Purpose of boilers

Solid fuel boilers are the best option for heating rooms of varying sizes.

Gas heating equipment, even with access to the central main line, requires significant costs and effort to connect an individual line.

Electric boilers are more convenient to use. But to service large facilities, models with significant power are required, the installation of which requires a three-phase power supply. This is accompanied by additional costs and the need to coordinate the wiring design. Also, in the event of an emergency power outage, the house will be left without a heating source.

Expert opinion

Torsunov Pavel Maksimovich

Solid fuel boilers are often the best choice for heating a room. And the long-burning function allows you to create heating systems for houses with large areas and provide objects with heat from a single source.

Double-circuit solid fuel boilers

Double-circuit heating boilers using solid fuel are intended for heating premises.

These devices can operate on wood, coal, biofuel from wood waste, etc.

Today, double-circuit solid fuel boilers are considered a relatively inexpensive and reliable option for heating a home and providing hot water.

These units are produced in two types:

- with a boiler built into the device;

- with built-in coil.

It should be noted that a feature of long-burning double-circuit solid fuel boilers is the inability to make precise heating adjustments, which makes it possible to ensure a stable temperature of the coolant for heating rooms. This is their main drawback, but this problem can be solved.

To make it possible to regulate the temperature in the boiler, this equipment should be connected together with a boiler boiler, the so-called indirect heating, which has a built-in coil that passes hot water from the unit through itself.

In this case, this element of the device performs the function of a heat exchanger and is mounted in such a way that uniform heating of the liquid is ensured. Since the heat exchanger has a large surface area, the water becomes hot in a short period of time.

All dual-circuit models that run on solid fuel have an identical structure. These are two cylindrical containers, one of which is located inside the second.

The internal one is responsible for heating the home, and the external one is responsible for supplying hot water. The heat exchanger itself contains a pipe that heats the water. It also makes it possible to remove gas from the furnace.

Any double-circuit boiler has a bracket-shaped pipe responsible for heat distribution.

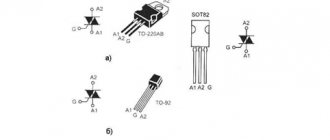

The solid fuel boiler diagram includes the following:

- draft regulator;

- combustion and heating chamber; combustion zone;

- flap;

- telescope tube;

- air distributor.

Each boiler holds approximately 30 kg of solid fuel at a time. This guarantees uninterrupted operation of the dual-circuit model for 8 hours. In most cases, the coolant is water, since it is an inexpensive and safe raw material.

However, it must be taken into account that in winter, if a double-circuit device is not used, the water will freeze. To avoid this, it is necessary to use antifreeze. Its use is not required for daily heating of the home.

A double-circuit boiler is made of steel or cast iron.

The second option is considered more durable, however, it is characterized by increased fragility, which increases significantly with strong heating.

Accordingly, during operation of a solid fuel boiler it is necessary to pay attention to the water temperature. To reduce it, the heating system is filled independently with cold liquid. A cast iron solid fuel boiler is considered to be of higher quality, because its assembly is done manually.

The steel counterpart has many features.

Although this equipment is more durable, it can corrode due to contact with moisture. When the temperature level is exceeded, the thermostatic valve will open automatically, which will cool the system.

It is worth remembering that a steel boiler is created by welding, and this affects the price of the equipment.

Features of devices

Long-lasting combustion is ensured by a large reservoir for storing firewood, as well as by the method of two-stage combustion of fuel.

Operating principle of the device:

- Firewood or other solid fuel is loaded into the firebox. The tank is filled completely, leaving a small space with small wood chips and branches just next to the window to facilitate ignition.

- Using paper or a torch, set fire to the bookmark. At this stage, enough air enters the chamber to begin intense combustion.

- When the fuel is occupied, the air flow into the tank is reduced to a minimum. This technique leads to a transition from combustion to smoldering of the material.

- During thermal decomposition, wood releases large amounts of gases with increased energy potential (pyrolysis process).

- In standard furnaces, pyrolysis gases rush into the chimney, and in long-burning devices they pass into the afterburning compartment. There, under the influence of oxygen and high heat, they ignite, completely burning out. This process is accompanied by the release of a large amount of heat.

During the operation of the boiler, solid fuel is processed into fine ash, and the gas burns out in the afterburning tank, which makes it possible to minimize harmful emissions and waste.

Types of boilers, their advantages and disadvantages

Modern technologies have made it possible to develop and produce several types of solid fuel boilers with a higher coefficient of sub-ice action, let's look at them in more detail.

