Types of saws based on operating principle

Power saws can be divided into three types depending on the principle of their operation: tools with a reciprocating mechanism (jigsaws, reciprocating saws, alligator saws), circular saws and chain saws. Each type is designed to solve its own range of problems. Jigsaws allow you to make complex, curved cuts in almost any material - wood, plywood, chipboard, OSB, MDF, other composite materials, plastic, non-ferrous metals, steel, ceramics, rubber, foam rubber, cardboard, sandwich panels, profiles, etc. (except for asbestos-containing materials). A jigsaw will certainly come in handy at the stage of finishing work: cutting a hole for a sink in a countertop, making holes for ventilation grilles, cutting laminate in place when laying, cutting a hole in ceramic tiles - this is not a complete list of options for its use.

Jigsaw Makita 4329

- Tools

Instructions for craftsmen: how to cut smoothly with a jigsaw

Reciprocating saws

Reciprocating saws were originally created as a tool for dismantling construction projects - and in this regard they are very convenient. This compact tool allows you to cut wood, metal, lightweight foam and aerated concrete, and in difficult conditions of limited space. A cordless reciprocating saw is simply indispensable for roofing work when sheathing is being installed. This tool is also very convenient for trimming twigs and thick branches in the garden.

Bosch Low Vibration technology reduces vibration levels in Bosch cordless reciprocating saws.

Greenworks

The Greenworks G24RS cordless reciprocating saw is powered by a 24 V battery, which is suitable for all 24 V Greenworks tools.

When working, the reciprocating saw should not produce too much vibration, which when purchasing is best assessed by turning on several tools for comparison.

Saw Hammer LZK 800 B

When choosing a reciprocating saw, be sure to take into account the nature of the future work with it in order to choose the right tool in size and weight. To dismantle a shed or reinforced concrete wall, you will most likely need a powerful tool with comfortable handles for both hands. And the weight of the instrument (3-4 kg) does not play a special role here. And if you are going to trim apple tree branches while standing on a stepladder, it makes sense for you to choose a reciprocating saw that is as compact and lightweight as possible (and of course, better with a battery) - models such as, for example, Makita JR100DZ, Metabo ASE 10.8 0 or Bosch Keo , which weigh 1-1.3 kg. The cost of such saws will be 5-10 thousand rubles, and heavier and more powerful ones, powered by the network, cost less, 3-5 thousand rubles.

Reciprocating saw BUS 18BL (AEG), 18 V, with PROFLUX brushless motor

Bosch

Cordless reciprocating saw Bosch AdvancedRecip 18

Leroy Merlin

Reciprocating saw Makita M4501, 1010 W (RUB 7,920)

Reciprocating saws, like jigsaws, are equipped with files with a standard shank. Files can be for different quality of work and for different materials. Moreover, the cost of some models of files can be quite high (500-1,000 rubles or more)

Brushless reciprocating saw R18RS7-0 (Ryobi), 18 V. The pendulum mode allows you to increase the cutting speed by up to 40% compared to the straight stroke.

Black & Decker

Reciprocating saw Black & Decker RS890K-QS (RUB 5,200)

Circular saws

A circular saw is used for precise and long cuts of wood and all types of materials based on it, and with special saw blades, the saw can easily cope with sawing plastic, non-ferrous metals, and aluminum alloy profiles. This tool is used at all stages of construction, from sawing boards to carpentry and furniture work.

Circular saw Interskol DP-190/1600M

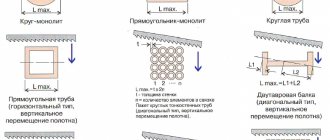

Circular saws differ in the diameter of the blade that can be installed on the saw, as well as in the diameter of the mounting hole. In everyday life, saws are used with a working blade diameter, usually from 120 to 250 mm, and with a mounting hole of 16, 20, 22, 30, 32 mm. Some size options are more common (for example, 165/20, 185/20, 210/30 mm wheels), while others are less common. In any case, make sure that you can easily purchase the right size disks at any time.

AEG

Brushless circular saw BKS 18BL (AEG).

Leroy Merlin

Working with the guide plate.

Greenworks

Cordless circular saw Greenworks G24CS 24 V (RUB 9,690)

Greenworks

For precise and accurate cutting, the circular saw is equipped with a laser cutting line indicator, a guide plate and markings. Cordless circular saw Dewalt DCS391N, 18 V, 165 mm (RUB 11,735)

ShutterStock/Fotodom.ru

For cutting longitudinal grooves, a circular saw is perfect, on which special adjustable groove saw discs are installed for this operation.

