TOP 10 main faults

Refrigeration equipment is a technology without which it is hard to imagine life. If any of the above malfunctions occur, you should immediately repair the breakdown or contact a professional.

This article is universal, suitable for one-two-chamber, three-chamber models of foreign and Russian production: Hotpoint ariston (Hotpoint Ariston), Ardo (Ardo), Beko (Beko), Bosch (Bosch), Candy (Candy), Daewoo (Daewoo), Electrolux (Electrolux), Gorenje, Haier, Hansa, Hitachi, Indesit, Liebherr, LG, Nord, Polair, Pozis, Sharp, Shivaki, Siemens, Snaige, Stinol, Samsung, Toshiba, Vestel, Vestfrost, Whirlpool (Whirlpool), Zanussi (Zanussi), Elenberg (Elenberg), Biryusa, Yuryuzan, Atlant, Oka Sviyaga, Ocean, Minsk.

Doesn't turn on

The refrigerator may not turn on for several reasons:

- First of all, you should check the voltage in the network. It happens that a voltage surge occurs and the plugs are knocked out, the RCD or circuit breaker in the distribution brush is turned off. To make sure there is electricity, plug in other equipment, such as a hair dryer or vacuum cleaner.

- It is also recommended to inspect the power cable and plug - if they are damaged (multi-colored wires, exposed wires, marks from animal teeth are visible), you need to replace the wire yourself or contact an electrician.

- the on/off button does not work (sticks, sticks or shorts);

- the thermostat is broken - the module starts the motor in the compressor when the air temperature inside the chamber rises above 3-12 degrees;

- Compressor defects are the most expensive repair, since in most cases the part must be replaced as an assembly.

- If the equipment turns on, works for a few seconds, and then a click is heard and it turns off, the reason may be a breakdown of the start relay.

Leaking

There are several reasons why a refrigerator could leak and form a puddle on the floor.

- The doors are not closed tightly or the seal is worn out. Warm air enters the cracks, causing condensation to form and flow onto the floor.

- The drainage system in the freezer or main compartment is clogged. Pieces of food could get into it; in this case, excess moisture will accumulate inside the chamber and flow out.

- The drain pipe has become disconnected. The problem usually occurs after moving equipment.

- The evaporator heater has failed (only in equipment with the No Frost system).

- The container for collecting and evaporating condensate has burst.

It gets very cold and frost appears.

If a snow coat appears on the walls of the freezer, and the refrigerator is not equipped with a No Frost system, this may indicate that it has not been defrosted for a long time.

Other causes of the defect include:

- overloading of equipment with products;

- compressor failure;

- breakdown of the thermostat or temperature sensor;

- the capillary tube is dirty, it needs to be washed and refilled with refrigerant;

- Freon leak.

More details in this article.

Doesn't freeze or cool

If the refrigerator stops freezing or cooling, you can look for the cause in several technical units.

- Incorrectly set temperature on the thermostat. You can fix it yourself by adjusting the parameters.

- The thermostat is broken; the part needs to be replaced.

- Contaminants have accumulated in the condenser, which is why the passing freon does not cool the chamber to the required levels.

- The seal on the doors is worn out. Cooled air leaves the chamber, and warm air accumulates inside.

- Refrigerant leakage occurs due to damage to the capillary system or tube.

- Compressor failure - the part must be replaced.

- The room may be too hot, which also leads to a similar breakdown. The equipment must not be installed near heat sources.

Read more here.

The motor runs non-stop

Under normal conditions, the refrigerator runs continuously for 12-20 minutes, then turns off. If the equipment works for a long time without breaks, the compressor may soon break down or the starter winding may burn out due to overheating.

The main causes of failure include:

- doors that do not fit tightly due to a skewed hinge or wear, a hole or a crack in the sealing rubber. Often accompanied by a squeak or other sound warning that the door is not completely closed;

- The express freeze function is turned on. It is impossible to leave it working for a long time in such modes, since the equipment is subject to wear and tear;

- failure of the temperature sensor or thermostat;

- incorrect operation of the main control module, it needs to be reflashed or replaced;

- freon leak - leaks and damage in the circuit are eliminated, refueling is carried out;

- a broken compressor does not pump pressure into the system and the electric motor idles.

Often the refrigerator runs almost non-stop if the room temperature is too high.

Very noisy

A refrigerator can make a lot of noise even if it is not installed correctly. During installation, it is worth making sure that the equipment stands on a solid, level surface. If the requirements are met, you need to look for a fault.