Classic boilers

All solid fuel boilers can be divided into two types - single-circuit and double-circuit.

The presence of an additional circuit makes it possible to provide a residential or industrial building with hot water. There are two types of structures for heating water - flow-through and storage; the flow-through system is made in the form of a coil or pipe system, and storage is a built-in container (boiler) in which there is always a certain supply of hot water. The advantages of a dual-circuit system are the compactness of the unit and ease of operation, but it is more expensive than its single-circuit counterpart and requires a minimum content of mineral impurities in the water, which cause deposits on the walls of the pipes.

When using a single-circuit boiler, providing hot water is only possible with the purchase of additional equipment - an indirect heating boiler. The advantages of this unit are low cost, high efficiency, and the ability to install a cast iron heat exchanger. Disadvantages include the need for additional space when installing a hot water supply system and the cost of a boiler.

Gas generator (pyrolysis) boilers

Among all solid fuel units, models using the pyrolysis process are the most efficient devices, their efficiency reaches 90%. The process is based on the principle of high-temperature decomposition of organic fuel. Combustion occurs in several stages: first, the fuel is heated with limited access to oxygen, heating causes the release of pyrolysis gases, which are burned in a separate chamber, and gaseous waste, having passed through an additional heat exchanger, is removed through the chimney.

Advantages:

- Efficiency 90%;

- minimal amount of ash and soot formation;

- laying firewood for 8-12 hours;

- minimum waste in the form of ash;

- reduced emissions of harmful smoke into the atmosphere.

Due to the high temperature in the combustion chamber, maximum heat transfer is achieved. The fuel used for this type of boiler is coal, wood chips, briquettes, pellets and firewood. It is very important for the efficient operation of the equipment to use fuel with minimal humidity. Strict requirements for humidity characteristics of no more than 20%, the high price of units and volatility are the main negative qualities of these devices, but nevertheless, the purchase of a pyrolysis boiler is justified, since it allows you to save on the amount of fuel, which is required significantly less than for classical models. You can read more about this type of boiler here .

Features of long-burning boilers

The main disadvantage of solid fuel thermal units is the need to constantly monitor the presence of fuel in the combustion zone. The design of long-burning heat generators, such as TT Energy boilers, allows the firebox to be loaded for a period from 12 hours to 5 days , depending on the type of fuel and the volume of the combustion chamber.

Most often, in structures of this type, top combustion is used, air is supplied through a telescopic air duct, the air is preheated in a special chamber, as the fuel burns, the air duct is lowered, ensuring combustion of the next layer of fuel mass; in some models of this type, direct (bottom) combustion is used. The temperature of the coolant is regulated by supplying air to the combustion chamber, which allows, if necessary, to transfer the combustion process to smoldering mode. Another feature of long-burning boilers is the large volume of the combustion chamber, which starts from 100 liters.

Advantages:

- non-volatile;

- loading the firebox once every 2-3 days;

- deep power regulation;

- low ash residue;

- average price range.

Video review of what you need to know and how to choose the right one, an expert explains

Solid fuel and electric heating

A solid fuel unit and an electric heater are, at first glance, not a very familiar combination, but when there is a threat of defrosting of the heating system, the function of the electric element becomes clear. Many models that use solid fuel require frequent loading, and if the moment is missed or the fuel simply runs out, the boiler operation stops. To prevent this from happening, the boiler is equipped with an electric heater. For double-circuit models there may be several shadows. The main task of electric heaters is to eliminate emergency situations, therefore their power does not exceed 1/3 of the boiler power; electric heating is turned on automatically.

Combined devices provide more comfortable use of boilers; there is no need to get up at night to load firewood again; you have the opportunity to leave home without the risk of an emergency situation in the heating system. But you have to pay for comfort; combined units are much more expensive than their counterparts without electrical heating.

Selection options

When choosing a solid fuel boiler, a number of important criteria should be taken into account:

- The power of the unit is selected depending on the heated area and the required coolant temperature.

- Availability of fuel.

- The type of traction in the pushing compartment is natural or forced. This characteristic affects the performance of the device and the possibility of its installation in a certain room.

- Heat exchanger construction material. The most common products are made of steel and cast iron. The reliability of the boiler and its heat-saving qualities depend on their quality.

- Efficiency factor (efficiency) is determined by the type of fuel used, the specifics of the design and the presence of additional elements, such as exhaust, automatic fuel supply, etc.

- The “water jacket” placement option allows you to optimally select the unit for installation in compliance with fire safety requirements.

- The method of loading fuel and the size of the combustion chamber allows you to calculate the operating cycle of the boiler and the possibility of automating its operation.

