Chainsaw engine malfunctions

The engine is the main component of the chainsaw, and most of the breakdowns that occur in it are associated with the gasoline drive. Correct diagnostics can determine the causes and troubleshooting methods even for an untrained user.

The main problems with starting the engine may be the following:

- the engine does not start;

- works unsteadily;

- startup occurs, after which the unit immediately stalls;

- stalls under load.

Ignition system malfunctions

First of all, the reason that the chainsaw does not start must be looked for in the ignition system of the unit. You need to start by checking the spark plug, since there is a possibility that the spark has disappeared.

By the state of the unscrewed spark plug, you can determine how the fuel system works. The spark plug is unscrewed with a special key.

The following figure shows 3 possible spark plug conditions.

A spark plug splashed with fuel indicates an excess of fuel in the cylinder. If the spark plug is flooded, then most likely the carburetor is incorrectly adjusted, or the rules for starting the engine were violated. The candle must be thoroughly wiped and dried. You should also drain the combustion chamber:

- shut off the fuel supply;

- With the spark plug unscrewed, pull the starter several times to remove all gasoline from the cylinder:

- Reinstall the spark plug and adjust the carburetor according to the instructions.

A large amount of soot on the spark plug is caused by an incorrect ratio between oil and gasoline during preparation of the fuel mixture, as well as problems in the fuel supply system. If the mixture is prepared correctly, using high-quality oil, then the carburetor should be adjusted. A spark plug with carbon must be cleaned by rinsing it in gasoline. After that, you need to wipe it dry, remove any remaining burnt residue with a needle, and clean the electrodes with fine sandpaper.

You should also check the spark plug for the correct gap between the electrodes. Normally, the spark plug gap should be in the range from 0.5 to 0.65 mm.

If the spark plug is dry, you need to check for a spark at its electrodes to rule out a malfunction of the ignition system.

- Place the cap with the high-voltage cable on the spark plug.

- Holding the cap, attach the spark plug threads to the cylinder.

- Pull the starter handle several times and see if a spark jumps between the electrodes. Normally, the spark should be bright. A weak spark indicates a possible problem with the ignition coil or the spark plug itself.

If there is a spark, then the problem needs to be looked for in the fuel system. There is no spark - the reason may lie in the spark plug itself (needs to be replaced) or the ignition system. The absence of a spark may cause a damaged cable, which should be checked by “ringing” the tester. If the wire is in good condition, you need to move on - check the ignition module. A malfunction of the ignition coil or an incorrectly set gap between it and the magnet can also cause the spark to disappear.

Ignition on a chainsaw is simple: a permanent magnet is attached to the motor shaft. A coil is fixed near it under a certain gap. When the magnet rotates, an electric current is generated in the coil, which is supplied to the electrodes of the spark plug. In the next photo the arrow shows where the correct gap between the coil and the magnet is set.

The gap between these parts should be 0.2-0.4 mm. The walls of a regular plastic bottle have this thickness, and you can make a template (probe) from it by cutting off a small strip.

The gap is set as follows:

- unscrew the screws holding the coil;

- place a template between the magnet and the coil;

- lightly press the coil against the magnet;

- tighten the coil mounting screws and remove the template.

Fuel system malfunctions

If the chainsaw does not start well, and everything is in order with the ignition system, then it is necessary to check the entire fuel system of the unit. First of all, you need to adjust the supply of the fuel mixture to the engine cylinder through the carburetor by setting it correctly.

Next, you need to observe how the chainsaw behaves.

- The device stalls after starting. If you prepare the fuel mixture incorrectly, adding more oil to it than required, the unit will immediately stall or run only on suction.

- The engine stalls at idle. This is a sign of a muffler clogged with carbon deposits (needs to remove carbon deposits), a clogged air filter (needs to be washed), or incorrect carburetor settings.

- The unit stalls at maximum speed. The fuel or air filter is dirty and needs to be cleaned thoroughly. Often this engine behavior can be caused by a clogged gas tank breather. It is cleaned with a regular needle. In addition, a malfunction of the membrane, which acts as a fuel pump, may also prevent the engine from reaching maximum speed. You will need to disassemble the carburetor and replace the membrane if it has lost elasticity.

