Scope of application of vacuum pumps

Vacuum pumps consume little energy and are small in size. Thanks to them, it is possible to quickly thin out the environment. The devices are used in various industries:

- chemical and oil refining, to maintain appropriate conditions for the reaction and separation of compounds;

- pharmaceutical, to quickly dry products;

- textile, to dry products without increasing the temperature;

- during degassing of metals and other materials, when parts with a homogeneous structure are created;

- food industry - during packaging of fish, meat products, as well as dairy drinks;

- during evacuation of refrigeration and other equipment that has increased criteria for the absence of humidity;

- for optimal operation of automatic conveyor lines, where special suction cups act as grippers;

- in laboratories of production and scientific departments;

- in medicine during the use of breathing apparatus, in dentists' offices;

- in printing, when it is necessary to fix thermal film.

Vacuum system in industry.

Operating principle of vacuum pumps

A vacuum is created when connections are mechanically removed from a closed space. This can be done in different ways.

The operation of a jet-type pump is based on the removal of gas molecules with a steam or water jet, which have a high speed and fly out of the ejector. Additionally, pipes are connected on the sides to create a vacuum.

Operating principle of a vacuum pump.

The advantage of such a mechanism is that it has no moving elements. Cons: low efficiency and mixing of compounds.

The most popular is the mechanical version of the device. In it, the main element is rotating or moves back and forth. In this case, a space is periodically created inside the mechanism, which is filled with a gas mixture from the pipe and then pushed out through the outlet hole. The designs of such pumps may vary.

Scheme of water supply using a vacuum pump.

Water ring vacuum pump. Operating principle of double-acting VVN

A double-acting VVN (Fig. 2) works in the same way as a simple one. The difference is that the axes of the wheel 1 and the body 2, made in the shape of an oval cylinder, coincide. When the wheel rotates, the inner surface of the water ring takes the shape of an oval 3 - and two cavities are obtained. This is why there are two suction 4 and discharge 5 windows.

If you thought that, all other things being equal, the speed of action of this explosive device should be twice as fast as a simple one, then in theory you are, of course, right, but in practice you were wrong. Due to the movement of gas in the dead volume 6 back to the suction and flows through the end gaps, the speed of action increases by only 1.4...1.5 times. But the oval shape of the body complicates the design, which increases the price, and increases the likelihood of a rupture in the flow of rotating fluid. Therefore, this design is rarely used.

Vacuum pumps. Liquid ring vacuum pumps

A plunger vacuum pump is a type of mechanical vacuum pump that is capable of compressing gases to atmospheric pressure. Such a device has a device similar to a double-acting piston compressor. The main difference is that a plunger vacuum pump has a higher compression ratio.

Image 1. Plunger pump.

On the left is the initial stage, 2 positions in the center are the intermediate stage, on the right is the final stage

The plunger includes a cylindrical part that surrounds the eccentric and a hollow rectangular part that moves freely in the hinge groove. When the flat part of the plunger rotates, the hinge also rotates freely in the pump housing seat. This plunger is equipped with a channel through which gas enters the pump chamber from the cavity being pumped out. The entry of a counter flow of gas into the inlet part of the pump is limited by preliminary closing of the inlet when the spool moves. There is also the possibility of reducing waste space. The tightness of the contact between the rotor and the cylinder in pumps is ensured by the fact that a thick layer of oil is formed in the wedge between the rotor and the cylinder.

Mechanical vacuum pumps pump out volume starting from atmospheric pressure. Due to the fact that the pumped gas is released into the atmosphere, relative to mechanical vacuum pumps such characteristics as the highest operating pressure, as well as the highest start-up and release pressure are not used. The key characteristics of mechanical oil seal vacuum pumps are:

- maximum residual pressure;

- speed of action.

Mechanical vacuum pumps

A mechanical vacuum pump is a gas removal unit that is used to obtain/maintain pressure below atmospheric in containers from which the working fluid is pumped out at certain intervals with a certain composition and amount of gas flow.

The operation of such a pumping unit is based on the fact that gas moves as a result of the mechanical movement of the working parts of the pump, thereby performing a pumping action. The volume that is filled with gas is cut off from the inlet and moves to the outlet. The gas is systematically promoted to the outlet of the pumping unit as a result of a momentum impulse that is transmitted to the gas molecules.

In accordance with the design features and method of operation of this type of pump, seven types of pumps are distinguished (screw / diaphragm / piston / rotary vane / spool / roots / scroll). Depending on the type of working fluid, mechanical pumps can be molecular (operate due to the flow of molecules of a substance) and volumetric (operate due to the laminar flow of a substance). Mechanical vacuum pumps are differentiated according to the level of vacuum concentration (high, low, medium). In addition, this type of pump is divided into those that can operate without lubricant and with lubricant.

This type of pumping units is used in a variety of industries: chemistry, metallurgy, electronics, food industry, medicine, astronautics. Mechanical vacuum pumps are also used in a wide variety of industrial installations, as well as in technical processes (for example, metal remelting, thin film deposition, simulation of space conditions, etc.).

Due to the growing need for pumping units, mechanical vacuum pumps are continuously being improved and developed, and pumping units with improved performance are being developed.

The operating speed of such pumps does not depend on the type of gas being pumped out. The residual pressure depends on the design of the pumping unit and the properties of the working fluid. The working fluid is usually oil, which has a list of necessary characteristics:

- low acidity;

- viscosity;

- good lubricating properties;

- low saturated vapor pressure in the pump operating temperature range;

- low absorption of gases and vapors;

- stability of viscosity with temperature changes;

- high strength of a thin (0.05–0.10 mm) oil film, capable of withstanding a pressure difference in the gap equal to atmospheric pressure.