Main reasons:

- fan breakdown or difficulty in its operation due to a thick layer of ice on the walls;

- incorrect installation of the compressor - during its operation it comes into contact with the tubes, which causes rattling;

- loose compressor fasteners.

You can learn more about noise sources and elimination methods from this article.

The light doesn't light up

If the light does not light in a working refrigerator, this may indicate the following malfunctions.

- The reed switch or magnetic switch is broken (the light in the chamber may blink). When the door is opened, the network closes and light appears inside the chamber.

- The light bulb has burned out.

- The cartridge has failed or the contacts have come loose.

Instructions for replacing a light bulb.

Water accumulates inside or under the bottom

Water under the vegetable container or under the bottom of the refrigerator is not a reason to panic and look for a new model. This is a breakdown that you can fix yourself.

Among the causes of the malfunction:

- the drainage system of the freezer or upper chamber is clogged;

- the doors do not fit tightly, warm air enters and condenses on the icy back wall of the chamber.

You can learn more about the problem from this article.

Unpleasant smell

An unpleasant smell from the refrigerator occurs for a number of reasons.

- The drain hole for draining melt water is clogged.

- The thermostat failed, so the food began to spoil due to incorrect temperature conditions.

- The wiring or electrical components are shorted out, and a burning smell appears.

If you are planning a long trip, the switched off equipment should be opened and thoroughly washed to prevent a musty smell from appearing.

Error or red light on

Modern refrigerators have a system for indicating problems that arise - the red indicator (exclamation mark) lights up or flashes (sometimes accompanied by a squeak) and an error code appears.

Common reasons:

- refrigerant leak;

- compressor breakdowns;

- failure of the thermostat;

- the automatic defrosting system has turned on;

- other faults, full list in the operating instructions.

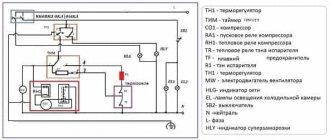

Beko refrigerator power and control boards

The power board is located under the top cover at the rear of the refrigerator. A rectifier and control relays are mounted on the board. Relays control the following refrigerator devices: damper, fan, evaporator heater and compressor. The low-current elements of the power board provide power to the control board and elements connected directly to it. On-off commands are transmitted from the control board to the corresponding devices through the mentioned relays.

Figure 2 shows the location of the relay on the power board and indicates the addresses and colors of the wires connected to it.

Relay No. 1 controls the damper. It is triggered by the presence of 100 VAC between the blue wire terminals of the transformer and the orange wire of the power board. If the damper does not work, check the wires and the damper.

Relay No. 2 controls the fan. It operates when there is 220V AC voltage between the blue wire terminals of the transformer and the pink wire of the power board. If the fan does not work, check the integrity of the wire, the serviceability of the door limit switches and the fan itself.

Relay #3 controls the evaporator heater. It operates when there is 220V AC voltage between the terminals of the blue wire of the transformer and the yellow wire of the power board. If the heater does not work in the presence of this voltage, check the integrity of the wire and the heater itself.

Relay No. 4 controls the compressor. It operates when there is 220V AC voltage between the blue wire terminals of the transformer and the black wire of the power board. If the compressor does not work in the presence of this voltage, check the wire contacts, serviceability of the relay, fuse and the compressor itself.

The control board is located under the control panel of the refrigerator. For the board to operate, the network voltage must be 192…242 Volts. The board contains a microprocessor that controls all functions of the refrigerator, as well as other elements of control circuits and indicator lamps.

The microprocessor processes signals coming from sensors, limit switches and control buttons, and supplies control signals to the power board.

Refrigerator system sensors

Sensors are used to measure temperature in various places of the refrigerator and transmit this information to the microprocessor of the control board.

The freezer sensor is located between the freezer door spring and the inside of the cabinet. The sensor measures the temperature inside the freezer and transmits a signal to the microprocessor. The data received from this sensor is used to control the freezer operation indicator, compressor and quick freeze readiness alarm.

The refrigerator compartment sensor is located in a special socket above the lamp box. The sensor measures the temperature inside the refrigerator compartment and transmits a signal to the microprocessor. The control of the refrigerator compartment indicator and the damper is based on the data received from this sensor.

The evaporator sensor is located above the evaporator next to the capillary tube. The sensor measures the temperature of the evaporator and transmits a signal to the microprocessor. Turning defrost mode on and off is based on data received from this sensor. The refrigerator uses a self-regulating defrosting system. The defrost time is determined automatically depending on the time of the previous defrost. If the duration of the first defrost is short, the compressor is switched on for a longer time before the second defrost. When the compressor runs for 8 hours, the defrosting time is a maximum of 60 minutes. Thawing starts at 0 °C and ends at 10 °C. The fan turns on 5 minutes after defrosting is completed.

