Hello dear reader of the kuzov.info blog!

This article will help you understand which spray gun to choose for painting your car. Here we will look at the basic characteristics by which you can choose a spray gun, and I will also talk about some manufacturers of inexpensive paint sprayers and manufacturers of premium paint spray guns.

Your requirements

How often will you use the spray bottle? If you plan to use the spray gun rarely, for small volumes of work, then there is no point in spending a lot of money and buying an expensive professional tool. On the other hand, you need a paint gun that will do the job well. For these purposes, you can choose an inexpensive HVLP spray gun with the necessary characteristics.

To choose a spray gun, you need to decide what tasks the spray gun will perform. There are paint sprayers that use different spray systems that have different characteristics. It is necessary to familiarize yourself with the theory and understand the variety of types and characteristics of spray guns offered. Then you can make smart choices. You can paint with any spray gun, but the better the tool, the better the paint coating and the more stable the result.

For novice painters, we can recommend purchasing a spray gun at a budget price, and later, as they gain experience, purchasing a high-quality professional spray gun.

How many spray guns should you have?

You can purchase several paint guns for different purposes and materials. There are spray guns recommended specifically for varnish, for primer and for base.

If you can afford to have three spray guns, then this will be ideal. In this case, there will be no problems with particles from the paint that was sprayed before getting into the varnish. Of course, it is not necessary to purchase three different spray guns. There are painters who have one spray gun with a 1.6 nozzle, with which they apply all materials from primer to varnish. This requires more time and effort to thoroughly wash the spray gun after spraying different materials for further use.

What is a spray gun

This equipment is designed for automatic painting of various (metal, wood, plastic, stone) surfaces and has universal characteristics. It is possible to adjust the operation of the tool, depending on the task. The device allows you to “evenly” apply a paint coating, forming a smooth layer, without fluff, pellets, or bristles, which are possible when working with a roller. The device consists of three main technical components:

- spray gun;

- paint storage tank;

- power supply systems for supplying the mixture.

Today, several types of equipment are produced for carrying out paint and varnish activities. The operating principle of all these units is approximately the same. In addition, using this automatic device, it is possible to apply paintwork not only to vehicle bodies. It is also used for:

- applying a decorative protective coating to a metal surface;

- spraying trees, shrubs, flowers in the country;

- treating premises against insects;

- surface priming during repair and construction operations;

- sanitary disinfection (from fungi) of rooms, workshops, apartments, private houses;

- processing of road infrastructure objects.

A pneumatic spray gun sprays any type of solution. The main thing is that individual fractions of liquid pass through the hole without problems. In this case, the viscosity of the mixture must correspond to the required technical parameters.

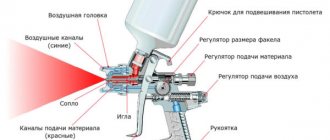

Diagram of the spray gun device

How many spray guns should you have?

There are units designed for applying paint, primer, and varnish. The best option would be to have three spray guns at hand. Each of the devices will perform its own “role”, spraying one or another type of liquid. This eliminates the risk of mixing varnish with primer or paint when using one device. It is possible to use one device for all types of solutions. But then you will have to additionally carry out the procedure of washing the equipment before pouring different mixtures. Next, we will tell you how to choose a spray gun for painting a car.

Please note: Painting a car with chameleon paint

Compressor

You need to choose a spray gun that matches the parameters of your compressor. Or, after purchasing a spray gun, choose a compressor for the gun.

The compressor must produce a certain volume at the required pressure constantly while using the spray gun. The rule is that the compressor should produce 1.5 times the cubic centimeters per minute required to operate the spray gun at a given pressure.

If the compressor performance is insufficient, good atomization will not be obtained.

The compressor may produce higher than the required pressure, but provide insufficient air.

The hose and fittings are also important. If you use a ¼ inch hose, the hose will block the normal flow of air. Use a 3/8" ID hose with couplings and fittings that allow rapid air flow. This will significantly improve air flow.

