An electric jigsaw is a universal tool that makes it possible to make curved and straight cuts in almost any material (soft wood, steel sheets, and glass).

But what is universal is the tool itself, and not its equipment - for any task you need a certain type of blade for cutting.

To understand how to choose a file for an electric jigsaw in each case, you need to figure out what aspects to follow when choosing, how the blades differ from each other, and how to find out about this from the markings.

Types of saw blade shanks for jigsaws

The first thing you should definitely pay attention to when choosing a file for a tool is the type of shank. This is really logical, because if your electric tool is not designed to work with this variety, then you simply will not be able to use a new attachment. There are really few options.

T-shape shank

It also has a second unspoken name, namely “Boshevsky”, because it was this manufacturer that developed this type of shank. Since BOSCH is a real leader in the market of tools and jigsaws in particular, other giants in this industry have begun to switch to the T-shape standard, so it will not be surprising that such a tool is the most common. T-shanks are suitable for most modern devices produced by companies such as Mitebo, Makita, Bosch, Itachi, Skill, Sparky, DiVault, Interskol and others.

Y-shape shank

The second most popular type of shank is the one with a Y-shape, the American standard. This is a universal type shank for older models of electric jigsaws. These files are suitable for all tools with screw and block clamps.

Shank from Makita

These are files with a shank that are compatible only with older models of electric jigsaws from the manufacturing company Makita.

Shank from VO S CH

But here the only difference from the T-shaped shank is that there is a second stop; such files are only suitable for older models of jigsaws from Bosch.

By the way, the last two types of shanks can be classified as rarities, because it is almost impossible to find such attachments in stores.

Nozzle sizes

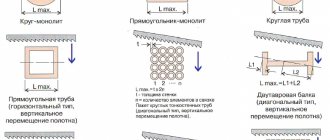

Canvas length. The length of the file can be varied over a wide range - from 4 to 25 cm. Please note that the longer the file, the thicker the workpiece it can cut. It is worth noting that the actual depth of cut that can be achieved will depend not only on the length of the saw blade alone, but also on the capabilities of the tool. To saw thin material, it is worth using short files, because their use will guarantee a clean and neat cut, because the process will not be hampered by the deformation of a very long blade.

Width of saw blade. The marking of files for an electric jigsaw also includes data such as width. It is selected depending on the type of work that needs to be done with an electric jigsaw. Wide saw blades are ideal for straight cuts - it will be easier to guide them in the required direction, and it turns out that the sawing line will be perfectly straight. But for figured cutting you will need a blade with a narrow back, which is easier to perform various maneuvers and “draw” smooth curved lines.

Thickness of the canvas. And now we come to the most important thing. The thicker the file, the less it will deviate from the vertical position when working, which means that the cut along its entire length will be perpendicular to the surface of the material. But when trying to get a perfect, even cut, you should not forget that too thick files may not fit an electric jigsaw with a quick clamping mechanism.

Varieties of cutting edge geometry

If you look closely at saws for electric jigsaws, you will definitely notice that they all differ in the size of the teeth set and the geometry of the cutting edge. The more they are spread apart, the wider the cutting line will be, due to which the speed of work will increase (however, the quality of the cut will decrease). Not only the cleanliness of the cut will depend on the routing method, but also what materials you plan to use such equipment to perform work on.

Milling with classic layout

Peculiarities. In saws with a standard setting, the teeth are bent in turn in different directions, just like the simplest hand hacksaw. Such a layout will help reduce the heating of the saw during work, because the blade will experience almost no friction in a large cut. It is almost impossible to create a beautiful clean cut with such a file, but the speed of work is very high.

Application area. The purpose of a saw blade with milled teeth and a classic setting is to quickly cut soft and hard wood, as well as non-ferrous metals and plastics.

Milling with wavy layout

Peculiarities. In a nozzle with a similar layout, the teeth will change direction not one by one, as in the previous case, but in cells, several in a row. Moreover, for each tooth the size of the deviation from the main axis is not the same as that of its neighbors - the working edge of the saw blade will create a wave.

