An angle grinder is an indispensable tool for carrying out construction work with various materials. It is also good because additional devices (attachments, disks) can be attached to it and/or converted with little effort into another highly specialized tool - for example, into a milling cutter. Of course, an original industrially manufactured tool will in many ways be superior to such a homemade one, but for household needs it will be quite enough.

In order to make a milling cutter based on an angle grinder, you will need the following tools and materials:

- The angle grinder is in working condition, the absence of any defects or malfunctions is mandatory;

- welding machine (if you are going to use metal);

- fasteners;

- screwdriver/screwdriver;

- electric drill;

- building level;

- ruler (tape measure) and pencil;

- square;

- a sheet of plywood or chipboard 1 cm thick or a sheet of metal approximately 3 mm thick;

- spanners;

- jigsaw or saws for working with wood/metal;

- metal corners or blocks of dense wood (5x5cm);

- punch;

- set of hex keys;

- file, coarse and fine-grained sandpaper.

First, decide which milling tool you need - stationary or manual. Both options have their own characteristics during assembly and operation.

If you need a stationary milling machine, keep in mind when designing it that its capabilities will depend on the power and rotation speed (number of revolutions) of the grinder motor, as well as the area of the table for work (workbench).

To process parts made of small, fragile wood, a small grinder with a motor power of 500 W is enough.

If the milling cutter has to work with metal workpieces, the power of the angle grinder motor must be at least 1100 W.

The design of the milling cutter consists of the following elements:

- stable base;

- movable/fixed tabletop with lined strip;

- drive unit.

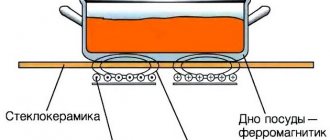

Lamella milling machines are distinguished not by a vertical, but by a horizontal arrangement of the working cutter. There are 2 options for designing a homemade milling machine:

- fixed table – movable tool;

- movable worktop - stationary tool.

In the first case, for horizontal processing of a part, the procedure is as follows:

- fix the angle grinder to the plate vertically (the cutter attachment is positioned horizontally);

- guides are installed around the table for moving the plate with the tool;

- the workpiece is fixed on the working surface.

Thus, processing of the fixed part is carried out with a movable tool. In the second case, you need to ensure the immobility of the grinder and the mobility of the working surface.

To move the tabletop, a structure of guides is constructed underneath it with the ability to fix the position of the working surface. The angle grinder, in turn, is mounted on a vertical frame on the side of the workbench.

When a machine with a vertically positioned working attachment is required, the procedure is as follows:

- assemble a frame from pieces of wood or corners, ensuring they are rigidly fastened to each other (using welding or fasteners);

- attach a sheet of chipboard or plywood to the frame;

- make a hole for the angle grinder shaft - the diameter of the recess must exceed the corresponding cross-section of the shaft;

- secure the tool inside the frame using clamps or punched tape on the bolts;

- on the working surface of the table, build guides (from slats, slats, etc.) to move the part;

- sand and paint all surfaces;

- The toggle switch for turning on the tool can be fixed for comfortable use.

All heads of self-tapping screws (bolts, screws) must be recessed and not protrude above the surface of the work area.

Keep in mind that the guide rails must be removable; different workpieces require different locations. It is most convenient to fix them using self-tapping screws.

The tool should be located conveniently and accessible for quick replacement of the working attachment (cutter, disk, etc.).

To fully use any homemade milling machine, you need to purchase cutters - additional attachments for the grinder in the form of cutting discs or key attachments. If the first ones replace the grinding disc of an angle grinder without any problems and are easily secured to the shaft with a clamping nut, then for the second type of attachments you will need an adapter.

The easiest option is to convert the grinder into a manual milling machine. Please note that in this case, it is necessary to securely secure the workpiece - using a vice or clamps, in order to eliminate the possibility of vibration or shifting of the workpiece. There are several ways to convert an angle grinder into a manual router. Here is one of them.