Makita

Compact cordless circular saw Makita HS301DZ (RUB 5,600)

Circular saws provide the highest precision when cutting wood. For construction work, this is perhaps one of the indispensable tools with which you can make split cuts, making boards of the required width. When longitudinally sawing thick beams and logs, high power of the tool is required, so if the volume of work is large, you should not skimp on this characteristic. It is better to choose a model with a power reserve (1,500-2,000 W) rather than burn the tool in the middle of work. To work with thermoplastic plastics, it is advisable that the circular saw be equipped with a speed regulator (thermoplastic materials are cut at low speed).

Circular saw BISON ZPD-2000

Discs are available for different types of wood and are also designed for rough or fine work. The diameter of the disc determines the maximum cutting depth, which is approximately 30–40% of its value. The tool should be selected so that the maximum penetration depth is sufficient to cut thick boards. Therefore, say, saws with a blade diameter of 130 mm and a cutting depth of 42 mm are not suitable for cutting boards of fifty (50 mm). On the other hand, such models are very convenient for work due to their compactness and low weight (the weight of such a saw can be 2.5 kg, and the weight of a saw with a 210 mm blade can be more than 5 kg). Perhaps, with a large volume of work, it makes sense to arm yourself with two models of circular saws with large and small working diameters of the disks. Fortunately, the cost of circular saws is not very high: for 4-5 thousand rubles. you can buy a tool of quite decent quality.

To cut boards with great precision, removable guides are used, which in some models are included with the saws, and sometimes are purchased separately. If there is a large volume of such work, it makes sense to purchase a sawing machine, since now you can find models for quite affordable money. Thus, models of Interskol, Ryobi, Bosch, and Einhell machines can be purchased for 10–25 thousand rubles.

Survey

| What brand of tool do you use? | |

| Einhell | 10% – 2 |

| Skil | 30% – 6 |

| Bosch | 35% – 7 |

| Makita | 15% – 3 |

| Another | 10% – 2 |

| Votes: 20 |

Share131-03-2011 15:35

- Author: Admin

- Administrator

- Registered: 03/27/2011

- Invitations: 0

- Last visit: 10-10-2014 19:11

Choosing a jigsaw

Before buying a jigsaw, think about what type of work you need it for. Despite the versatility of this tool, not all jigsaw models cope with various tasks equally successfully. When choosing a jigsaw, be sure to ask whether it is equipped with a pendulum mechanism. A jigsaw with a vertical stroke makes only up and down movements, while in the case of a pendulum stroke, the saw also makes forward movements. If you have a pendulum mechanism, you will need less effort to move the jigsaw along the cut - accordingly, the speed of work will increase. Although the cleanliness of the cut may deteriorate, especially when sawing hard materials. Therefore, for example, when sawing wood in shapes, the pendulum mechanism in a jigsaw is not so necessary. It is best used when cutting soft wood, plywood, chipboard, as well as foam and other non-hard materials. If you plan to use a jigsaw to cut steel sheets, we recommend that you choose models with high power and a rigid saw attachment. Household jigsaws consume from 280 to 550 W, the effective power is 130-340 W. It is also important that the electric jigsaw has control electronics. It ensures a constant set stroke rate under different loads and cutting different materials - the result is that even at a lower stroke rate the jigsaw works at full power. Jigsaws with a pendulum mechanism and a higher saw stroke speed benefit in the speed of sawing wood. Most models allow you to select the optimal operating mode by adjusting the frequency from 400 to 3,500 per minute. The choice of sawing speed depends on the material - for example, when processing plastic, it is better to turn on the jigsaw at low speed - the edges of the cut will melt less. But it is advisable to cut steel sheets at high speed: the material heats up and becomes more viscous and pliable. When cutting shapes on wood for harder materials, it is recommended to run the jigsaw at high speed, although you must also take into account parameters such as the desired accuracy and cleanliness of the cut.