The stability of the characteristics of mechanical vacuum pumps depends on the size of the gaps between the surfaces, the number of these gaps, as well as the quality of the oil lubricating the rubbing surfaces.

The plunger vacuum pump can be equipped with a bypass device to increase efficiency. Bypass devices may differ in design. Their function is to equalize the pressure on both sides of the piston at the end of the piston stroke.

Image 2: Vacuum pump cylinder equipped with bypass ports

In the absence of these channels, the remaining compressed gas from the harmful space expands as the piston moves from left to right. In this case, the remaining compressed gas has a pressure level p2. Curve ea1 up to suction pressure p1 and p1 and λ0=V1/V. In a vacuum pump, when the piston is in the extreme left position, the remaining gas moves into the right cavity of the cylinder, where the pressure is equal to p1. The pressure in the harmful space drops from p2 to pв, and the remaining gas expands along the fa curve. Suction begins at the very beginning of the piston stroke (λ0=(V'1/V)>λ0). A similar process occurs when the piston moves in the opposite direction (from right to left). As a result, the volumetric efficiency increases from 0.8 to 0.9 λ0.

The presence of harmful space is the reason why a piston vacuum pump is not capable of creating an absolute vacuum and has a theoretical limit to this value, which corresponds to a certain residual pressure ppr. The value of ppr in the absence of a bypass is greater than in its presence.

If the vacuum pump operates continuously, then the volume of sucked gas is equal to the volume of process gases emitted into the atmosphere and the volumes that are sucked in from the outside through leaky areas do not change over time. The power indicator on the vacuum pump shaft is also not subject to change. It should be noted that this parameter is several times higher for machines equipped with a bypass, because the expansion work of the bypassed amount of compressed gas is lost.

Advantages of vacuum pumps

Vacuum pumps have many positive characteristics:

- High level of strength;

- Reliability of the design;

- High speed of water pumping;

- Low noise and minor vibrations during operation;

- High starting pressure;

- Environmentally friendly.

High-quality water supply equipment has the simplest and most durable design, which has a positive effect on operating efficiency. It is distinguished by isothermal sealing and is often supplemented with a dirt separator.

Pump classification

Water vacuum pumps can be classified in different ways, for example based on their operating principle. Thus, there are 4 types. If we subdivide depending on the pressure values at which productivity becomes maximum, we can distinguish 3 types of units:

Forevacuum

The units are used for preliminary vacuum. They are used to create favorable conditions for the operation of a high-vacuum pump or to save energy.

- High vacuum

Create a high vacuum.

- Booster

The units create a medium vacuum. They are used to increase the pressure in the water supply system, used for pumping wells, irrigation, fire extinguishing, arranging fountains, irrigation, and other household tasks and production processes. The booster pump is most often found in everyday life.

Separation by operating principle

- Vortex installation. The device has a high suction capacity, but is completely unsuitable for pumping dirty water, since it is overly sensitive to suspended particles. The vacuum in the installation is created during the rotation of the wheel with blades.

- Centrifugal view. The operation of the unit is associated with the creation of centrifugal force. It arises from the action of the wheel blades, creating the required liquid pressure.

- Hand pump. We are talking about the simplest and most budget option, since physical effort is enough for its operation. The device can be vane or piston.

- Vibration type. The main element of this pumping equipment is an electromagnet. It affects the movement of the armature, which is built into it, and the piston. When oscillating, excess liquid is pushed out. The main advantage of the installation is the absence of an electric motor and rotating elements.

The most common varieties

- Piston installations. They do not require oil and are very easy to use.

- Plastic-rotor units. Eco-friendly and silent. They are used for long-term work, because they can function uninterruptedly for a significant period of time.

- Plunger designs. They are distinguished by high speed and reliability.

- Diaphragm equipment. The most reliable type of those listed. Does not require complex care.

Types and types of vacuum pumps - classification

Under normal conditions, creating a vacuum in a vacuum system requires removal of gases contained in atmospheric air from a given vessel or chamber. Thus, high vacuum technology involves a rarefaction of the atmosphere by 15 orders of magnitude (from 103 to 10-12 mbar). The process would be relatively simple and the pump for the vacuum chamber would do an excellent job if the walls of the chamber did not contain adsorbed and dissolved gases. The constant outgassing of occluded and adsorbed gases usually makes constant pumping necessary, even if a high vacuum must be maintained only within the chamber, particularly in the space between the double walls of the thermos. After pumping, the sealed space must contain some means of removing gases, such as reactive metal films.

There are several basic ways to remove air (or other gas) from the vacuum chamber space:

- Gas can be removed by changing the volume of gas using pumps with reciprocating and rotating pistons, rotating blades, gears, cams, meshed augers, volutes, etc.

- Another method is to partially displace the gas or transfer an impulse to it from fast moving surfaces (rotors or turbines), a high-speed jet of steam or a moving liquid (ejector).

These vacuum pumps use mechanical methods to move gas, which is compressed and released into the atmosphere. Therefore, these types of pumps are called gas pumps.

The operation of other types of vacuum pumps listed below is based on physical and chemical methods of creating a vacuum, which is why they are called absorbent:

- A vacuum can also be created by cooling a gas to a temperature at which the gas either becomes a solid or can be adsorbed onto the surface of a special porous material.