First, make the basic base of the tool according to the drawings. The ideal option would be a base made of a metal sheet of sufficient thickness and weight, because the weight of the base directly affects the stability of the device.

Then make a fixing plate - a bracket to hold the angle grinder. The material is the same as at the base. You need to make a hole for the back of the tool, the one where the handle is located.

Cut out the blanks into the shape you want.

Weld sections of square pipes to the ends of the product to move along vertically located guides. The guides will be longer sections of square pipes, but with a smaller diameter. They need to be welded to the base.

To increase the reliability of fixing the tool, you can make and weld unique “ears” from a metal sheet. To fix the tool at the desired height, it is necessary to make a mount. You can weld 2 nuts, screw threaded rods into them, onto which wing nuts are attached by welding.

With this device you can easily and quickly change and secure the required position of the tool.

Now you need to install the drill chuck as an adapter for the working cutter attachment. Pre-cut a thread inside it that matches the angle grinder shaft. Then screw it onto the shaft and fix the necessary cutter in it. Assemble the machine. Fix it in the bracket.

Test its operation. If there is no excess vibration or uncontrolled shifts during operation, everything is in order. Otherwise, you need to check where the inaccuracy came from and correct it.

When performing milling work on wood, do not forget to follow simple rules:

- compliance of the nozzle on the angle grinder with the material being processed;

- Removal of the protective casing is not allowed;

- Set the angle grinder speed to minimum;

- really evaluate your strength - a large grinder can easily be snatched from your hands;

- work with protective gloves or firmly secure the tool;

- first check the homogeneity of the workpiece - whether there are any foreign metal parts;

- work must be carried out in one plane, distortions are unacceptable;

- do not block the button in operating mode;

- Before replacing the accessory/blade, be sure to turn off the power to the power tool.

To learn how to make a router from a grinder, see below.

Source: https://stroy-podskazka.ru/instrumenty/bolgarka/frezer-svoimi-rukami/

???? Manual milling cutter from an ordinary grinder: a useful homemade product for the home craftsman

Some stories coming from our readers to the Homius editorial staff are striking in their simplicity and, at the same time, genius. Today we will talk about just such a life hack.

Egor Vasilyevich Semchenko sent us his report on the work done from the city of Nizhnevartovsk, Khanty-Mansiysk Autonomous Okrug - Ugra.

In it he will tell you how to make a good manual router from a simple angle grinder.

Recently I was thinking about making a small router for home projects. Purchasing such a device in a store is very expensive, and, frankly, boring. The fact is that, as a military man, I retired early, so I still have enough strength and energy, as well as free time. I present for your consideration what I came up with.

Required materials and tools

For work I used:

- the grinder itself, which will subsequently transform into a router and back;

- a section of I-beam;

- square steel profile in two sizes - 20×20 mm² and 25×25 mm²;

- small galvanized sheet;

- grinder wheels – cutting, grinding and metal brush;

- M14 tap with a thread pitch the same as that of the clamping nut of an angle grinder;

- drill chuck with threaded connection;

- welding machine.

And naturally, I had various bolts and nuts on hand from which I could choose what was required.

I decided to use this grinder as a “guinea pig”

Step one: prepare the material, get to work

The first thing I needed to do was to unravel the I-beam by cutting out the central part of it. This will be the basis of our design. This is not difficult to do, but for those who rarely deal with angle grinders, I will say that it is advisable to use protective equipment - gloves, glasses, a thick apron.

Lamellar router from an angle grinder or how to make a groove without a router

It's not every day that a furniture maker needs to glue, and not everyone will even have to assemble wooden parts in place in their life. Perhaps this is why I learned about what a lamellar router is only when I was faced with the task of gluing together wooden blocks of which I had accumulated a lot during the renovation.

