The principle of operation of the refrigerator

The operating principle of almost all such equipment is the same. The place of cold concentration is located inside the device. And the generated thermal energy is removed outside. To solve work problems, so-called freons are used, this is a popular type of refrigerant. Troubleshooting requires a minimum level of training in this regard.

Freon includes several main components in the form of chlorine with ethane, fluorine. The main difference between the material is the change from the liquid state to the gaseous state, when pressure fluctuations inside the walls begin.

The cooling procedure itself can be described as follows:

- The operation of compressors helps draw the refrigerant inside. The design of the refrigerator is almost always the same.

- Next, the composition moves through the tubes with the participation of a piston.

- The refrigerant condenses during heat transfer.

- The freon form becomes liquid.

- Moisture turns into gas after being absorbed by the sorbent.

- Transfer of refrigerant into the capillary tube.

- The temperature of the gas and the pressure inside drop almost simultaneously.

- The properties of freon change as it passes through the evaporator.

- In the gas state, the refrigerant passes to the compressor of the Stinol no Frost refrigerator.

Models are being sold that have not one compressor, but two devices at once. Although this technique is considered more effective, maintenance does involve some problems. Possible malfunctions will be given below.

Refrigerator Features

The freezer compartment of the Stinol refrigerator is made of polystyrene. The space between the compartments is filled with polyurethane foam for thermal insulation. The capillary pipeline is used as a throttling device, which makes the refrigerator sensitive to changes in humidity and air pollution.

All Stinol refrigerators are divided into evaporative and compressor types. They work as follows: the device uses a substance called refrigerant for cooling - this is a liquid that evaporates at room temperature.

The operation process of the refrigerator is as follows: freon (refrigerant) vapor is constantly supplied to the radiator, which is located at the back of the refrigerator. The freon then condenses in the radiator, where it releases heat, after which it enters the capillary tube, from where the freon is injected into the evaporator, and then the process is repeated again.

A refrigerator can have either one or two compressors, depending on the model. The compressor is a steel coil, which is fixed with metal plates. The presence of several compressors allows you to separately configure the operation of each compartment of the refrigerator.

Refrigerators have two types of evaporators:

- static, located on shelves;

- “NoFrost” system, which is located in a special compartment.

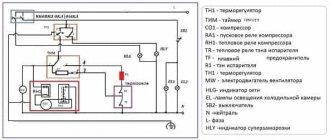

An important element for stable operation of the refrigerator is the electrical system. It consists of the following elements:

- thermostat, needed to maintain a given temperature level;

- thermal protection;

- electric motor;

- start relay.

This system has the following operating principle:

- When voltage is applied, the current moves from the thermostat to the forced defrosting button, then to the thermal protection, then to the starting relay and from it to the motor winding. The current supplied to it produces a voltage higher than required, this is because the start relay only trips and closes its contacts at that voltage level.

- After this, the relay transfers current to the starting winding, and the engine begins to rotate. The motor runs and the refrigerator starts to freeze. When the temperature reaches the set level, the thermostat turns on. It opens the contacts, stopping the flow of current to the compressor, causing it to stop. Operation resumes as soon as the temperature reaches the required level.

- In case the motor overheats, there is a thermal protection relay. When the temperature becomes too high, a special part on the relay - a bimetallic plate - bends and opens the contacts, so that the cooled element then comes back and closes the contacts again.

Compressor electrical system design

The motor is the main element inside the refrigerator. Without it, freon or refrigerant simply will not move through the pipes.

But this unit is not the only one; it is complemented by other parts:

- Protective relay that prevents engine overheating.

- A thermostat that sets the temperature at a certain level.

- Start relay which should work fine after troubleshooting.

The engine has a rotor and a starter. Essentially, the latter is copper coils in some quantity, assembled together. The rotor is a conventional steel shaft, working in conjunction with a piston system. Possible malfunctions of this part of the equipment also have their own.

Electromagnetic induction is generated inside the coils when the motors are turned on. Due to this source, torque is generated. Centrifugal force contributes to the rotation of the rotor itself, and at the same time the piston moves.

The modern Stinol refrigerator is distinguished by the location of the engines inside the compressor. Then the probability of spontaneous leakage remains a minimal problem. The initial design of the system leads to frequent vibrations. A special suspension on metal springs is created just to prevent such situations.