Application area. The purpose of a saw with a wavy layout is to obtain a clean cut not only on wood, but also on plywood, chipboard, and also to work with plastic and non-ferrous metals.

Grinding with standard setting

Peculiarities. The teeth of such a blade will be spread apart and undergo a grinding process, and the cutting line of such a blade will be quite wide.

Application area. Files with ground teeth, which are set using the classical method, are required to obtain a quick but clean cut of wood, as well as derivatives in the form of fiberboard, chipboard and other things.

With conical grinding without routing

Peculiarities. The blades of such saws will not have a spread of teeth, but their segments will undergo grinding, and this will ensure a thin cutting line and evenness of the cut.

Application area. Makes it possible to accurately cut laminate, wood and polymer materials.

What to look for before buying files

The characteristics and capabilities of the files can be found from the markings. A specific designation standard has not been developed, but most manufacturers try to use similar designations. Most often, markings consist of a combination of numbers and letters.

Markings on the jigsaw file

The first letter usually identifies the shank type (U,T). The number following it symbolizes the length of the file:

- 1 - up to 75 mm;

- 2 - from 75 to 90 mm;

- 3 - from 90 to 150 mm;

- 7 - from 150 mm.

Then follows the letter from A to D. A is the smallest teeth, D is the largest. The last letter of the marking is additional information (R - reverse teeth, F - bimetal, O - figured cutting, etc.).

The scope of application of the files can also be determined by the color of the shank:

- black - universal file;

- gray - wood;

- blue - metal;

- red - synthetic materials;

- white - metal and wood.

The material used to make the file is usually indicated at the transition from the shank to the working area. Combinations of letters indicate the type of steel:

- HCS - high carbon;

- CV – chrome vanadium;

- HSS – high speed;

- HM – tungsten carbide.

In addition, most files have inscriptions explaining the scope of use of the files, as well as some of their characteristics.

Buying files in a set is an excellent option to provide yourself with a supply of consumables for a jigsaw. In this case, you can pay attention both to sets with a large number of different files, and to those in which one or two types of blades are presented, but in large quantities. The first option is preferable for the home craftsman, the second is suitable for professional use.

Video - Comparison of jigsaw files, which are the best and which are best to buy

Classification by type of processing material

The types and markings of jigsaw files are very important. Initially, the tool was invented to work only with wood, and modern tools have learned to saw both plastic and metal, but their main purpose still remains derivatives of wood and natural materials. It is for this reason that most of the saw blade range is designed to work with such materials. Wood files are divided into several groups according to the type of work for which they are needed.

- Quick cut When performing certain types of work with wood, accuracy is often not as important as speed of execution. Saws for quickly cutting wood can provide a high degree of productivity. It will be easy to distinguish them from the rest by the following characteristic features - the length of the canvas is from 6 cm, large teeth from 0.6 cm and a large size of the mark (from 0.1 cm).

Helpful advice! In order to saw wood across the grain, blades with straight teeth are also suitable, and for longitudinal cuts, saws with oblique teeth are perfect.

Clean cut Cutting furniture panels made of chipboard or trimming parquet boards requires a neat and smooth cut. When solving such problems, where the quality of the work performed, rather than productivity, comes first, blades for clean cutting are used, which have an average tooth size (no more than 0.3 cm) and a small gap. A large number of files have teeth directed towards the electric jigsaw, and in order for the front side of the material after cutting laminate or chipboard to be as neat as possible, without burrs or chips, the workpiece should be placed with the back side facing the tool or towards you. To cut from the front side, use a blade with a reverse tooth, and although it is more difficult to work with, the effect is much better.

Helpful advice! Panels laminated on both sides can be cut without chipping and accurately using a special saw with two rows of teeth.

- For metal. It should be recognized that an electric jigsaw is almost unsuitable for cutting metal - the tool can hardly cope with the loads, the process is slow, and the files become very dull. But in certain cases, even this method may be justified.

