When and why do you need to replace a worn chainsaw sprocket?

The drive sprocket of a chainsaw or electric saw is one of the most important parts of the sawing machine. The main function of the chainsaw sprocket is to transmit engine torque to the saw chain. This transmission is carried out through a centrifugal clutch. By type, sprockets can be divided into professional and household, just like chains. During the operation of the chainsaw and sawing wood, the drive sprocket, like the chain, gradually wears out.

Husqvarna drive sprocket

Let's find out in more detail why it is necessary to replace a worn chainsaw or electric saw sprocket and when is the best time to perform such a replacement.

The main signs that the sprocket needs to be changed:

- The chain on your chainsaw has been replaced twice (one of the current operating rules for chainsaws and electric saws is that if you use the tool frequently and actively, after two chain changes you should replace the drive sprocket);

- the quality of sawing deteriorated, the chain began to need tightening more often;

- you have installed a new chain to which the old drive sprocket does not fit (this part is not universal, and also has its own pitch, in addition, the pitches of the drive and driven chain sprockets must match, otherwise the tool will not work);

- you are using a different tire, shorter or longer.

Video about replacing a sprocket on a chainsaw:

Why is it necessary to replace the drive sprocket?

Among the most common reasons why a tool may need repair is the replacement of the drive sprocket. This part becomes unusable due to:

- chain jamming if any defect occurs during equipment operation;

- high sprocket wear during prolonged use of the chainsaw.

Regular use of the tool contributes to increased wear of the part due to the increased load when sawing wooden materials. There are several known ways to use the tool:

- By using one chain saw.

- Through the alternating use of several chain saws.

In the first method of using the tool, the saw is used until it is completely worn out. This method has certain disadvantages, among which we can note the problem when carrying out manipulations that control wear as a result of intensive operational activities.

When working with two or more chains, you can get even wear on each chain and sprocket, which will significantly extend the operation of the unit and reduce the need for frequent drum replacement. In addition, it is important to remember the condition of the bearing installed in the drum. The operation of this structural element occurs at any engine speed. When replacing the sprocket, it is also important to take care of replacing the bearing and clutch.

Untimely repairs contribute to the occurrence of increased vibration, which affects the increase in wear rates of parts that are installed in the engine of the device on the crankshaft axle shaft. The maximum depth for wear of sprocket teeth should not be more than 0.5 mm. The service life of sprockets is twice that of chains. For this reason, it is recommended to use two circuits.

When the resource of each chain is exhausted, it is necessary to simultaneously replace the chains and the drive sprocket.

Why do you need to replace the sprocket?

A worn sprocket must be removed for the following reasons:

- with an old sprocket, the saw chain will stretch very quickly - after just a few uses the chain will hang, and tensioning will not help;

- if you put a new chain on an old sprocket, the smoothness of the chain will decrease, the quality of the cut will deteriorate, the chain will lead to the side when cutting;

- the general wear and tear of the chainsaw will accelerate, the tool may fail at any time;

- The chain may break or the chain will jam during operation (danger of hand injuries and damage to the body of the electric saw or chainsaw);

- the tire will heat up faster, which will lead to rapid overheating of the chainsaw;

- the load on the engine and body will increase.

Important! You cannot change sprocket sizes at your own discretion during repairs; use the manufacturer’s standard. Unauthorized replacement will lead to deterioration in the technical performance of the chainsaw or electric saw.

Video on how to change the sprocket on a chainsaw:

Sequencing

Chainsaw sprocket, ring and bearing

The vast majority of household saws are sold under the Partner brand. It is enough to simply change the sprocket in them, even at home, by purchasing a repair kit.

Since most often the sprocket in household saws is a assembled mechanism, it rotates due to the bearing. That is, when changing the sprocket, you inevitably change the bearing and the shaft.

In professional models (such as Shtil and Husqvarna), as well as in household ones, if it is not possible to have a specialized wrench on hand for removing the star, they use a soft cord with a diameter of 5-6 mm.

In all cases, the sequence of actions is as follows:

- The side cover must be opened to gain access to the tire and sprocket.

- Next, you need to remove the tire by loosening the chain.

This is what a chainsaw tire looks like

- Once the sprocket is free, you need to unscrew the spark plug to gain access to the engine piston.

You may also be interested in an article on how to make a vibrating table for paving slabs: //6sotok-dom.com/instrumenty/vibrostol-svoimi-rukami.html

- Manually rotating the sprocket, bring the piston almost to the very top of the channel and fill the resulting hole from the spark plug as tightly as possible with a soft cord, thereby blocking the movement of the piston.

- Depending on the saw model and gearbox type, use an open-end wrench and unscrew the sprocket.

Thus, following the recommendations given in the article, you can easily remove the sprocket from the chainsaw yourself.