- Gas can be removed from the volume through a chemical reaction that produces a solid product.

- Finally, the gas is ionized and removed from the volume either through the action of electromagnetic fields or by introducing gas molecules into the solid surface of the pump due to high speed in a high voltage field.

The word "pump", usually associated with liquids, has only a historical meaning in high vacuum technology. Gas transfer pumps can be called “compressors for creating a vacuum”, and gas absorption pumps can be called “condensers”; there are also gas pumps for vacuum presses.

Fig 1. Classification of modern vacuum pumps.

As a rule, it is not easy to design a single pumping device that would operate effectively under conditions of changes in the density of the medium within 15 orders of magnitude. All pumping devices have pressure or density ranges in which they are characterized by operating efficiency, size, weight, noise level, cost, etc. Typically, two pumps with different operating principles are used to obtain a high vacuum. They can be easily designed as a combination of low and high vacuum pumps. Low-vacuum pumps are used to remove the bulk of the gas from the chamber (gas that was in the space or volume), and high-vacuum pumps are used to maintain a vacuum by removing gas that leaks from surfaces. In general, we can say that these two types of vacuum pumps operate under viscous and molecular flow conditions.

Compared to a conventional compressor, which operates at near-atmospheric pressure, gas flow under high vacuum conditions is characterized by high volume, low mass, high pressure differentials between the pumped volume and the external environment, and low pressure differentials within the vacuum system. Moving the molecular flow creates additional complications. First, under molecular flow conditions the pressure differences are very small (although significant density gradients are usually present). Thus, for example, individual molecules enter the pump not under the influence of reduced pressure, but as a result of their normal thermal movement. Therefore, when molecules bounce off a surface, they are equally likely to move toward or away from the pump. An additional complication with molecular flow pumping is the different behavior of the molecules of the different gases present in the mixture. Due to the absence of collisions between molecules, pumping occurs at different pump speeds and degrees of compression.

The absence of pressure gradients creates lower values of the maximum possible volumetric flow through the orifices. In the viscous regime, the volume flow is almost 2 times higher than the molecular flow (for air at room temperature approximately 20 l/(s cm2) and 11.6 l/(s cm2), respectively). Typically, if the orifice diameter is less than or equal to the average free path length, the volumetric flow can be 11.6 L/(s cm2). Also, under molecular flow conditions, relatively high resistances can exist within a fairly short element of the vacuum system. For example, a conventional elbow can create a 50% reduction in volumetric flow compared to only a few percent reduction in viscous flow. Therefore, the conductivity of the channels of a high-vacuum system plays an important role.

Conductivity is usually measured in liters per second (l/s). However, it would be more correct to measure it in Torr l/s pump performance per Torr pressure drop.

Main types of vacuum pumps

Metal and durable plastic are used to create housings and moving parts. An important point is their resistance to the aggressive environment of pumping substances. Particular attention should be paid to the strength of the structure and high precision of fit of all parts. Taken together, this will create a hermetic contact and direct the flow of molecules in a single direction. Let's look at some types of vacuum pumps and their operating principles.

Water ring

Water is used to create a rarefaction environment. The pump is made in cylindrical form with a rotor located inside, equipped with blades that rotate on an off-center shaft. To start such a unit, it must be filled with liquid.

This vacuum pump has the following operating principle. After starting the engine, the impeller disperses water along the inner walls of the working chamber. A vacuum environment is formed between them. Gas is supplied from the inlet pipe, which is mixed and discharged into the outlet pipe. Such units are often used in gas purification.

The use of liquid provides many advantages:

- water enhances the tightness of the structure, it does not allow gas to flow in the opposite direction;

- it cools and wets the rotating elements, reducing the friction process;

- such units are considered economical and durable;

- It is possible to work with gases in combination with water elements.

Such a pump is often used for pumping gases with water impurities. This is an excellent option for air conditioning and refrigerator.

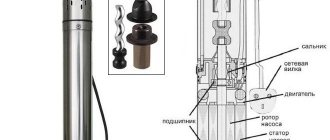

1.1 Design and principle of operation

A liquid ring pump is a cylindrical drum with inlet and outlet holes, around which there is a sealing ring in the form of a gasket (into which, accordingly, unpurified gas enters and then purified gas comes out). Inside it there is a rotor with blades.

Before starting work, the pump is filled with working fluid (in our case, water). The rotor is located slightly away from the center and during its rotation between the water, which is pressed against the walls of the cylinder under the influence of centrifugal force, and the rotor, a rarefied vacuum cavity is formed, resembling a sickle in appearance. This is the working cavity of the device.

Since the rotor blades are located unevenly, they divide the working cavity into parts of unequal volume. Due to the pressure difference, gas passes into the center of the device, is purified using a water-ring mechanism and fills the cells between the rotor blades.

During subsequent movement, these cells are connected to the outlet, where the purified gas exits. Since the rotor rotates continuously, the cleaning process is also continuous, which allows cleaning to be carried out without wasting time and energy resources.

Vacuum liquid ring pumps (VVN) are widely used today in many areas of business. They have a number of advantages, such as:

- reliability;

- efficiency;

- simplicity of design;

- ease of use;

- durability;

- repairs without special costs.

The undoubted advantages of using water ring pumps include simplicity of design and the absence of high-precision parts. In VVN, the only moving part is the rotor with blades; all parts of this liquid ring pump do not come into contact with each other, therefore there is no wear of parts and there is no need for repairs.