Some useful tips: – When working, do not “help” the jigsaw - do not press on the saw blade, otherwise it will become very hot, and this may lead to its breakage. – Long, straight cuts are best made with a wide blade - the file stabilizes the position of the jigsaw, and the cut turns out smoother. – Change the blade more often; a dull saw only “pulls” rather than cuts the material, which increases the load on the engine and decreases productivity. When cutting metals, especially non-ferrous and aluminum alloys, as well as plexiglass, you need to moisten the blade with water or liquid machine oil. This makes cutting easier and extends the life of the file. – When cutting metal less than 1 mm thick, place a sheet of plywood under it and saw with low feed to avoid vibration. – When working with a low stroke frequency, let the jigsaw “rest” more often - working in this mode worsens the cooling of the electric motor. – Strictly follow the jigsaw care instructions – clean and lubricate your jigsaw, this will ensure its reliable and long-lasting operation.

Share221-11-2011 18:35

- Author: Admin

- Administrator

- Registered: 03/27/2011

- Invitations: 0

- Last visit: 10-10-2014 19:11

Choosing a circular saw

Circular saws are an almost ideal tool for precise longitudinal and bevel cutting. The productivity, quality of the cut line and speed of the circular saw far exceed the capabilities of a jigsaw. But it is impossible to obtain a curved cutting line using a circular saw. There is one more point that must be taken into account. Using various saw blades, you can successfully handle wood, fiberboard, chipboard, plywood, various polymers, and multilayer materials. As well as copper, aluminum, other non-ferrous metals, foam materials, etc. But steel and ferrous metals are too tough for a circular saw. Now let's look directly at the device itself. 1. Any circular saw consists of an electric motor, often more powerful than that of jigsaws. The power consumption of circular saws ranges from 550 W to 2.2 kW. Such a large spread is determined by the functionality of a particular instrument model. The logic of choice is extremely simple. The maximum permissible power of a circular saw determines the maximum possible size of the saw blade and, as a consequence, the maximum possible thickness of the material being processed. In addition, the more powerful the tool, the faster it will cope with the required amount of work, and the less often you will have to “smoke.” 2. The saw blade is fixed to the motor shaft. There are no fundamental differences in the fastening mechanism of different manufacturing companies, however, when choosing a saw blade, you need to remember the diameter of the mounting hole and the outer diameter (maximum blade size). The first will show whether the blade is suitable for your model of circular saw. If the hole dimensions are slightly larger than the diameter of the motor shaft, you can use special adapter bushings (it is better to use adapter bushings from the manufacturer, or at least make sure that there is no beating of the saw blade during operation). The second size must be known so that the diameter of the saw blade does not exceed the maximum permissible parameters of your circular saw. Both of these sizes are usually indicated on the saw blade packaging. The saw blades are secured with a screwdriver or wrench, depending on the model and manufacturer. 3. The engine is installed on the base plate using a special mechanism. Thanks to the design of the base plate, you can cut sheet materials at different inclination angles (in almost all models of circular saws, the inclination angle is steplessly adjustable). In addition, thanks to the fastening mechanism, the cutting depth can be adjusted. By the way, cutting depth is one of the main characteristics of circular saws. Typically, the technical data sheet of the device indicates the maximum depth of cut at an angle of 90° and 45° to the surface. These figures in some models of circular saws can reach 130 and 95 mm, respectively. Looking ahead a little, we note an important feature: not only the shape of the teeth, but also the number of teeth, the properties of the materials, the number of revolutions of the machine, the speed of passage and the angle of entry of the blade play a significant role in the quality of cutting and its power.

Tip: the blade should protrude beyond the material by an amount approximately equal to 1-1.5 tooth sizes, then the teeth will enter the material at an optimal angle of 45°. A few more notes about the base plate. Almost all models of circular saws have a mechanism on the base plate for using a rip fence. The purpose of the latter is extremely clear: obtaining parallel cuts of high quality (the simplest example: obtaining boards of the same width from a large sheet). The base plates of some models of circular saws have a special longitudinal groove for use when cutting a special guide bar. Thanks to this device, you can obtain high-quality cuts at any angle to the edge of the surface being processed. Guide bars come in various lengths. However, if the bus length is still not enough, several buses can be connected using connecting adapters. The base plates of some models of circular saws have special holes for attaching the tool to a workbench or special bed. In this case, the cutting process will occur in reverse: the saw is fixed stationary, and the workpiece can move relative to it along the guides. 4. To protect the operator, all models of circular saws, without exception, are equipped with a protective pendulum casing, which, when the tool is brought to the workpiece, smoothly moves back, and after cutting is completed, returns to its original position, thereby preventing possible injuries. 5. When considering the issue of safety when working with a circular saw, it should also be noted that all models are equipped with a protection mechanism against accidental activation. In order to turn on the circular saw, you need to press two buttons in a certain sequence. In addition, as soon as you release the start button, the saw will immediately stop working. An exception is the case when a circular saw is used in conjunction with a special sawing table, which is equipped with a special clamp for continuous operation of the saw and additional safety devices. A few words about dust and debris. The circular saw is designed in such a way that it independently removes sawdust through a special hole in the casing, to which, in turn, you can attach either a special dust bag or connect a vacuum cleaner. A little about electronics. The rotation speed of the saw blade in circular saws ranges from 1800 to 5000 rpm. To more accurately read the specifics of the materials being processed, some models of hand-held circular saws are equipped with a speed controller. To ensure that there is no jerk when starting the tool, some models of circular saws are equipped with a soft engine start system. For constant tool rotation speed, regardless of load changes, constant electronics are designed. In addition, a number of models of hand-held circular saws are equipped with a motor overheating protection system.