- The chainsaw stops working under load. This is a sign of improper carburetor adjustment, improperly prepared mixture, or a dirty air filter.

- Fuel pumping does not work. If the primer does not pump gasoline, and this happens most often after a long break in the operation of the unit, then you need to check the carburetor. What the primer looks like and where it is located on a Husqvarna chainsaw is shown in the following photo.

There is a spray valve inside the carburetor that can stick if fuel is left around it for a long time. To eliminate the malfunction, you need to thoroughly rinse the carburetor with gasoline or flushing fluid, and then blow out all the holes with compressed air. - The chainsaw does not start when hot. If you turn off the chainsaw and after a short period of time unsuccessfully try to start it, then in most cases this is caused by a loss of compression in the piston group.

Compression is checked with a compression gauge, which is screwed into the cylinder instead of a spark plug. Next, you need to pull the starter and observe the instrument readings. Normally, a new chainsaw shows compression ranging from 8 to 12 atmospheres. If the reading is below 8 atmospheres, the engine will not work.

Compression may be lost due to scratches on the inside of the cylinder and the side surface of the piston. In this case, you will have to change the entire piston group.

The chainsaw starts and stalls - the reason

If the chainsaw starts and stalls during the first attempts to do the job, then the reason may be problems with the chain brake or its jamming due to lack of lubrication. In this case, measure the oil level. If the amount of lubricant is sufficient, then the reason may lie in the tube that leads it to the lubrication mechanism.

Another reason could be a carburetor failure. If it only needs adjustment, you can do it yourself according to the instructions. If the carburetor needs cleaning or repair, then you cannot do without the help of professionals.

Another possible cause of this malfunction is a low fuel level in the tank. In this case, the chain saw stalls when tilted, since the remainder of the fuel mixture ends up in the part of the tank opposite to the place where the suction tube is located.

Read more: Satellite dish for car

Chainsaw chain problems

In addition to problems with the engine, the chainsaw may experience operational problems due to a malfunction of the cutting (sawing) unit, consisting of an oil pump, bar and saw chain.

There is no oil getting to the tire

Usually, if oil does not flow to the chainsaw chain, you need to check the channels through which oil is supplied to the tire and clean them of dirt. If the previous steps did not reveal the cause of the problem, then you will have to check the oil pump. To do this you need:

- remove part of the chainsaw casing;

- remove the coupling;

- unscrew the 3 screws and remove the cover hiding the pump;

- get to the worm gear gear that rotates the pump shaft.

If the thread on it is worn out, the shaft does not rotate, the pump does not work, and the chain is not lubricated. A worn gear needs to be replaced. You can also remove the oil pump itself and manually try to pump oil through it. If it does not pump, the pump should be replaced.

Chainsaw oil filter

Be sure to remove the oil filter from the reservoir and clean it if necessary.

Also, a lack of lubricant may be due to its leakage. You should check how tightly the pipes coming from the oil pump are connected. If the tightness is broken, the tubes are replaced with new ones.

The chain breaks

If the chain breaks while the chainsaw is running, this could happen when it hits a hard object, such as a nail. If the chain constantly breaks, then the reasons may be the following.

- Low quality of the metal from which the saw chain is made. It is necessary to buy gas cutter saws from reputable brands.

- Chain overheating due to poor lubrication. As a result, the saw overheats, the properties of the metal change, and it breaks under load. It is necessary to check the entire chainsaw lubrication system (discussed above).

You can also learn about the reasons for frequent circuit breaks from this video.

The chain doesn't turn

This nuisance often plagues inexperienced chainsaw owners. They forget to remove the brake after starting the engine. As a result, the chain does not spin, the brake system overheats, and the clutch mechanism fails. The problem is solved by removing the saw from the brake. If the clutch is not burnt out, you will notice the chain turning. Otherwise, the clutch mechanism will need to be replaced.

