Water heater design with indirect heating

DHW heating in an indirect heating boiler (IHB) is carried out by using thermal energy from an independent source. Most often it is connected to the boiler unit. The heated coolant from the boiler at a temperature of 60 to 95 C enters the internal heat exchanger, made in the form of a coil.

Water heater device

The heated water in the tank comes into contact with its surface, through which the process of heat transfer from the hot medium to the heated medium takes place. The maximum heating temperature in such devices is 70 C. Up to 150 liters, tanks are wall-mounted, and those with larger volumes are floor-mounted.

In modern heat supply schemes, today they began to use an even more progressive system for preparing hot water using the principle of layer-by-layer heating.

Layer-by-layer heating of water is carried out first by a flow method in the built-in plate heat exchanger of a double-circuit boiler, and then stored in an external storage tank, so the process of switching coolants between heating circuits does not occur, which has a positive effect on the operation of the heating system.

Before you make an indirect heating boiler with your own hands, you need to know the operating principle and purpose of the BKN. The master will also need to decide which basic design elements he can use:

- BKN body: made of stainless steel, steel, enameled or glass-porcelain coated, like 80-liter Thermex boilers. In the most budget option, it can even be in the form of a plastic barrel.

- Thermal insulating shell to create accumulative qualities to keep heated water hot for as long as possible.

- The internal heat exchanger is usually in the form of a coil.

- Shut-off and control valves for do-it-yourself boiler maintenance and repair.

- The control and protection unit can be connected independently from ready-made systems, freely sold through the retail chain.

The BKN boiler is connected according to the scheme of countercurrent movement of media: heating and heated, they are directed towards each other.

Diagram of a homemade indirect heating boiler

The standard design of a water heating device in the form of a boiler may have significant differences depending on the type and design features. Indirect heating devices are not capable of independently producing thermal energy, but can be equipped with built-in heating elements, through which the water temperature is effectively maintained within predetermined limits.

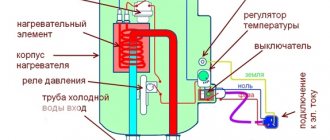

The device diagram assumes the presence of the main components in the design, represented by:

- storage tank;

- outer casing;

- thermal insulation;

- heat exchanger;

- a place for connecting an additional heating element;

- inspection hole;

- cold water inlet;

- input and output for thermal fluid;

- thermometer connection point;

- recirculation line;

- hot water outlet;

- magnesium anode.

A heating element with a supplied coolant is built inside the insulated tank. Cold water enters through the lower part of the tank, and hot water is taken from the upper part.

Water heating equipment of this type is equipped with a protective magnesium anode. The most modern and expensive models are equipped with a pair of redundant coils. Maintaining the temperature is ensured by a heating element with a thermostat built into the upper part of the tank.

Heating diagram for two types of boilers

Boilers with an indirect heating type are also produced, completely devoid of a coil. This special design is called a “reservoir in a tank”, which is due to the presence of a second tank inside one tank. Water heating in such water heating devices occurs inside the tank, and the coolant moves between the walls.

Factory models of boilers with indirect heating and a circulation pipe are equipped with mandatory elements, represented by a magnesium anode and a safety group, as well as a temperature sensor.

Necessary materials

Before making a boiler with your own hands, you need to not only prepare all the materials, but also mainly decide on the working volume of the tank, which will be able to provide the load on the hot water supply for household needs.

It should be taken into account that the heating rate in these types of boilers is less than that of electric models, so the heating time is longer.

In order to ensure a comfortable water supply for the whole family, a large-volume BKN design is chosen. After determining the working volume, as-built drawings are prepared, source materials are selected and their quantities are calculated.

Basic materials and tools for making an indirect heating boiler with your own hands:

- Working storage capacity. Choose sheet metal or a finished tank design. The metal should resist corrosion in a water environment as much as possible: stainless steel, heat-resistant plastic housing or an enamel-coated tank.

- The heat exchanger is of a coil type, using a stainless or copper pipe.