Read also: What is a nut tap

Share321-11-2011 18:40

- Author: Admin

- Administrator

- Registered: 03/27/2011

- Invitations: 0

- Last visit: 10-10-2014 19:11

Choosing a reciprocating saw

Reciprocating saws are an indispensable tool for installation work of various equipment and communications, when it is necessary to make small-diameter cuts in hard-to-reach places. One of the advantages of a reciprocating saw is its versatility: it can be used for cutting hard and soft wood, plastic, composite materials, aerated concrete, plasterboard, sheet metal, stainless steel, aluminum, etc. - i.e. almost any building material. You just need to choose the appropriate file for the task.

Reciprocating saws are a tool related to jigsaws. They are also equipped with a blade that moves in a straight line and makes small pendulum movements (raises during the reverse stroke), but the shape of a reciprocating saw resembles a large drill with files extended forward. Saw blades vary in size (from 100 to 350 mm) and tooth design, designed for sawing various materials.

Usually, reciprocating saws are classified as professional tools - it is unlikely that this specific tool can be used frequently in everyday life. But for construction specialists - installers, carpenters, roofers, finishers, mechanics, as well as rescue workers - this universal tool is simply irreplaceable.

Modern manufacturers offer cordless and corded reciprocating saws. Battery models, as a rule, have less power, but are much more convenient to use, because not limited by range - it is not always possible to stretch the wire, for example, to the roof of a country house. But they also have their drawbacks: charging a reciprocating saw battery lasts for an average of 1 hour, after which the tool must be recharged again.

Share430-05-2013 14:22

- Author: San

- Participant

- Registered: 05-04-2011

- Invitations: 0

- Last visit: 06/29/2013 21:09

I apologize if this is not entirely on topic, but this also applies to sawing

I would like to introduce you to a homemade support device for sawing firewood with a chainsaw.

This is a special supporting device that allows you to single-handedly, quickly and comfortably cut logs into firewood with a chain saw (gasoline or electric). Watch the video:

External dimensions: 1 m x 1 m, folded thickness 12 cm Recommended diameter of sawn logs – up to 40 cm

Advantages: – There is no need to move the log during sawing, which significantly increases sawing speed and overall productivity.

– Clamping of the chain by the sawn log is eliminated, as a result of which the service life of the tire is significantly increased.

– The log is cut into identical blocks of a predetermined length.

– The sawn blocks roll away to the side opposite to the sawyer’s position and do not pile up under the feet.

– The device folds easily and quickly, convenient for transportation and storage.

You can make this device yourself at home according to the drawings offered on this page. The necessary tools are a drill and a jigsaw. The drawings contain the exact dimensions of all components and assembly instructions.

The cost of a file with drawings and assembly instructions is 3 USD. SMS possible – payment PAY AND RECEIVE

The main purpose of a jigsaw is to make curved cuts in sheet materials. It can also be used for sawing boards, trimming limbs, or making straight cuts, but the jigsaw will not be as efficient for these tasks.

A circular saw is better for making straight cuts, and a reciprocating saw is better for cutting branches. All the advantages of a jigsaw become noticeable when making curved cuts.

Therefore, this tool is usually used: – In furniture and carpentry workshops for cutting out furniture elements, flat balusters, staircase parts and decorative elements. – In construction, for cutting passage holes in wooden floors and plasterboard ceilings, roofing parts made of corrugated sheets, metal tiles and roofing iron. – In metalwork workshops for the manufacture of shaped parts from sheet metal. – For finishing work for shaped cutting of drywall, floor coverings and tiles.

