Principles for determining the fault code

In cars equipped with an information display, it is not difficult to find out the error code - it will appear in bright yellow or green.

But if the model is less “advanced”, to find out the cause of the breakdown you will have to unravel the code programmed by the manufacturer, based on the prompts of the indicator lights.

Numerical values of indicators for calculating the failure code on the panel of a Hotpoint-Ariston washing machine that is not equipped with a digital display

Algorithm for determining a breakdown based on the light bulb signal:

- We remember the model of our Ariston machine (or check the information on the case or in the instructions).

- We remember which indicators indicate a breakdown.

- We find our device in the pictures.

- We determine the digital value for each indicator.

All that remains is to put the received data together and decipher the problem code.

The sum of the numerical values of the numbers of flashing lights on the panel of Ariston AVSL and AVL models will help decipher the code programmed at the factory

For example, if the lights corresponding to the values “2” and “1” are blinking on the washing machine, then you should look for the causes of the problems coded as F03 (or F3 , which is basically the same thing). Using this simple algorithm, other typical breakdowns are also determined.

Unlike most Ariston machines, in the AQUALTIS model internal problems are signaled not by washing modes, but by water heating temperature indicators

When the error code is clarified, all that remains is to determine the essence of the breakdown, and then decide whether it can be fixed with your own hands or whether it is better to immediately contact the experts.

Problems with the motor or control board

If you have loaded things into the device compartment, turned on the appropriate mode and pressed the “Start” button, but the drum does not rotate, most likely the problem lies in the operation of the motor or control controller, which the display will signal to you with code F1 , F2 or F18 . Although such breakdowns can occur at any other stage of washing, they are most often displayed precisely at the start of the program.

Irregularities under code F01 (F1)

Error F01 indicates problems in the control circuit of the motor that drives the drum of the washing machine. If there is no response to a signal from the electronic controller (board), the device will not work, and when you try to switch to any other program, it will continue to persistently display a fault code.

The causes of failure of the motor control module with code F1/F01 are most often problems with the voltage in the electrical network or high humidity in the room

Self-fix process:

- A universal option for any codes is to unplug the washer from the outlet, wait 10-15 minutes and turn it on again - there is a chance that the electronics will reboot and stop giving an error. But even if everything worked out and the device started working, it is worth taking precautions so that the “first sign” does not lead to serious damage.

- F1 signal can be triggered by a decrease in network voltage (below 200 V) or a sharp jump, as well as damage to the plug or bending of the power cord. Try not to turn on the washing machine at the same time as other powerful energy consumers or through an extension cord, because ideally this device needs a dedicated line with its own machine.

- Inspect the cord, the plug and the outlet itself - perhaps the reason is their malfunction.

- High humidity in the bathroom can also cause problems with the motor control circuit. Remove moisture from the board contacts and ventilate the room often so that the humidity level does not exceed 70%.

- The cause of the error may also be a disconnection of contacts in the engine control circuit. If you have skills in working with electronics, you can independently check the circuit from the device motor to the board for the quality of the connections by ringing with a multimeter all areas that cause suspicion.

If independent repair attempts do not lead to a positive result, the reason may lie in a breakdown or failure of the control board firmware, erased electric motor brushes, a burnt out motor winding, or damage to the cable with wires. To restore or replace these parts, it would be better to contact a service center.

Decoding signals F02, F2

This error most often occurs at the start of the program or at the spin stage, when the machine picks up speed to spin the laundry (at the same time, the drum itself may twitch or rotate intermittently). The device will display code F02 and at the same time begin to drain water.

Typically, this signal indicates a malfunction in the motor circuit or a breakdown of the tachogenerator - a small part with a ring that controls the speed of the washing machine engine.

To inspect the tachogenerator, you will have to partially disassemble the device, get to the engine and find a metal ring with wires on its shaft

Solution to the problem:

- If the machine displays an error for the first time, the cause may be a one-time failure in the operation of the electronics due to network surges. Disconnect the device from the power supply for 10-15 minutes to allow the equipment to reboot.