- The weight of the device is taken into account when determining the basis for installing the equipment. The surface must be durable and resistant to deformation.

- The location of the ash pan and its design determine the ease of maintenance of this element during operation of the equipment.

- Price depends on the characteristics of the device and the popularity of the brand.

A short overview of long-burning solid fuel boiler models

This section will consider several popular models of solid fuel boilers among Russian consumers, which have proven themselves to be reliable and easy-to-use heating devices.

Solid fuel boiler “Stropuva S40P”

The heating boiler “Stropuva S40P” is a Lithuanian model, designed for heating fairly large areas and can operate on coal, wood, as well as wood and peat briquettes.

Stropuva boilers immediately stand out from the general background with their characteristic shape

The boiler has a top-burning design and consists of two cylinders, one of which is located inside the other. The space between the cylinders is, in fact, a water jacket, that is, a heat exchanger for the coolant of the heating system. The inner cylinder contains a volumetric combustion chamber, into which air, which supports surface combustion of the fuel fill, is automatically supplied through a telescopic distributor. As the fuel burns, the distributor lowers, creating optimal conditions for its smoldering. In the upper part of the chamber, the final combustion of pyrolysis gases occurs.

The boiler has a cyclic operating mode; fuel is loaded into the combustion chamber manually.

Due to its shape, the unit has compact dimensions in plan, but has a considerable height - 1900 mm. Therefore, the room for its installation must have a sufficiently high ceiling.

Technical characteristics of “Stropuva S40P” are determined by the following parameters:

| Parameter name | Indicators |

| Boiler type | long burning solid fuel boiler |

| Type of fuel used | firewood, coal, briquettes, Eurowood, pellets |

| Number of circuits | one (heating only) |

| power, kWt | 40 |

| Maximum heated area, m² | 400 |

| Efficiency, % | 85 |

| Presence of a fan for air injection | There is |

| Built-in circulation pump | No |

| Minimum coolant temperature, ˚С | 60 |

| Maximum coolant temperature, ˚С | 95 |

| Maximum pressure in the heating system circuit, bar | 1.5 |

| Primary heat exchanger material | steel |

| Chimney diameter, mm | 200 |

| Thermometer | There is |

| Control type | mechanical |

| Energy dependence | Yes |

| Availability of safety valve | There is |

| Device weight, kg | 308 |

| Linear parameters (height, depth, width), mm | 2120×680×680 |

The average cost of the device for 2021 is 105,000 ÷110,000 rubles.

You may be interested in information about what bimetallic heating radiators are

Solid fuel boiler "Buderus Logano G221-20"

The Buderus Logano G221-20 model is a solid fuel boiler made in Germany, characterized by high stability and operational reliability. The heating device can operate on different types of fuel - wood, coal, briquettes and coke. The use of more heat-intensive types of fuel is permissible, since the boiler is equipped with a cast iron heat exchanger.

The Buderus Logano G221-20 boiler accepts almost all types of solid fuel

The features of the solid fuel boiler “Buderus Logano G221-20” include the following:

- Large loading volume of fuel and ash chamber.

- The ability to reinstall the firebox door to the other side - sometimes this needs to be done for ease of use.

- Easy access to cleaning the combustion chamber and ash chamber.

- This boiler model can be easily integrated into an existing heating system, for example, as a backup heating source.

A whole line of solid fuel heating devices “Buderus” of the “Logano G221” series with different technical characteristics is supplied to the Russian market. Therefore, from them you can choose a unit that has the required heating power for both residential and industrial buildings.

The technical characteristics of the Buderus Logano G221-20 are as follows:

| Parameter names | Indicators |

| Boiler type | long burning solid fuel boiler |

| Type of fuel used | firewood, briquettes, “eurowood”, coal, coke. |

| Number of circuits | one (heating) |

| power, kWt | 20 |

| Maximum heated area, m² | 200 |

| Efficiency, % | 78 |

| Coke consumption, kg/h | 3.9 |

| Coal consumption, kg/h | 3.6 |

| Firewood consumption, kg/h | 5.6 |

| Maximum coolant temperature, ˚С | 90 |

| Maximum pressure in the heating system circuit, bar | 4 |

| Primary heat exchanger material | cast iron |

| Chimney diameter, mm | 150 |

| Thermometer, pressure gauge | There is |

| Control type | mechanical |

| Energy dependence | Yes |

| Device weight, kg | 210 |

| Linear parameters (height, depth, width), mm | 1370×820×605 |

The average cost of such a device for 2021 is 110,000÷115,000 rubles.

