- Information

- Washing machines

- Error codes

- Siemens

- E17

Error code 17 usually appears in Siemens washing machines under the following circumstances:

- immediately when turned on: the unit locks the door as usual (a click is heard), but water does not fill the tank;

- at the washing stage: in this case, the machine starts to fill, but the water fills in too slowly and error F17 comes on.

- during rinsing: washing proceeds normally, but when the cycle approaches rinsing, the SMA does not pour water and signals a problem.

Note! Codes E17 and F17 are the same error. F is used in older models (short for the word fault in English - Error), and E - in modern ones (the first letter in the word Error in English - error).

Errors E17, F17 in Siemens without display

Models not equipped with an LCD screen indicate a problem using warning lights.

- Siemens IQ series . In machines of this line, with error E17, the upper spin speed indicator (1000 or 1200) and the lowest indicator, indicating the “no spin” program, blink.

- Siemens Siwamat series. In the SMA of this model range, when error E17 occurs, the middle LED in the vertical row of indicators blinks (as a rule, this is the “work” indicator).

Error E17 - when you can fix it yourself

Code 17 does not always indicate a breakdown. Situations when the SMA is in good order occur quite often. And most problems can be fixed on your own.

| Signs | What is the reason | How to fix |

| Siemens does not fill in water and goes into error F17 or E17. | There is no water in the water supply. Check if there is water by turning on the tap. | Contact the water utility or management company to restore water supply. |

| The water supply to the machine is cut off. Check that the shut-off valve is not closed. | If the valve is closed, turn it to the fully open position. | |

| The inlet hose is squashed or kinked. Perhaps some heavy object fell on it, or one of the household members unsuccessfully moved the hose and bent it. | Inspect the inlet hose. If you find bends, places of compression or twisting, straighten it. | |

| The Siemens machine “murmurs” water for a long time, and then error E 17 is displayed. | Low pressure in the water supply. Check the water pressure by turning on the tap. | To resolve the low pressure problem, contact your water management company. |

| The shut-off valve is not fully open. The shut-off valve may not be fully open. | Turn the valve to the fully open position. | |

| Self-draining of water due to improper installation. Probably, the drain hose is located on the floor - below the level of the tank, which is why the water drains from the SMA by itself. | Check that your Siemens is connected correctly. If you find that the hose is below the tank level, reinstall the washing machine according to the instructions. Or use it to connect washing machines. | |

| The water is gathering very slowly. After which an error code appears. | The input filter is clogged . To protect the MCA from impurities from tap water, a mesh filter is installed on the inlet valve. If it is very clogged, the water will take a long time to fill and the machine will show error E17 or F17. | The filter needs to be cleaned. You can do this yourself according to our instructions or order a filter cleaning service from a specialist. |

If you checked all the specified components, but the error was not resolved, unfortunately, your Siemens is broken.

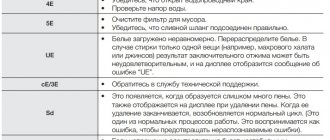

Bosch / Siemens washing machine errors

Bosch/Siemens washing machine malfunctions

The main problem of these brands is expensive spare parts, although the machines themselves are not cheap. Despite the fact that, at first glance, they are crammed with a bunch of electronics, they are no more difficult to repair than the same Ariston. The main thing here is to identify the malfunction, and replacing the broken part is a matter of technology. To quickly diagnose a malfunction of a particular spare part, the control module contains a self-diagnosis function, which displays an error code in the form of numbers and letters of the Latin alphabet. The most common breakdowns are the failure of the heating element, pump and engine; I mentioned these spare parts for a reason. Since my site is largely created to help novice craftsmen and ordinary users, I will focus on common faults that you can fix with your own hands. Before starting repairs, be sure to make sure that the current in the network corresponds to the norm; these washing machines really do not like both low and high voltage. Check the water supply to the washing machine, that is, unscrew the filling hose, lower it into a basin and open the tap; it often happens that people simply forget to turn on the water or use some filters, due to which the pressure drops. Don’t rush to blame the control module right away, in these SMAs, it fails very rarely, most failures are associated with other parts. You must remember that the error code does not always indicate correctly; it usually points to the failed circuit to which this or that part belongs. If your washing machine does not have a display, then this article will most likely help you →, in it I talk about how to count errors in such washing machines, but first, still read about what this or that code means