Saw alligators

The alligator saw is an interesting type of tool with a reciprocating mechanism. It uses two cutting blades at once, moving in a support rail in counter motion to each other.

Saw BOSCH GFZ 16-35 AC

Thanks to this, the tool works easily, without jerking and vibration typical of, say, a reciprocating saw, the sole of which must be pressed tightly against the surface being processed. The alligator saw is a fairly powerful and productive tool; in terms of the range of tasks it is close to reciprocating saws.

Alligator saws are used to cut a wide variety of materials.

Bosch

The long bar allows you to cut thick logs.

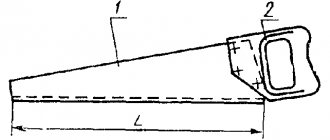

Jigsaws

When choosing a jigsaw, pay attention to the design of its body and especially the sole. It is desirable that it be designed in such a way as to prevent its deformation during intensive work (a slightly curved guide leads to defects during operation). It’s good, for example, if the sole is cast from an aluminum alloy with stiffening ribs. The body of the instrument must be balanced so that it can be held suspended with one hand without any effort. The handle of an electric jigsaw can be of two types - closed and open. The closed handle is considered the most universal. At the same time, jigsaws with an open handle are considered more suitable for figured cutting.

Jigsaw RJS1050-K (Ryobi). A good overview of the cut is achieved due to the narrow contour of the gearbox, LED lighting and the sawdust blowing function.

AEG

Electric jigsaw: BST 18BLX (AEG), battery 18 V, 4Ah

Electric jigsaw: G24JS (Greenworks) cordless, 24 V

Electric jigsaw: “Interskol MP-85/700E”, “Home Craftsman” series, power 700 W

The main technical characteristic of jigsaws is the number of saw strokes per minute. The greater the number of “stitches”, the higher the speed of work. Most modern models have the ability to adjust the speed (just as it is possible to adjust the shuttle speed of an electric sewing machine). For a less experienced user, it is better to choose low or medium speed (1,000–2,000 strokes per minute). Many jigsaws have a pendulum mechanism (the file makes not only translational movements back and forth, but also oscillatory movements, like a pendulum). This mode of operation increases productivity several times, but reduces the quality of the cut, so it is good to use for rough work.

Jigsaw Kolner KJS 500

Jigsaws in general are relatively inexpensive tools. For 3-5 thousand rubles. You can purchase models from such well-known manufacturers as Bosch, Makita, Metabo, Ryobi, Interskol. Most modern jigsaws use files with a T-shank; other variants are very rare (and it is better not to choose such a tool, so that later there will be no problems when finding the necessary files). Saw blades are available for different materials (hard and soft wood, metal, plastic, etc.), so choose a file according to the type of material and the nature of the work.

Bosch

The design of the handle and a good view of the cutting site are important when cutting shapes.

Bosch

The Bosch Electronic system allows you to adjust the stroke frequency using a push switch.

Leroy Merlin

Cordless jigsaw Dexter, Li-ion, 18 V (RUB 3,654)

Leroy Merlin

Jigsaw “Fiolent PM 3-650E”, 650 W (RUB 2,700)

Characteristics of jigsaws

By handle type

There are two types of jigsaws - with staple and mushroom handles.

The first are more universal, allowing you to work with one hand (freeing up the second to hold the part).

Power

The size of the jigsaw determines its performance - the more powerful the jigsaw, the faster it will make the cut. In addition, the maximum thickness of the material being processed also depends on the power - a low-power tool will not cope with a thick board or sheet iron.

However, high-power jigsaws are heavier and significantly more expensive. If, for example, a tool is purchased exclusively for working with plywood and chipboard, then excess power will only be harmful.

Maximum wood cut

depends on the power of the tool. Many manufacturers indicate maximum cuts in the parameters, but you should not blindly rely on this parameter. There is no clearly defined procedure for determining the maximum cutting depth, so there are also 350 W models on sale with a maximum wood cut of 55 mm and 600 W models with a maximum wood cut of 50 mm.

Read also: Steel grade 09g2s characteristics

In addition, the maximum cut of wood strongly depends on the type of wood, its humidity, the type of saw, the presence of a pendulum stroke, etc.

Those. With a 600 W jigsaw you can comfortably cut boards up to 6 cm thick.

A 350-watt jigsaw will, of course, “take a board,” but its performance will be low, and the increased load can lead to overheating of the tool.