How to remove and replace the drive sprocket on Husqvarna and Stihl chainsaws is described in detail in this video:

Are there ways to extend the life of an existing sprocket?

The main ways to extend the working life of a chainsaw drive sprocket:

- use several chains (preferably three). This method is the most gentle and convenient for the chainsaw owner in that there is no need to constantly tighten a chain worn out by intensive work. Operating three chains in turn will save the life of the sprocket and delay its replacement;

- high-quality maintenance of the drive sprocket bearing. This part plays an important role in the functioning of both the drive sprocket and the engine. For lubrication, it is recommended to use a special lubricant. The sprocket bearing is not constantly engaged, but only at idle speed, and therefore requires periodic lubrication. You can use a tire nose lubricant, such as standard lubricant from Repsol or Husqvarna.

Replacing the drive sprocket on a Husqvarna chainsaw

Many owners of gasoline chainsaws, after a device breakdown, are concerned about how to remove the chainsaw sprocket.

When replacing a sprocket, all work must be carried out carefully and carefully.

The design of the chainsaw device. This is a classic mechanism that is driven by an internal combustion engine. The design of the unit uses one of the most common single-cylinder two-stroke carburetor engines running on gasoline. The simplicity of the motor and the design of the chainsaw as a whole is the key to uninterrupted and reliable operation of the device in difficult operating conditions. Operating a chainsaw does not require a huge amount of knowledge and ability from the operator. The only condition for long and trouble-free use of the device. Carrying out regular technical inspections and maintenance of the device. While working with the device, it is necessary to frequently replace worn parts. To reduce tool wear, you should monitor the quality of saw lubrication, its tension, the degree of chain wear and the degree of wear on the drive sprocket.

Before repairing a chainsaw, you should study its design. To replace one of the main structural parts of the drive sprocket device, it is necessary to study the clutch mechanism of the block.

What tools are needed to replace the sprocket?

To replace the drive (drive) sprocket you will need the following tools and components:

- a special key for removing this part (usually supplied with expensive branded chainsaws; cheap saws are not equipped with such a key);

- a drift made of aluminum or copper (only from soft metals and only in the absence of a key);

- hammer (for striking the drift while unscrewing the sprocket);

- flat screwdriver for tightening the nut;

- sprocket bearing grease.

Replacing worn parts

If the gear has a replaceable ring, you should carefully check the condition of the base. If nicks, chips, deep scratches, changes in geometry or corrosion are detected, not only the crown, but the entire part should be replaced. The combined operation of worn and new parts in one assembly will lead to a reduction in the service life of the entire assembly. The risk of jamming or circuit breakage increases significantly.

In addition, the vibration load on the clutch, transmission and engine of the device will increase. The same factors arise during prolonged operation of one circuit.

Folk “craftsmen” sometimes revive a stretched chain sheet by simply throwing out one or a link and re-pressing the axles. In this case, the chainsaw needs to replace the sprocket.

You should also not change the diameter of the gears (and, accordingly, the number of teeth). When working with an enlarged or reduced sprocket, forces arise in the transmission and engine that the designers of the device did not expect. This will shorten the tool's service life and will not improve its performance.

Despite the presence in the design of the chainsaw of safety systems that instantly stop the movement of the blade when it breaks or the tire is destroyed and protects torn links from scattering, it is better not to lead to such situations. The need to replace the gear is only increased by safety requirements.

Design problems, differences between different models

Branded chainsaws have a special design that does not allow replacing a worn drive without removing the clutch and other parts of the chainsaw. That is, the saw needs to be almost completely disassembled. More modern models of expensive chainsaws are always equipped with a special key.

Replacing a sprocket on a chainsaw

Also, the owner of a chainsaw may encounter the following nuance: on Chinese imported chainsaws or electric saws, the sprocket on the clutch mechanism may be located in an unusual way. On older models, when the chain teeth wear out, you need to unscrew and replace the one-piece drum with the drive. On newer models, the sprocket can be replaced separately.

Replacing the drive sprocket on a Husqvarna 445E (435-440-450) chainsaw

This shows how you can change a worn sprocket

Husqvarna

chainsaws .

The chainsaw clutch closes the sprocket.

Firstly, it should be noted that when buying spare parts for a chainsaw, you must strictly observe the type of drum or take the advice of a specialist when it comes to upgrading it. Typically, when replacing the drum and saw chain at the same time, the drum bearings are also replaced.

In any case, the main prerequisite for replacing the sprocket. this is the wear of her teeth by the chain. In this case, a durable drum is installed in the device, the surface of the chain is cut through it almost one hundred percent, which requires a complete replacement of the entire part. If the chainsaw has a drum with a variable crown, here you can limit yourself to only changing the crown.