New models differ in that the springs are fixed inside the housing. In old ones, this component is located inside. The first option was always considered more practical, since it allowed vibration to be dampened from the inside. But then repairs are more difficult to organize if the suspension breaks. The two-chamber type of technology is no exception.

The motor runs until a certain temperature level is established inside the chambers. After this, the thermostat is connected to operation. The motor stops receiving current with the contacts open. The compressor stops working. When the temperature rises, the contacts close again. The work cycle continues.

Important! Most often, problems occur in models that belong to the middle and lower price categories. It is more practical not to repair the device, but to buy a new one; replacement is much cheaper.

For what reasons does the Stinol two-chamber refrigerator not work?

It happens that a two-compartment refrigerator does not freeze, but the light in the compartment is on. The reason may again be the release of freon. You can tell by the presence of ice on the evaporator or in the area of the leak. The following is also checked:

- In modern models, the installation is checked. If the body is tilted forward, the door may have opened slightly, allowing warm air to enter the chamber. The refrigerator “understands” that there is no point in starting the motor. The body should be slightly tilted back. To do this, tighten the front legs of the refrigerator.

- When the cells are warm and the lights are off, the electrical parts are inspected: wiring, plug, power cord, socket. Maybe something got pinched or damaged. Then you need to replace the damaged element.

To make it easier for you to deal with the breakdown, we advise you to pay attention to the signs of a malfunction:

- Have you noticed that the light in the chamber is on, but the compressor does not start? You may hear a clicking sound from the relay that is trying to start the engine. This means the motor burned out. The burnt part cannot be repaired; a new element is installed.

- Refrigeration equipment (RE) with electromechanical control does not work, but the light in the compartment is on. The temperature controller is faulty. It does not send data to the control board, so the module does not turn on the cooling.

- If the light is on in an electronically controlled cold storage unit, but the compressor is “silent,” the thermistor is checked. It measures the temperature in the chamber.

- The light in the chamber does not light up, the equipment does not turn on. There are problems with the start-up relay that starts the motor-compressor. The relay is replaced with a new part.

- If the refrigerator does not show “signs of life” at all, and the wiring is in good order, the problem is in the control module; it cannot control the units and parts in the equipment. Therefore, diagnostics, flashing or replacement of the module are carried out.

No cold in the freezer

Most modern models of Stinol refrigerators are available with two motors. Each of them is responsible for the operation of the upper and lower chambers. If the freezer compartment has defrosted on its own and is no longer cooling, there may be two reasons:

- One of the compressors is broken. This is easy to check: touch both compressors. If they are hot, then the problem is an interturn short circuit. Perhaps the problem with the windings occurred as a result of a short circuit. The windings are tested with a multimeter and repairs are carried out.

- When one compressor heats up and the other does not, the problem is in the automation or the No Frost cooling system. The reason may be the evaporator, relay, temperature sensor. Diagnostics will help determine the exact cause.

To cope with the breakdown, watch the video on the topic:

Following the operating rules will help you avoid troubles with your refrigerator, as well as extend its service life:

- Correct placement. It is unacceptable to install equipment near hot radiators, stoves, close to walls and furniture.

- Timely defrosting. In this case, mechanical removal of pieces of ice in the chamber is not allowed.

- Correct loading. Overloading the XO shelves and its doors leads to rapid wear of parts.

- Product temperature. Only cooled food can be placed in the refrigerator.

- Temperature control on the regulator. Do not set the thermostat in the compartment to full power for a long time.

If you find a malfunction, do not delay repairs, call a specialist. Now you know what to pay attention to so that your equipment works smoothly for many years.

Refrigeration unit diagnostics

A thorough inspection of the unit helps to identify problem components:

- Be sure to check the main details. Have they developed corrosion or other deformations? Are protective coatings damaged? Other mechanical damage is also highly likely to occur when the Stinol refrigerator does not freeze.

- The tightness and fastening strength of the structural parts also deserve a separate analysis, especially if the Stinol refrigerator does not freeze.

- Of all the properties, there are three main ones - power consumption, temperature in the freezer and near the back wall of the cabinet. You need to understand whether the start relay of the Stinol refrigerator needs to be replaced.

Typical faults

The differences in the design of the models do not allow us to give comprehensive general recommendations. However, you can rely on recommendations related to individual components and parts present in most units.