Another subtlety applies to jigsaws with a maximum wood cut of more than 50 mm. The files of this tool are quite flexible, one end of the file is not fixed in any way, therefore, under the influence of the uneven inclination of the wood fibers, the file will inevitably be pulled to the side - and the greater the depth of the cut, the stronger. It is very difficult to accurately cut a shaped part with a thickness of more than 50 mm using a jigsaw. And with a tree thickness of about 100 mm, the lower end of the file can move to the side by tens of millimeters. A jigsaw cannot replace a band saw.

Maximum metal cut

can be approximately determined by dividing the power by 100: 5 mm for 500 W, 8 for 800, etc.

Stroke length

(the amplitude of the saw stroke) also affects performance - the longer the stroke length, the faster the jigsaw will cut (of course, if there is enough power). When purchasing, you should pay special attention to this parameter if you plan to frequently use the tool for cutting sheet metal - with a long stroke, the file wears out more evenly, in addition, the productivity of the jigsaw at minimum speed increases (and when sawing metal, the minimum speed is used). In this case, it is better to take a jigsaw with a stroke length of 20 mm or more.

Universal jigsaws have a stroke length of 15-20 mm.

With a stroke length of less than 15 mm, there may already be problems due to local wear of the files when working with thin sheet materials. But jigsaws with short stroke lengths provide better cutting accuracy.

Most saws have teeth sharpened only on the front – cutting – edge. The trailing edge of the teeth is not sharpened and, when the saw moves backwards, it creates resistance, increasing the load on the engine and practically not increasing the depth of cut.

When cutting lines with a small bend radius, it is better to disable this function. It is also recommended to turn off the pendulum stroke if an accurate and clean cut is required - the pendulum stroke increases the number of chips, worsening the quality of the cut.

Blade movement frequency

affects the functionality of the jigsaw - the stronger the material, the lower the frequency of movement needed to cut it. For tiles, the lower the frequency, the better; for metal, 500-800 strokes per minute is sufficient; wood is best cut at 1500-2000 strokes/min; soft wood, the higher the frequency, the better. Plastic slightly deviates from this pattern - its hardness is low, but it should be sawed at a frequency below average - 800-1200 strokes/min; at a higher frequency, the file heats up and melts the workpiece.

Fortunately, most jigsaws are equipped with speed control.

– this allows you to use the same tool for different materials. Keep in mind that under load the stroke rate will usually drop - unless the tool is equipped with constant stroke electronics to maintain a constant stroke rate.

Smooth start

allows you to gradually increase the set speed, reducing the starting load on the electric motor.

Sole type

affects the accuracy of the cut - the stamped steel sole can be deformed under heavy loads. For cheap “stamping” saws, a few cuts with reverse saws (for a clean face cut) may be enough for the position of the file to move away from the vertical due to deformation of the sole.

Adjusting the inclination of the sole

allows for cutting at an angle. But, unlike using a similar option with circular saws, maintaining an angle when cutting thick material with a jigsaw requires considerable experience. A little more force when moving the jigsaw or uneven feed of the jigsaw when turning will inevitably lead to the file leaving and disrupting the cutting angle.

Quick-release fastening of the file

significantly speeds up the replacement of equipment and allows you to forget about unpleasant moments when you urgently need to change the file, but the hexagon for the clamping screws is lost somewhere. The only drawback of the quick-clamp fastening is that a file that breaks at the very base sometimes jams inside the clamp. However, this happens rarely and is not an insoluble problem.

Low accuracy, “spontaneous” movement of the file from the cutting line is one of the main complaints of jigsaw owners. This is due to both the design of the tool and the features of some models - inexpensive jigsaws often have play in the pressure roller and the rod itself, which causes the file to move away.

Also, the cutting accuracy is affected by the stroke length and the distance from the maximum extended rod to the sole - the smaller they are, the more accurate the cut.

Laser marker

, “drawing” a line in front of the file, has almost no effect on accuracy. On the contrary, being carried away by aligning the marker with the marked cutting line, the master often does not notice that the file itself has long gone to the side.

Control of the cut when sawing is carried out directly on the file - and for this you should promptly remove sawdust in the sawing area. Blowing sawdust

or

the ability to connect a vacuum cleaner

allow you to keep the surface clean without unnecessary labor costs.

The backlight also makes it much easier to control the cut.

sawing area.

