Why do air conditioners need brackets?

The need to use brackets for proper installation of the air conditioner is associated with the typical design of most models. They consist of three main elements:

- indoor unit responsible for cooling the air in the room;

- an outdoor unit that releases heat to the environment;

- a system of tubes that circulate freon between blocks.

Indoor units are mounted under the ceiling using a special plate included in the kit or even installed on the floor. In order to reduce the length of communications, external equipment must be placed on the wall of the building on the street side. Typically, the outdoor unit of an air conditioner requires brackets to bear the entire weight load. They try to install them at a height inaccessible to accidental damage or access by intruders.

Standard sizes of air conditioner

Split systems come in different types: domestic, semi-industrial and industrial. A wide range of this equipment makes it possible to choose the model that is optimal in size and design for any room.

One series from a particular manufacturer may include low, medium and high power air conditioners. Accordingly, their sizes will differ.

Standard indoor and outdoor units are rectangular in shape. The size of these units is characterized by three dimensions: width, height and depth. Home split systems are small in size. Industrial devices are more powerful, so their size is larger.

Indoor unit dimensions

Today, manufacturers produce air conditioners in different variations of the design of the indoor unit. This affects the length, width and height ratio of the device.

More often, split systems with a rectangular internal module are installed in apartments.

Rectangular air conditioners are very popular. Due to the fact that their shape is elongated, they do not look as bulky as square split systems. In addition, they can be placed above a window or doorway

The minimum dimensions of the indoor unit of a split system are represented by the following values: height 24-25 cm, depth – 18-19 cm, width – 70-74 cm. Some companies produce wall-mounted air conditioners with an internal module depth of 18 cm. This significantly expands the possibilities for installing such equipment in different zones of a small room.

The width of the internal unit of a medium-power household air conditioner varies from 70 to 80 cm. Less common systems are up to 90 cm. The height is usually 25-29 cm. The average value is 27 cm, with a depth of 24 cm.

The maximum height of the wall-mounted indoor module is 30-32 cm, depth – 30 cm, and width – 110-120 cm.

If the indoor unit has a non-standard shape, for example, it is designed for vertical placement, then its dimensions will be different. The compact ceiling module is often made in a square shape. Its length and width are 50-100 cm.

Ceiling air conditioners evenly distribute air masses around the entire perimeter of the room. In this case, direct contact of air with a person is excluded. This reduces the risk of catching a cold. Ceiling air conditioners are also quiet. Therefore, such split systems are recommended to be installed in bedrooms.

For columnar blocks of split systems, which are mounted on the floor, the height reaches 100-150 cm. The width and depth are 70 and 80 cm, respectively. Due to such dimensions, column modules are not placed in small rooms.

If a device of different sizes from the standard is required, then most likely it will have to be made to order.

Outdoor unit dimensions

The dimensions of external air conditioner units are influenced by their design. The outdoor module can be square or rectangular. The largest parts of this unit are the radiator and compressor. Therefore, the larger they are, the larger and more powerful the device will be.

Split systems with a capacity of up to 2.7 kW have an external unit height of 42-60 cm. On average, this value is at the level of 50 cm. The width of a standard outdoor module varies between 66-80 cm.

The external block is usually placed 15 cm from the building wall. Taking this into account, the system protrudes approximately 42 cm from the cladding of the house

In medium-power air conditioners, this parameter is 70 cm. The depth of small outdoor units of split systems is 23-30 cm.

Higher performance devices have a larger external module. Its width can reach up to 86 cm, height – up to 65 cm, and depth – up to 32 cm.

Dimensions of mobile split systems

Mobile air conditioners are popular. Their design is similar to wall-mounted options. They also consist of indoor and outdoor units. But their structure is slightly different.

The compressor is located in the indoor module. The external unit contains a fan and a condenser.

A mobile air conditioner is not capable of cooling a large area. It has compact dimensions and, accordingly, has low power. Therefore, such a device is usually installed in small rooms.

Both parts of the mobile split system are equipped with small wheels for easy transportation. The modules of such equipment are compact: their length is 50-70 cm.

Types of brackets

Brackets for stable mounting of air conditioners have horizontal elements on which the installed unit is placed and secured against spontaneous displacement, and vertical parts that are pressed tightly against the wall. For ease of fastening, holes are provided.

In most cases, the brackets take the form of L-shaped parts, used in pairs. The differences usually relate to the shape of the profiles used in the manufacture and the presence of additional elements intended to strengthen the structure.