Error code F01. The hatch door is not tightly closed

It is quite possible that the door is not closed tightly, but this is mainly due to a broken lock or a malfunction of the mechanism on the hatch itself. If you close the door several times and the error repeats. Try the following: take a screwdriver and imitate the door hook, that is, you need to press the locking mechanism in the lock with a screwdriver, while the machine must be plugged in and connected to the water supply. If water starts to flood, check the mechanical part of the hatch or change the lock. Here depending on the circumstances

Error code F02 (F17). Water does not fill in for a certain period of time

First of all, you need to check the tap, often household members turn it off, sometimes when you arrive for an application you just open the tap and the machine starts working. Secondly, you need to unscrew the filling hose from the machine, lower it into a basin or bucket and check the water pressure. And lastly, check the valves; sometimes one of the valves sticks. Below you can watch a video about this

Error code F03 (F18). The washing machine did not drain water for a certain period of time

I wrote above that spare parts for Bosch and Siemens are very expensive, especially for the drain pump (pump). First you need to clean the filter, then blow out the drain hose, and be sure to clean the pipe that goes from the tank to the pump body. To clean the drain hose, you need to unscrew the filter, the fact is that there is a plastic ball in the pipe from the tank to the pump, and if you blow into the drain hose, this ball can jump out of its socket, which is very undesirable. When you clean the filter, take a flashlight and shine a good light on the pump impeller; very often coins, matches and other small foreign objects get under it. Unscrew the filter and turn on the machine in drain mode, watch how the impeller on the pump rotates. If all this does not help, call a technician, most likely the problem is in the control module

Error code F04. Water leaking from the tank in the washing machine

This is a secret behind seven locks. The problem is not so rare, but it lies in the fact that at the bottom of the washing machine there is a protective mechanism against water leaks from the tank; it consists of several parts. Foam float and mic, in case of leakage, the float rises and opens the contacts on the mic, this is the whole secret, but the craftsmen stubbornly remain silent about it. First of all, you need to check the connections of the pipes, look for water leaks from under the bearing block, and generally check everything that is connected with water leaks

Error code F16. Same as F01

In general, there is practically no difference, you need to check how the hatch door is closed. This happens due to the failure of the control module, if this is the case, it is better to call a qualified technician, because Bosch equipment is very complex

Error code F19. The washing machine does not heat the water

This state of affairs may arise due to several reasons.

- The heating element, that is, the heating element, burned out. We take a multimeter in our hands and call it

- The heating element relay has burned out, it is located on the control module, it often gets stuck, as a result, electricity is not supplied to the heating element

- The temperature sensor does not respond to changes in water heating; it is also called a thermistor or thermistor. Usually it stands on the heating element itself, to check it, you need to remove it and measure the resistance in different temperature conditions, it should change

- The washing machine is in a cool place, this may seem strange to you, but it happens. The fact is that if the water is not heated within a certain period of time, then this error will appear

Error code F20. The heating element suddenly began to heat the water

First of all, you need to check the heating element relay on the control module, but before that, look at the thermistor, that is, the temperature sensor; it rarely lights up, but it does happen. It happened that the memory itself began to invent something, as a result the processor generated such an error, stopped washing and switched the machine to the “IMPORTANT FAULT” mode.