The damper is located inside the thermostat box in the refrigerator compartment at the point where cold air enters the refrigerator compartment. If the temperature in the refrigerator compartment rises above the set point, the damper opens, cold air enters the chamber and the temperature in it decreases. When the temperature in the chamber drops to a predetermined level, the damper closes and blocks the access of cold air. The damper is powered by an alternating voltage of 100 Volts, control is carried out by supplying a constant voltage of 5 V. In order for the set temperature to be maintained in the refrigerating chamber, air should not penetrate into the chamber through the gaps between the thermostat box and the walls of the chamber. Therefore, for thermal insulation you should use only branded gaskets.

The refrigerator electronics power supply transformer is located inside the top door. It provides the 12 Volt AC needed to power the electronic boards and the 100 Volt AC needed to power the damper. The 12 Volt AC voltage is converted to 5 Volt DC voltage by a rectifier mounted on the power board.

The fan is located inside the refrigerator on the back cover of the evaporator. It creates a flow of air passing over the surface of the evaporator and through both chambers of the refrigerator. Thanks to this, a constant temperature is maintained inside the refrigerator. The fan does not operate during defrosting. For the fan to operate effectively, the back cover of the evaporator must be closed and a proprietary insulating gasket must be installed above it to prevent air from entering through the cracks. The refrigerator has three heaters. Their location and functions are indicated below.

Evaporator Heater - A sandwich type grill heater is located on the evaporator. It turns on only when the refrigerator is defrosting and serves to remove snow and ice from the evaporator.

The drain channel heater is located in the drain channel under the evaporator. It turns on only when the refrigerator is defrosting and serves to remove ice from the drainage channel, ensuring unimpeded water flow.

The air duct heater is located on the rear surface of the air duct of the refrigerator compartment. It prevents water from condensing at the front of the duct and switches on and off with the compressor.

The fuse is located on the lower left side of the evaporator on the surface of the heater and is wrapped in aluminum foil. The fuse is installed in case of a malfunction in which the heaters are constantly on. It prevents the temperature of the refrigerator from rising unacceptably. When the fuse trips, the heaters turn off. The fuse must then be replaced. The refrigerator has three lamps: one in the refrigerator compartment and two in the freezer. For efficient operation of the refrigerator, it is necessary to use lamps with a power of no more than 15 W.

Refrigerator malfunctions - self-diagnosis system

The self-diagnosis system notifies the user of a malfunction and the need to call a specialist for maintenance or repair the refrigerator. If any malfunction occurs, the refrigerator compartment indicators begin to flash (Fig. 6). Before sounding a fault alarm, the refrigerator control system turns off the processor, fan motor and heaters. The damper opens completely. The fault alarm is turned off only when entering the automatic test mode. The refrigerator compartment temperature indicator also serves as a malfunction indicator. If the indicator lamp is on without blinking, the indicator indicates the temperature of the refrigerator compartment, but if the indicator lamp is blinking, this indicates a malfunction. If the control system detects any malfunction, the indicator lamps begin to flash and the compressor automatically turns off (except when a signal is given that one of the buttons remains pressed). The fault indication continues until the fault is eliminated and the refrigerator is switched to automatic test mode.

Simple repair

In some cases, you can return household appliances to working condition after carrying out simple repairs yourself.

Changing light bulbs

Replacing a burnt out light bulb with a similar new one is not a difficult job for a professional. You can read the instructions in the article; it describes in detail the procedure for removing the lampshade, how to correctly unscrew the remains of the base and other nuances.

Cleaning the drainage system

During operation, contaminants appear in the drainage system of the refrigerator - small pieces of food, grease, dust. To ensure that there is no moisture under the vegetable compartment or under the bottom, it is worth cleaning the drainage tube regularly.

Replace the rubber seal

Wear of the seal occurs due to careless operation and leads to a change in the temperature regime inside the compartments. You can learn about replacing this component from the article.

Eliminating compressor rattling

Noise that occurs during operation of the refrigerator may be due to improper operation of the compressor. The technician needs to inspect the equipment and determine whether the engine is in contact with pipes and other mechanisms.

We rehang and align doors

For ease of use, modern kitchen appliances are equipped with the ability to hang the door. Such repairs will be carried out by professionals; details can be found in this article.

Checking the correct installation

The refrigerator must be placed on a hard and level surface. To ensure that the requirement is met, you can use a building level. The equipment should not wobble or be skewed to one side. In modern models, the legs are distinguished by the ability to adjust in height, so unevenness can be eliminated. More details here.