Device automation

This category includes problems with the following elements of Stinol refrigerators:

- starting or thermal relay;

- compressor;

- violation of insulation resistance;

- fan;

- timer and thermostat;

- defrosting heater and thermal fuse (for devices with the No Frost system);

- drainage system;

- pan heater.

The issue with these components is resolved through repair or replacement. If you have the appropriate electrical knowledge, you can make repairs yourself.

Important: the electrical diagram of the device is attached to the user manual, and it can also be found on the Internet.

Refrigerator case malfunction

The accumulation of frost and, as a result, excess water in the condensate container are symptoms of a leak in the cabinet. The cause of such a defect may be:

- seal damage;

- deformation of the device body;

- the presence of gaps at the junction of the seal with the chamber.

Important: repairing the seal of the Stinol refrigerator is possible with your own hands if the problem is deformation of the rubber element. To do this, heat the damaged area of the rubber layer and give it the appropriate shape. There is no need to remove the device doors.

Refrigerant problems

Violations associated with an excess or lack of freon in the system manifest themselves as follows:

- the temperature in the freezer and refrigerator compartment is above or below normal;

- the capillary tube is covered with frost or condensation;

- frost forms on the back wall;

- oily liquid leaking from the housing.

These manifestations indicate an incorrect level of freon in the system. Only a master can eliminate this deficiency if he has the appropriate equipment. A preliminary diagnosis and measurement of the freon level in the system is carried out.

Frequent problems with the Stinol refrigerator

Reliability is a distinctive feature of all refrigerators from this manufacturer included in the model range. But even in this case, no one provides complete protection against breakdowns during daily use. Dealing with a problem becomes easier if you know the causes and effects from the very beginning. There is a separate instruction manual for the Stinol refrigerator compressor.

Cabinet breakdowns

A thin layer of frost will appear on the static evaporator if the cabinet has been inoperative for some time. Because of this, liquid accumulates in large quantities inside the container.

Because of this, the tightness of the No Frost system is compromised, which is caused by:

- Gaps that appeared between the rubber seal and the cabinet doors.

- The appearance of deformations.

- Broken seal or loose seal.

A 1-1.5 kW hair dryer for drying and styling hair will completely cope with the problem if the defect is not very serious. It is enough to apply a hot jet to the place where the seal is adjacent to other parts of the structure. Then the material is stretched so that its shape is adjusted. When the manipulation is completed, the door is closed. If there are breaks in the protective layer, the latter is changed so that the freezer continues to work.

Malfunctions of electrical circuit and automation elements

Electrical circuit components and automatic parts also often cause breakdowns. Here is a list of only the most common ones:

- The drainage system became clogged with small particles, after which the Stinol refrigerators stopped working.

- The evaporator tray heater was broken.

- Defects appeared in the freezer and timer.

- Malfunction related to the thermal fuse or defrost heater.

- The insulation resistance in the electrical system has decreased.

- The fan or compressor or other main parts of the system have broken down.

- The start or thermal relay is faulty, causing the freezer to stop working.

Identification of a defective element and repair are the main actions that are associated with solving the problem in this case. If the issue cannot be resolved simply, the part is simply replaced with a new one.

Problems with refrigerant

In the freezer, the temperature level will be less than -18 degrees if the volume of refrigerant when filling the device was too high. The refrigerator compartment will remain too cold.

The return pipe is covered with condensation or a layer of frost. It is better to adjust the dose of freon after a two-hour break-in; this helps to cope with problems, for example, if the upper chamber does not freeze.

The refrigerator will remain warm if the dose of liquid, on the contrary, is underestimated. Temperatures drop more than 25 degrees below zero. In such a situation, frost often appears on the back walls. It is necessary to adjust the dose until the readings become normal so that the Stinol refrigerators start up immediately.

Common breakdowns of Stinol equipment

The full line of Stinol refrigeration equipment models has fairly high reliability indicators and is able to operate without breakdowns for several years. However, these units, like the refrigeration equipment of every other manufacturer, do not have insurance against the sudden occurrence of malfunctions, and also have weaknesses.

"Diseases" of the body

When the steel cabinet of a refrigerator is damaged, a small amount of frost forms on the evaporator, which leads to the accumulation of a significant volume of liquid in the condensate container. This condition is the result of a violation of the chamber’s tightness for the following reasons:

- loose fit or defects (rupture, etc.) of the rubber seal;

- deformation of the metal body and its parts;

- gaps between the surfaces of the freezer and the sealing rubber.

