents the tool from turning on if the switch is accidentally pressed. It is usually installed by pressing two keys simultaneously.

All models of circular saws have a function for setting the depth of cut. When purchasing equipment, it is recommended to pay attention to the convenience and accuracy of fixing such adjustments.

Safety precautions

Using a circular saw requires caution. To prevent accidents from occurring during the operation of electrical equipment for cutting wood, basic safety rules should be followed:

- Before connecting the device to the network, you must make sure that the equipment is turned off;

- While working, use protective equipment - gloves, glasses, clothing;

- do not allow water to come into contact with the instrument;

- do not use the circular device in places with high levels of humidity;

- equipment can be moved or lowered to the floor after shutdown only when the disk is completely stopped;

- prevent engine overheating;

- exclude access to the instrument for children;

- cutting boards should not contain foreign objects - bolts or nails;

- Before work, check the reliability of fixation of the material.

Proper use of a circular saw will allow you to accurately cut any number of boards with high quality. And compliance with all operational requirements will completely secure the work process.