- Pipes for piping the boiler and BKN.

- Heating element for combined BKN.

- Shut-off and control valves.

- Locksmith tool

- Welding with electrodes.

Project development

The BKN boiler is carried out according to a project based on as-built drawings. They are made independently, taken on the Internet according to the required tank volume and coolant temperature, or borrowed from users who have successfully installed and operate the required volume of BKN. In the project, thermal and hydraulic calculations are performed and the specifications of the necessary equipment are determined.

Main design parameters of BKN:

- hourly volume of DHW water consumption, m3;

- coil location;

- coil configuration;

- coil heating area.

In addition, the “automation” section is being prepared, which provides for emergency shutdown of the BKN and automatic maintenance of the operating temperature of the hot water supply in the boiler.

When choosing the parameters of the tank and coil, you should not get carried away with the large dimensions of the structure, as this will lead to a decrease in the overall efficiency of the installation due to increased heat losses.

Calculation of the volume of the manufactured boiler

In the case when the boiler is already installed in a private house and is designed for heating, the tank volume must be calculated based on the maximum operation of the boiler for heating and the remaining power reserve for DHW service. If this balance is upset, the system will begin to operate with underheating in both the heating system and the domestic hot water supply.

If the boiler has not yet been installed, then first the heating load is determined, then the DHW load, and then the boiler power is selected, taking into account a 10-15 percent reserve.

For example, a Termex 80 indirect heating boiler with a volume of 80 liters will require a boiler power reserve of 14.6 kW at a boiler water temperature of at least 80 C.

The load on the hot water supply is determined by the volume of water use; the practical relationship between the volume of the BNK tank and the thermal load on the hot water supply is:

- 100 l - 16 kW;

- 140 l - 23 kW;

- 200 l - 33 kW.

In order to carry out more accurate calculations, a formula is used that is based on the heat balance:

Vbkn = = P x.v (tk - tx.v): (tbkn - tx.v).

Where:

- Vbkn is the design capacity of the indirect heating tank;

- P h.v - hourly consumption of hot water supply;

- tk is the temperature of the boiler heating water from the primary external heating source, usually 90 C;

- th.v. — cold water temperature in the pipeline, in summer it is assumed to be 10 C, in winter 5 C;

- t bkn - the temperature of the water heated by the bkn is set by the user from 55 to 65 C.

What material is the container made of?

The container for BKN is usually selected from available materials; it is usually made independently from sheet steel, large pipes, or used liquefied gas cylinders are used.

Sheet steel

In this case, the masters do not have much choice. When choosing a material for a tank, you need to take into account its durability and strength, since it operates in a highly corrosive environment and under pressure.

In the world, the best indirect heating boilers presented by European manufacturers are considered to be devices with glass-ceramic coating. Stainless steel containers, although more durable, are less popular due to their high cost. In addition, there are budget BKN with a protective layer of enamel, but they have the shortest service life.

Coil size calculation

Calculation of the heating area is basic for creating a BNC with the required thermal power. It is determined by the length of the tube in accordance with the formula:

l = Р/n*d*DT

In this formula:

- P is the power of the heat exchanger, taken at the rate of 1.5 kW for every 10 liters of tank volume;

- d is the diameter of the coil, usually 0.01 m;

- n- number pi;

- l is the design length of the coil tube, m;

- DT is the temperature difference at the inlet of 10 C and the outlet of 65 C. As a rule, it is taken as 55 C.

What material is the heat exchanger made of?

To make a BKN water heater in the form of a coil, take a copper/brass tube D from 10 to 20 mm. It is twisted into a spiral and an interturn gap of 2-5 mm is left. The gap is made to ensure compensation for the thermal expansion of the pipe.

With this version of the spiral, good contact of the coolant with the pipe heating surface is formed. In the trading network you can find ready-made copper spirals, which can initially be produced for technological equipment. This is not so important if the dimensions of the coil correspond to the necessary calculations.

DIY manufacturing technology

Before you start making your own boiler, you need to decide on its parameters and characteristics:

- water consumption and tank volume;

- type of coil and calculation of its dimensions;

- the presence of additional devices - heating elements, thermostat.