Cloths for metal

Jigsaw blades are usually made from high-speed steel. This product is quite hard and has a bluish tint. The file has a different tooth shape and the geometry of the blade itself. Depending on what kind of cut is needed, products with fairly fine teeth that are exactly the same size are used. As a rule, a blade with such teeth is used for soft metals.

If the choice fell on a product that has teeth with varying geometry , the file is used for cutting harder metals. This product has teeth, where the pitch and size increases towards the edge. The advantage of this option is the direct simplification of the cut, since this structure of the teeth, as it were, planes the metal, with each of the teeth performing its own function. This structure of the file minimizes the load on the tool, therefore increasing its service life. The same function is performed with a slightly curved blade at the bottom.

Read also: Table of roller bearing sizes by diameter

All jigsaw files for metal have fine teeth. These products have a certain marking, where you can always see the Latin letter “A” in the last or penultimate place. This letter indicates the strength of the metal. Before choosing a saw for cutting metal, you need to understand what material it will be intended for. Because the harder the metal, the smaller the tooth should be.

When choosing a file for a jigsaw, it is worth taking into account the peculiarities of the material, because the wrong tool will not bring the desired result. To choose the right file, it is important to study the following marking list:

- T111CHCS - a carbon steel product that is used for cutting wood and plastic (length 75 mm, tooth pitch 3 mm);

- T119B0HCS – carbon steel, designed for working with soft wood (length 56 mm, tooth pitch 2 mm). As a rule, it is used when performing delicate work, figure cutting;

- T101BHCS is a carbon steel blade used for cutting soft wood. The advantage of such a blade is an even cut (length 75 mm, tooth pitch 2.5 mm);

- T101BRHCS - carbon steel is also used for manufacturing; the main nuance of the blade is reverse teeth. Designed for working with soft wood (length 75 mm, tooth pitch 2.5 mm);

- T118AHSS – hardened steel is used for manufacturing and is intended for hard metals (length 50 mm, tooth pitch 1.2 mm);

- T144D HCS – carbon steel is used, the blade has set teeth. The direct purpose of the blade is cutting hard and soft wood. (length 75 mm, tooth pitch 4 mm);

- T127DHSS – hardened steel is used, designed for working with non-ferrous metals. The blade has milled set teeth (length 75 mm, tooth pitch 3 mm);

- T118GHSS – made of hardened high-speed steel. The main difference is the wavy teeth and is used for hard metals. (length 50 mm, tooth pitch 0.8 mm);

- T118BHSS – made of hardened high-speed steel, tooth shape – slotted wavy. Main use for cutting hard metals (length 50 mm, pitch 2 mm).

Such markings can be found directly at the foot of the jigsaw blade.

Naturally, when choosing jigsaw files, you cannot remember all the nuances and criteria. When buying jigsaw files, pay attention to the following points:

- a file, which has large and, at the same time, rare teeth, is used for rough cutting of soft wood. Wide is used for straight cuts and large radii. Narrow - exclusively for figured cutting;

- a file with medium and rare teeth is used if it is necessary to achieve a clean cut of wood;

- with fine teeth used for straight cutting of metal and plastic;

- with medium isosceles teeth is used for figured and clean sawing of wood with a small radius.

Speaking about the manufacturer, you can safely talk about Makita, Praktika. Jigsaws from these manufacturers have proven themselves to be excellent in quality and durability. When choosing a file, remember its intended purpose, otherwise your goals will not come true. Knowing the types of files used, and paying attention to the markings, method of fastening, as well as the manufacturer, the correct choice is guaranteed.

A jigsaw is a high-speed device, which is why do not neglect safety rules!

An electric jigsaw is a device of regular practical use for every woodworker, and the development and improvement of technology has expanded the scope of its practical use. Now the device can be successfully used when working with other materials; the only thing that should be taken into account is the correct choice of saw blade. Jigsaw files are classified according to several of the most significant characteristics, which allows you to initially select the right attachment depending on the features and type of cutting. Let's try to figure out how to choose the right file for your jigsaw, and what types there are.