- Check that the drum itself is not blocked - it should turn freely by hand. But if during washing a small object gets between the drum and the tub, the culprit of the breakdown should be carefully removed and the machine restarted.

- Problems with contacts - it is necessary to check the serviceability of the connections from the board to the electric motor, including the section with the tachogenerator.

But error F2 can also be a consequence of more serious failures, the elimination of which will require replacing the motor, tachogenerator or control board. In such cases, it is better to contact a workshop; you may be able to get by by replacing faulty solders on the control module or restoring damaged wiring.

Communication or board memory error with codes F09, F18

A signal about a malfunction of the electronic controller under code F18 can only be issued by Aristons with an asynchronous motor (models Hotpoint-Ariston, Margherita, AVSL, AV, AVL, AVTL, CDE); such errors do not occur on devices with a commutator motor.

The controller is an electronic board that is responsible for selecting the washing mode and displays it on the display, gives commands to the intake and drain valve, pump, pressure switch and controls the operation of the engine

Signs of controller malfunction:

- Incorrect engine operation - sudden changes, too high or, on the contrary, unreasonably low revolutions.

- The drum does not rotate when starting the washing mode.

- Spin does not work.

- The machine fills with water and immediately drains, displaying a signal about damage.

F09 – a memory error can occur when the network voltage surges or decreases. But it may also indicate a failed control unit.

The first action after displaying codes F09 and F18 is identical to previous problems - turn off the power to the machine, give it time to reboot and turn it on again. If the reason is not a failure, it is necessary to check the board microcircuits.

But if you do not have the skills for such repairs, you need to entrust it to professionals who can reflash the controller, solder the contacts, replace only some elements (for example, the power capacitor) or replace the entire board

Electrical check

Error F with the numeric designation 06 suggests a malfunction in the electronic module, control panel board, or somewhere in the circuit between these two elements. So the first thing we need to do is remove the control panel of the washing machine of this brand.

- First, unscrew the two screws that are located immediately under the top cover on the back wall of the washing machine body. They hold the top cover. After this, we move the cover back a little, and then lift it up and put it to the side.

- Now we go around the front of the washing machine and remove the detergent drawer.

- At the top of the ends of the front panel, in the corners, we find two self-tapping screws that also need to be unscrewed.

- Next, unscrew the screws that are located around the powder receptacle niche.

While the powder receptacle is in the niche, you cannot unscrew the screws around it, but if you remove it, everything can be done quickly and conveniently.

- Now all we have to do is pull the panel up a little and towards ourselves, it should come off. True, you need to be careful here so as not to damage the delicate plastic fasteners.

After we remove the front panel, we will see a huge bundle of wires that goes from the board to the sliding segment with the buttons and a couple of wires go to the “Power” button. This washing machine has a special design and, by the way, is inconvenient, especially when it becomes necessary to ring the contacts of all the buttons and check their power wiring. But let’s not get into philosophy, but let’s get down to business.

First, let's inspect each wiring and each contact of the control panel button. A visual inspection will give us a first impression. If somewhere there are traces of burning or melting on the wiring and contacts, we will definitely notice them. After a visual inspection, take a multimeter and begin to check each contact of all available buttons one by one, noting those that do not function. Next, we check one by one all the wiring going to the contacts of the buttons; this work is scrupulous, but it will not take as much time as it might seem.

Professionals advise checking each contact and each wiring several times to eliminate errors, because if you miss a faulty segment, you will have to start all over again.

We mark broken wiring, if, of course, there are any. After the check is completed, we need to remove the faulty button contacts from the special grooves, order similar ones and install them in place of the old ones. After that, connect the wiring to them according to the diagram. If you couldn’t get the diagram or you have problems reading it, just take a photo of the wiring arrangement at the very beginning, and then, based on the photo, connect everything as it was.

If, during checking the contacts and wiring, you did not find a single faulty element, you need to pay attention to the control module. It is very possible that the electrical communications going from the control module to the control panel and the button have nothing to do with it. Most likely, the electronic module is to blame; this needs to be checked! About other malfunctions of this machine can be found in the article Repairing an Ariston washing machine.