You might be interested in information on how to choose a wood stove for your home

Solid fuel boiler “Protherm Beaver 50 DLO”

"Protherm Bober 50 DLO" is a long-burning boiler made in Slovakia, made of cast iron. The device is intended for heating both residential and industrial facilities.

Massive, reliable cast iron boiler “Protherm Beaver 50 DLO”

The efficient operation of the heating device is guaranteed with high-quality installation, as well as with regular maintenance throughout the entire period of operation. The Protherm Beaver 50 DLO boiler is designed to operate in a system with both natural and forced coolant circulation. Therefore, this model can easily function even in the complete absence of power supply.

Thanks to the cast iron heat exchanger, the sections are heated evenly, which increases the boiler efficiency to 90%.

The housing is equipped with a cooling circuit that prevents the coolant temperature from rising above 110 degrees.

Foil-coated mineral wool was used as housing insulation, which helps to increase the heat capacity of the unit and the safety of its operation.

The design is simple, and such a boiler is capable of operating in a heating system with natural circulation of coolant in conditions of complete absence of a source of electricity

The device is equipped with a special thermostat, the regulator of which is located on its cover. The required temperature regime is set manually.

Technical characteristics of "Protherm Beaver 50 DLO" are shown in the table:

| Parameter names | Indicators |

| Boiler type | long burning solid fuel boiler |

| Type of fuel used | firewood, briquettes, “Eurowood”, coal. |

| Number of circuits | one (heating) |

| power, kWt | 35 |

| Maximum heated area, m² | 265 |

| Efficiency, % | 90 |

| Maximum coolant temperature, ˚С | 85 |

| Minimum coolant temperature, ˚С | 30 |

| Maximum pressure in the heating system circuit, bar | 4 |

| Primary heat exchanger material | cast iron |

| Chimney diameter, mm | 150 |

| Thermometer, pressure gauge | There is |

| Control type | mechanical |

| Energy dependence | No |

| Device weight, kg | 380 |

| Linear parameters (height, depth, width), mm | 935×740×440 |

The average cost of the device for 2021 is 95,000 ÷ 105,000 rubles.

You may be interested in information on how to choose an electric boiler for heating a house of 100 square meters

Long-burning solid fuel boiler "Teplodar Kupper OK30"

The unit, produced by a domestic manufacturer, is especially popular for use in private sector residential buildings with a small area. Its demand is explained not only by its high technical characteristics, but also by its affordable price.

The Teplodar Cooper OK30 boiler is popular due to its good performance characteristics and quite affordable cost

“Teplodar Cooper OK30” has compact dimensions, so it does not take up much space, and you do not have to build a separate spacious room for it. The device is able to effectively heat the coolant within 20 minutes from the start of the fire, which ensures that the rooms reach a comfortable temperature in a short time. The advantage of this heating unit is that it can operate on any solid fuel, and if necessary, it can also be converted to electricity or natural gas - it is possible to install standard modules.

In practice, it has been verified that the optimally long operating life on one bed of this model is achieved by using two types of fuel simultaneously. For example, firewood is first placed horizontally into the combustion chamber, it is ignited, and then coal is added through the upper loading channel.

The technical characteristics of Teplodar Cooper OK30 are summarized in the table:

| Parameter names | Indicators |

| Boiler type | long burning solid fuel boiler |

| Type of fuel used | firewood, briquettes, “Eurowood”, coal. |

| Number of circuits | one (heating) |

| power, kWt | 30 |

| Maximum heated area, m² | 300 |

| Efficiency, % | 90 |

| Water circuit volume, l | 50 |

| Maximum coolant temperature, ˚С | 95 |

| Minimum coolant temperature, ˚С | 30 |

| Maximum pressure in the heating system circuit, bar | 2 |

| Primary heat exchanger material | steel |

| Chimney diameter, mm | 150 |

| Thermometer, pressure gauge | There is |

| Control type | mechanical |

| Energy dependence | No |

| Device weight, kg | 145 |

| Linear parameters (height, depth, width), mm | 1000×645×420 |

The average cost of the device for 2021 is 24,000 ÷ 30,000 rubles.

You may be interested in information about what characteristics a double-circuit wall-mounted gas boiler has

Device classification

Boilers are divided into several types according to the type of fuel combustion:

- Pyrolysis - equipped with a pair of combustion chambers. In the first, smoldering occurs and gas is formed, which is mixed with oxygen in the second compartment and burned. Such equipment emits a small amount of pollutants into the atmosphere and is considered environmentally friendly. Also, after fuel combustion, little soot remains. Automatic models are additionally equipped with a power regulator.