Everything would be fine, but the disassembled old window frames have a very complex profile in cross-section; I will say more, all of their edges are not parallel to the opposite ones. Planing them to a regular parallelogram resulted in a bar 20 by 20 mm with the original dimensions of almost 50 by 50 mm. Therefore, I decided to minimize losses and bring the bars to a figure that has a rhombus or a truncated pyramid in cross-section. And then another question arose: how to glue them so that they do not move apart. The simplest thing is to make a groove or hole in them for dowels. There is another option to buy a very expensive milling cutter and an equally expensive milling machine for it and, by reducing the bars further, make them fold like clapboard. But no, this option is not suitable for used material with a lot of nails, putty and paint.

Turning my gaze to existing models, I realized that the cheap ones had many shortcomings (usually large gaps) and are not being produced at the moment, and those devoid of these defects are prohibitively expensive for such experiments and decided to make my own version, as always with minimal costs time and effort. Going from simple to complex. At the beginning, I decided to attach an aluminum profile to the grinder, which would set the same size for all the bars, but this turned out to be not enough. The design turned out to be flimsy and the disk made a crooked groove.

At this point I paused and recorded a video question on YouTube

It’s clear that I answered because I have 15 subscribers and haven’t received a single view.

But in the morning a decision was born in my head, how to improve the unit with little “blood” without machines and welding, and most importantly, without buying anything new. To begin with, I strengthened the mechanism by making slots in it and, without cutting the profile, I bent it with the letter “P”

All that remains is to come up with a mechanism for raising and lowering the platform that would limit the height of the groove relative to the workpiece. The difficulty was that I was going to attach the guide to the block, since I thought that the angle grinder would try to “run away” or tear out the block. But it turned out that the saw blade is very sharp and it fits into the pine like butter, you still need to fix the workpiece and you need to hold the angle grinder with only two hands so that if it jams, it won’t be thrown onto the “operator.” Therefore, I was distracted for a while and gave birth for this his new “dinosaur” clamps, which he also made a video about. But we digress. When I realized that the grinder didn’t tear even like a regular router, I decided that any strip attached to my “U” shaped holder would do the job, and that’s where those “sleds” that I wanted to use as guides came in handy, I simply folded them along palmed and secured with a pin

This turned out to be quite enough for now. How would you improve this device?

How to make a router from a grinder with your own hands

If it is necessary to perform milling work and there is no money to purchase a factory tool, it is possible to make a milling cutter from an angle grinder at home.

Although it will be inferior to industrial analogues, it can be used to make grooves and tenons in wood blanks, drill holes, process edges, and cut out places for installing door locks and hinges.

Milling can also be performed with some other materials, the list of which is determined by the power of the angle grinder used as a basis. For a home workshop, a homemade tool is a good option that requires minimal financial outlay.

Stationary frame-table for attaching an angle grinder

Necessary materials and tools to complete the work

A milling cutter is a device designed for processing various materials (wood, metal, plastic, textolite and others): drilling, creating grooves, cutting edges and carrying out other technological operations.

It can be made in the form of a hand-held power tool or a stationary machine. For use at home, you can make a router from a grinder.

At the same time, it is possible to implement both stationary and manual versions.

To make a router, in general, you will need the following materials and tools:

- a working angle grinder that will serve as a drive mechanism;

- welding machine (needed when using metal);

- fasteners - punched paper tape, bolts and nuts, self-tapping screws or self-tapping screws;

- a screwdriver equipped with different bits;

- drill with a set of drills;

- tape measure and marker (or pencil);

- level;

- square;

- plywood (chipboard) or metal sheet (about 3 mm thick);

- set of wrenches;

- screwdrivers;

- jigsaw or saws for wood and metal;

- iron corners or wooden blocks (5 by 5 cm);

- core;

- hex keys;

- sandpaper, files.

Sheets of plywood or chipboard with a thickness of 10 mm are suitable for the work.

The possibilities of a permanent installation will be determined by the following parameters:

- angle grinder electric motor power;

- number of revolutions (rotation speed) of the motor;

- the dimensions of the work table, which determine the dimensions of the workpieces being processed.

To work with small wooden parts made of fragile wood, a grinder with a 0.5 kW electric motor will be sufficient. If you have to process metal workpieces, you will need a device with a motor of 1.1 kW.