The chain gets dull quickly

Basically, the reason that the chain becomes dull quickly is the poor quality of the saw. Trying to save money on buying branded chains, chainsaw owners buy saws from unknown manufacturers, or, due to inexperience, purchase counterfeits of well-known brands. It is best to buy a cutting element for a gas cutter in company stores. Stihl saw chains are very popular among owners of this equipment.

The chain doesn't stop

If, when working with a chainsaw, you notice that the saw chain does not stop at the right moment, then this breakdown may have 2 options.

- The brake band is dirty. When operating the saw, dirt, sawdust, dust, etc. may get under the band. As a result, the brake mechanism becomes blocked and the chain does not stop when the gas is released. The problem is eliminated by cleaning this unit.

- The brake band is worn out. This element of the brake system needs to be replaced.

The chain is jammed

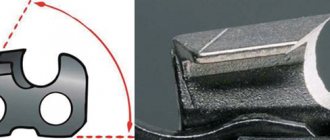

This happens when the drive or driven sprocket wears out. The chain usually starts to jam under load. But without load the saw can rotate. The photo below shows a worn chainsaw drive sprocket.

The next photo shows that the reason why the chain jams must be looked for at the location of the driven sprocket.

But what to do if the chainsaw is completely jammed, and all attempts to pull the starter are unsuccessful? This malfunction sometimes occurs on Chinese-made chainsaws. It is caused by the bolts that screw the engine to the plastic casing of the unit becoming loose due to vibration. These bolts are located directly under the flywheel (magneto). In the photo below, arrows show the location of the problem bolts.

As they unscrew, they begin to rub against the flywheel and can completely jam the chainsaw. The following photo shows the flywheel with some scuff marks from the bolts.

To fix the problem, you will need to remove the flywheel from the engine shaft and tighten the bolts.

The chainsaw cuts crookedly

This problem can occur if the chain is dull or improperly sharpened. This applies to a greater extent to new chainsaws. But if the tire is worn out, then even after replacing the chain you will notice that the saw is pulled to the side. Tire wear can be easily determined by placing it on a level table and applying a square to it, as shown in the following photo.

In this case, you can see that there is a gap of about 2 mm between the tire and the corner. It is because of this one-sided tire wear that the chainsaw cuts crookedly. The problem can only be solved by replacing the tire with a new one.

Important: to extend the life of the chainsaw bar, it must be removed and turned over from time to time. Thanks to this, the tire will wear more evenly and will not cause chain misalignment.

What to do if the chainsaw stalls when you press the gas

In addition, this malfunction may be associated with a defect in the fuel tank breather. Due to the formation of a vacuum in the fuel tank during the operation of the chain saw, the required volume of the fuel mixture does not enter the engine, as a result of which it cannot gain speed or stalls. If you stop the chainsaw, open and close the fuel tank and turn it on again, it will work normally for about five minutes, and then again stop picking up speed or stall.

Read more: Replacing the low beam bulb on a gazelle

Another possible reason that the chain saw is not able to gain speed may be excess carbon deposits in the muffler, which makes it difficult for exhaust gases to escape, which reduces engine power and speed.

Add a comment Cancel reply

You must be logged in to post a comment.

Home page » Chainsaw Heats Up and Stalls Reasons

Why is oil leaking?

Many owners of chainsaws are faced with the problem of oil leaking from under the unit. Most often, oil leaks due to damage to the oil hose connected to the oil pump. The photo below shows exactly the case when the end of the hose has torn and does not fit tightly onto the pump nozzle.

But to get to this place, you will need to remove the clutch mechanism from the shaft. In some models of chainsaws, oil may leak out at the junction of the oil pump with the oil tank hose (indicated by an arrow in the photo).

To eliminate the lubricant leak, you will need to pull this hose out of the seat. To do this, you can use pliers to pull the outer part. At the end of the hose you will see a rubber plug, which is the cause of oil leakage. This plug needs to be wiped well to remove any remaining oil, after which its seat needs to be sealed with something. You can use automotive sealant or fum tape, as shown in the following photo.

Next, insert the hose into the hole, install the plug in place and seal it using a flathead screwdriver. At this point, the operation to eliminate the oil leak can be considered completed.