Error code F21. Typically indicates engine failure

First of all, we check the engine itself, that is, its windings, check for leaks on the housing, and be sure to check the brushes. It also happened that the contacts were oxidized or the wiring was broken. Below you can watch a video about this, and at the same time you will see how to check the heating element correctly. If everything is in order with the engine, you need to check the triac on the control module and the parts that control it

Error code F22. Temperature sensor is shorted or broken

Guys, in my practice, I only changed these sensors a few times and in half the cases, it was due to the fact that the owner himself stuck who knows what there. What usually happened was the following: SMA owners, thinking that any temperature sensor would be suitable for their washing machine, installed one from Zanussi, Indesit, and sometimes from Whirlpool, no need to get weird here. Please note that the thermistor burns very rarely, and checking it is very simple, to do this you need to take an ordinary multimeter and measure the resistance, holding this sensor in your hands, if the resistance begins to change, then the sensor is suitable for work. In case of this malfunction, first of all, check the contacts and terminals, special attention should be paid to connecting the wires; if all the manipulations did not help, then you need to look at the breakdown on the module

Error code F23. Water has collected in the washing machine tray

In principle, the same as F04; in the event of this error, the module stops washing. In short, you need to look for a leak and see in what position the float is in the pan; it happens that something gets under it and as a result the microphone is triggered

Error code F25. The water turbidity sensor has failed

Whatever the bourgeoisie can come up with, just turn it off for us. In general, this breakdown is associated with the drainage of water, the pressure switch, and the sensor itself. First you need to pull out the sensor and wash it, it’s quite possible that some kind of crap has accumulated on it and it just doesn’t see a damn thing

Error code F26. Water level sensor malfunction

Actually, the manual says the following → “Malfunction of the analog pressure sensor (protects against voltage errors)”, I don’t know what they meant, but the problem is related specifically to the pressure switch, and not some other crap. If this error occurs, the hatch door is blocked, the pump begins to completely drain water from the washing machine, and the indication is also blocked. First of all, turn off the machine, this way you will reset this error. Check the contacts and blow out the pressure hose to the pressure switch

Error code F27. The pressure switch has not been adjusted and the machine erases according to the old value

The same thing as the F26 only in profile, the bourgeoisie themselves don’t know what they are inventing, well, we’re not smart. In short, we check everything connected with the pressure switch and at the same time pay special attention to the wiring, often there is a break in the connection of the contacts

Error code F28. The water flow sensor is faulty

They come up with such crap that it won’t fit your ears. I wonder who needed to measure the speed of water flow, pour it in and let it fill it, no, damn it, let’s do something new. In any case, you will have to look for this sensor and check it, I don’t know how to do this, thank God I have never encountered such a problem before

Error code F29. No water flow detected into water flow sensors

Yes, there is something to laugh at, at least someone can explain to me why the hell this error is necessary and why this sensor is needed in general. In short, the same error as F28, only with scientific explanations. In general, here you need to google, but first pick up a calculator, a pressure gauge and calculate how much water should pass through this sensor so that the pressure on it is at least 1/bar, and then you can adjust the water supply so that the sensor can see that is exactly how much water passes through it. Complete nonsense, I mean, what kind of crap do the bourgeoisie suffer from?

Error code F31. Too much water in the tank

This error occurs if the water level sensor is not working correctly; it also happens that the valve allows water to pass through. But more often this problem is still associated with the control module. It’s strange, but first of all you need to look at the valve control circuit, and also check the pressure switch control circuit. Although in the smart magazine it is written that first of all you need to check the drain hose, pump and everything else that is connected with draining water, from my personal experience, I can say that this error has never appeared to me as a result of improper operation of the drain

Error code F34. The hatch door lock does not work

First of all, you need to check the lock itself; usually the problem is there. The best way is to find the same or similar machine and, by replacing it, make sure it is in working condition. If you are a technical person, then you can disassemble it and see the condition of the thermoelement; if it is scattered or there are chips on it, then the lock will not work 100%

Error F36. The hatch lock control circuit is faulty

First, check the lock, as I said in the previous paragraph, it is better not to climb into the control module, the spare part is very complex and requires certain skills and knowledge, if you have already decided to climb into the module, then pay attention to the lock control triac. But still, first, it is advisable to check the lock itself and the wiring, especially at the lock contacts

Error code F37 and F38. Water heating sensor malfunction

It is absolutely no different from the F20 code, so I will not describe these errors much. It is clear that first of all you need to check the sensor, and then ring all the wiring, it is this that fails more often than the thermistor, if this does not help, look at the control module