Compressor selection

When selecting this technical unit, you should take into account what type of spray gun it is. We remind you that there are electric and pneumatic. The second model is considered preferable in terms of performance indicators. Each type of equipment (HP, HVLP, LVLP) has its own characteristics. Based on them, the compressor is selected. HP units require 4 atm for manipulation, while the spray gun incurs noticeable losses during operation (which is why they are gradually going out of use). A compressor is required that is not very productive (100-300 l/min.) with an indicator of 6 atm. AURORA BREEZE-8, KOLNER KAC 24 L are suitable. Devices designed according to the HVLP type require 2-3 atmospheres for spraying. When choosing a compressor for this type of device, we pay attention to technical products with a capacity of 360 l/min, and from 1.5 to 4 atm. The following types of equipment have proven excellent: QUATTRO ELEMENTI 248-504 KM 50-380, FUBAG VDC 400/50 CM3, GARAGE PK 50.MKV370/2.2. LVLP is a technologically advanced instrument, operating in the range from 0.7 to 1.5 atm. A compressor with a capacity of 150-300 l/min is required. The output indicators must be at least 2 atm. We recommend purchasing: QUATTRO ELEMENTI SENZA-24, ZUBR ZKP-190-24-1.5.

Compressor AURORA BREEZE-8

Compressor QUATTRO ELEMENTI KM 50-380

Compressor BISON ZKP-190-24-1.5 Pay attention to: How and with what to paint plastic in the car interior

Nozzle size selection

The nozzle (paint nozzle) has a certain size. The paint material flows through the nozzle, and the tip of the needle is inserted into it, regulating the flow of paint. The needle is moved back and forth by a trigger. When the trigger is fully released, the needle is pressed by a spring and hermetically closes the nozzle. For materials with different viscosities, nozzles of different diameters are used.

- 1.2 – Local painting.

- 1.3 – 1.6 – application of base and varnish. Also suitable for applying water-soluble paints.

- 1.4 – 1.7 – application of varnish and acrylic.

- 1.6–2.2 – priming

- 2.5–3.0 – application of liquid putty.

These are general rules that do not have to be followed strictly. Some painters choose one nozzle size and apply any materials perfectly.

Applying primer requires a larger nozzle, otherwise you will have to dilute it very thinly, which is not advisable. For acrylic primer, its filling capacity is important, and with a large amount of thinner it decreases.

Recommendations for choosing spray guns for car painting

A spray gun is a device that sprays paint and varnish materials. It is convenient to use when painting a car body, since it allows you to distribute liquid materials in an even layer. In particular, with the help of such an aerosol gun you can spray primer, paints and varnishes, and liquid rubber.

Spray gun - a device that sprays paint and varnish materials

Painting devices are divided into two types:

- electrical;

- pneumatic.

The former are also called airless. This is their main difference from pneumatic models. Such spray guns are well suited for treating small areas on the surface of the car. For example, if it is necessary to paint over damaged areas, where it is not so important to obtain an ideal surface of the paint layer. Another advantage is their quick preparation for painting and compact size.

If you want to completely renew the paint on your car body, choose only pneumatic devices. Despite their higher cost compared to electric sprayers, simpler and budget models powered by a compressor can be found on the market. For this reason, professionals recommend that even beginners purchase pneumatic devices.

Let's consider the main criteria for choosing compressor spray guns.

- Device performance. In accompanying documents it is usually indicated as the volume of air consumed. Keep in mind that at the outlet, due to air compression, the productivity will be approximately 1.5 times lower.

- Where is the container with liquid located - top or bottom. In the first case, the paint flows down under its own weight, is picked up by the air flow and then sprayed. From the tank below, the composition is sucked in due to the pressure difference formed inside the device body. In machines with a single spray system, performance is independent of the location of the paint container.

