You inserted the paper, placed the original, pressed the green button, and the photocopier made an exact copy for you. That's just how simple it works. However, if you look inside, everything turns out to be much more complicated. A copier is a rather complex digital device that understands the user and knows what they want from him. He has his own “brain” with built-in algorithms.

The principle of operation of a copier can be described as follows:

- Charger . At this stage, the rotating drum is charged (a negative charge is transferred to it);

- Overexposure . At this stage, the drum passes under the laser beam. The beam “draws” an image on the drum, which must be applied to the paper in the future. Under the action of the laser, certain areas of the drum lose their negative charge and it turns out that the entire surface of the drum has a negative charge except for those areas that were highlighted by the laser (these will be letters or pictures on paper).

- Applying toner . Here a prototype image is formed on the drum using toner. It (the toner) is attracted to the surface of the drum under the influence of a magnet and sticks only to those areas of the drum that were previously illuminated by the laser.

- Transferring toner to paper . The drum continues to rotate with the toner already applied to it. It is in contact with the paper on one side, and on the other side the paper is in contact with the transfer roller, which has a positive charge. As a result, the toner particles on the drum are transferred to the paper and an image (or text) is created on the paper.

- Fixing the toner . The toner simply falls onto the paper, and at this stage it needs to be fixed. This is done using heat. The paper with the “spread” toner moves further, where it passes through 2 contacting shafts. The lower shaft presses the paper against the upper one, and the upper one heats it up to 180 degrees. As a result of this heating, the toner melts and literally sticks to the paper.

- Cleaning the drum . The penultimate stage of the copier operation, at which the drum is cleaned of any toner remaining on it. Cleaning is performed using a special cleaning blade - it removes the toner and directs it to the waste bin.

- Erasing the prototype image from the drum . After printing, a prototype of the laser-etched image remains on the drum and must be erased. At this stage, the charging roller simply coats the surface of the drum with a negative charge.

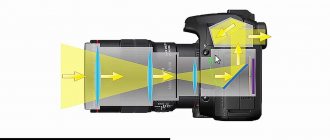

Schematically, the principle of operation of a copier looks like this:

- information is read from the original;

- information is transferred to the copy like an electric charge;

- the toner adheres to the paper in accordance with the distribution of charges on it;

- The image with toner “poured” onto the paper is fixed by heating.

This is, in fact, what happens when you press the green button on the copy machine. Below is a video that describes schematically and in detail the principle of operation of a laser printer. Apart from some little things, the same processes occur in the copier:

The photocopying system relies on the operating principles of electricity and photoconductivity. Inside the machine there is a light-sensitive photoreceptor that first attracts and then transfers toner particles onto plain paper to form a copy of the document.

Photocopier parts

A photoreceptor drum (or belt) that is coated with a layer of semiconductor material such as selenium, silicon, or germanium. This is perhaps the most important part of the machine.

Toner , which is basically just a pigmented liquid. Sometimes called "dry ink", toner is a dry mixture of small, negatively charged plastic particles and dyes that create a duplicate image on a sheet of paper.

Color laser printer toner cartridges (Photo: Flickr)

Corona wires , which at high voltage transfer a field of positive charge to the surface of the photoreceptor drum and carbon paper.

A light source and multiple lenses that shine a bright beam of light on the original document and focus a copy of the image to a specific location, respectively.

A light beam shines across the main document (Photo: Wikipedia Commons)

The fuser can be considered the "final" main component of a photocopier as the fuser unit melts and presses the toner image onto the copy paper and imparts the finishing touches to the duplicated image just before it is ejected from the machine.

How does a photocopier work?

As the conveyor belt (coated with photoconductor) moves, it also takes the electrical shadow along with it. Particles with a negative charge of the toner stick to the electric shadow, and the original copy is printed on the conveyor belt.

A blank sheet of paper is fed into the photocopy from the other side, which slowly moves to the photoconductor belt. As it moves along the conveyor belt, it is given a strong positive charge. The strong positive charge on the blank paper pulls the negatively charged toner particles toward it. Consequently, a duplicate image of the master copy is formed on blank paper.

Finally, before spitting out the paper, the fuser unit (a pair of hot rollers) applies heat and pressure to keep the toner particles permanently attached/fused onto the paper. This is why a freshly ejected duplicate copy is quite warm to the touch.

A freshly thrown copy is quite warm to the touch

Copy machine

(abbr.

copier

; duplicating machine;

xerox

) - a device designed to produce copies of documents, photographs, drawings and other two-dimensional images on paper and other materials. Unlike printing machines, it can be used to produce small runs of books, brochures, etc. In addition to special machines, copying machines include a fax machine, a duplicator, and an interconnected scanner and printer, including within a single multifunctional device.