Another interesting point is that water-air liquid ring pumps are lubricated with a working fluid and for this reason their repair becomes extremely rare. Also in VVN there are no valves (often in need of replacement), gears (which constantly require lubrication and replacement due to abrasion).

And since the liquid ring pump has water as its working fluid (one of the few inexpensive, publicly available and renewable resources), the only part of the liquid ring pump that needs lubrication is the rotor bearings.

If a liquid ring pump operates with gases that contain a lot of impurities of various solid particles (dust, sand, etc.), then the sealing ring and gaskets may require replacement, as they will be damaged by these solid particles.

It is important to make sure that the o-ring and all seals in the pump are in good condition, because their failure leads to serious problems and the threat of breakdown of the entire mechanism.

All of the above together makes the liquid ring vacuum pump a device that is simple and unpretentious to operate, reliable, economical, and low in cost.

2 Main characteristics

Now let's look at the main properties and parameters that water-air liquid ring pumps demonstrate during operation.

Liquid ring vacuum pumps have the following main characteristics:

- pumping speed varies from 1.1 m3/min to 12 or more m3/min;

- engine power from 4 kW to 40 kW or more;

- dimensions change accordingly;

- weight varies from 25 kg. up to 2000 kg. and more.

Today, liquid ring vacuum pumps are available on the market, both domestic and foreign.

It is worth noting that, due to the simplicity of their design, domestic VVNs are worthy competitors to their foreign counterparts. They are durable and can be used in any economic field. The most popular domestically produced models are: ВВН1-1.5, ВВН2, ВВН1-6, ВВН1-12, ВВН1-25, ВВНЗ.

Vane rotor

These pumps are made in a cylindrical casing with a smooth inner surface and an active rotor. The offset axis allows for different side clearance. The rotor has movable plates that are pressed against the body by springs, due to which the free space is divided into sectors with varying volumes. After starting the engine, gases begin to move, forming a vacuum in the intake pipe and excess pressure at the outlet.

In the manufacture of plates, antifriction materials or special oils with low viscosity are used. Such water pumps are capable of creating a strong vacuum, but they are too sensitive to the quality of the pumped substance. Therefore, they require periodic cleaning, as a result of which they contaminate the water with lubricant fractions.

Diaphragm piston

The driving element of this design is a membrane, moving due to a lever mechanism. It must have sufficient strength to withstand mechanical stress. Along the edges it is securely fixed to the inner walls of the housing, and the central part is attached to the moving rod. Due to this, the volume of space inside the working chamber is constantly changing.

Such vacuum pumps for water work by drawing in and pushing out the pumped substance. By combining the work of two such membranes in antiphase, the pumped substance moves in a given direction. This mechanism has no rotating parts and there is no friction effect.

The advantages of this design include:

- there is no contamination of the pumped substance with lubricant products;

- the tightness of the structure completely eliminates possible leakage;

- has good flow control and is economical;

- long-term operation in dry mode is possible;

- Can be used when working in explosive environments.

It all depends on the strength of the membrane, which is constantly in motion.

Screw

At the heart of such a vacuum water pump is a rotating screw located in the center of the working chamber. When it rotates, water is pushed out.

The structure consists of:

- moving drive;

- one or two rotors;

- stator.

Let's look at how this technique works. Precision fitting of parts prevents changes in the direction of the pumped liquid. Thus, a vacuum is formed at the inlet, and excess pressure is formed at the outlet. The best models in their class.

Design advantages:

- slight noise during operation;

- uniform flow;

- possibility of pumping liquid substances with a mechanical drive.

It is important to control the lubrication of rubbing parts.

Vortex

They are based on the use of centrifugal force. A vacuum pump for pumping out water has a main unit, which is a wheel with blades rotating on a central shaft. The inlet pipe is located on the side of the housing, and not close to the center of the axis.

The small gap between the blades and the body contributes to the efficient direction of fluid movement. This design is characterized by the ability to pump high pressure and the presence of a self-priming effect. It is easy to use, easy to repair, but has low efficiency. The ingress of foreign small fractions will lead to mechanical damage to the blades.

Industrial vacuum pumps, equipment and machinery

Our catalog presents a large selection of gas-displacing vacuum pumps, varying in design, design, power parameters, performance and maximum residual pressure. We offer oil and oil-free dry vacuum pumps to solve any production problem - in the company’s range you will find suitable equipment for working with both clean and contaminated vapor-gas mixtures, including those containing dust, solid particles and droplets.

The following types of equipment are always in stock:

- Water ring vacuum pumps.

- Rotary vane vacuum pumps - one- and two-stage, dry, oil-filled and oil-lubricated.

- Diaphragm vacuum pumps in single and multi-stage versions.

- High performance double rotor Roots vacuum pumps.

- Scroll vacuum pumps.

- Screw vacuum pumps.

- High vacuum turbomolecular pumps, etc.

For industries working with active, aggressive, toxic, high-temperature and explosive environments, devices are offered in chemical-resistant or explosion-proof (ATEX) versions, adapted for use in harsh conditions.

You can also buy equipment from us that operates on the principle of gas absorption - getter, getter-ion, cryogenic and magnetic discharge vacuum pumps. All products are of high quality, have certificates and meet international standards. During production, vacuum pumps undergo mandatory tests.

Vacuum pumps for degassing chambers

The most popular equipment for equipping such equipment is liquid ring compressors. They are tolerant to various contaminants of the working substance. Despite this, vacuum pumps for degassing chambers can be spool, plunger, rotary vane, spiral, sorption and other units. It is necessary to select equipment in accordance with the established requirements for equipping the degassing system.