What to do with the electronic module?

The electronic module is a part that is quite difficult to repair. Firstly, you need to have the necessary tool, secondly, you need to have work skills and knowledge in this area, and thirdly, you will need parts - “donors”, that is, those elements that are to be soldered. First you need to find these elements on the board, ringing each one in turn. In 99% of cases, this work is entrusted to a master, which is what we advise you to do.

The module in the Hotpoint Ariston washing machine is located in the lower left part of the machine closer to the rear wall.

There were cases when the board was not repaired, but rather broken, due to ignorance of many nuances. Replacing this part also has its own characteristics. And the point here is not how to remove the electronic module itself, but whether it is programmed, because if there is no software, then it needs to be installed. In the language of the master, this means “flashing” the board.

So, the F06 error is not as simple as it might seem when reading its transcript. To eliminate it yourself, you need to know many nuances. If you have nothing to risk, and you are learning how to repair, go for it, the road will be mastered by those who walk!

Interesting:

- Fuzzy logic function in a washing machine

- Review of built-in dishwashers Ariston 45 cm

- Comparison of technical characteristics of washing machines

- Malfunctions of Hotpoint Ariston washing machines

- Error F 08 in the Ariston washing machine

- Error F01 in Ariston washing machine

Reader comments

- Share your opinion - leave a comment

Problems with water heating

If during the washing mode the washing machine freezes for a long time, stops, does not heat up, or constantly drains water, the causes of the breakdown should be sought in the heating circuit. The device will signal these problems with codes F04 , F07 or F08 .

Failure of the heating element or pressure switch and codes F04, F07

In washing modes where heating is required, the error may appear immediately after startup, or after drawing water, but rinsing or washing in cold water will work normally. In this case, there are several options for solving the problem (besides the standard turn on/off the machine to reboot the controller).

If the code appears on the display during the washing phase or during startup (the machine does not even want to draw water), most likely the reason lies in the heating element itself. It can “pierce” onto the housing when the contacts come off or simply burn out.

To fix the problem, you need to get to the heating element, check all its connections, change the resistance with a multimeter (with a power of 1800 W it should produce about 25 Ohms).

To replace a faulty heating element, disconnect the cable with wires, unscrew the fastening nut (1), press on the pin (2) and pry off the sealing rubber (3), then install a new part and reassemble in the reverse order

If the device collects and then immediately drains water, the cause may be a breakdown of the pressure switch - the water level sensor. If there is a problem, this element can provide the controller with information that the heating element was not immersed in water, which is why the machine does not start heating.

In this case, it is necessary to check the water pressure sensor tube with the pressure switch (the hose may become clogged, kinked, frayed, or come off). At the same time, inspect the contacts of the sensor itself - they may need to be cleaned. But more precisely, code F04 - most likely, the part will require replacement.

To check the operation of the pressure switch, you need to put a small piece of hose with a diameter identical to the removed tube onto its inlet fitting and blow - characteristic clicks will be heard from a working part

In some cases, the problem may be in the board itself, faulty wiring or contact groups in the area from the board to the heating element or water level sensor. Therefore, you should ring all the elements of the control unit associated with the operation of the heating circuit, and if necessary, replace the burnt tracks or the controller itself.

Heating circuit faults and F08 symbol

If the water heating does not work correctly (or the machine “seems” that it starts when the tank is empty), error code F08 . The cause is most often a malfunction in the pressure switch circuit.

This problem can occur due to high humidity in the room, which negatively affects the controller. To make sure the board is in order, inspect it, wipe it dry, or blow it with a hairdryer.

Another simple solution to the issue could be the disconnected contacts of the heating element and the pressure switch, especially if the device was started for the first time after transportation. In other cases, a more professional inspection will be required with possible replacement of parts.

First, make sure that there is really no water in the tank, then remove the back panel of the machine and check the heating element with a tester

Possible malfunctions of Ariston machines, indicated by code F8:

- If the washing mode is interrupted immediately after starting or during the washing phase and the device does not heat the water, the heating element will most likely need to be replaced.