Based on the answers received, you can choose a container for the storage tank, a material for making the coil, as well as decide on the dimensions and make a sketch of the future boiler.

Volume calculation

To ensure you have enough hot water, you need to be aware of your daily consumption. It is generally accepted that each person permanently living in a house needs 50-80 liters of heated water per day.

This amount will allow you to take a shower or bath, and will also satisfy the need for hot water for laundry, cleaning and washing dishes. Thus, for a family of 3-4 people you will need a boiler with a 200 liter tank.

If water is needed only for household needs, for example, washing hands and dishes, a smaller tank of 50-70 liters is sufficient. You should not unnecessarily choose a tank that is too large - this will increase the heating time of the water and lead to a decrease in the efficiency of the heating system.

Selection and calculation of the coil

The coil in the boiler can be made of a metal pipe in the form of a spiral or snake, or it can be a smaller internal tank.

It is better to make it from a material that has high heat transfer and resistance to corrosion, for example, copper. You can also use a stainless steel pipe, but it is more difficult to bend and give it the desired shape. It is not recommended to use ordinary steel pipes - running water, when heated, will release oxygen bubbles, which will cause rapid corrosion of the metal. The most convenient is a copper tube with a diameter of 10 mm - it bends without using a torch according to a template.

Some craftsmen also use metal-plastic pipes. They are resistant to external and internal corrosion, but they must be used strictly at temperatures below 90 degrees. Any overheating will lead to deformation of pipes, leaks and mixing of water in the circuits. Under certain conditions, this can lead to air pockets and poor circulation.

A pipe coil is wound in the form of a spiral from the calculated number of turns and placed in the lower part of a circular tank. For normal heat transfer, it should not touch the walls. When making a rectangular tank, the heat exchanger is made in the form of a snake and placed near one of the walls.

The dimensions and number of turns of the coil will be determined using the formula:

In this formula:

- P is the thermal power of the coil, which should be 1.5 kW for every 10 liters of tank volume;

- d is the diameter of the pipe used, expressed in meters, we take 0.01 m;

- l is the total length of the pipe, in meters;

- ∆T is the temperature difference before and after heating, usually 65 degrees is taken for preliminary calculation.

For a 200 liter tank with a power of 30 kW the calculation will be as follows:

Having measured the required length of the pipe, you also need to calculate the diameter of the coil. To ensure that the spiral does not touch the walls, it is taken 10-12 cm smaller than the diameter of the storage tank. The calculated values for some tank sizes are given in the table.

| Boiler tank volume, l | Thermal power, kW | Coil length, m | Boiler tank diameter, m | Coil diameter, m | Number of turns |

| 200 | 30 | 15 | 0,5 | 0,4 | 12 |

| 150 | 22,5 | 11 | 0,5 | 0,4 | 9 |

| 100 | 15 | 7,5 | 0,4 | 0,3 | 8 |

| 50 | 7,5 | 4 | 0,4 | 0,3 | 5 |

It is advisable to make the distance between the turns 5-8 cm to improve the heat transfer conditions. In this case, it is important to calculate the total height of the coil so that it does not block the inlet and outlet pipes for heated water.

The heat exchanger in the form of a tank is usually made of the same material as the tank itself, and its dimensions are 1/5-1/8 of the total volume of the boiler.

Heating element, thermostat and other auxiliary devices

One of the disadvantages of an indirect heating boiler is that it can only be used during the heating season. There are two ways to solve this problem:

- install a short closed circuit from the boiler, designed only to heat water in the boiler;

- install a heating element in the tank itself.

The first method is associated with unnecessary consumption of time and fuel - when loaded at partial capacity, the boiler will operate with reduced efficiency, and in the case of using solid fuel - also with the formation of an increased amount of soot and soot. In addition, it will take time to maintain, load and clean it.

Installing a heating element in the boiler tank itself will allow you to use it in the summer as a regular water heater. To reduce energy costs, heating can be done at night at lower tariffs or a solar collector can be connected to the system.