Note. It is not recommended to use membrane compressors when operating degassing equipment. They get clogged quickly.

Two stage vacuum pump

The equipment body is equipped with metal parts. In view of this, the working substance must be chosen that does not react with them. The two-stage vacuum pump is represented by two types of units: piston and rotary. They are practical, durable and versatile.

Rotary vane and piston compressors are used to create any level of vacuum. They are used in various industries and agriculture: metallurgy, woodworking, pharmaceuticals, medicine, dairy production and other technological processes.

Structurally, the units are represented by a durable housing, inside of which there is a rotating rotor with blades (blades). This is volumetric type equipment. The working space changes depending on the speed of rotation of the rotor or wheel. The latter indicator is based on the power of the engine with which the installation is equipped.

Dry Vacuum Pump

The equipment operates without additional lubrication of parts and components. A dry vacuum pump allows you to create a clean vacuum environment without impurities of oil mixture molecules.

This category of equipment includes the following modifications of compressors:

- spiral;

- rotary;

- screw;

- centrifugal;

- water ring and other installations.

They are used to pump various substances: liquid, steam, gas and air. The equipment is able to work stably with aggressive agents. The technique became most widespread in the metallurgical industry. With its help, new film coatings are developed, tests are carried out, and heat treatment of raw materials and finished products is carried out.

Oil-free vacuum pump

A similar unit as the previous one. An oil-free vacuum pump is a compressor that runs dry. That is, without lubricating parts and components of the structure. There are different types of equipment, which allows you to choose the necessary installation to complete the assigned tasks.

How to choose?

When choosing a vacuum pump for a water well, you should pay attention to the following characteristics:

- Maximum and minimum pressure level;

- Indicator of outlet pressure at the outlet section;

- Water pumping speed.

In addition, you need to consider:

- Manufacturer;

- Life time;

- Duration of warranty;

- Materials and product quality;

- Reviews.

Criteria for choosing the right pump

Vacuum pumps have a wide variety of different options for pumping liquid or gaseous media, which allows you to choose the most suitable model for your needs. Such a pump is useful for draining a basement or swimming pool, for irrigating greenhouses and plantings in your garden. When choosing a pump for domestic needs, pay attention to low vibration levels, maximum starting pressure, reliable design and build quality. Study not only the manufacturer’s technical documentation, but also reviews from direct users who have tested the equipment in real life.

Popular manufacturers

There are many manufacturers of such pumps. One of the most popular is Vakuummash. It produces devices of the dry mechanical type, with oil seals, water-ring, water-steam, etc.

The manufacturer ERSTEVAK produces devices that generate 1 mbar pressure. The company creates water ring, vortex and vane-rotor mechanisms.

The manufacturer BUSCH produces oil and dry devices with different performance and functionality. The product range includes diffuse, turbomolecular, vortex, liquid-ring, vane-rotor mechanisms.

How does a vacuum pump work for pumping out water?

Water vacuum pumps, which belong to special pumping equipment, can be equally successfully used for pumping water, a gaseous medium, as well as gas mixed with liquid. Such equipment is actively used both in various industries and in everyday life (in particular, autonomous water supply and irrigation systems are equipped with such devices; they are used for pumping water from various reservoirs and transporting it to the point of consumption).

Operating principle of a water vacuum pump

The principle on which a vacuum pump for water works is as follows.

- The water in the working chamber is captured by the impeller blades and also begins to move.

- As a result of the rotation of the wheel blades together with the liquid, a centrifugal force is exerted on the latter, which leads to the repulsion of the liquid towards the walls of the working chamber.

- As a result of the processes described above, a vacuum of air is created in the central part of the working chamber (and in fact a vacuum, since the body of the device is reliably sealed). The gas or liquid pumped out medium is drawn into this area of the working chamber.

The degree of tightness of the working chamber of a vacuum pump for water can be adjusted, which allows you to reduce or increase the pressure of the pumped medium in the pressure line.

Externally, a vacuum water pump is similar to a conventional centrifugal type device

Vacuum pumps for pumping water, as you can see, are not much different in design and principle of operation from centrifugal-type pumping devices. Meanwhile, such devices have a number of significant advantages.

- The structural elements of the equipment have high strength and, accordingly, higher reliability.

- During operation, the device creates a low level of noise and vibration.

- Pumping and supply of water occurs at high speed.

- The substance pumped out by such a device (liquid, gas, liquid mixed with gas) is supplied to a pressure line with a higher productivity.

- Due to exceptionally high-quality sealing, an isothermal environment is formed in the working chamber of such a pump.

Modern vacuum pumps of this type are often equipped with a built-in dirt separator, which prevents solids contained in the pumped medium from entering the internal chamber.

Domestic vacuum pumps

The equipment was first used in industry in the 20th century. At that time, it consisted of simple systems with the help of which water was pumped or tests were carried out. Modern domestic vacuum pumps are modernized designs that are used in various industries and agriculture.

Popular models of equipment are NVR, VVN and AVZ units. Some equipment models are no longer produced. Their analogues are newer modifications of installations, which are not inferior to their predecessors in power and performance.

Vacuum pumps NVR

The units are used for pumping non-aggressive substances, gas and air masses from sealed containers of any size. NBP vacuum pumps are rotary vane compressors. The operating principle of the equipment is similar to a water ring installation.