Device power

can be both mains-powered and battery-powered. Cordless jigsaws have all the basic functions of corded jigsaws and will be of particular interest to builders and carpenters working on sites that do not have a 220V connection. Unfortunately, cordless jigsaws are noticeably more expensive than their networked counterparts.

a rubber-coated handle is enough to protect against vibration.

– but only when cutting wood or plastic.

When working with metal, the vibration level increases noticeably. If you plan to frequently use a jigsaw for cutting metal, you should choose among models with an anti-vibration system

.

Benefits of cordless tools

Cordless models are now found in almost all types of power tools, including in categories that were previously considered not very suitable for batteries, such as circular saws (for example, the Ryobi R18CS-0, Makita HS301DZ, Bosch UniversalCirc 12 0, Greenworks G24CS 0) or, say, chain saws (models Greenworks G40CS30, DeWALT DCM565P1, Husqvarna 120i). This happened thanks to modern battery models that are capable of operating at any intensity mode, especially if you have a spare battery. Their high cost is the main disadvantage (several thousand rubles apiece). In other respects, battery technology is much more convenient: it is more compact, lighter and much quieter when compared with models with internal combustion engines). And, of course, no fuss with power cables.

Options for choosing jigsaws

If you need an inexpensive tool that can make curved cuts on plywood, thin boards and roofing iron, choose among budget jigsaws.

If you need a convenient universal tool that can perform maximum operations with various materials, choose among jigsaws with variable speed, tilt adjustment and pendulum action.

Jigsaws with sawdust blowing and lighting will provide convenient control of sawing accuracy, and models with lighting and connection to a vacuum cleaner will also keep your workplace clean.

If independence from mains electricity is important to you, choose from cordless jigsaws. And the presence of several batteries in the set will increase the operating time of the tool.

The presence of a case in the kit will simplify the transportation of the tool and keep the workshop tidy. In addition, experience has shown that a tool stored in a case usually lasts longer.

To process thick metal, you will need a powerful jigsaw with a large maximum metal cut.

Good day to all! I have no experience with this tool. Can you tell me what is better to use: a circular saw or a jigsaw? It is used mainly for fitting door trims and eurolining. Do I understand correctly that when sawing along trims with a jigsaw, due to lack of experience, it will not be possible to achieve a straight line on long cuts?

Read also: DIY folding grill

2Andrey Kr While you are searching, I will say that if the cuts are only straight and you are not planning any carpentry work in the future, then a circular cutter, otherwise both and plus trimming.

Thanks I looked at the forum. (I didn’t immediately realize that it was better to look for “circular” in the search. That’s why I asked the question) In general terms, it became clear.

A jigsaw is a very versatile tool. Two years ago I gave it to a friend as a gift, he accepted the gift with bewilderment, now I’m asking how? he says - I even sawed wood and threw away the hacksaw. A circular saw for large jobs is quite heavy, noisy, and dangerous.

Skobar wrote: A circular saw for large jobs is quite heavy, noisy, and dangerous.

A screwdriver is also dangerous, you can poke it in the eye.

WEREG wrote: A screwdriver is also dangerous, you can poke it in the eye.

And drop a sledgehammer or a hammer on your foot, or hit yourself on the fingers

Why are you laughing? A jigsaw is actually safer than a circular saw. Circular saws and grinders are generally the most dangerous tools and require _increased_ caution and attentiveness. Of course, all safety regulations must be strictly observed. Only the consequences of violating them with different instruments are different.

Solovushka wrote: Why are you laughing?

Of course I laugh. Only once when I was chopping wood with a cleaver and missed the log and hit my leg, it wasn’t funny

Solovushka wrote: A jigsaw is really safer than a circular saw. Circular saws and grinders are generally the most dangerous tools and require _increased_ caution and attentiveness.

So no one argues that a jigsaw is safer. And it's more versatile. And besides the circular saw and grinder, there is also a chainsaw, which is also very dangerous. Although if you follow the safety instructions and operating instructions, nothing will happen. For example, I would happily observe TB all the time, but it doesn’t work out

I believe that one cannot replace the other.

The budget, however, will not allow for both. I still can't decide. For some reason it seems to me that a circular saw would be more useful in the house. I can’t think of why I would cut curved blanks. The main work is still straight cuts, but here a circular cut is preferable.

Andrey Kr wrote: For some reason it seems to me that a circular saw would be more useful in the house. I can’t think of why I would cut curved blanks.