The power of the heating element must correspond to the volume of the tank. On average, for a volume of 50 liters a heating element with an electrical power of 1.5-1.8 kW is required, and for a 200 liter boiler - 5-6 kW. These values can be slightly changed, but it is worth remembering: the higher the power, the shorter the heating time, and vice versa.

When installing a heating element in the boiler tank, be sure to install a thermostat that turns off the heating at a temperature of no more than 90 degrees!

It is also recommended to install a magnesium anode in the tank, which distracts the processes of electrochemical corrosion inside the tank. It gradually dissolves as it does so and may need to be replaced after a few years.

In this article you will find out what is better: buy an electric boiler for a private home or make it yourself. How to choose the right electric boiler for heating a house with an area of 100 square meters, read here

Manufacturing and installation procedure

After carrying out all the necessary calculations and preparing a sketch, you can assemble an indirect heating boiler with your own hands.

- Assembly begins with the preparation of the most important part - the storage tank. You can use any ready-made container made of stainless steel, aluminum or heat-resistant plastic, or weld a tank from sheet metal and pipe scraps of a suitable diameter. The main requirement is sufficient wall thickness and strength of the tank and resistance to corrosion.

- It is enough to simply make a tank from a used gas cylinder. To do this, the top part of the cylinder is cut off, the inner walls are thoroughly cleaned, washed several times and ventilated in fresh air for 3-5 days. Otherwise, the water will smell like gas. After drying, the surface is primed with waterproof paint.

- In the tank, in accordance with the sketch, you need to make several holes: to connect the coil, for the inlet and outlet pipes, as well as for the heating element and thermostat when installing them.

- The pieces of pipe - pipes - are welded, and threads are cut on the outer part to connect the hot water supply circuit and the outlet from the heating circuit.

- Next you need to make a coil according to the calculated dimensions. It is convenient to wind the spiral according to a template, which is used as a pipe of the required diameter, a log or any durable cylindrical object. The winding should be loose enough so that the finished coil can be removed from the mandrel.

- The coil is attached to the nozzles by soldering, checking the tightness of the connections. This can be done using compressor air and soapy water. The pressure during pressure testing must exceed the operating pressure in the heating system by at least 1.5 times.

- If necessary, install a heating element, thermostat and magnesium anode in the tank. Connect a copper cable of the required cross-section to the electrical part - for a heating element of 2 kW - 1.5 mm², for 4 kW - 2.5 mm², for 5 or more - 4 mm².

- Place the tank in the housing, if provided for by the design. Temporary or permanent spacers are installed between the walls of the tank and the housing to maintain the same distance on all sides. Fill the space with insulation, for example, polyurethane foam.

- After the foam has dried, the excess is cut off, the pipes are processed and the housing cover is attached. You can paint it with metal paint in light colors for less heat emission and longer service life.

- Connect the boiler to the heating and hot water system according to the diagram shown.

Making an indirect heating boiler with your own hands is quite simple and inexpensive, and its efficiency and economy will quickly pay for all costs . Hot water with a stable temperature will make life in a country house provide the comfort familiar to city dwellers.

Making a boiler with your own hands

Indirectly heated water heaters can have a wide variety of designs and configurations. The main thing is that they must be carried out precisely according to calculations, using high-quality materials and in accordance with established processing technology, in order to obtain a product capable of operating at high temperatures and under pressure. The production process is divided into several important stages.

Preparing the boiler tank

When choosing a tank design, you need to pay attention to how the coil will be wound into the body. If the housing has a mounting cover, then there will be no problems for the technician with piping the heat exchanger.

In the case where the container is intact, you will need to make the lid yourself by cutting off the top part and securing it to a bolted connection along the entire circumference with preliminary installation of a rubber gasket. The most convenient option for installation is considered to be a design that has two covers - upper and lower.

Next, two holes are drilled on the body for the end sections of the coil. The diameter of the holes must be consistent with the thread diameter of the fittings plus 1-2 mm. The fittings are passed into the technological holes, with the preliminary installation of O-rings.