The NVR pump consists of the following parts:

- housings;

- electric motor;

- filters and seals;

- sensors;

- couplings and half-couplings;

- housing covers;

- cylinder;

- rotor with plates.

The liquid that is pumped during equipment operation must be cleaned of various aggressive impurities and contaminants. It is not recommended to use equipment for working with explosive and fire hazardous substances. Varieties of unit models: NVR, 2NVR, 3NVR. They, in turn, are classified into other types of highly specialized installations.

Vacuum pumps VVN

Liquid ring compressors are in demand in various industries. VVN vacuum pumps belong to the category of positive displacement units. Water is used as the working fluid. It must first be cleaned of various impurities and contaminants.

Explanation:

B – vacuum;

B – water ring;

N – pump.

Another name for the equipment is VZHN (vacuum liquid ring pump).

The equipment is equipped with a durable casing, inside of which there is an impeller with blades. The latter elements affect the change in the volume of the internal space, since when the equipment is started, they begin to rotate along with the wheel.

The installation has a hollow shaft on which partitions are installed. It is also equipped with inlet and outlet pipes, channels for supplying and discharging working fluid. The unit operates using electrical energy. It is started by an electric motor.

The operating principle of the equipment is quite simple. Water fills the workspace. When the wheel with blades rotates, it is pressed against the inner walls of the chamber. The workspace is divided into areas of varying volumes. As a result, suction occurs. Once the areas are connected, injection occurs.

Vacuum pump repair

Repairing a vacuum pump is a complex technological process that requires a specialist to have the necessary qualifications and experience. It should be noted that devices of this type are characterized by high service life and reliability. However, in order to avoid unexpected failures and breakdowns, scheduled preventive inspections of the unit and replacement of worn parts are required.

There are many reasons why a unit may fail, for example, aggressiveness of the environment, wear of parts, intensity of use, but, thanks to the simple design of the unit, it is often possible to repair the vacuum pump with your own hands.

Common types of faults

Despite the reliability and high service life of the vacuum unit, like any other equipment, such a pump requires attention, namely, carrying out preventive inspections and promptly replacing worn parts. The most vulnerable components of the design are seals, hoses and membranes, so special attention should be paid to these parts. The pump housing can last for many years without defects.

The most common vacuum pump malfunctions are:

- mechanical wear of elastic parts such as oil seals and membranes;

- the device does not turn off;

- uneven intensity of fluid flow;

- spontaneous activation of the pump;

- The unit fails due to lack of oil.

Mechanical wear of parts

Intensive use of the pump at extreme conditions, aging of polymers, and natural abrasion of consumables leads to mechanical wear of parts, which leads to failure of the vacuum pump.

Vacuum pump membrane location.

Most manufacturers of pumping equipment supply special repair kits with the unit, which allow you to fix the breakdown in the shortest possible time and are also versatile. For example, in the automotive industry, a repair kit for the T4 model vacuum pump is widely used, which has become popular among motorists due to its good price-quality ratio and reliability. The kit includes pump valves, a diaphragm and various fasteners. These are the parts that are most susceptible to wear during operation of the device, but some repair kits also include a pump.

Problems with turning the unit on and off

If the pump turns on spontaneously, the following conclusions can be drawn:

- The pressure sensor is faulty - in this case it needs to be replaced; this element cannot be repaired;

- when the equipment operates, an air mass is captured - a thorough inspection of the system for leaks is required, as well as checking the liquid level where it is taken in;

- lack of pressure in the tank - information about the current pressure is displayed on the pressure gauge, which is included in the product;

- The rubber membrane needs to be replaced. You can determine the malfunction by pressing the nipple in the rear compartment of the tank - if liquid comes out, the membrane is faulty.

These equipment malfunctions also cause uneven fluid flow.

What does the working membrane look like and when it is worn out?

Poor quality of the pumped liquid or an unadjusted relay can cause a problem with turning off the pump: a faulty product can pump liquid without even reducing performance, but will not turn off when required.

If we are talking about the water supply system at home, then the reason may be the oversaturation of the water with calcined salts, and when operating a car vacuum pump, it may be the presence of foreign fractions that clog the hole of the control relay. If even cleaning the relay hole and adjusting it does not solve the problem, then you should contact professionals to conduct a thorough diagnosis and repair of the pump.

Also common is the problem of turning on pumping equipment due to incorrect power supply or contamination of the sensor contact. In the first case, if there are problems with the power supply to the pump, you should transfer the solution to the problem to specialized specialists, and in the second case, you can clean the contact yourself. A malfunction of the electric motor is also the cause of problems with turning on the product; this malfunction is easily identified by a characteristic burning smell. Unfortunately, the engine cannot be repaired in most cases, which means it will need to be replaced.

Damage to the vacuum pump due to lack of lubricating oil

The wear rate of the pump is greatly influenced by the quality of the oil and the oil supply. Therefore, lack of oil supply and poor quality of lubricating oil is one of the most common causes of unit failure. This is explained by the fact that if there is a lack of oil in the system, a leak may occur, as a result of which the required vacuum is not achieved. Old and used oil contains many contaminants, leading to premature wear of the vacuum pump. For a more detailed introduction to the topic, below is a video about the importance of oil in the pump system.

Repair of rotary vane vacuum pumps

Work with a sealed space is ensured by units of a vane-rotor design; they are classified into models using an oil seal and a dry type device. Oil-filled vacuum pumps require frequent maintenance, including regular replacement of the lubricating oil, oil mist filter, bearings, seal and rotor vanes.