Algorithm for making a milling cutter from an angle grinder

The manufacturing algorithms for a stationary milling installation and its manual counterpart are different. The latter option is easier to implement: less labor and materials are required.

Stationary machines

The milling machine consists of the following structural elements:

- strong, stable frame;

- drive;

- table for performing work with a ruler (slat).

Accordingly, when creating a working model of the installation, you will need to make these parts and then connect them together. An angle grinder will be used as an electric drive. It will need to be securely fastened to the table top.

The stationary machine can be made in two versions: with an angle grinder fixed on the table or with a movable installation of an angle grinder. The first one is quite easy to implement practically with your own hands. It should be taken into account that the working tool can be secured so as to perform processing in horizontal or vertical planes. The order in which the installation is assembled depends on this.

A machine for processing a workpiece in a horizontal plane (with a vertical cutter position) is assembled in the following sequence:

- make a frame from metal corners (they are connected by welding) or wooden blocks (fastened with self-tapping screws);

- sheathe the frame with chipboard or plywood, securing the sheets with bolts;

- a hole is cut out in the tabletop for the angle grinder shaft (larger in diameter than its cross-section);

- using punched paper tape or clamps, attach the grinder to the table top with bolts from below, approximately as shown in the photo below;

- on the surface of the tabletop, planks are installed from wooden slats (pieces of chipboard or plywood), which act as guides along which the workpiece will move;

- wooden and metal parts of the structure are painted (after having been cleaned with sandpaper);

- For ease of operation, attach the toggle switch for turning on the grinder.

The bolt heads located on top of the tabletop must be flush with its surface. Therefore, you will need to drill holes of the appropriate size for them. The guides are removable structural elements. They need to be rearranged for each workpiece. They are often fixed using self-tapping screws.

It is necessary to provide such access to the grinder so that it is convenient to change attachments.

Using a toggle switch, you can supply power to the power tool by simply locking its button in the on position. A more difficult option would be to remake the electrical circuit of the angle grinder.

The option with a horizontal cutter arrangement is implemented in a similar way, only the grinder is fixed to the side of the structure, resulting in something like a circular saw. The appearance of the created machine is demonstrated in the photographs below.

To use the machine, you need to install cutters. There are varieties of them on sale that resemble ordinary cutting discs, which are fixed to the shaft using a clamping nut. An adapter is required to use key bits. Moreover, on one side it has a threaded seat (for screwing the grinder onto the shaft instead of a nut), and on the other, for fixing the cutter.

Manual frezer

With a movable version of fixing the angle grinder, it is easier to remove it if necessary in order to use it for its intended purpose.

Algorithm for making a milling cutter from an angle grinder

The manufacturing algorithms for a stationary milling installation and its manual counterpart are different. The latter option is easier to implement: less labor and materials are required.

Stationary machines

The milling machine consists of the following structural elements:

- strong, stable frame;

- drive;

- table for performing work with a ruler (slat).

Accordingly, when creating a working model of the installation, you will need to make these parts and then connect them together. An angle grinder will be used as an electric drive. It will need to be securely fastened to the table top.

The stationary machine can be made in two versions: with an angle grinder fixed on the table or with a movable installation of an angle grinder. The first one is quite easy to implement practically with your own hands. It should be taken into account that the working tool can be secured so as to perform processing in horizontal or vertical planes. The order in which the installation is assembled depends on this.

A machine for processing a workpiece in a horizontal plane (with a vertical cutter position) is assembled in the following sequence:

- make a frame from metal corners (they are connected by welding) or wooden blocks (fastened with self-tapping screws);

- sheathe the frame with chipboard or plywood, securing the sheets with bolts;

- a hole is cut out in the tabletop for the angle grinder shaft (larger in diameter than its cross-section);

- using punched paper tape or clamps, attach the grinder to the table top with bolts from below, approximately as shown in the photo below;

- on the surface of the tabletop, planks are installed from wooden slats (pieces of chipboard or plywood), which act as guides along which the workpiece will move;

- wooden and metal parts of the structure are painted (after having been cleaned with sandpaper);

- For ease of operation, attach the toggle switch for turning on the grinder.