- What is the tank made of? Typically metal or plastic is used. Plastic containers are often made transparent, which allows you to control the volume of remaining material. However, unlike metal tanks, they are more difficult to clean from paint residues.

- Tank volume. If the part is located on top, its capacity is usually about 1 liter. For this, a lightweight plastic container is used. Bottom suction spray guns use a larger metal tank.

- What compounds can the gun be used with? Depending on the density of the material and its viscosity, different device models will be required. Some models, in addition to paintwork materials, can spray primer and liquid putty.

Pneumatic spray gun

We will pay special attention to three particularly important parameters.

Compressor

It is important that the device can maintain a constant volume and pressure of air. The compressor also needs to produce more air mass than specified in the recommendations for the spray gun. This will compensate for losses from air compression in the gun. If the compressor is not efficient enough, the quality of the material atomization will suffer.

What other parameters are important when choosing a compressor?

- receiver volume. An air output of about 50 liters per minute is enough for domestic use. For industrial use, it would be optimal to take a receiver with a capacity of 100 to 500 l/min.

- power. On average, this figure ranges from 1.1 to 1.3 kW.

- type of power supply - from the mains or from a battery. The first one is suitable if you need to carry out large-scale work, when the battery may be discharged.

Note! It is advisable to first buy a spraying apparatus, and then select a compressor for it.

Compressor for spray gun

Nozzle diameter

This part is also called a nozzle. An air-color mixture passes through it. The amount of liquid is regulated by a needle inserted into the nozzle. The needle moves by moving the trigger back and forth, and when it is completely released, the nozzle opening is hermetically sealed. The needle is held in place by a special spring.

The diameter of the nozzle directly determines what materials can be sprayed. Common nozzle sizes are:

- 1.2 mm - for processing small areas, fine work;

- 1.3-1.6 mm - for water-based coatings;

- 1.4-1.7 mm - for spraying varnish or acrylic;

- 1.6-2.2 mm - for priming;

- 2.5-3 mm - for spraying liquid putty.

Some experienced painters, instead of several devices, use one universal one - usually with a nozzle diameter of 1.6 mm - to carry out all types of work.

Video - How to choose a nozzle (nozzle) depending on the material being applied

Comparison table of pneumatic spray guns.

| Model | Spray type | Nozzle diameter, mm | Paint supply | Air consumption, l/min | Price, rub |

| PATRIOT LV 162B | LVLP | 1,5 | Lower | 400 | 900 |

| VOYLET H-827 | HVLP | 1,7 | Upper | 218 | 1 900 |

| Wester FPG-30 pro | LVLP | 1,5 | Upper | 100 | 2 700 |

| HUBERTH LVLP R500 (1.4) | LVLP | 1,4 | Upper | 85-110 | 3 400 |

| JONNESWAY JA-6111 | HVLP | 3 | Upper | 396 | 5 800 |

| DeVilbiss FLG-5 | R.P. | 1,4 | Upper | 277 | 9 000 |

| JONNESWAY JA-LVLP-25G | LVLP | 1,8 | Upper | 283 | 14 200 |

| Walcom Genesi Top Line SP HVLP 1.3 mm (945013) | HVLP | 1,3 | Lower | 350 | 40 000 |

Types and markings of spray guns for cars - choosing the best

When searching for the right nebulizer, you will come across three groups of devices. They differ in markings that reflect the main methods of creating an aerosol effect.

HP

Formation of a torch under high pressure (High Pressure). To ensure their operation, you do not need to use a powerful compressor, since not too much air flow is supplied to the gun. An inlet pressure of 3-4 bar will be required. Under the same pressure, the liquid composition will be sprayed at the outlet. Using this device, you can quickly paint and obtain a uniform application of the composition. The disadvantage of such a device is the small percentage of transfer of the coloring liquid to the surface.