Dry-type devices operate without lubricating oil, since the pump working plates are made of anti-friction materials, which reduces the frequency of replacing parts to two years of operation.

A typical problem for rotary vane pumps is contaminated or oxidized oil that has reached the end of its life, which causes a deterioration in its lubricating properties. The power of the installation is negatively affected by the presence of water in the oil, since this leads to the formation of steam during pumping. The use of silicone oils allows you to reduce oxidation processes during operation.

As a general rule, a rotary vane vacuum pump should be serviced every 3000 hours, including changing the lubricating oil. The working blades must be checked for defects, such as cracks, and, in case of significant wear, they must be replaced.

Typical malfunctions of a device of this class largely coincide with those common for vacuum pumps described above, but they also have their own characteristics:

- The presence of strong noise during operation;

- Jamming of mechanism parts;

- Excessive heat during operation

Rotary vane vacuum pump.

Jamming of device parts is possible when foreign particles penetrate inside, as well as corrosion processes from condensate sedimentation.

The reasons for the increase in operating noise include reduced engine power, defects in plates, bearings, and also in the case of using the wrong type of oil.

Overheating of the unit occurs due to poor ventilation, blockage in the air intake device, as well as valves or filters, or low lubricating oil level. In addition, high ambient temperatures lead to faster overheating of the pump.

It should be noted that, in order to avoid complete failure of the device, it is better to entrust the repair of a complex technical device to professionals.

Repair of liquid ring vacuum pumps

A distinctive feature of water ring vacuum pumps is the simplicity and reliability of their design, which is based on the principle of discharging the air and gas environment using a water ring. The design has no rubbing parts, which in turn provides good noise and vibration characteristics, and also significantly reduces the overall wear of parts. In pumps of this type, the main working parts do not come into contact with the casing. Also, these devices are less susceptible to the ingress of abrasive particles and provide high durability of the components.

Despite all the advantages of this type of units, they are also subject to various malfunctions and malfunctions:

- Leakage of working fluid;

- Violations in vacuum formation;

- Increased noise and vibration impacts during operation of the vacuum pump.

Malfunction of the product may be due to insufficient water in the pump chamber. The solution to this problem may be to restore the required water level necessary for normal operation. Also, contamination of the working mechanisms can be an obstacle to the operation of the vacuum pump. This problem can be eliminated either by blowing out the system with compressed air or by disassembling and directly cleaning each unit.

Insufficient vacuum formation can be caused by wear of the sealing rings, as a result of which the air mixture enters the working chamber of the pump. To solve this problem, you need to check the fastening of the seals or replace the seals.

More serious repairs of this type of units should be carried out by highly qualified specialists.

Recommendations for maintenance and repair

- First of all, before diagnosing and troubleshooting the vacuum pump, you must completely turn off the system and lift the pump out of the water. The tightness of the device and its pipelines is checked, as well as the proper functioning of the check valve.

- Secondly, you should inspect the joints of the structure for foreign objects such as leaves, soil, sand, and so on. Foreign bodies may cause the check valve to malfunction.

- The pipeline located between the pump and the water source is checked. If there is no water, the unit must be turned off, and the pipeline must also be filled with water, using a special hole for filling the housing with water.

- If the pump is used to supply water to a house from a well, then you should check the presence of water in the well. When the water level drops, the hose of the device must be lowered deeper, taking into account that the distance from the surface of the water to the pump should not exceed the distance specified by the manufacturer. The water level in the well must be monitored regularly.

- Often the pump fails due to the abrasiveness of the liquid. The abrasive forms a gap between the pump housing and the impeller, so it is recommended to take water samples from the source and, if increased abrasiveness is detected, install a filter and other special means that reduce the abrasiveness of the water.

- Another common cause of vacuum pump failure is a voltage drop or surge in the electrical network. If such phenomena are detected, it is necessary to use special equipment capable of maintaining the required voltage in the network.

Selection and design of vacuum pumps for air conditioners

A vacuum pump for air conditioners is needed to remove air, debris, water, and dust from the air conditioning system. Without this, stable operation of the system and its long service life are impossible. There are several types of such equipment. Which vacuum pump is best for air conditioning? One that matches its characteristics.

In the photo: standard vacuum pump for household air conditioners

How to choose and which one is better

The model of air conditioner determines which vacuum pump is needed. For example, if the equipment is for home use, the air conditioner has a small route, you can safely purchase a pump whose performance is low. For industrial use, the pump must be more powerful and efficient.

Do you have a hood in your kitchen? Read how to choose the right carbon filter for it: https://ventilsystem.ru/vytyazhka/elementy-vytyazhki/filtr/ugolnyj.html

Types of vacuum pumps for refilling air conditioners

- Rotary vane vacuum pump. There are 4 varieties of this unit: VE, Vi (220 Volt network required), VRD, HBP (380 Volt network). Their productivity is maximum 63 liters per second. 0.5 Pa - maximum residual pressure.

- Water ring vacuum pump for pumping air out of an air conditioner. 2 varieties: BBH and HBB. These pumps require water to operate. They create a shallow vacuum, but are inexpensive and last a long time.

- Diaphragm vacuum pump HBM. Require periodic replacement of valves and membranes. Provides a shallow vacuum. Used in industry.

- Spool vacuum pump ABZ. Heavy, bulky, expensive to produce. Vacuum is deep, 0.05 mm.

- Vacuum pump with oil seal. 3 varieties: BHA, RA and VSV. The pump has a separate oil tank, from where oil is supplied to the chamber in portions, and a filter.