If there is a lot of ice in the freezer

Ice in the freezer may indicate that it is necessary to temporarily turn off the equipment, defrost it, and then thoroughly wash the unit. You can learn how such simple repairs are performed from this article.

Drain hole is clogged

The refrigerant, which cools the internal volume, is pumped by a compressor into the evaporator located under the bottom of the freezer. As a result of circulation, condensation forms on the walls, which gradually turns into ice.

The appearance of water under vegetable containers indicates a malfunction of the drainage system, which occurs when the tube is clogged:

- pieces of food;

- dust;

- fat;

- food residues frozen to the evaporator wall.

To clean the tube, use a hand pump, syringe, or soft wire. Before starting maintenance work, disconnect the device from the network. Cleaning is carried out with warm water with the addition of detergent.

It is difficult to eliminate a clogged drainage system of refrigerators with No Frost technology; this requires knowledge and experience in repairing household appliances. In units of this type, the drainage hole is located behind a special partition, so experts do not recommend self-prevention.

The reason for contacting the service center if the Veka refrigerator breaks down may be the presence of water under the vegetable trays. This problem relates to equipment maintenance activities. To prevent clogging, it is recommended to regularly clean the walls and shelves of food residues.

More complex repairs

When a serious refrigerator breakdown occurs, you should immediately contact a repairman. A timely response will extend operating life and help avoid costly repairs, for example, to the compressor or refrigerant circulation system.

Refrigerant replacement

Freon leakage is one of the most common breakdowns.

To fix the problem, the technician needs to:

- using special equipment, find the location of the leak;

- repair the damage and check for leaks;

- Refill the tank with freon.

You can learn more about this type of repair from this article.

The control board is burnt out or faulty

Modern refrigerators are equipped with a control board. It is responsible for display operation, maintaining optimal temperature conditions, turning on the light when the chamber is opened, and starting the compressor and fan. Restoring functionality usually involves reflashing the module, since due to power surges, non-volatile memory becomes glitchy and sometimes overwrites data. If the board burns out, a new part is installed; repairs are not economically feasible.

If the thermostat is broken

When a thermostat fails, it must be removed and a new, similar one installed in its place.

Evaporator defect

A defect in the evaporator is manifested by an increase in temperature inside the refrigerator compartment, the appearance of an unpleasant odor and an icy coat. The technicians search for freon leaks, restore the tightness of the tubes and refill with refrigerant. If the evaporator is worn out, it must be replaced.

Temperature sensor glitches

There are several ways to eliminate incorrect operation of temperature sensors.

- Repair the open circuit in the control circuit contacts.

- Eliminate the effects of oxidation (clean off rust).

- Restore the normal position of the sensors.

- Replacement of the assembly, since the module is not repairable.

Temperature fuse blown

The temperature fuse may blow out because the evaporator defrost heating element has overheated. And to protect household appliances from fire, the fuse broke the circuit.

Ideally, check the resistance of the part with a multimeter, or at least ring it. If an open circuit is detected, the heating element is replaced with a new one. You can try to “cheat it up” by closing the circuit with a wire of a suitable cross-section, but there is no answer to how long such a structure will last and whether it is safe.

Malfunctions of NoFrost systems

The operation of the fan is checked manually - carefully rotate the blades, if the impeller rotates freely, check the electronic part. Ring the engine starter, if there is a break in the winding, replace the whole thing. The fuser may fail - this part is removed and checked with a tester. If the resistance is close to zero, then the part is considered serviceable. If both technical units are working normally, the electric timer needs to be replaced; it cannot be repaired.

Ice maker not working

It is impossible to determine the cause of the ice maker failure without diagnostics.

The most common factors:

- low water pressure;

- the intake valve is broken;

- the generator unit is faulty;

- the door switch does not work correctly;

- you need to change the filter.

Compressor repair

Resuscitation of a compressor is one of the most expensive jobs.

Entire replacement

In most cases, the compressor cannot be repaired and must be replaced. To do this, order a suitable model and install it yourself or call a specialist.

Start relay problems

In the start-up protection relay, the contacts can jam, the winding of the electromagnets can burn out, and the spring plate loses its elasticity over time. Usually you hear clicks, but nothing happens. If the part has not completely failed, the coil is repaired, the contacts are connected or cleaned. The easiest way is to throw out the old one and buy a new one for 500-1000 rubles, and not waste a lot of time looking for “phantom pains”.