Next, on the outside of the body, turn the counter fittings and tighten them tightly. This connection gives stability to the coil structure, which is further reinforced by supports inside the housing to prevent vibration and noise during circulation of the heat exchanger.

Nozzles for the inlet/outlet of the heated medium and drainage lines are pressed into the tank body, on which shut-off and safety valves are installed. On the body, determine the insertion location for the dial thermometer.

Manufacturing and processing of coils

Making a heat exchange spiral on your own is not difficult for an experienced craftsman. In this method, the main condition is to produce high-quality winding.

It is advisable to make it from pipes that have good heat transfer and anti-corrosion properties: copper and stainless steel. Although the latter option is difficult to bend and give the desired shape.

Ready coil

Advantageous for these purposes is a copper tube, which bends without preheating with a torch. For winding, use a drum made of the required material with a smaller diameter of the working tank of the water heater by 8-12%. After winding is completed, the turns of the pipes are moved apart from each other by up to 5 mm.

Manufacturing and tying of BKN

First of all, a self-made indirect heating boiler is connected to an external heating source: central heating pipes or to an independent circuit of an autonomous heating boiler unit.

The manufactured spiral is placed inside the housing and tied with the supply coolant. Before closing the housing with a lid, pressurize the heating circuit. To do this, start the coolant circulation by opening the supply and return valves and carefully inspect the coil for leaks.

BKN piping scheme

Next, according to the diagram, the structure is connected to the hot water supply line through shut-off and control valves. According to the diagram, the tank is connected to the cold water supply, the hot water outlet is connected to the in-house hot water pipeline going to the mixers and drainage lines for draining water during repairs and maintenance. A thermometer and a pressure gauge are installed at the outlet of the BPS so that the parameters of the heated water can be monitored.

If the tank has an automatic control and protection system, install primary temperature and pressure sensors to protect the BKN from high heating parameters.

Thermal insulation

In order to reduce heat losses from the BKN and provide it with accumulating thermal properties, external thermal insulation of the structure is performed.

Thermal protection measures are most often carried out before the container is assembled. It is possible to use any heat-protective material, including conventional polyurethane foam, as a heat insulator.

The heat insulator is fixed using assembly adhesive, wire ties or other means. It is of great importance that the housing is completely protected, since the efficiency of the system and how long the tank can store hot water will depend on the quality of the thermal insulation.

Very often in practice, thermal insulation is performed using a second tank of larger diameter, into which a working container is inserted, and the space between them is filled with insulation.

How to make an indirect heating boiler with your own hands - manufacturing procedure

To independently manufacture a large storage tank (tank), independent of energy sources, a tank made of corrosion-resistant materials, as well as a spiral-shaped tube with a circulating coolant, are used.

Boiler in the boiler room

Uniform heating of the water inside the boiler tank is ensured by the movement of the coolant from the heating system, and a high-quality heat-insulating layer contributes to maintaining the temperature regime. Ease of use is due to the installation of special fittings in the form of ball valves.

Do you know why water heater safety valve drips? Let's look at the causes of breakdowns and methods for eliminating them.

We will explain below what a toilet installation is and what it is used for.

The diagram for connecting an instantaneous water heater to the electrical network is described in this publication.

Instructions for the first start-up of the BKN system

After the BKN is completely connected to the coolant and the hot water supply line and pressurized for leaks, proceed to its first start-up:

- Open the taps on the supply and return of the coolant from an external heating source.

- Open the hot water tap on the mixer and release the air until a steady flow of water comes out of the tap, after which the water on the mixer is turned off.

- Set the heating temperature using the thermostat and wait for the water to heat up to the desired temperature or control it using the readings of a dial thermometer.

During the heating process, a thorough external inspection of the structure is once again carried out for density and the thermal insulation qualities of the tank are checked.

During the first start-up, the heating time of the boiler at maximum coolant parameters is monitored, as well as the operation of the automatic control and safety system.