VVN - water ring vacuum pump

Two stage

Rotary vane vacuum pumps can be 1-stage or 2-stage. In two-stage, the ultimate vacuum is 99.5 percent (23 millimeters of mercury), in single-stage - 95 percent (53 millimeters of mercury).

Vacuum pump for air conditioners Ve115n

Taiwanese 1-stage vacuum degasser. Its productivity is 51 liters per minute. Ultimate vacuum - 150 micrometers.

Pump VALUE VE 115N, intended for home use

Vacuum pump device for air conditioners

The design of the vacuum cleaner depends on its type. Let's look at how the BBH vacuum pump works. Its design is horizontal, the gas is directed along the axis through windows (suction and discharge). The liquid ring is needed to compress the gas. The paddle wheel sets the ring in motion. The pump has a shaft, bracket and disc.

The vacuum dehumidifier body is cast iron, it has 2 cavities: one for suction, the other for discharge. Both of them are connected to the working cavity. There is a hole in the lid for supplying water. An overview of the types of grease filters for kitchen hoods is on our website.

The tightness of the connection between the housing and the lid is ensured by a rubber ring. The bronze disk is keyed to the shaft. The disk moves freely on it. The bracket is needed as a support for the mechanical part of the vacuumizer.

Diagram of one type of vacuum pump

How to use

The air conditioning system includes 2 blocks: a compressor with a condenser (external unit) and a turbine with an evaporator (internal unit). The sections of the system are connected by a pipe with refrigerant circulating through it.

Evacuation of the air conditioner is carried out when the air duct is assembled and all equipment is connected. Air is pumped out of the system by a vacuum pump for air conditioners (vacuumizer), which is connected to the pipe of the external unit. The ventilation system of the bathroom and toilet may be common. How? Read here.

Step by step about the procedure:

- A manifold with a vacuum gauge is connected to the filling pipe.

- With the valves on the mixer open and normal atmospheric pressure reading on the vacuum gauge, a vacuum pump is connected to the manifold.

- The pump pumps air out of the system until the pressure gauge reads 0. The ballast valve on the vacuum pump must be open.

- After evacuation, the pump is not disconnected from the system for several hours: nitrogen is pumped into it. The pressure should rise to 1. Nitrogen binds the remaining water vapor in the system. After filling the system with gas, leave it alone for an hour.

- The arrow rises without approaching 1 - steam has not been removed from the system, and the pump must be turned on again. The vacuum gauge needle frozen at position 0 for 20 minutes indicates effective pumping of air from the air conditioner.

Refilling the air conditioner without a vacuum pump

The external unit of the air conditioner may contain more freon (50 grams) than is needed for the air conditioner to operate. In this case, manufacturers provide for the first start-up of the system without using a vacuum pump. To displace air, open the valve located on the liquid pipe for 10 seconds.

The process of refilling the air conditioner with freon in the photo

Then check the tightness of the areas with nuts and again unscrew the valve with a wrench, opening the service port. Use the key to press the port rod for 3 seconds and wait for a minute. The procedure is repeated three times. Next, the service port is closed and air is released from the valve on the gas pipe.

If the pipes are no longer than 5 meters, all the air from them is displaced as a result of these actions. Plugs are placed on the valves.

How to connect an air conditioner without a vacuum pump

If the instructions do not say about additional grams of refrigerant for the first start-up of the system, it is not recommended to install the air conditioner without vacuuming. The connection of equipment in this case cannot be called high-quality.

The cooling effect of the refrigerant reduces air and moisture. It is impossible to completely remove them from the system without a vacuum pump, without releasing the freon necessary for the operation of the air conditioner. Are you interested in the types of ventilation systems? Read our article about heated air supply ventilation.

Cost of a vacuum pump for air conditioners

The cost of the pump is determined by the characteristics of the air conditioner (the purpose of its use, how often vacuuming is required, how deep it should be, etc.). The minimum price is 2.5 thousand rubles. Maximum - 15 thousand rubles.

Where to buy a vacuum pump for air conditioners?

In Moscow:

- “Artholod”, address: Maly Kupavensky proezd, 3, tel.: (499) 755-9566.

- “Nika-holod”, address: st. Stakhanovskaya, 24/32, tel.: 8-499-270-07-28

- Gebr. Becker GmbH, address: st. Trofimova, 33, tel.: (495) 647-49-05.

- "Bush Vacuum Russia", address: st. Kotlyakovskaya, 6, building 9, tel.: +7-495-6486726, +7-495-6486724.

- “Ampika”, address: SEAD, Ryazansky Prospekt metro station, st. 3rd Institutskaya, 15, right porch from the street, tel.: (495) 744-00-15.

In St. Petersburg:

- , address: st. Bela Kuna Building 30, Business Center "Sofia Square", office 301, tel.,.

- “Smart Electronics”, address: st. Poltavskaya, 7A, office 29

- “Cryosystems-SZ, address: st. Serdobolskaya, 65a, office. 517, tel..

- "Olmax", address: st. Professora Kachalova, 3, Lit.V, tel.: 8 (812) 412-30-44,.

Read about the types of check valves in ventilation by following the link.

When choosing a vacuum pump, be guided by the following indicators: its performance (i.e. the speed of air removal from the air conditioner), motor power (it can be determined by how long the engine has been running without stopping) and residual pressure (the lower it is, the better the vacuum process).

Jul 30, 2015ventsyst