- With an overhead combustion compartment . Easy to maintain devices, with a minimum of automatic functions required for operation. They can operate autonomously, without access to the power grid. But as a result of work, a large amount of ash accumulates, and not all types of fuel are suitable for them. For example, sawdust and fine chains cannot be used.

- Pellet boilers are boilers for which special compressed briquettes are used for lighting. Such equipment is economical, durable, environmentally friendly and efficient in operation. The disadvantages of the devices are high cost, demanding fuel storage conditions. Pellets are stored only in a dry room.

What long-burning solid fuel boiler is installed in your home?

Pyrolysis Pellet

Types of solid fuel boilers

Based on the heat exchanger material, solid fuel boilers are:

- steel;

- cast iron

Cast iron ones are more durable, but they are very heavy and very inconvenient to maintain.

It is technologically impossible to produce multi-channel cast iron heat exchangers, since cast iron parts can only be manufactured by casting. It is also impossible to weld a separate heat exchanger element to a cast iron section. Cast iron heat exchangers have a smaller heat exchange area, and therefore lower efficiency.

A steel solid fuel boiler has a smaller safety margin. This is due to the thermal expansion of steel.

Over the course of many years of operation of such a boiler, such a process destroys the structure of the heat exchanger. But, as a rule, high-quality steel solid fuel boilers can operate for at least 15 years.

Next, heating boilers are divided according to the type of fuel loading:

- with manual fuel loading;

- with automatic feeding.

A boiler with automatic fuel supply operates on special granules, the peculiarity of which is a low percentage of ash, moisture and their flowability.

The latter feature allows them to easily get from the hopper to the burner of the heating boiler using a special screw drive. A full bunker is enough for 3 – 5 days of continuous operation.

There are systems for accumulating granules in separate, specially equipped large rooms.

Fuel is filled there in such quantity as to last for the whole heating season. From this warehouse, supply is organized using a screw or pneumatic drive directly to the heating boiler.

Such equipment also has the function of automatically cleaning the heat exchanger and controlling all processes using a mobile phone. This makes it possible for the heating system to operate for a whole season without human intervention.

Basically, people can afford to buy a small-sized solid fuel boiler with a small chamber for loading fuel. They burn on one load for no more than 6 hours. This is their drawback.

Since we cannot be away from the boiler room for a very long time. Their advantage is their relatively low price and small overall dimensions.

There is another type of wood and coal boilers - these are stove boilers.

They are suitable not only for heating rooms, but also for cooking. The principle of their operation is the same as in simple boilers. They have a water volume that transfers heat to the heating system.

But their peculiarity is the presence of a hob on which food is prepared. As a rule, they can burn for no more than 4 - 6 hours and have a low cost and small dimensions.

In addition, we note 4 main designs of boilers for the home:

- Constant burning - boilers in the budget segment.

They have a simple design, where there is a water jacket around the combustion chamber, through which the coolant circulates and distributes throughout the entire heating system.

Sometimes they are equipped with water-cooled grates or a stove for cooking.

- Long burning boilers.

This type of solid fuel boilers implies a more modern equipment design.

There are always water-cooled grates, a developed smoke removal system (so-called convection channels), nozzles for supplying air to the combustion chamber and, of course, automation (control unit and forced air fan).

Long-burning boilers also include candle-shaped top-burning boilers.

- Pyrolysis boilers.

The design of this type of boiler has two combustion chambers. In the first, wood is burned (humidity no more than 25%), and in the second, the pyrolysis gas released by the wood burns. The efficiency of such boilers reaches a record 95%, but there are, of course, a number of disadvantages.

- Pellet solid fuel boilers.

They often have a long-burning boiler design, but in the bottom door there is a special pellet burner, to which pellets from the hopper are automatically supplied.

The supply of such a bunker is enough for 2-5 days. Sometimes they are equipped with an emergency cast-iron grate, on which you can burn ordinary solid fuel - wood or coal.

Boilers can also be single-circuit or double-circuit.

A single-circuit boiler is a device that is intended only for heating a room. That is, to heat the water in this case you will need to provide something else. The design of such a device consists of a coolant and a spiral. The coolant can be water or special antifreeze.

Solid fuel double-circuit heating boilers, in turn, have two functions, used for heating the room and heating water. Such devices consist of two spirals. Heating in the boiler, the water passes through pipes throughout the room, returns to the boiler and from there enters the water supply.