Usually, in order for a chainsaw sprocket to fly off This activity does not look complicated, but it requires all the necessary parts and tools. The sprocket replacement process is similar for any device model.

Algorithm for self-replacement of the clutch drum with sprocket

How to replace the drive sprocket on an electric saw or chainsaw - more on this below.

To replace the sprocket, you need to do the following:

- remove the chain brake cover and pull it towards you (avoid contact of the brake band with the clutch parts);

- using a wrench, loosen the nuts holding the chain tension and the chainsaw cover;

- remove the chain and then the bar, removing debris and sawdust from the mounting holes;

- we fix the piston in the cylinder using a regular cord, but if possible, you need to use a piston stopper or a special lock;

- the clutch begins to rotate and does this until the piston touches the exhaust port;

- after which the stopper or cord is lowered into the candle opening and fixed there by tying several knots (the stopper will fix itself);

- unscrew the clutch nut (note that the thread of this nut is left-handed, take this into account when unscrewing);

- It is prohibited to use hard tools so as not to break the soft metal of the clutch nut;

- then the clutch is removed;

- then remove the sprocket gear itself;

- replace the old sprocket with a new one;

- Reassemble the structure in reverse order.

Causes of malfunctions and how to determine the need for replacement

When idling, the spring compresses the cams and they do not touch the drum. As the speed increases, the centrifugal force exceeds the spring stiffness and the cams come into contact with the walls of the drum. The latter begins to rotate.

The teeth of the saw chain mesh with the teeth of the drive sprocket. One of the functions of an automatic centrifugal clutch is to protect the engine when the load on the chain increases beyond the permissible limit. This can occur when the chain gets stuck.

The outer part of the drum is covered by an emergency brake band. When the handle is folded back, the belt is pressed against the drum and slows down its rotation. The effect is the same as when the chain jams.

A feature of all chainsaws is that the drum and clutch cams are attached to the shaft using a nut with a left-hand thread so that the mechanism does not unwind during operation.

Wear on the drive sprocket teeth can occur for several reasons:

- natural wear and tear along the chain teeth;

- accelerated wear as a result of excessive chain tension or lack of lubrication;

- incorrectly selected chain;

- technological defect.

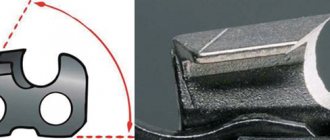

Metal wear can be determined visually by inspecting the sprocket without removing it from the saw. Dents and chips on the surface should not exceed 0.5 mm.

The need for replacement is determined by increased noise when the chain moves, but this is typical only in the presence of deep potholes. It is difficult to notice shallow wear during operation, but the chain will wear out greatly. When the teeth are broken, the chain may move jerkily, which is especially noticeable during operation.

The clutch operates automatically, depending on the number of engine revolutions.

The units are equipped with a centrifugal clutch, which operates automatically, depending on the number of engine revolutions.

When the engine of the unit operates at idle or low speed, the elements of the clutch basket, which have friction linings, have a certain level of freedom in the circular direction. The presence of freedom of movement leads to the fact that, under the action of springs, the elements are attracted to the center of the rotation shaft and do not transmit rotational motion to the sprocket drum.

As the engine speed of the device increases, the centrifugal force exceeds the force of the springs, which leads to displacement of parts with friction linings. Replacing the piston on a Chinese chainsaw. Replacing the piston group of a Chinese chainsaw 4500replacement piston group of chainsaw 4500 cylinder-piston group for a 45 mm chainsaw replacing the piston group on a chainsaw stihl ms180 chainsaw china replacement.

Replacing the sprocket on how to unscrew the clutch on a chainsaw. On a Chinese chainsaw. These elements are pressed against the inner walls of the drum under the influence of centrifugal force. Due to this contact, rotational motion is transmitted to the drum and sprocket, which drives the saw chain of the tool.

More common reasons that force tool repairs associated with replacing the drive sprocket are:

- chain jamming due to defects appearing during operation of the unit;

- the highest wear of the sprocket as a result of long-term operation of the unit.

- professional;

- household.

The main difference between them is the frequency of replacement and the rate of wear: in the models of the “Pro” series, wear occurs faster and repairs occur more often.

The latter consist of a hub with a stationary crown of a certain number of teeth. Their factory pressing does not allow the crown to be removed separately from the hub. This situation is typical for many Chinese chainsaws, for example, from the Champion brand.

The situation with prefabricated sprockets is simpler: the removable crown is quickly unscrewed from the drum axis, so repairs do not cause any particular difficulties. This option is an advantage of most saws of European origin, for example, Shtil or Husqvarna.