In order for the sealing elastic to return to its original parameters when it is stretched, it can be “tightened” using a low-power hair dryer with a power of up to 1.5 kW. To do this, heat the rubber seal in the contact area with hot air and pull it a little to restore the original shape of the part. Upon completion of the manipulation, the doors of the refrigerator cabinet are closed. Continue to use the refrigerator only after the rubber seal has completely cooled down. When the protective layer is torn, it is replaced.

Failure of automation and electrical circuit elements

Often malfunctions occur with electrical circuit components or automation devices. These include:

- malfunction of the starting or thermal relay.

- malfunctions of the fan, compressor and other components;

- reducing the insulation resistance of the electrical circuit;

- defects in the timer and freezer;

- clogging of the drainage system with food particles and the like;

- Evaporator pan heater malfunction.

Elimination of automation breakdowns in Stinol units consists of identifying a defective component, repairing it, and when this is impossible, replacing the element with a new part.

Refrigerant

When the volume of freon is exceeded while filling the pipeline. the temperature is less than -18 °C, the refrigerator compartment is cool, and the return pipe is covered with a layer of frost or covered with condensation. To normalize the functioning of refrigeration equipment, after running for two hours, correct the volume of refrigerant.

When the filling dosage is reduced, the refrigeration unit is quite warm, and the temperature is lowered by more than -25 C. Frost can form on the back wall. The solution to the problem is similar to what is used when the volume of refrigerant is too high - the dose is adjusted to normal.

When there is a freon leak, oily spots are observed in the area where the pipeline seal is broken. To eliminate the malfunction, it is necessary to seal the breakdown site and charge the unit with refrigerant.

Attention! After any work with refrigerant, the room in which it was carried out must be ventilated for 15 minutes or more.

Thermostat problems and their diagnosis

The temperature regulator fails quite often and this is a consequence of the fact that the German-made part from Ranko is designed for operation for five, but not more than 6 years. When the thermostat fails, the compressor also does not turn on, and in order to prevent further malfunctions of other components that will begin to occur when the thermostat is broken, the temperature controller must be repaired. It is difficult to diagnose the functionality of a component at home, but it is possible. There are two options for checking the operating status of the thermostat:

- The thermostat contacts must be closed, due to this the continuity of the electrical circuit is maintained and energy is supplied to the compressor input. They check whether there is power and, when it is not, they ring the integrity of the circuit completely - from the outlet. When power is present, it is turned off and specific contacts are called. When they are torn, the thermostat must be replaced with a new one.

- The input contacts of the thermostat are closed using a jumper (between each other, a tool with an insulated handle and a conductive working part is used). When the compressor starts working, this indicates a malfunction of the thermostat. When the compressor does not start, it is not the problem. It is also possible to detect a malfunction “by ear” - when you mechanically turn the thermostat switch, there is a click, and when there is no click, the thermostat is most likely faulty.

Each malfunction of Stinol refrigeration equipment, the age of which exceeds 10 years, must be examined by a specialist. Repairing these units mainly involves replacing a faulty part with a working one.

Signs of problems with the refrigerator and possible malfunctions

One of the common problems is when the power to the refrigerator stops turning on. Here are just a few possible defects:

- The timer in the defrost position is broken.

- The thermostat and start relay stopped working.

- The compressor winding is broken.

- Malfunctions and problems with the plug and power cord of the refrigerator.

It often happens that food is frozen too hard. This happens if the quick freeze button is stuck or the thermal handle has been adjusted incorrectly.

If the freezing is weak, then there are also several possible problems and reasons:

- Lost electrical circuit integrity.

- Compressor performance is low.

- Loose fit of the filler, loss of its elasticity.

- Damage to the thermostat and control element. The electrical circuit of the refrigerator is checked separately.

Interesting. Freezer malfunctions have also become a fairly common problem. It also happens that this part of the installation refuses to work at all. System depressurization and freon leakage are the most common causes. A breakdown in the No Frost system leads to large amounts of heat accumulating inside the refrigerator freezer. In this case, the problem can be resolved only by contacting specialists from service centers. They are definitely familiar with all the malfunctions of the Stinol refrigerator and their elimination.