Error code F40. Occurs due to increased or decreased voltage

I think everything is clear here, check the voltage in the network, if it does not correspond to the parameters, wait until it returns to normal. There have been cases, just recently, that people waited for weeks for this normalization. In general, I advised them to buy a 3 kW stabilizer, only then did their machine start washing normally, but according to the owner, they could have waited a month

Error code F42. high engine speed

Although everyone first of all tries to check the tachogenerator, which is on the motor, I personally first of all check the triac on the control module and the circuit that controls it. It’s better not to come here without knowledge and experience. Checking the tachometer is quite simple, there are two contacts on the motor that come from the back of it, place the multimeter in the ringing position and rotate the motor shaft, if you receive intermittent signals, the tachometer is most likely normal. Such a breakdown often occurs as a result of a water leak on the tachometer, as a result the SMD resistors on the module burn, in general you need to check the circuit using the tachometer

Error code F43. No engine rotation

Here, first of all, you need to check the tachometer, as I described in the previous paragraph. See how the drum rotates, with and without a motor, that is, remove the belt from the motor shaft. If this does not help, you need to look at the main triac and control circuit. Be sure to check the brushes and terminals

Error code F44. No engine reverse

Well, from the name itself it is clear that you need to look at the reverse relay on the control module, on a washing machine like Lg, this is a common glitch, on Bosch and Siemens, they are much less common, but it does happen

Error code F59. 3D sensor malfunction

When repairing these washing machines, I personally have never encountered this problem, so in principle I can’t tell you anything about it, but I think we need to stupidly find this sensor and replace it

Error code F60. Water flow sensor shows too high or low value

I already talked about this crap, in short, we need to change it. I don’t know why the bourgeoisie invented some kind of sensor to measure the speed or pressure of water. But still, first, look at what pressure you have, it is quite possible that it is lower than 1 bar, if we translate one atmosphere into our language

Error code F61. The loading hatch is not tightly closed

The same thing as F01, in general, as you see in Bosch and Siemens, error codes are repeated many times. In general, in this case you need to look and check the lock, try closing the door again, if it doesn’t help, read what I wrote at the very beginning, that is, where I described the f01 code

Error code F63. Processor failure

That's it guys → there will be no more movies, on Bosch the processor costs as much as the control unit itself, you can of course look for something cheaper, but my attempts were in vain. As a result, we still had to change the module. But still, don’t make hasty conclusions, check the wiring well, that is, call it, maybe you’ll get lucky

Error code F 67. Incorrect card encoding

In general, there is no correspondence between the parameters of the control module and the control panel; sometimes the firmware helped, but this is in rare cases. Try restarting the program, unplug the machine from the network, I mean unplug it from the socket and then restart the machine, sometimes it helps. There was a case when I simply turned the plug, that is, changed the phasing and the machine is still working

Error code E02. Motor problems

First of all, you need to check the brushes on the motor, be sure to check for current leakage to the housing, as I explained how to do this in the video which you can watch above. Pay attention to the wiring, often contacts oxidize or wires break

Error code E67. Incorrect module encoding

Of course you can reflash, sometimes even this helps, but very rarely. Basically you have to change the control module, this is the worst error, which indicates that the processor has burned out

Possible faults requiring repair

According to the experience of RemBytTech specialists, the appearance of the E17 code in Siemens brand washing machines is associated with the following breakdowns.