Thermal protection relay failure

If the thermal protective relay fails, the cycle of switching on and off the equipment is disrupted, and the electric motor overheats. Repair is allowed if the rod is jammed. If there is damage to the winding, the part must be replaced.

What to check first

There may be several reasons why the above-described operational disturbances may occur. If you have at least minimal knowledge of the structure of household appliances, you can identify the breakdown yourself. Professionals advise sticking to the following operating algorithm, but here you need to take into account the type of thermostat.

View » Why the refrigerator does not turn on but the light inside is on

For devices with a mechanical thermostat, there are 3 possible causes of failure:

- damage to the start relay;

- thermostat failure;

- Compressor malfunction.

The order in which all the listed details should be checked is not very important. You can start with the node that is most accessible. This rule applies to those devices that stand against a wall or in a niche.

The thermostat should be checked after turning off the device. All those parts that may interfere with the inspection are removed. First of all, these are lampshades and covers.

The next stage is connecting the wires to each other (those that go to the contacts). In this case, the ground wire should not be touched (most often it can be recognized by the green winding). The types of thermostats located in the lighting shade also have a blue wire, which is also not used. After completing this work, the device is connected to the mains. If startup occurs, then the problem lies in the thermostat. If there are no changes, then proceed to checking other elements.

If the refrigerator has an electronic thermostat, then it can be classified as a more complex device. To identify faults, it may be necessary to check the entire module electrically. This kind of work should be entrusted to a specialist.

However, some details can be checked on your own. This is the presence of burnt out elements, the absence of damage to the cable, as well as the strength of the contacts. All these manipulations are carried out only after disconnecting the device from the electrical network.

If a breakdown has not been detected and the equipment does not want to start, then you should proceed to checking the start relay.

In this case, the refrigerator will have to be moved away. In addition, some models are equipped with a partition that completely covers the engine compartment - this must be removed. In most models, the relay is located on the left. After opening the lid you can get to the inside. If no external damage is observed, the connections are removed from the contacts and checked using a multimeter. The problem may lie in the compressor winding.

Tips and tricks

In order for household appliances to work without failures, you should follow the recommendations:

- Drip-type refrigerators must be defrosted regularly.

- The device must be placed on a flat and solid surface.

- The upper and lower compartments should not be overloaded with products.

- It is prohibited to install household appliances of this type near heat sources.

- The evaporator (radiator on the rear wall) must be protected from the possibility of mechanical damage.

- The device must be transported carefully.

If your household appliances are not equipped with a No Frost system and you need to defrost, you need to wait until the ice melts on its own. You cannot pick at it with sharp objects - there is a risk of damaging the refrigerant pipes.

It is prohibited to place hot food - violation of the temperature regime and the formation of a large amount of moisture will lead to serious damage. If malfunctions occur, you should immediately contact a specialist: independent repairs can only worsen the situation.

It is not recommended to ignore minor defects: over time, a serious problem may develop that requires expensive repairs.

Bad seal

Before you find out why the Beko refrigerator began to freeze poorly, you need to familiarize yourself with the principle of operation of the device. If the appliance is not cooling and the freezer is operating normally, you need to check the temperature control buttons and the integrity of the seal. The unit consists of the following components:

- compressor;

- capacitor;

- evaporator;

- connecting tubes.

A refrigerant characterized by low boiling and evaporation temperatures circulates in a hermetically sealed system. If the refrigerator has stopped freezing or the upper chamber does not work, then first it is recommended to carry out an initial diagnosis.

Sometimes a malfunction may be associated with connecting the device to the network, pressing the defrost button, or incorrect installation. Independent troubleshooting is allowed in cases provided for in the user manual. If the upper chamber of the Veko device does not freeze, then you need to pay attention to the condition of the seal.

It is made of special rubber and serves to ensure the tightness of the chambers. If the seal is damaged, heat will flow into the compartments, and the device will operate at full power, trying to maintain the set temperature.

Damage to this part can be determined by the presence of ice on the rear wall of the refrigerator. If this structural element has dried out, no longer fits tightly, or cracks have formed on it, then it needs to be replaced.

The gap between the seal and the door is determined using a sheet of paper.

If it passes freely, then replacement is needed.

This repair does not take much time; you can do it yourself. In some cases, a deformed seal is restored using a hair dryer. To do this, the problematic part is heated and reshaped manually. If the deformation is large, the seal is removed, immersed in hot water and inserted into place.

Installing rubber involves dismantling the damaged part using tools. After cleaning, a new seal is installed in the grooves. To eliminate the formation of gaps and ensure reliable fastening, glue is used. Replacing this structural element will resume the operation of the device.