Popular models

The most famous suppliers of solid fuel units are the following brands:

- Lithuanian Stopuva;

- German Buderus;

- Czech Wattek;

- Belgian ACV;

- Austrian Wirbel;

- Russian NMK, Zota and TeploGarant LLC.

Among the models on the market from various companies, there are several popular devices.

Stropuva Mini S8

A power-independent unit serving an area of up to 80 square meters. m. Works with three types of fuel and is distinguished by its small size. Equipped with a convenient vertical firebox door.

The special design of the ash pan allows you to reduce the need to clean it to twice a month. One bookmark is enough for daily heating; the pellets burn out in 48 hours.

Advantages:

- high efficiency;

- quality of construction;

- safety;

- presence of a thermometer.

Flaws:

- heavy weight;

- The rough surface of the door makes it difficult to clean.

Reviews

| Roman Oborin: | Igor Falaev: |

| “Economical and compact unit, burns for a long time. It consumes little fuel, heats the house well, and does not produce soot. The only negative is that it’s a bit heavy.” | “A small, convenient barrel, the device is immediately ready for use, you don’t need to assemble or screw anything in. The door handles are of high quality and reliable, they do not open spontaneously. It takes a long time to heat, it can burn for up to 20 hours.” |

Teplodar Cooper Expert-15

Russian model with the ability to install a burner.

In the upper half of the housing there is a fitting for air outlet. Compatible with firewood, coal and briquettes. Three air entry zones and top combustion ensure long-term heat maintenance. At the bottom there is a water reservoir that prevents excessive heating of the floor. A steel plate protects the door from heat. You can additionally attach a draft regulator.

Advantages:

- possibility of installing a pellet or gas burner;

- convenient door placed at an angle;

- continuous burning for 24 hours.

Flaws:

- complexity of installation;

- small firebox.

Reviews

| Oleg Egorin: | Semyon Ivin: |

| “It’s a convenient boiler, you can buy an additional burner, it works for a long time and even after switching off the house remains warm.” | “It’s not a bad unit, it’s enough for almost a day of heating, but it consumes a lot of fuel. Convenient door design for stowage." |

ZOTA Topol-16VK

A device with a water circuit at an affordable price. The triangular shape of the pipe avoids blockages and increases the service life of the device. To refuel the boiler, you can use firewood, coal and pellets.

The model is distinguished by a spacious firebox and the possibility of top and side fuel storage.

Advantages:

- low price;

- ease of use and cleaning;

- efficiency.

Flaws:

- low efficiency.

Reviews

| Vladimir Kharitonov: | Alexey Zaitsev: |

| “A high-quality device at an affordable price for its segment. Works flawlessly." | “The device is pleasant to use, cleans without problems, you can load different types of fuel, both briquette and regular.” |

Teplodar Cooper Expert-22

The device is small in size, capable of operating in 4 modes: fast heating, classic, medium and maximum. Combustion from top to bottom ensures uniform and longer combustion of the material and good heat transfer.

The upper cleaning hatch is protected by a steel screen that prevents burning.

Advantages:

- two hatches for cleaning;

- inclined door for top loading;

- top burning function.

Reviews

| Evgeny Zherdev: | Ivan Alaev: |

| “Sophisticated heating adjustment, you can adjust the burning duration from 30 minutes to a day. Easy to clean, special cleaning accessories included.” | “A high-quality model, the design allows you to connect heating pipes from either side. The device comes with a heating element and a thermomanometer.” |

Stropuva S30

Solid fuel boiler for placement in commercial and residential premises. Equally effective for year-round and seasonal use. It is characterized by high efficiency, is independent of power supply and is compatible with a variety of fuel materials.

The device has compact dimensions and is environmentally friendly. The duration of firewood burning is up to 30 hours, briquettes can smolder for up to 2 days.

Advantages:

- safety of use;

- high efficiency;

- durability;

- build quality.

Flaws:

- high price.

Reviews

| Kirill Malin: | Maxim Kansky: |

| “It burns for quite a long time, it is demanding on the quality of fuel. Soot forms on the outer skin.” | “It uses fuel economically and can be cleaned without any problems with a special powder. The downside is the high price.” |