Important! The production of brackets used outdoors uses stainless or ordinary structural steel with anti-corrosion treatment.

Corner brackets

This simplest type of fastening is made by perpendicular welding of corners with a shelf thickness of at least 2 mm.

It can withstand moderate loads, but over time, vibration negatively affects the strength of the seam. In addition, accidental damage to the anti-corrosion coating can lead to a rapid decrease in the strength of the product and a change in its configuration.

Structures made of U-shaped profiles connected by bolts

Such brackets are more reliable due to the presence of additional stiffening ribs and a bolted connection that is resistant to vibration. Fasteners made of galvanized steel do not corrode for a long time and can be replaced with new ones if damage is suspected.

Brackets for outdoor unit

Brackets made of U-shaped profile with additional reinforcement

This design is similar to the previous one, but has slightly elongated vertical elements, to which an additional jib is attached at a certain angle. It gives the entire system absolute rigidity and allows it to be loaded with a fairly heavy load.

Brackets made of U-shaped profile, fastened with a horizontal strip

Such devices, in addition to all the positive qualities of the previously described models, also have resistance to horizontal displacement and ease of mounting to the wall. They can be installed under the most expensive and critical equipment.

For information! The presence of elongated holes on the horizontal shelves of the brackets makes them suitable for installation under any brand of air conditioners.

Mounting requirements

Fastenings for mounting the outdoor unit of an air conditioner located at a high altitude are unlikely to be subject to maintenance or at least careful inspection during operation. Therefore, increased requirements are initially placed on them:

- minimum dead weight and reliability of all connections;

- compliance of the bracket with the mass of the intended load, while a double safety margin is desirable;

- the diameter and position of the holes must be suitable for the appropriate fasteners for the air conditioner being installed;

- the ability to maintain its strength properties over a wide range of temperatures and in conditions of high humidity.

Correct mounting of the outdoor unit

Attention! For a well-made bracket, the holes are drilled before painting. Otherwise, they will become the source of spreading corrosion.

Production materials and coating

The most durable brackets are made of stainless steel. But the increased cost has become a significant obstacle to their widespread use. Therefore, the most popular products are made of galvanized steel, additionally treated with other anti-corrosion coatings. Among them are:

- paint and varnish enamels;

- polymer compositions;

- powder dyes.

The latter option is also characterized by increased strength to mechanical stress, which can protect against accidental damage to the protective layer during careless installation.

Installation of an external unit on a ventilated façade

There are situations when the installation of an external unit is carried out on a ventilated facade. This type of facade is very popular in the decoration of modern residential apartment buildings. In its design and technological design, the hinged ventilated façade is almost the same. The main difference is the material of the facing panels. Composite materials, porcelain stoneware, vinyl siding or natural stone can be used for finishing. And depending on the cladding material, installation of the external block on the ventilated façade can be carried out in different ways.

Installation of the outdoor unit of the air conditioner on different types of ventilated facades

If the ventilated façade is made in the form of small ceramic tiles, then to install the outdoor unit you will need to first dismantle them. Next, brackets for the outdoor unit are attached to the wall of the building. Then the necessary slots are carefully made in the removed tile for the legs of the brackets so that it can be put in place. After which the block itself is installed on the assembled structure. Dismantling and installation can be carried out either by an installation team or with the help of an industrial climber. disassembling and assembling the ventilated facade will be added to the total installation cost . The price for this service is presented in the price list.

If the cladding of the ventilated facade is made of a composite material (aluminum alloy), then in this case it is possible to install the external unit on the tile itself. That is, the brackets are screwed directly to the façade cladding material using roofing screws. It is important to understand that this design is not as durable as possible, and implies the possibility of installing standard lightweight outdoor units of split systems with a power of up to 2.5 kW. Otherwise, the installation process will be similar to the installation process on ceramic tiles of the facade.

Installation of an outdoor air conditioner unit on an insulated facade

Very often it is necessary to install the outdoor unit of an air conditioner in panel houses on an insulated facade. Insulation in this case is carried out by attaching thermal insulation to the wall of the house and then applying plaster to it. Installation of an outdoor unit on such a facade is possible, but not simple. There are several reasons for this. Firstly, the structure of the insulated facade itself is not strong, which means it will not be possible to attach brackets to it. Secondly, the standard length of anchor bolts is often not enough to screw them to the wall itself through the insulation layer. The solution in this situation would be to construct a frame on the facade from studs and crossbeams. The studs are screwed deeper into the main wall, and on the outside of the insulated facade, cross-beams from the traverse are attached to them. This design allows you to attach brackets to yourself for subsequent installation of the unit itself on them. That is, with such an installation, a service such as non-standard fastening .