Is a copier harmful?

There are a number of requirements for organizing the work of copiers. SanPiN 2. 2. 2. 1332-03 contains recommendations to reduce the harmful effects on the body. It is also established that the distance from the side of the service area must be at least one meter, and from the wall to the edge of the duplicating equipment at least 60 cm. But, as we know, it is impossible to completely eliminate the negative impact of the copier.

The copier consists of drums coated with selenium and cadmium sulfide. During drum operation, a high charge and evaporation of these substances occurs. This causes nasopharyngeal irritation, nausea, vomiting and rhinitis . Toner contains carbon monoxide, which is released when the image is set. A large concentration of such carbon can cause headaches, rapid pulse and weakness . The toner is unsafe, and in terms of its harmfulness it can be compared to coal dust, since it consists of inorganic additives, iron oxide, polymer compounds and carbon.

We recommend reading: Taking Care of a Child Moscow Region

Image acquisition methods [edit | edit code ]

The electrographic printing method is the most common in photocopiers. For large runs, the screen printing method is used. Also (in fax machines and inexpensive color copiers) the inkjet printing method and the thermal printing method are used. Other methods of obtaining images did not become widespread or were forced out of the copier market.

Based on the method of processing the original image, copiers are divided into analog and digital. They differ in the way the image is transferred from the original to the copy. In analog (electrographic) devices, light reflected from the original through a system of moving mirrors and a lens is transmitted to the photodrum. In digital, an image from the original is first scanned using a line of photosensitive elements (photodiodes) into the controller’s memory, processed according to a certain algorithm (sometimes containing errors [1]), and then printed through a printer, which, in this case, is an integral part of the copy machine. device (multifunctional device - MFP or multifunctional device - MFA).

Digital copiers are divided into monochrome and full color.

Based on productivity, copiers are classified into low (up to 20 copies/min), medium (20-40 copies/min) and high (over 40 copies/min) productivity.

Based on their layout, copiers are divided into floor-standing and desktop. From desktop ones, portable (portable) ones are separately distinguished.

Low-capacity desktop devices in A4 format are usually called personal. Separately, there are large format copiers (A0, A1), which are often called engineering systems.

Printers and copying equipment and their impact on the human body

The very first device in the world, which became the ancestor of numerous printer models that subsequently appeared, saw the light back in 1834. True, only in a hypothetical drawing format. Its creator was Charles Babbage. The “ancestor” of modern printers was a mechanical computer that also had a printing function and was called a difference machine. This model was never released, and only 150 years later, according to Babbage’s drawings, a unique mechanism weighing 5 tons was assembled, which today is kept in one of the museums in London[3].

We recommend reading: Preferential travel tickets for pensioners in 2021 in Orel

It is worth noting that in the first copying machines, the ink did not adhere well to the page; it had to be heated very much. That's why the first copiers caught fire from time to time. From 1950 to 1960, they were produced with a built-in fire extinguisher[2].

Classification [edit | edit code ]

- By dimensions:

- portable;

- desktop;

- productive stationary.

- According to scanning principles:

- analog;

- digital.

- According to color rendering:

- monochrome;

- colored.

- By functionality:

- standard (for A4, A3 paper);

- special (for publishing complexes);

- wide-format (for making drawings).

- According to permissible load:

- 30 copies/day;

- 100 copies/day;

- 600 copies/day;

- 10,000 copies/day;

- 1,000,000 copies/day.

- By copy speed:

- up to 6 kopecks/min;

- up to 20 kopecks/min;

- up to 40 kopecks/min;

- up to 100 kopecks/min.

About the name "Xerox" [edit | edit code ]

In Russia and the countries of the former USSR, “copiers” are called any copying equipment, regardless of the manufacturer, due to the fact that the first copying machines that came to the USSR from abroad were produced by Xerox (pronounced “ zirox”

”, however, in Russian-speaking countries the “

copier

” option has taken root). Accordingly, the process of making a copy of a document began to be called “photocopying,” and the resulting copy became a “photocopy.” Also used are the verbs “xerit”, “xerit”.

Despite the widespread use of the name “copier,” they try to avoid it in official literature and especially advertising materials due to its similarity with the name of the Xerox company. Its devices based on xerography technology (from the Greek word meaning “dry” and “writing”) at one time dominated the market, displacing other copying technologies, and therefore its trademark became a household name for an entire class of devices. The very name “copier” for copying machines based on xerography technology (or, more scientifically, electrography) was proposed by the inventor of the method, Chester Carlson, and the Xerox company received its name after the renaming, when its machines with this name became very famous [2] [3].