- If the machine stops after starting, when switching to the rinsing mode, or does not spin, it is possible that the contact group of the heating element relay is “stuck” on the controller when it is on. In this case, you can replace the failed elements of the microcircuit and, if necessary, reflash the board.

- If the device “freezes” in various modes (and this can be either washing, rinsing or spinning), the wiring or contacts in the heater circuit may be damaged, or the pressure switch may break down, which considers that not enough water is entering the machine.

But if, when checking all the connections of the circuit and separately the pressure switch, the heating element relay and the heating element itself, no damage is detected, you will have to change the controller.

What does this error code mean?

The F01 error options are clear, all that remains is to learn how to decipher them. This code indicates that there has been a malfunction in the electrical circuit responsible for the operation of the Ariston car’s motor. Such a dry formulation does not explain anything to the average user. But if we talk about error F01 in more detail, it should be noted that the control module sending signals to the engine does not receive anything in response. It turns out that there are three possible options:

- the control board has failed and is issuing incorrect commands;

- the motor broke down, losing the ability to obey the board’s commands;

- the problem has occurred in the circuit connecting the motor and the control module, and you need to look for it in the wiring or contact group.

Initially, this decoding of error F01 may seem somewhat scary. There is a feeling that the malfunction is serious. But in reality, everything is much simpler, since such a failure often occurs due to a normal failure of the electronic module.

It is already known that in almost all Ariston machines the error code F01 is explained in the same way. But every rule has exceptions. And the Ariston machine from the AD series is slightly different in the principle of self-diagnosis - in it, error F01 indicates an interruption of communication from the modular zone to the control panel display. Simply put, such a problem means that the management module has lost the ability to contact the panel responsible for control, and it has begun to show “inadequacy”.

Errors in the operation of the drain or water intake

If the machine cannot draw water or, on the contrary, stops working, although its tank is full, codes F05 , F11 or H2O . Let's try to understand the essence of such breakdowns.

Drain violations and codes F05 or F11

Error F05/F5 always lights up when the drum is full, but attempts to force drain it remain unsuccessful - the machine “does not release” water and continues to signal a breakdown.

In this case, a cracking noise may be heard, as if some foreign object had hit the fan impeller, or a humming sound from the pump. Such a breakdown is a fairly common occurrence with Ariston machines, and in most cases you can fix it yourself.

Most often, the problem lies in a banal blockage of the drain filter or drain hose - when washing, various hairs, threads, buttons, particles of dirt and small debris are separated from things, which gradually clog the gap for water to exit.

To remove them, you need to manually drain the water through the filter (if it is not the hose that is clogged) or manually scoop out the drum.

If the machine has blocked the doors and the water does not drain through either the filter or the hose, you can remove the liquid by unscrewing the drain pipe

Then check the condition of the drain filter (small hatch at the bottom of the machine), the pipe itself, and rinse the hose under good water pressure. At the same time, inspect the siphon or pipe if the drain is organized directly into the sewer.

Then reassemble the system in the reverse order, turn on the machine to the rinse program, make sure that it has filled with water, and forcefully switch to spin - if error F05 does not appear and the drain works, then the problem is solved.

To avoid breakage, wash wool and fur items in a special bag, be sure to check the pockets of clothing before loading and arrange a preventive inspection of the filter at least once every two to three months

If the problem is not a blockage, the following options are possible:

- Failure of the drain pump/pump - the part may simply require replacement, having honestly exhausted its service life, or it may fail due to the penetration of a foreign object, a broken motor coil, or a short circuit. First, you should disassemble the pump, remove debris, check the chain and try to start the machine again. If the problem persists, you will have to replace the filter.

- Malfunctions in the operation of the electronic controller - the corresponding tracks or radio components on the microcircuit may burn out or oxidize (most often due to the same high humidity), or a firmware failure may occur.

- Failure of the pressure switch - if the sensor provides information that the tank is empty, the machine simply will not start the draining program, so the faulty part must be replaced.