The bolt heads located on top of the tabletop must be flush with its surface. Therefore, you will need to drill holes of the appropriate size for them. The guides are removable structural elements. They need to be rearranged for each workpiece. They are often fixed using self-tapping screws.

It is necessary to provide such access to the grinder so that it is convenient to change attachments.

Using a toggle switch, you can supply power to the power tool by simply locking its button in the on position. A more difficult option would be to remake the electrical circuit of the angle grinder.

The option with a horizontal cutter arrangement is implemented in a similar way, only the grinder is fixed to the side of the structure, resulting in something like a circular saw. The appearance of the created machine is demonstrated in the photographs below.

To use the machine, you need to install cutters. There are varieties of them on sale that resemble ordinary cutting discs, which are fixed to the shaft using a clamping nut. An adapter is required to use key bits. Moreover, on one side it has a threaded seat (for screwing the grinder onto the shaft instead of a nut), and on the other, for fixing the cutter.

Manual frezer

With a movable version of fixing the angle grinder, it is easier to remove it if necessary in order to use it for its intended purpose. It is much easier to make a manual router than to create a mechanism that allows it to move back and forth, as well as left and right. Working with such a tool will require securely securing the workpiece so that it does not vibrate or move, for example, in a vice or using clamps. This will largely determine the quality of the work performed, as well as the convenience (speed) of its implementation.

There are many options for making hand-held tools from angle grinders for milling. At the same time, different materials are used in the work. The method for creating a hand-held wood router from an angle grinder is demonstrated in the video below.

Manual devices are more reminiscent of attachments for an angle grinder, allowing you to use it like a router. The simplest models do not provide for vertical movement of the cutting attachment. They are designed to perform simple operations.

If we compare the manual and stationary versions of homemade milling cutters, it should be noted that the quality of processing of the latter is higher. But the first ones are easier to make, and the grinder can be easily removed if necessary. The tool must be handled carefully, following safety precautions. It’s great when an angle grinder has a speed controller. This allows you to set the desired rotation speed of the cutter while working with different materials.

Making a router from a grinder with your own hands: materials and assembly algorithm

For various jobs in a home workshop, it is not always advisable to purchase specialized power tools, which, as a rule, are quite expensive. Do-it-yourself devices, which include a milling cutter made from an angle grinder, are more relevant in such situations.

Using such a device, the basis of which can be a household electric drill, it is possible to perform various technological operations - milling, edge processing, forming tenons and grooves on the surface of wooden workpieces, preparing seats for door hinges and locks, etc.

Homemade milling machine with a side-mounted tool

Materials used

Making your own milling cutter from an angle grinder to equip a home workshop requires meeting certain conditions, the main of which are ensuring reliable fixation of the power tool in a vertical plane and its movement relative to the surface of the workpiece.

Scheme for securing the grinder

In order to make your own milling machine from a grinder that satisfies the above conditions, you will need the following components and consumables:

- an angle grinder or an electric drill, the drive motor of which must be in working order (in addition, the structural elements with which these devices will be fixed to the supporting structure must be sufficiently strong and reliable);

- the base on which the future router will be fixed (the surface of a desktop or workbench can be used as such a base, which should be highly reliable and stable, and also ensure ease of working with a home-made milling installation);

- thick plywood or thin sheet metal (from which you will make with your own hands the part of the router structure on which the grinder or electric drill will be fixed);

- welding machine (if sheet metal will be used in the design of your router);

- fasteners (clamps, screws, bolts and nuts);

- standard set of locksmith tools.

Option for placing an angle grinder in a homemade machine

Thus, to make a milling cutter from an angle grinder with your own hands, you will need materials that are available in almost every home workshop or in any garage. Accordingly, in order to make such a machine and start using it, significant financial investments will not be required, which cannot be said about the situation when a serial model of such a device is purchased.