You can get acquainted with the cost of services for installing an external air conditioner unit on the facade of the house, as well as the cost of all related and additional services in the price list below.

Criteria for choosing a mount for an air conditioner

If you decide to choose brackets for mounting your air conditioner yourself, you must take into account a number of important factors:

- Check the maximum weight that the bracket can support. Typically, the manufacturer already provides in advance a double safety margin necessary to compensate for winter icing or falling icicles.

- When equipping brackets with fasteners, it is necessary to take into account the wall material. The length and diameter of the anchors used depends on this.

- If there is a ventilated facade or an additional layer of insulation is applied to the wall, it is necessary to consider a method of fastening only to durable parts, which include either a load-bearing wall or a metal frame of the front layer.

- When fixing external units weighing more than 120 kg, only reinforced brackets with a metal thickness of at least 3 mm are used.

- In the standard case, the fastening kit should include 4-6 dowels with a diameter of at least 10 mm for fastening to the wall, galvanized bolts of 8 (10) mm with corresponding nuts and washers for fixing the unit on horizontal shelves.

- To reduce the noise level emitted by the operating unit and dampen vibration, it is recommended to place special rubber washers under the fasteners.

Important! No changes to the bracket design, including drilling additional holes, should be allowed.

Application of brackets

Typically, outdoor air conditioner units are installed on the rear or side facades of buildings. At the same time, for a classic household air conditioner, two brackets are enough. But remember, the number of brackets depends on the weight of the equipment, so it is better to double-check the technical specifications of your air conditioner.

Brackets for air conditioners on the facade

Step-by-step instructions for installing the climate system

When installing a split system yourself, it is recommended to follow the following action plan:

- Choosing a location for installing an air conditioner. A flat vertical section of a load-bearing wall without visible damage is suitable for this. It should be remembered that to minimize energy losses, the recommended length of communications should not exceed 15 meters. It is not advisable to have foreign objects in the immediate vicinity that would interfere with normal air exchange. For installation of an outdoor unit, the northern or eastern side of the building on an open balcony or in the immediate vicinity of a window opening is considered optimal.

- Installation of brackets for air conditioning. Markings are made in a place convenient for work in accordance with the dimensions of the bracket for your air conditioner. Holes for anchors are drilled and parts are secured. In this case, it is necessary to achieve a tight fit to the wall of the vertical racks and the horizontality of the shelves.

- Attaching the outdoor unit. It is fixed to the brackets using bolts and nuts. At the same time, airflow from all sides must be ensured, so sufficient clearance must be left on the wall side. If possible, install a canopy that protects from water and falling icicles.

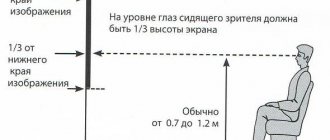

- Attaching the indoor unit. It is placed strictly horizontally at some distance from the ceiling. An indentation of 10 cm will be quite enough. First, a mounting plate is attached to the wall, on which the unit itself is then fixed. It should not be near heating appliances or electrical wiring.

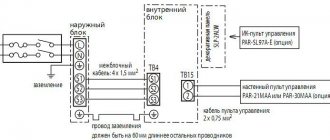

- Electrical connection. Each air conditioner comes with instructions with a switching diagram. This work must be carried out by a specialist. It is important that the connection is made through an emergency shutdown circuit breaker.

- Recommendations for laying pipes. Copper pipes are used to circulate freon. They are laid with a small margin in length in case of temperature deformations. Connections are made using rolling. After installation, all communications are covered with thermal insulation materials.

- Evacuation of the system. Using a vacuum pump, all air and drops of moisture that could negatively affect the operation of the compressor are pumped out of the system. After making sure that the equipment is completely sealed, it is filled with refrigerant.

Installation of brackets and fastening of the outdoor unit

Attaching the indoor unit

Pipe laying

Evacuating the system

Important! Only after checking the stability of the climate control equipment can installation be considered successful.

The installation of any technical device ends with commissioning tests. Turn on the air conditioner, checking it in all modes provided for in the instructions. If no defects are found, you have completed the installation task successfully.

Watch a video about air conditioner brackets