The fact that in the absence of a tool, the first thing you need is a circular saw, is indisputable. But don’t forget about a jigsaw; they can do a lot of things on wood, plastic and metal. I would set my priorities like this: 1. circular saw, 2. plane, 3. jigsaw. Screwdrivers, sanders, etc. according to needs. And they are growing

Techred wrote: I think that one cannot replace the other.

This is of course correct. But if you are planning long straight cuts, then of course a circular saw, although a jigsaw is more versatile.

go wrote: I would set my priorities like this: 1. circular saw, 2. plane, 3. jigsaw.

I agree, the first thing you need to do is take a circular.

That's for sure

Cutting with a circular saw in an apartment is some kind of sadism. I say - a jigsaw is a universal tool and basically everything is cut in a straight line, although it is called a jigsaw, in fact it is a mechanical hacksaw. Even a child can cut with a jigsaw, just give it to him, but with a circular saw.

In addition, if you are cutting 50mm boards or cutting a cross, you need a wild saw; if you are covering a wall with clapboard, then a jigsaw is better, but God himself ordered to cut firewood with a chainsaw. But according to my experience working in the country, a jigsaw is one of the most popular tools, like a drill.

Andrey Kr wrote: For some reason it seems to me that a circular saw would be more useful in the house.

Depending on what you mean by the word “house”, if it’s an apartment, then a jigsaw is better.

Skobar wrote: Using a circular saw in an apartment is some kind of sadism.

In relation to whom? To yourself or to your neighbors? I worked as a Rebir in an apartment, anyone who heard how it works will understand

agrey wrote: Depending on what you mean by the word “house”, if it’s an apartment, then a jigsaw is better.

A jigsaw, as I already said, is more versatile, but is not suitable for straight cuts.

Skobar wrote: if you are covering a wall with clapboard, then a jigsaw is better,

Better crosscut

What is it?

veers wrote: A jigsaw, as I already said, is more versatile, but is not suitable for straight cuts.

Let him explain this to the neighbors

agrey wrote: Let him explain this to the neighbors

If you come out with a working circular and wave it in front of their noses, I think they will understand

Hello. The choice is to buy a Makita jigsaw or a Makita circular saw. Dear forum members, I am interested in your opinion, what is better, what is more practical, what is more universal in use? WHAT IS BETTER TO BUY.

since the author did not voice the work IMHO jigsaw

Anatoly77 wrote: The choice is to buy a Makita jigsaw or a Makita circular saw. Dear forum members, I am interested in your opinion, what is better, what is more practical, what is more universal in use? WHAT IS BETTER TO BUY.

Well, if, for example, we are talking about quickly, quickly chopping 5 kilograms of sausage into pieces in the garage, then a jigsaw will probably be more convenient. But if the task is to give your neighbors a heart attack with loud noises at 4 o’clock in the morning, there’s no way without a circular

- It's been discussed many times on the forum, do a search.

- A jigsaw is somewhat safer and allows you to make curved lines. Straight lines come with dances (you need good guides, thick files, etc.), has problems with the perpendicularity of the end to the edge (the file moves away) on thick (well, somewhere from 30 mm) parts

- A small advantage of a jigsaw is that the upper and lower cutting points in the material are located one above the other. Well, for example, if you wanted to make a corner cutout, there’s no problem with a jigsaw, but you’ll have to finish it a little with a circular saw.

- A jigsaw is more convenient and safer in matters of fitting, when you need to cut directly on the spot, not on the workbench. Again, point 3 is important here.

A jigsaw is much more convenient and safer when working with small parts, cuts up to, say, 10 cm long, small samples, say you need to cut a square hole 5x5 cm (okay, 10x10) for a socket, for example - a jigsaw + drill will do the job, a circular saw will do the job no (her disk simply won’t fit there)

- A circular saw is MUCH more convenient, faster and better when it comes to straight cutting. By the way, most operations involve just such a cut. Well, cutting boards to size, maybe sawing/sawing beams and so on.

- Generally more stable in terms of edge verticality, i.e. angle 90 degrees. does not float like a jigsaw.

- Well, it is much more productive, but also more dangerous than a jigsaw.

So - if there are no complex curved holes, for example, furniture, and the tasks are more construction, then a circular one. If you want to make a lot of fancy, beautiful furniture or there will be a lot of different fitting/finishing work, then use a jigsaw. In principle, if you have a router, then infrequent curved shapes can be made without a jigsaw - only with a router and a circular saw.