HVLP

This marking indicates that the spray gun uses an increased volume of air and creates an air-paint mixture under low pressure (High Volume Low Pressure). At the moment they are in greatest demand among professionals. The transfer coefficient in such pistols is much higher. The input air supply is at a pressure of approximately 2.5-3 atmospheres, the output value is reduced to 1 atmosphere. Due to the quality of paintwork application, these spray guns are suitable for painting the body in colors with metallic or pearlescent shades.

LVLP

Stands for Low Volume High Pressure. These spray guns are supplied with small volumes of air, and paint is sprayed under reduced pressure. According to professionals, these devices combine the main advantages of HP and HVLP systems. A distinctive feature of the guns is low air consumption and a high coefficient of liquid transfer to the surface being painted. With their help, you can effectively apply almost all types of paintwork materials.

Video - How to choose an HP, HVLP, LVLP barrel

In the table below we have compared the production capabilities of all spray systems. You can rely on these indicators when choosing the best device.

| Characteristic | HP | HVLP | LVLP |

| How much paint gets on the surface of the body | 30-45% | 75% | 70% |

| Compressor requirements | Low, air consumption less than 300 l/min. | High, air flow from 360 l/min | Average, air consumption about 270 l/min |

| Inlet pressure, atmospheres | 3-4 | 2,5-3 | 1,6-2 |

| Output pressure, atmospheres | 3-4 | Less than 1 | 0,7-1,2 |

| Fogging | High | Low | Low |

| Does dust kick up | Yes, due to the strong air flow, turbulence is formed. Raised dust settles on the applied paintwork | No. Low pressure air flow does not raise dust in the painting area | No. Low pressure air flow does not raise dust in the painting area |

| Easy to use | Yes. A wide torch is formed at the exit, the paintwork is applied easily and quickly | No. Skills and experience are required to obtain a uniform layer of paintwork without drips | Yes. The composition is applied evenly, but the size of the spray torch is smaller than in HVLP |

| Performance | Low | High | High |

Important! Instead of the LVLP marking, some manufacturers use other abbreviations - GTI PRO for DeVILBISS, RP for SATA, HTE or GEO for Walcom.

Paint spray systems

To understand the differences between the types of paint guns, let’s consider, in a simplified way, the principle of spraying. Compressed air from the compressor under pressure enters the spray gun, paint from the barrel flows through another channel, passing through the air cap, it splits the paint coming out of the nozzle and forming a torch. The pressure with which the spray gun sprays the paint material determines the type of spray gun. Below are the main spray systems by which spray guns differ.

- HP (High Pressure) – high pressure.

- HVLP (High Volume Low Pressure) - high volume, low pressure.

- LVLP (Low Volume Low Pressure) - low volume, low pressure.

- HTE (High Transfer Efficiency) – High transfer efficiency.

HP system spray guns

This is an outdated spray system. Paint guns of this type have been used for a long time to paint cars in body repair shops.

For their operation, an input pressure of 3–4 atmospheres is required. Actually, at the moment of spraying the pressure is approximately the same. These spray guns require a small volume of compressed air. They do not require a very powerful compressor to operate. HP system spray guns are capable of creating a wide spray pattern and uniformly applying the paint material. The main disadvantage of such spray guns is the low coefficient of transfer of sprayed materials to the surface. When sprayed, such spray guns produce a paint mist that does not fall on the surface to be painted. Thus, 30–45% of the sprayed paint forms a paint coating, and the remaining 55–70% settles outside the painted surface.

So, to summarize, we will describe the advantages and disadvantages of spray guns with the HP spray system.

Advantages:

- No high performance compressor required.

- A wide torch is formed, which facilitates uniform application of the paint and varnish material.

- High speed of application of paint and varnish material.

Flaws:

- Low coefficient of transfer of sprayed materials to the surface to be painted.

- The high pressure of spraying raises dust in the workshop, which then settles on the painted surface.