- Wiring problems - you need to check if there is power to the drain pump when it is turned on.

Similar problems can occur with error F11 . Although most often this code indicates a breakdown of the drain pump (this is where the inspection should begin), it can also be due to incorrect operation of the pressure switch, controller, or damaged wiring.

Problems with water intake and H2O code

Another common error, familiar firsthand to owners of Ariston machines, is the H2O , which indicates problems with the water supply. Usually it occurs 5-7 minutes after start (in rare cases - during rinsing), and the device may not let in water at all, or may collect too much of it.

The water supply error is perhaps the only one that is intuitive among other codes, since it is associated with the chemical formula H2O

Sometimes the H2O can appear chaotically in different programs, but its characteristic feature is that the drain and spin modes always work flawlessly.

The H2O code is often issued when the fill valve mesh is clogged, so you need to remove it with pliers and thoroughly rinse the cells under water pressure

Possible causes of failure:

- Lack of water in the water supply, insufficient pressure or the supply valve to the device is closed. The actions here are clear: open the tap, wait for the water supply to be restored.

- Damage to the water intake valve, which “allows” water into the device - if it breaks, it is easier to replace this part with a new one than to try to repair it.

- Malfunction of the pressure switch - if the hose is clogged or damaged or the sensor itself breaks down, the machine will constantly draw in and immediately drain water, displaying the H2O .

But if all the elements work, the problem may be a signal break due to damaged wiring or failure of the electronic controller.

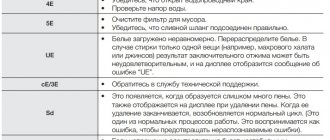

Other errors and their interpretation

In total, Ariston machines have 19 code signals indicating problems, of which we have examined the most common ones.

But let’s briefly talk about other possible malfunctions in the operation of equipment:

- F03 – temperature sensor failure. You need to check the resistance of the sensor itself (normally about 20 ohms), as well as the circuit to the controller. If necessary, replace damaged parts.

- F06 - indicates a problem in the circuit of the hatch locking device for Ariston cars on the Arcadia platform (Low-End and Aqualtis series), as well as problems with the control buttons for Dialogic models. In the first case, you should see if any item in the load is preventing you from slamming the door until it clicks. In the second case, the problem may be with sticking buttons or damaged contacts.

- F10 – no signal from the water level sensor. The device can generate such an error if the drain is connected incorrectly to the sewer, there is insufficient water pressure, or there is an open circuit from the sensor to the board.

- F12 – lack of communication between the controller and the display module. If rebooting does not help, you need to check the control board, display unit and their connection.

- F13 - an open circuit or breakdown of the drying temperature sensor will require replacement of a part or worn contacts.

- F14 or F15 – malfunction of the drying heating element or an open circuit in the heater circuit.

- F16 – signal for machines with vertical loading that the drum lock sensor is broken. Most often it happens due to simple inattention - for example, the doors are not closed until they click. In other cases, the reason may be weak contacts in the section of the circuit up to the board or failure of the sensor itself.

- F17 or door – “indicates” that the hatch is not closed tightly enough. Perhaps the problem lies in an intruded foreign object, a weak hinge fastener, or a dirty lock for the door “tongue”. If no external culprits are identified, most likely the device that blocks the door while the machine is operating is faulty and should be replaced.

And in any of the options, the rule applies: in addition to the specific part that the device “indicates”, the breakdown may lie in a faulty board, damaged contacts or non-working wiring.

What does the code mean?

We managed to figure out the variants of the F01 code, now let’s decipher it. Error code F01, as well as F1, means a failure in the electrical circuit that controls the motor. A rather dry formulation that will not tell a layman about problems, absolutely nothing. If we begin to describe the error in more detail, we must say that the control module, sending signals to the engine, does not receive a response from it. This means that three situations are potentially possible:

- the control board itself has failed and therefore the commands it issues are incorrect;

- the engine has broken down, which means it is simply not able to respond to commands from the control board;

- The problem has occurred in the path between the engine and the control module (wiring or contacts).