Model characteristics:

| Model | Stropuva Mini S8 | Teplodar Cooper Expert-15 | ZOTA Topol-16VK | Teplodar Cooper Expert-22 | Stropuva S30 |

| Number of circuits | 1 | 1 | 1 | 1 | 1 |

| power, kWt | 8 | 15 | 16 | 22 | 30 |

| Combustion compartment | Open | Open | Open | Open | Open |

| Non-volatile | Yes | No | No | Yes | |

| Heated area, sq. m | 80 | 150 | 160 | 220 | 300 |

| Control type | Mechanical | Without control panel | Without control panel | Without control panel | Mechanical |

| Fuel | Firewood, wood briquettes | Firewood, coal | Coal and wood briquettes, firewood, coal | Firewood, coal | Firewood, wood briquettes |

| Efficiency, % | 85 | 75 | 75 | 85 | |

| Installation | Floor | Floor | Floor | Floor | Floor |

| Coolant heating, °C | 60-95 | 50-95 | 95 | 50-95 | 60-95 |

| Maximum water pressure in the circuit, bar | 1,5 | 3 | 3 | 3 | 1,5 |

| Weight, kg | 145 | 148 | 108 | 165 | 257 |

| Price, r | 52000 | 34500 | 29500 | 42400 | 85000 |

Types of designs of long-burning solid fuel boilers

From the information presented above, it is already clear that the main task when operating boilers of this design is to achieve the correct dosage of air flows: primary air entering the fuel chamber, and secondary air, which is responsible for the high-quality complete combustion of pyrolysis gases.

Models from different manufacturers solve these problems in different ways. That is, the design of boilers can be equipped with additional devices that balance the processes taking place.

Prices for solid fuel boilers

solid fuel boilers

Forced air boilers

One of the design options is boilers with a built-in fan, which is used to pump air. The distribution of air flows among the chambers through internal channels is carried out using an automatic control unit.

Diagram of a long-burning boiler with a built-in fan for air injection

Almost all boilers equipped with fans are arranged in such a way that the main loading chamber is located in the central part of the structure.

Thanks to the presence of a fan, the fuel quickly flares up, and the heat-resistant materials with which its internal walls are usually lined (ceramic concrete or fireclay) perfectly accumulate heat. The draft created in the furnace constantly supplies the pyrolysis gas released by the fuel to the afterburner chamber, which in some models is located at the bottom. At the entrance to this space, special ceramic nozzles are installed that can withstand temperatures reaching up to 1000 degrees.

When burned, pyrolysis gases heat the water jacket pipes. In turn, the heating circulation pump, installed in the heating circuit and also connected to the automatic unit, ensures the required intensity of coolant movement throughout the entire heating system.

In some models of solid fuel boilers, the afterburner may be located in the rear or upper part of the boiler structure.

A variant of a long-burning boiler with an afterburner located in the rear part of the structure.

If the afterburning chamber is located at the rear of the boiler, it has a rather complex design of heat exchange elements, which facilitates rapid heating of the coolant. Thanks to this, high efficiency of the device is achieved, sometimes reaching 90–95%.

Such designs of electronically controlled boilers have a large number of advantages, but they also have their own significant drawback - they are energy dependent. In the event of a power outage, the fans, pump, and naturally, the entire automatic unit do not function, which leads to a suspension or complete stop of the movement of coolant through the heating circuit. If power outages are not uncommon for the area where the house is located, then it is necessary to have an autonomous power supply system - this could be an electric generator, which must always be kept in a state of full readiness. UPS, uninterruptible power supply units specially designed for this purpose, help prevent infrequent and not too long interruptions.

You may be interested in information on how to make a heat accumulator for a solid fuel boiler with your own hands

Another serious disadvantage of a boiler with an electronic control system is its high sensitivity to voltage changes. Therefore, it is necessary to provide them with protection by installing a separate voltage stabilizer.

Voltage stabilizer - guarantees correct operation of the boiler electronics

You shouldn’t waste money on this device - its cost is not comparable to the cost of a boiler full of electronics, and skimping on such precautions can result in much higher costs! How to choose a voltage stabilizer for a heating boiler - read in a special publication on our portal.

Non-volatile heating devices

To avoid dependence on the stability of the power supply, it is worth choosing long-burning units with natural air draft and equipped with a mechanical control system. There are many such models on the market. For example, these are the familiar domestic or Trayan boilers.

Solid fuel boiler "Burzhuy-K".

Prices for solid fuel boiler "Burzhuy-K"

Burzhuy-K

These devices have a volumetric fuel chamber located in the lower part of the structure, under which there is a blower, which simultaneously serves as an ash pit. The damper for air access, located at the bottom of the door, is connected by a chain to the thermostat.

When igniting firewood loaded into the firebox, it is necessary to open the damper as much as possible to ensure active combustion of the fuel and start the pyrolysis process. To achieve it, a temperature of at least 200 degrees is required.