HVLP spray guns

HVLP (High Volume Low Preassure - high volume, low pressure). Spray guns of this type have become widespread and are now successfully used by painters when painting cars. These paint guns use a large volume of air to operate and spray at low pressure. HVLP spray guns with a sufficiently high input pressure (2.5 - 3 atmospheres) spray paint materials at low pressure (less than 1 atmosphere). Due to the low spray pressure, a large percentage of the sprayed paint material is transferred to the surface to be painted (about 75%).

Spray guns of this type have proven themselves well when applying paints with metallic and pearlescent effects.

Let's look at the advantages and disadvantages of HVLP paint guns.

Advantages:

- High percentage of transfer of paint and varnish material to the surface to be painted when sprayed.

- Low fogging when spraying.

- Low spray pressure does not raise much dust in the painting area.

- High performance.

Flaws:

- A powerful compressor is required to constantly supply a large volume of air to operate the spray gun.

- It is required to use a hose to connect the compressor to the spray gun with an increased diameter.

- It is required to apply paints and varnishes at a short distance from the surface. This requires a certain level of professionalism from the painter in order to paint without smudges.

Low pressure spray guns LVLP system

LVLP (Low Volume Low Pressure - low volume, low pressure). Spray guns of this spray system were invented to eliminate the disadvantages of HP and HVLP sprayers. Different manufacturers may have different abbreviations for paint guns with a similar spray system. For example, SATA has a similar technology called RP (Reduced Pressure), DeVILBISS has GTIPRO, Walcom has GEO and HTE (High Transfer Efficiency). The purpose of these spray guns is to combine low air consumption with a high transfer coefficient of paint and varnish material.

These sprayers operate at an input pressure of 1.6–2 atmospheres, and atomization is carried out at a pressure of 0.7–1.2 atmospheres. LVLP spray guns have reduced air consumption compared to HVLP spray guns. This allows the compressor performance requirements to be reduced. In this case, the percentage of transfer of paints and varnishes to the surface to be painted during spraying is about 70%.

LVLP paint guns have proven themselves well when applying all types of paints and varnishes.

So, let's list the advantages and disadvantages of sprayers with an LVLP spray system.

Advantages:

- It does not require too much air volume when operating the spray gun (about 200 l/m is required).

- High percentage of transfer of paint and varnish material to the surface to be painted.

- Due to the low spray pressure, it does not raise much dust in the painting area.

- Low fogging when spraying.

- High performance.

- No dependence on pressure drop.

Flaws:

- Low Spray Speed

- Creates a smaller spray pattern than HVLP spray guns

Spray systems

To understand the difference between different types of pistols, you need to consider the design and principle of operation. So, compressed air enters the device, and dye from the barrel is supplied through another channel. As the paint passes through the air cap, the air will break down the paint and form a spray. The pressure determines the type of paint sprayer.

There are several types of sprayers:

- HP – for high pressure;

- HVLP – high volume at low pressure;

- LVPL – low volume at low pressure;

- HTE – high efficiency.

In the video: which pistol to choose - HP. HVLP. LVPL.

HP system

This system is now considered outdated. Guns of this type have long been used for painting cars in workshops. For their operation, a pressure of 3-4 atm is required. At the moment of spraying, the pressure should be approximately the same.

These atomizers also require a small volume of air. Select a compressor for them with medium or low performance. The torch is wide, allowing you to apply paintwork evenly. The main disadvantage is the low coefficient of paint transfer to the surface being painted.

Such tools create a mist during the spraying process that does not reach the surface. So, only 30-45% of the paint sprayed with this sprayer reaches the surface, the rest will settle in other places.

HVPL system

These tools are widely used today and are used by most professional painters. An HVPL spray gun requires a large volume of air and the spraying process is carried out at low pressures. To operate the gun you need from 2.5 to 3 atm. The spraying process is carried out at a pressure not exceeding 1 atm. Due to the low pressure when spraying paint, almost all of it will settle on the surface being treated.