The word “copier” entered the Russian language in the 1970s, when the first Xerox copying machines appeared in the USSR. Also widely used at that time were domestic copying machines “ERA” and REM.

Copiers in the USSR [edit | edit code ]

In the USSR, under a planned economy, the problem of prompt copying of documents was not as acute as in countries with a market economy. Copying of documents in Soviet institutions was carried out photographically, including microfilming. Design and technological documentation was copied manually onto tracing paper and then reproduced using photocopying methods. Nevertheless, the need for operational copying machines existed; therefore, in the 1960s, purchases of such equipment began abroad, as well as the development of our own samples.

In 1953, V. M. Fridkin, who had just graduated from the physics department of Moscow State University, created the first Soviet copying machine, and subsequently developed the theory of electrophotography [4].

The first foreign copying machines that appeared in the USSR in 1966 [ source not specified 3801 days

], were Xerox machines, as a result of which “copier” became a common name for such equipment. At the same time, for example, Mongolia was the first to supply copying machines), which is why in Mongolian copying machines are called “canon”.

Starting from the late 1960s, the USSR produced copiers of its own design. The pioneer in this field was the Kazan optical-mechanical (rotary electrographic machine), which was produced in two modifications REM-420 and REM-620. The numbers in the designation indicate the width of the roll paper. Later, other factories began producing similar devices, in particular BelOMO and the Grozny Printing Machines Plant (under the ERA brand). In Grozny, in particular, they produced small-format devices (A3 and A4 formats), working not only with roll paper, but also with sheet paper. “SEM” and its modifications in general, in terms of the principle of operation and optical design, repeated the Xerox devices of the 1950s and 1960s.

In the countries of the socialist camp, copiers were produced: Pentakon, Robotron (GDR), Dokumator (Poland).

In the USSR, copying and duplicating machines (hectographs) in service in government agencies were required to be registered with the KGB [5]. The obvious purpose of these measures was to combat samizdat and the dissemination of classified information (including topographic maps).

Early photocopiers, both Soviet and foreign made, were fire hazards. When the movement of the paper stopped (jamming in the conductive channel or a drive failure), it almost immediately caught fire under the influence of a powerful flow of heat from the infrared emitter of the toner fusing system. Therefore, in the rooms where copying equipment was located, a fire extinguishing system was necessarily installed, and a carbon dioxide fire extinguisher was attached to the machine body. The electrical power of the first devices was very high. So REM-620 consumed almost 8 kW of electricity.

All about the copier

A progressive solution was the combination in one body of several key functions that are most necessary for office work or printing: printing, scanning, copying. Such devices are called multifunctional devices (MFPs).

The term “copier” has already become a common name for a conventional copying machine and is widely used in colloquial speech. This concept refers to specialized equipment for creating copies of text, illustrations, and graphics from paper media on a production scale. The main task of the machine is autonomous copying in large volumes. The copier is capable of producing an average of 999 copies per cycle, without the need for any auxiliary equipment for the operator. All control is concentrated on a small panel, where there are only a few buttons and an LCD display.

01 Aug 2021 jurist7sib 97

Share this post

- Related Posts

- I can’t pay for government services with a card

- Legality Abcrazborru 2021

- Payment of discounted travel for full-time Mosgortrans students

- Primary Documents When Returning Goods from Safe Storage

In forensics [ edit | edit code ]

Just like the forensic examination of typewriters, printers and copiers can be identified by certain distinctive features due to imperfections in the printing process. Deviations in the operation of the mechanisms of the toner and paper supply systems can cause color banding, which can reveal information about the individual mechanical properties of the device. It is often possible to determine the manufacturer and brand, and in some cases, a specific device, by comparing print results among other similar devices or devices of the same model. [6]

Also, some color printers and copiers steganographically add their identification code to the pages they print to protect against counterfeiting.

How harmful is a photocopy machine?

Toner is a combination of polymers, carbon, iron oxide, and inorganic additives. The composition of toner varies and may contain carcinogenic substances. In terms of the degree of harm to human health, it can be comparable to coal dust. The toner affects the respiratory system, causes irritation of the mucous membrane of the eyes, nasopharynx, and skin irritation.

In SanPiN 2.2.2.1332-03 “Hygienic requirements for the organization of work on copying and duplicating equipment”, which standardize work on “copiers”, it is established that the distance from the wall or column to the edges of the copying machine must be at least 0.6 m, and with sides of the service area - at least 1.0 m.

We recommend reading: Child support in Kazakhstan for two children in 2021