After a fire, the damper should be closed, reducing to a minimum the access of oxygen to the fuel chamber, transferring the combustion to the smoldering stage. Further, as already described above, pyrolysis gases are released, which enter and ignite in the afterburner.

Thanks to this design, the heating device is completely energy independent, so even in the absence of electricity, the house will continue to be supplied with heat.

This type of boiler is inferior in efficiency and fuel economy to energy-dependent devices, however, it is its independence from the availability of electricity that makes it popular among consumers. In addition, you will also not have to pay for energy consumption, which will also help save on the operation of the heating system as a whole.

Solid fuel boilers with top combustion

Another design option for heating units is the original technological systems with the direction of wood burning from top to bottom. A similar principle is used not only in many models of solid fuel boilers, but also in stoves operating on the principle of long combustion.

Boilers with top ignition, as a rule, have the shape of a cylinder located vertically. Almost all types of solid fuel are suitable for this type of heating units - firewood, briquettes, coal, wood chips, sawdust, etc. The chamber in such boilers has a very large volume, which allows them to operate on one fuel load for a long time: this duration depends on the specific model and fuel type. For example, some of them are capable of working with wood from 24 hours to three days, and when using coal - even from three to seven days.

Solid fuel boiler of a cylindrical shape with top combustion of wood.

The operating cycle of such a boiler can be represented in the following order:

The principle of operation of a boiler with top combustion of fuel filling

So, such a boiler has a cylindrical vertical body (item 1).

Through a special door (item 2) the selected fuel (item 3) is loaded into the chamber. At the very bottom there is a door (item 4), which serves to clean the chamber from ash before the next loading.

If firewood is used for heating, then large-diameter logs are laid down and in the middle of the stack, and wood chips are loaded around them and on top. Then, using paper, the top thin wood is ignited. To ignite fuel, you can use liquids specially designed for igniting stoves.

In the upper part of the housing there is an air supply channel (item 5) to the boiler, equipped with a valve. The valve can be manual or semi-automatic, operating on the principle of changing the configuration of a bimetallic plate under the influence of temperature. Air from this channel enters the heating chamber (item 6), where it is heated under the influence of the heat generated by the boiler.

As soon as surface burning of the wood begins, a special air distributor (pos. 7) is lowered onto the stack. This is a rather massive part made of a metal profile, inside of which there are channels for uniform distribution of air over the surface of the burning fuel. With its weight, the distributor rests on the burning bookmark, and as it burns out, it gradually falls down. To do this, it is connected to the air heating chamber by a pipe of a special telescopic design (item 8).

The air heating chamber has a damper (pos. 9), which regulates the flow of secondary air into the upper part of the combustion chamber (pos. 10).

Pyrolysis gases released during the smoldering of the top layer of the fill rise to the upper part of the fuel chamber, where they meet the flow of hot secondary air coming from above. That is, all the necessary conditions are created for their complete afterburning with a large release of heat. After this, gaseous waste is discharged through the pipe (item 11) into the chimney.

The generated heat is transferred to the water jacket of the boiler (item 12), which is connected to the heating circuit of the system through the return (item 13) and supply pipes (item 14).

As you can see, in fact, in this design there is no obvious division into a chamber for preliminary combustion of wood and final combustion of gases - the total space is divided into these zones by the position of the air distributor, and the sizes of these zones change as the unit operates.

Such boiler models can also be equipped with a built-in fan, which provides forced air supply. However, even their work can be carried out in the presence of only natural traction. Therefore, the heating of the house will work even in the absence of electricity.

This design has shown its effectiveness, so some home craftsmen take it as a basis when creating their own products. A striking example of this is the popular wood-burning stove with the unusual name “Bubafonya”.

You may be interested in information about what a bypass is in a heating system

Tips for choosing

Before choosing a boiler, you need to calculate the required power, based on the area of the room, the presence of insulation, the height and thickness of the walls. The selection of the burning time for one bookmark also depends on these parameters.

Most devices use the following types of fuel:

- briquettes;

- coal;

- pellets;

- peat;

- wood;

- oil shale.

You should also decide on the type of fuel in advance, giving preference to a more affordable option.

The material from which the heat exchanger is made is also important. Cast iron products have a sectional structure and are of high quality, but are poorly protected from thermal shock. Steel models are produced in the form of monoblocks. They withstand thermal shock better, but are difficult to transport and repair.

The cost-effectiveness of operating a unit is determined by the totality of service costs, suitability for repair and efficiency indicator.

When choosing a heating device, you should correctly compare its functionality and the size of the room so as not to overpay for excess power. It is better to give preference to models from trusted manufacturers that use affordable fuel.