Such spray guns showed excellent performance when working with metallic and pearlescent paints. Disadvantages include the need for a powerful compressor and a hose with an increased diameter, as well as the need to work at a distance.

LVLP system

A spray gun of this type eliminates the shortcomings of the sprayers discussed above. Different manufacturers use different designations for this system. The task of these devices is to combine low air flow with a high percentage of paint transfer to the surface.

Guns of this system operate at pressures from 1.6 to 2 atm. Paint is sprayed at a pressure of 0.7-1.2 atm. The device consumes less air compared to HVLP models. This makes it possible to significantly reduce the power and performance of the compressor. The percentage of paint transfer to the surface is more than 70%.

Electric spray guns

Along with pneumatic equipment, there is also an electric spray gun. Its advantage is that this system does not require a compressor. A turbine is used instead. Professional car painters do not use an electric spray gun due to its disadvantages.

It is stated that during operation there is a large consumption of paint. The nozzles included in the kit are too large to paint the car. Even if you know how to paint correctly, you won’t be able to get a quality result. It is difficult to adjust the appropriate pressure, so the paint comes out differently. The result is shagreen and other defects.

An electric spray gun is applicable if it is necessary to paint a car, when the quality of painting is not important. If you need quality, then a pneumatic tool is a must.

Which spray gun is better depends on many factors. For experienced masters - professional Italian, for beginners - also Italian, but simpler. However, when painting with pneumatic equipment, the result will be many times better.

Manufacturers of spray guns

Spray guns from Italy

GAV

Inexpensive spray guns. Can be recommended at the initial stages of mastering the painting business. Mainly to practice applying base and acrylic. Models with large diameter nozzles can be used as separate guns for applying primer and liquid putty. For example, the Record 2200 model.

WALCOM

The Walcom trademark belongs to the manufacturing company Walmec, which has been on the market of professional painting equipment since 1945. It has various models of spray guns recommended for various paints and varnishes. You can choose a high-quality model for use in a body repair shop.

Spray guns from China

Many Chinese manufacturers make uncertified copies of spray guns from well-known manufacturers. Most often they turn out to be similar in appearance, but not in quality and characteristics. Some Chinese paint guns can be used to paint more or less normally, but they are characterized by instability in operation. As you can imagine, many Chinese manufacturers are reducing the cost of production technology for paint sprayers.

Among the budget spray guns made in China, we can note the products of the company VOYLET .

They produce paint sprayers of various models, intended for both industrial enterprises and car repair shops. They have acceptable product quality. VOYLET spray guns meet the requirements of modern standards for applying various paints and varnishes.

Auarita paint guns , which have positive reviews, given their inexpensive cost and Taiwanese STAR .

Expensive segment spray guns

Manufacturers of professional spray guns, which are leaders and occupy the market segment of expensive premium paint sprayers, are described below. These are not the only brands of expensive professional spray guns, but they are the most famous.

DeVilbiss

DeVilbiss is a British company that has been manufacturing spray guns for over 100 years. In many countries, professional painters use paint sprayers from this company. DeVilbiss spray guns are lightweight and ergonomically designed.

DeVilbiss has recently had its own representative office in Russia and you can easily purchase any model of spray gun and accessories.

SATA

The spray guns of this company are developed by German engineers. They are of high quality and have their own developments. The paint sprayers of this company are characterized by high wear resistance, which is important for continuous use in workshops.

IWATA

Anest Iwata is a Japanese company that has been around for over 80 years. Produces very high quality spray guns. Has its own innovative developments. The model range includes paint sprayers with a side-mounted tank that can be rotated. By changing the angle of the barrel, it is very convenient to paint hard-to-reach places, as well as horizontal surfaces, and you are not afraid that the paint material will spill out or stop spraying due to the unstable supply of paint from the barrel.

Having personal experience of using a spray gun from this company, I can say that the gun is easy to set up, applies any paint and varnish materials perfectly and copes well with painting with a “transition”.