At first glance, the decryption sounds quite scary, hinting at a serious breakdown, but in fact, everything can turn out to be much simpler, because this error often appears as a result of a local failure in the electronic module. You can fix such a failure in a few minutes with your own hands.

On 99% of Ariston family washing machines, code F01 is deciphered exactly the same. But, as you know, there are exceptions to every rule. So in our case, Ariston AD line has a slightly different self-diagnosis system, in which this error means a loss of communication between the electronic module and the control panel display module. In other words, this error indicates that the control module loses the ability to communicate with the control panel, from which the latter begins to “behave inappropriately.”

In fact, in the Ariston AD line washing machine, the error code F01 is, by decoding, a complete analogue of the F12 error, which is found on absolutely all other Ariston washing machine models.

Eliminating the reasons for the appearance of the code

Let's move on to the most difficult part - finding and eliminating the reasons why the F01 or F1 code appeared. Our experts recommend starting to sort through the possible causes of this error code, starting with the simplest ones, gradually moving on to the most complex ones (requiring disassembly of the SM).

First, you need to check the control module of the Ariston washing machine for a local failure. This is done very simply, we disconnect the power cord from 220V for 5-7 minutes, then turn it back on and try to start the “home assistant”. If rebooting doesn't do anything, try rebooting the machine a couple more times. In rare cases, a local failure can be resolved by two or even three reboots.

An indirect cause of malfunction of the Ariston washing machine motor may be too low voltage in the electrical network. In small towns and villages this happens all the time. The Ariston machine does not always respond to such a fall with error F01, but it’s worth checking, because problems with the electrical network can lead to very serious damage to the washing machine. In general, if problems with voltage drop occur frequently in your home, you need to purchase a voltage stabilizer for your washing machine and connect your “home assistant” to it, this will simply save her.

Next, you need to take a special device called a multimeter and check the integrity of the power cord, as well as the socket. Of course, there is little chance that this error appeared due to the power cord or socket, but they still exist, and it doesn’t hurt to check, especially since it’s quick. Once all the simple reasons have been swept aside, let's look inside.

- Somewhere in the room, if it is not possible to drag the washing machine into the garage or shed, we will free up some space so that nothing interferes with the repair and move the washing machine there.

- Let's take out the powder receptacle and put it aside.

- We unscrew the screws that hold the back wall of the Ariston washing machine.

- We remove the drive belt that is interfering with us.

- We take a photo of the location of the wires on the engine and remove them.

- We unscrew the engine mounts, then pull it off.

Having removed the motor, we must first check its brushes and then the windings. You will also need to look to see if there is a leak on the housing. We do the following:

- on the sides of the motor housing we find small screws that hold the brushes and unscrew them;

- we take out the brushes and inspect them; if at least one is worn out, we replace both;

- we install the multimeter probes on the winding and begin to systematically check the turns for breakdown;

- If everything is fine with the winding, check if there is a leak to the housing.

If you manage to detect a breakdown in the winding or a leak in the housing, feel free to throw out the engine, since the cost of repairing such a thing is comparable to the cost of a new part.

If the engine is in order, we begin to methodically check the wiring that powers the motor with a multimeter. We previously disconnected it. In this case, we recommend checking each transaction 2-3 times to avoid errors, otherwise you will have to start all over again.

Lastly, check the control board. For our part, we traditionally do not recommend tackling this part yourself, because if you do not have the appropriate qualifications, you can easily damage it, and this is a much more expensive repair with all the ensuing consequences. It would be much better to entrust this matter to a professional. You will ultimately save nerves, effort, time and possibly even money!

In conclusion, we note that if code F01 suddenly appears on your Ariston brand washing machine, do not panic. Read our article and hope that the control module remains intact. Happy renovation!

Interesting:

- Review of built-in dishwashers Ariston 45 cm

- Decoding the markings of Bosch washing machines

- Ariston washing machines

- Repair of malfunctions of Ariston washing machines

- Reviews of Hotpoint Ariston dishwashers

- Review of Ariston top-loading washing machines

Reader comments

- Share your opinion - leave a comment