Drive gears, according to their design, are divided into:

- Whole. The part includes a hub into which the crown is pressed. You can only remove the part for replacement in its entirety. In the industrial conditions of the manufacturing plant, it is possible to ensure the design values of the interference. Special equipment is used for this. This operation cannot be carried out in a home workshop. Difficulties also arise when trying to buy a crown separately - the manufacturer does not consider it an independent part and does not supply it to stores and service centers.

- Prefabricated. The crown is made as a separate part; it can be removed using a special puller or special tricks with a universal tool.

Solid sprocket

Experts identify the following signs of wear on the drive gear teeth:

- semicircular depressions are visible at the base of the tooth;

- the thickness of the tooth varies with height;

- chipped zones at the top;

- scratches appeared inside the hub hole;

- the chain has worn out the groove on the sprocket;

- When starting, the chainsaw jams.

A chainsaw sprocket with such signs should not be used; it must be removed and replaced.

According to the manufacturer's recommendations, the tool should be inspected before starting work. In this case, be sure to check the condition of the saw bar and whether it is securely fastened. If the screw that regulates the position of the chain roller and its tension is loosened, or the nuts securing the bar to the body are loosened, it deviates from the plane of the chain.

Sprockets with replaceable and stationary crown

After tightening the fasteners and making adjustments, do a test run. If free play remains, the sprocket will have to be removed and replaced.

The Husqvarna 137 chainsaw is an amateur, semi-professional class tool. The model achieved high popularity among consumers due to its good performance, light weight and versatility. These days, the Husqvarna 137 chainsaw is actively used not only by gardeners, but also by utility workers.

There are already several 10-cylinder chainsaws in operation from different manufacturers, capacities, and most importantly for special purposes. Saws are divided into:

- prof (for felling and construction);

- household (garden).

Currently reading: Chainsaw Friendship 4 technical specifications 1969 Guards. Chainsaws Druzhba - characteristics of models, options for homemade garden tools

Accordingly, their drive gear will be different, as well as the sequence of actions. Discover 253 best selection of husqvarna chainsaw sprockets 142 chainsaw chainsaw replacement. Assembling a husqvarna 142 chainsaw. Husqvarna 140 chainsaw. Replacing a chainsaw sprocket. Husqvarna 340 chainsaw repair, chainsaw replacement sprocket.

In this regard, you need to know how to remove the sprocket from the chainsaw correctly so as not to damage the tool. This part is also called a centrifugal mechanism or clutch disc.

To better understand the entire process, it is necessary to understand what an asterisk is and how it is used.

You may also be interested in the article,

DIY chainsaw chain sharpening

.

The main malfunctions of chainsaws and steps to eliminate them are described here.

And in this article, you can learn how to repair a Parterre 350 chainsaw.

If the part is not replaced in a timely manner, the stability of the tool will be impaired. A worn part provokes excessive vibrations, which, in turn, have a negative effect on the crankshaft bearings.

Tooth wear of up to 0.5 mm is considered normal. However, users often bring the part to a deeper groove of about 1 mm, not realizing that operation causes damage to other parts of the chainsaw. Naturally, subsequently there is a breakdown of the bearings, which need to be replaced.

When the engine of the unit is running at idle or low speed, the elements of the clutch basket, which have friction linings, have a certain level of freedom in the radial direction. The presence of freedom of movement leads to the fact that, under the action of springs, the elements are attracted to the center of the rotation shaft and do not transmit rotational motion to the sprocket drum.

When the engine speed of the device increases, the centrifugal force exceeds the force of the springs, which leads to displacement of elements with friction linings. These elements are pressed against the inner walls of the drum under the action of centrifugal force. Due to this contact, rotational motion is transmitted to the drum and sprocket, which drives the saw chain of the tool.

The main advantage of this type of clutch is that when the saw chain jams, elements with friction linings slip, which protects the internal combustion engine from serious damage.

The main malfunctions of chainsaws and steps to eliminate them are described here.

Features of the Husqvarna 137 chainsaw, which is suitable for all types of work in gardens and households, plantations, small factories and more, is designed with a 2.2 horsepower engine. The fuel tank is designed for 0.4 liters. Recommended tire for Husqvarna 137 chainsaw.

H30, and the length can vary from thirty-four to thirty-eight centimeters. It should be borne in mind that in order to avoid early wear and unforeseen failures, you can not only meet the manufacturer's performance requirements, but also use original spare parts for the Husqvarna 137 chainsaw, which are in an affordable price range.

How much does a sprocket and its replacement cost?

The chain saw chain varies greatly depending on the manufacturer and is slightly lower than the cost of the saw chain. To avoid regular replacement, manufacturers recommend operating the saw with multiple chains and periodically changing locations. In this case, the wear of the sprocket teeth is more uniform.

The cost of replacement in service centers is proportional to the price of the part itself, so it makes sense to do this work yourself, especially since you don’t need to make any adjustments after that.