Manufacturing algorithm

Making your own milling cutter based on a grinder or drill is carried out in the following sequence:

- The base of the milling machine is made from thick plywood, chipboard or thin sheet metal, which consists of two walls located opposite each other. One of the walls of such a base, which is not used to fix the grinder or drill, can be made movable. This will allow you to change its spatial position depending on the length of the part that will be processed.

- A metal cone is fixed on the moving part of the future router, which is used to hold the workpiece during processing.

- The tool with which processing is performed on a home-made machine is placed on the side of the frame. You can use tools of almost any configuration and any size on such a router.

Homemade woodworking machine from an angle grinder

In the event that the milling machine will be manufactured not on the basis of an electric drill, but on the basis of an angle grinder, a special adapter will have to be included in its design, which will ensure the fixation of the sleeve used to rotate the workpiece. If the basis of a homemade router is a drill, then such a sleeve is simply fixed in the chuck of the power tool.

Homemade router from a drill

Thus, making a router from a grinder or an electric drill with your own hands is simple. To do this, you don’t even need to invent your own device design - just use ready-made ideas that have already been tested in practice by many home craftsmen.

Source: https://met-all.org/oborudovanie/prochee/frezer-iz-bolgarki-svoimi-rukami-po-derevu.html

Materials used

Making your own milling cutter from an angle grinder to equip a home workshop requires meeting certain conditions, the main of which are ensuring reliable fixation of the power tool in a vertical plane and its movement relative to the surface of the workpiece.

Scheme for securing the grinder

In order to make your own milling machine from a grinder that satisfies the above conditions, you will need the following components and consumables:

- an angle grinder or an electric drill, the drive motor of which must be in working order (in addition, the structural elements with which these devices will be fixed to the supporting structure must be sufficiently strong and reliable);

- the base on which the future router will be fixed (the surface of a desktop or workbench can be used as such a base, which should be highly reliable and stable, and also ensure ease of working with a home-made milling installation);

- thick plywood or thin sheet metal (from which you will make with your own hands the part of the router structure on which the grinder or electric drill will be fixed);

- welding machine (if sheet metal will be used in the design of your router);

- fasteners (clamps, screws, bolts and nuts);

- standard set of locksmith tools.

Option for placing an angle grinder in a homemade machine

Thus, to make a milling cutter from an angle grinder with your own hands, you will need materials that are available in almost every home workshop or in any garage. Accordingly, in order to make such a machine and start using it, significant financial investments will not be required, which cannot be said about the situation when a serial model of such a device is purchased.

Do-it-yourself milling cutter from a grinder. How to do it right?

Do-it-yourself milling cutter from an angle grinder

In a home workshop, every type of tool will be available, by the way, the same applies to a homemade milling cutter from an angle grinder.

And if we talked about how to make a polishing machine, a homemade tile cutter and a sheet bender with your own hands earlier, then it’s time to talk about how to make a router from a grinder with your own hands.

In fact, everything is quite simple, and if you have an old unnecessary drill or grinder in the garage, then a milling machine can be made quite simply. The main parts of a milling machine made from a grinder or drill are a cutter, a rod on which it is attached and a motor that rotates it. That's all there is to it in order.

Do-it-yourself milling cutter from an angle grinder

So, to make a router from an angle grinder with your own hands, first of all you will need to prepare:

- The base on which the grinder or drill will be attached. It could be a table or a homemade workbench for the garage, it doesn’t matter. The main thing is that the base is reliable, does not wobble, and you can comfortably work on it with a homemade router.

- An old unnecessary drill or grinder. There is no need to disassemble this power tool. At the same time, it is worth understanding that the elements by which it will be fixed firmly to the base must be strong and as reliable as possible.

- A piece of 12 mm plywood or thin metal. Working with plywood is much easier, but if metal is chosen to make a milling machine from an angle grinder, then welding may be required to fasten all the parts of the homemade router.

In principle, that’s all, although in the process of making a router from an angle grinder with your own hands, you may need additional bolts or screws, but this stuff, as a rule, abounds in every garage or in the utility room of a home craftsman.