Refrigerator won't turn on

If the refrigerator does not work, there may be several reasons for this:

- The device is not connected to the network, the power cord is damaged, or the lights in the apartment have been turned off.

- Refrigerant leakage also causes the refrigerator to stop working. It is almost impossible to accurately determine the location of the breakdown without special equipment, but there is one visual sign - the insulation has swelled on the outside at the back.

- Another reason could be a failure of the compressor or a breakdown of the breaker relay. A characteristic sign of a broken relay is a sharp, loud click that is heard after the refrigerator is turned on, after which it turns off.

If the problem is a temporary lack of electricity in the apartment or a loose fit of the plug contacts in the socket, then these problems can be easily eliminated on your own. If this does not help and the Stinol refrigerator does not turn on, disconnect it from the network and call a specialist. The refrigerator does not turn off

There are several situations when the Stinol refrigerator does not turn off and continues to work for a long time without rest. In most cases, this is not normal, because the operation of the motor is cyclical, which means turning the unit off and on regularly.

In this case, the freezer or refrigerator will run continuously until it reaches the default temperature. In this mode, the compressor does not turn off and continues to pump in cold for up to 8 hours in a row.

The refrigerator will always strive to achieve the required mode, but due to the presence of warm air, the compressor will work all the time. An indirect sign is frost around the perimeter of the door.

A special sensor inside the freezing chamber or refrigerator compartment determines the current temperature and, when the set value is reached, sends a signal to the control module, which commands the motor to turn off. If there is a failure in one of the nodes (sensor or module), the compressor does not receive commands and continues to operate. If you do not contact a specialist in time, the compressor will quickly fail as it will wear out.

Read more: Installing an overhead sink, step-by-step instructions for self-installation

Features of operation

It is worth considering what owners most often encounter in practice.

- Stinol 102.

The installation includes two compressors with the unique NoFrost system. Two thermostats are added to the front trim. The model uses a fan heater, due to which the internal compositions move. Thermal relay malfunctions are the most popular problem among those who have this particular model. The control panel may also break, although the reasons will be different.

Usually, the wires are removed from the contacts to make sure that there is a breakdown and its correct origin. Then the parts are connected to each other using a jumper. If after such manipulation everything starts, it means that the problem was definitely in the relay. Repair of the Stinol 102 refrigerator should be entrusted to professionals.

- Stinol 103, which has its own electrical circuit.

In this case, the temperature regulator often breaks down in order to repair the Stinol 103 refrigerator . All structural parts are designed for a maximum five-year service life. Defects lead to the temperature inside the chamber becoming too high. Oxidation of the contacts occurs, due to which the tightness of the connection of the parts to each other is broken over time. Contacts can burn, break, and lead to other types of breakdowns. It is not difficult to change the starting relay for equipment.

- Stinol 110.

The malfunctions are in many ways similar to the problems characteristic of the 102 model. Old models also fall under the rule - Stinol 101, Stinol 107, Stinol 110 itself.

About checking the thermostat

The temperature regulator often fails, as can be understood from previous stories.

This is due to the working life of the equipment, which lasts for a maximum of 5-6 years. The refrigerator compressor does not start when this part is broken. Things are different when the upper chamber does not freeze in Stinol models.

There are two ways to determine the working status.

- The regulator contacts must remain closed. Stinol 101 is no exception.

The refrigerator does not freeze well or has stopped producing cold at all.

In addition to everyday reasons (accidental shutdown from the control panel or blackout), the refrigerator does not freeze only in a few cases:

- Refrigerant leak.

- Compressor failure.

- Failure of the motor protective relay.

- Failure of the solenoid valve (for two-chamber single-compressor refrigerators).

Each of the malfunctions can lead to the refrigerator stopping freezing for no apparent reason.

Things are a little different when the Stinol refrigerator is in working order, but the cold produced is not enough. The most common reason is accidentally adjusting the thermostat knob (lowering the temperature). If the handle is mechanical and is located inside the refrigerator compartment, then it can be easily touched when loading/unloading products (especially in the upper chamber). If the model is electronically controlled, then a possible reason will be an initially incorrect setting of the operating or play mode of children. Check the position of the thermostat knob or the set temperature on the display. Also, one of the reasons may be incorrect factory calibration of the temperature sensor and control unit. In this case, you should contact specialists who will repair the refrigerator at home.