| Signs | Breaking | Repair or replacement | Cost* (work only) |

| The Siemens washing machine does not draw water at all or only during the rinsing stage. Code E 17 appears on the screen. | The fill valve is broken. This part consists of a housing, a damper membrane and an electromagnetic coil. Normally, the coil opens the membrane and the machine fills with water. Typically, it is the coil that fails, causing the valve to stop functioning. If the SMA is equipped with a single valve, water will not flow into the machine at all. If the valve is two-section, then two options are possible: water will not be collected only for washing or only for rinsing. | The faulty valve must be replaced with a new one. | from 1500 rub. |

| The machine does not fill with water and goes into error F17 or E17. | The pressure switch is faulty (water level sensor in the tank). It is likely that:

| The technician diagnoses the level sensor and, based on the nature of the malfunction:

| from 1600 rub. |

| Error code 17 appears immediately when turned on, the SMA does not fill with water. | (electronic controller) has failed Individual elements of the microcircuit are faulty or the contacts/tracks in the fill valve control circuit are burnt out. | Board diagnostics will be required. According to the results of the master:

| from 2000 rub. |

| A failure occurred in the firmware of the control module (SMA memory) . As a rule, the firmware crashes due to power surges. With this breakdown, there can be a wide variety of “glitches” in the operation of the machine, including problems with filling water. | The master unsolders the control module memory from the board, programs it again and solders it in place. | ||

| Damaged wiring or contacts in the water supply valve circuit. Most often, wiring and contacts suffer due to vibrations during operation of the SMA. In the private sector, wires are often chewed by mice and rats. | It is necessary to find and eliminate the break point. To do this, the wizard:

| from 1500 rub. |

* The price is only for the work of the master, spare parts are paid additionally.

If your Siemens issues code E17 or F17 and you cannot fix the error yourself, it’s time to call the specialists:

+7 (495) 215 – 14 – 41

+7 (903) 722 – 17 – 03

Or submit an online application.

RemBytTech specialists have repaired more than one thousand Siemens washing machines. They will help yours too. We carry out all work at home, we leave within 24 hours of receiving the application, we provide a guarantee for up to 2 years. We will take care of your equipment!

Rate this article: 4.7 1 5 12 votes (average 4.7 based on 12 votes)

Water level monitoring element

Next in line is the pressure switch. An incorrectly functioning level sensor can signal that the tank is full even before filling begins, sending the appropriate command to the board . Naturally, the module stops drawing water, and the Siemens washing machine remains empty. To reset the error and restore the operation of the machine, it is necessary to diagnose the pressure switch. We proceed like this:

- disconnect the washing machine from the power supply;

- turn off the water supply tap;

- remove the top cover by unscrewing the corresponding bolts from the rear panel;

- At the side wall we find a pressure switch - a device with a tube lowered into the tank;

- disconnect the pressure hose from the sensor;

- take a tube commensurate with the diameter of the pressure switch fitting;

- We apply the found tube to the fitting and lightly blow into it.

Then we listen: a working pressure switch will respond to the air flow with 1-3 clicks, a broken one will remain silent. Diagnostics continues by visual inspection of the part. The sensor should be checked for defects, blockages and mechanical damage. If contamination is found in the tube, the situation can be corrected by cleaning the hose under the tap.

When replacing components with Siemens, you must select only original spare parts that match the model by serial number.

It’s better not to stop at just a visual check and test the sensor with a multimeter. First, we study the electrical circuit of the pressure switch and find terminals suitable for diagnostics. Then we turn the tester into buzzer mode and apply the probes to the relay contacts. Normally, the resistance indicator should “jump” when the contacts are activated. A static value will indicate a breakdown has occurred.

It is impossible to repair a pressure switch at home; it is easier and cheaper to replace it. There will be no problems finding a new water level sensor: just dictate to the seller the serial number of the Siemens washing machine . The cost of the device ranges from 500-2500 rubles.

The new valve is installed in place of the old one and secured with bolts. The tube and previously discarded wires are connected to it. Afterwards, we return the top cover to the body, establish a water supply with power supply and start a test wash. If error E17 disappears and the machine is full, then the problem has been resolved. Repeated output of E17 when starting the wash will indicate another problem. It’s better not to experiment and contact the service.

Interesting:

- Bosch dishwasher errors

- Siemens dishwasher error codes

- Gorenje washing machine error codes

- Review of built-in dishwashers Siemens 60 cm

- Review of built-in dishwashers Siemens 45 cm

- Miele dishwasher errors

Reader comments

- Share your opinion - leave a comment