More about diagnostics and existing problems

Water often appears and accumulates inside units with a drip system inside the refrigerator compartment. A clogged drainage system is the main cause of problems. The purpose of the structure is to drain water from the chamber. It runs inside the body of the Stinol 101 refrigerator.

If a snow coat appears in the freezer, this is also one of the signs of a malfunction. Drainage begins in the compartment where food is stored. Therefore, it is imperative to have a water seal in this part to avoid problems in the future.

Note. In practice, this part looks like a bend of small dimensions. Contaminants and other similar components are retained inside such a part. The manufacturer often sells additional tools that are used for cleaning.

After such actions, the outflow of water should improve. If the blockage is severe, such actions do not help; it becomes necessary to break through the structure.

The main thing is to take a careful approach. The tubes are made of thin sheet plastic, which is too easy to damage. It is recommended to use fishing lines that have a slightly melted end. You will get an improvised cable, which, after diving inside, will clean the system. Then everything is filled with a cleaning solution, and the insides of the Stinol 101 equipment are washed with water.

Compared to “crying” systems, the “no-frost” options are considered more complex structurally. They differ from existing analogues in that they contain a blowing system to remove excess moisture. The fan, fuser and timer are the weakest points of the systems.

The fan comes from the freezer. The part can be closed or open depending on the model.

Open devices with electronic control are practically not subject to self-repair; you just need to call a specialist. It’s another matter when the device is simpler, with electromechanical elements. It is enough to gain access to the inside. When they get to the fan, they carefully study the design and check the impeller. The knot definitely requires disassembly if everything is tight and cannot be moved. Stinol 110 is repaired in almost the same way.

Diagnostics and repair

Diagnostics of a refrigeration unit includes the following steps:

- Checking metal parts. Items should be inspected for signs of deformation, corrosion, or wear of the protective coating.

- Assessing the tightness of the housing. The surface is inspected for holes or dents. It is necessary to pay attention to the reliability of fixation of parts.

- Measuring air temperature in chambers, inspecting the rear wall, determining power consumption.

The method for identifying problems and fixing them depends on the causes of the breakdown.

Refrigerator won't turn on

If the refrigerator does not turn on, you need to do the following:

- Check the connection of the network cable to the outlet. Perhaps the reason lies in a loose plug or a power outage.

- Inspect the cooling system. It is impossible to find the damaged area without using special instruments. However, there is one external sign - swelling of the insulation on the back wall of the refrigerator. In this case, the hole is sealed and the system is charged with refrigerant.

- Check the operation of the compressor and protective relay. If the latter breaks down, turning on the device is accompanied by the appearance of clicks. It is difficult to fix these problems yourself; repairs should be entrusted to a specialist.

Sometimes the refrigerator does not work for several hours, and then it starts to start on its own. This problem should not be left unattended either; the compressor eventually breaks down and stops turning on.

The refrigerator is not freezing

If the refrigeration chamber does not work, you need to inspect the following equipment components:

- compressor;

- capillary system;

- motor protection relay;

- solenoid valve (for two-chamber models with a single motor).

To troubleshoot problems, perform the following steps:

- Set the thermostat knob to the correct position. Sometimes the thermostat moves, causing the refrigerator to turn on but not freeze well. The mechanical handle moves when loading products. If there is an electronic control unit, the modes are reconfigured.

- Calibrate the thermostat. You will not be able to perform this action yourself. You need to contact the service center.

- Replacing the temperature sensor. The part is removed from the seat, which is located near the control unit, and the cables are disconnected. Installation of a new element is performed in the reverse order.

Doesn't cool well, but freezer works

Modern models of refrigerated cabinets are equipped with 2 compressors. Each person is responsible for the operation of one of the cameras. If the freezer is working, but the lower compartment has stopped cooling, perform the following actions:

- Compressors are inspected. If they are hot, we are talking about an interturn short circuit. The problem occurs when voltage surges or improper operation of the equipment. The windings are checked with a multimeter and, if necessary, repaired or replaced.

- Check the cooling system pipes. If only 1 compressor overheats, the reason lies in poor refrigerant circulation or failure of the automatic defrost system. The problem is being resolved by specialists.

If the temperature in the refrigerator rises while the freezer is working normally, you need to check the evaporator, protective relay, and thermostat.