The service life of new chainsaw equipment largely depends on the quality of its preparation for subsequent operation. How to properly break in a European or Chinese-made chainsaw with maximum efficiency?

The process of running in a new tool, which is low in time and material investment, has a positive effect on its performance characteristics and duration of use.

Moderate loads during the first stage of running-in contribute to the full grinding in of internal parts, the complete and inexpensive development of the designated overhaul and operational service life.

Advantages of factory break-in

It should be noted that new saws from many leading manufacturers do not require running-in. The running-in of the piston group and working equipment using special technology is carried out directly during the control tests.

Reducing the time of this stage is facilitated by chrome plating the inner diameter of the cylinder and applying wear-resistant coatings to the working surfaces of loaded parts. However, recommendations for a gentle treatment during the first hours of operation of the instrument remain valid.

Features of running in a chainsaw engine and its elements

It is necessary to break in the chainsaw for a total of at least three to four hours - this means starting it up and letting it run at idle, with a release of gas every thirty to forty seconds. Engines from some manufacturers, such as Shtil, Husqvarna, Partner, have one feature: they are not designed to operate at idle for a long time . Therefore, after all the preparatory work, the first start-up and several gas cycles, they need to be allowed to idle for 3 to 5 minutes. Then you should begin cutting trees and branches whose diameter does not exceed 10 cm. This procedure is recommended to be carried out at the following intervals: 1–2 seconds of operation only at medium speeds and 15–20 seconds at minimum speeds without load.

Domestic chainsaws, such as Ural, Druzhba, developed back in Soviet times, require 3-4 full tanks to be used at idle speed to reach full power and run-in. Only after this can you cut with a partial load up to about 5–7 full tanks. Only after such a rather thorough and costly procedure is it possible for them to reach maximum power.

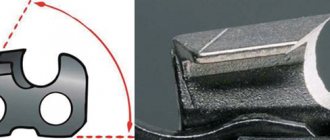

To prepare the chain for the first start and break-in, you need to immerse it completely in oil for a couple of hours. Next, install it on the unit and tighten it so that the chain can be turned by hand, but does not hang down. Then the first start is made, and after 3-5 minutes of operation the tension is checked.

The saw bar does not require special preparation or running-in; it is enough to correctly install, tension and prepare the chain itself, and, of course, the engine.

If you properly break in a new chainsaw, it will serve its owner for a long time without any problems or emergency downtime.

Criteria for independent selection of motor and chain oils

Motor and chain oils recommended by the manufacturer contain special additives that provide full lubrication to working surfaces over a wide range of operating temperatures.

You should not skimp on the quality of lubricants, so when choosing, you should give preference to lubricants from the Stihl, Husqvarna or Oregon brands. Motor oils from these manufacturers for two-stroke internal combustion engines can be purchased in specialized stores or sales offices of dealer companies.

Features of fuel preparation

Each chainsaw differs from similar models in terms of design features and dosage of the fuel-oil working mixture, so even if you have the proper experience, it is recommended that you familiarize yourself with the contents of the attached operating instructions.

To prepare fuel, it is recommended to use fresh gasoline with an octane number of at least 90 and heat-resistant motor oil recommended by the manufacturer, in the dosage specified in the instructions.

The fuel mixture in an amount sufficient for one-time operation is prepared in a fireproof metal container, preferably with a sealed cap. In the absence of oils recommended by the manufacturer, replacement with a full-fledged analogue of the JASOFB or ISOEGB category is possible.

Gasoline with an oil component should not be stored for more than 2 months. The performance properties of an overexposed gasoline-oil mixture deteriorate significantly over time.

Preparing for the first launch

Before starting the chainsaw, you must make sure that the emergency stop mechanism of the headset is turned off. The engine is started in the sequence recommended in the instructions.

After a short warm-up, it is recommended to bring the power unit to medium speed to check the lubrication system. To do this, just hold the headset over a sheet of paper. The presence of an oil streak indicates the serviceability of the system and complete lubrication of the saw chain.

The bearings of the driven sprockets of guide bars with a length of 16 inches or more are individually lubricated after 8-10 hours of operation.

Carburetor adjustment

A full run-in of a new chainsaw involves properly setting up the fuel system. Standard factory carburetor adjustment is made on the basis of averaged data, therefore, depending on external factors, it needs to be adjusted.

A saw with an adjusted carburetor should quickly pick up speed, equally stable at operating mode and at idle speed. The proper quality of the air-fuel mixture is also indicated by the brown color of the spark plug insulator.

Running in chainsaws Shtil, Husqvarna and other brands

The running-in of the Shtil chainsaw is carried out in the same mode, according to the same chronology as Husqvarna, Partner, and Chinese-made tools. Before carrying out full work with a saw, the operator or its owner needs to understand the importance of the break-in process. When carrying out this procedure, all parts after factory assembly, transportation and receipt of the gasoline-oil mixture must try to harmonize with each other, demonstrate their operating potential and each choose comfortable temperature conditions for themselves.

It is for this reason that it is not worth loading the saw while grinding in elements or running them in, but there is no point in running them in at idle either. Whether you are working with the popular Shtil MC 180 model or other gasoline-powered tools, the two-stroke engine definitely needs to be broken in. If you need spare parts for a chainsaw, KosiKosa will help you with this by offering products from the store catalog.

Recommendations for the initial break-in stage

- The practice of running in a new chainsaw without a saw set is fundamentally wrong, since all its moving elements need to be broken in.

- The standard break-in time is several hours. In any case, the design of chainsaws of any quality and price level does not provide for prolonged operation of the engine at idle speed.

- In this mode, the loaded parts of the piston group and connecting rod-crank mechanism experience a significant lack of lubrication, which inevitably leads to overheating and forced wear of the working surfaces.

- The total running-in time at idle with periodic gas releases of 25-30 seconds should not exceed 15-20 minutes.

Running a run-in engine without load at high speeds is strictly prohibited. Moreover, running in the tool at idle speed is ineffective; the best result can be obtained when subjected to moderate loads. The new chainsaw can be used to cut wood of medium density and small diameter within 100 mm.

How to properly break in a chainsaw

Today, chainsaws are produced by different manufacturers (well-known ones - Shtil, Husqvarna, Makita, Interskol and others, and little-known ones - Carver, Echo, etc.), but the running-in process will be the same for all devices. It involves performing the following actions:

- After starting the engine, you need to let it run for 3 minutes (until it warms up), while regularly re-gassing. Leaving the chainsaw constantly idling is strictly contraindicated. No matter who advises you to do this, however, this approach is fundamentally wrong.

- Start sawing small logs (gradually increase their diameter), which is carried out at reduced high speeds (600-700 revolutions per minute lower than the maximum value).

- Every 5 minutes of sawing logs, breaks are taken. During the sawing process, you also need to take breaks, for example, sawed off one log, and let the tool work for XX 15-30 seconds, after which we continue further. After 5 minutes of sawing, let the engine run at idle again, after which you need to turn it off and let the tool cool.

- If this is a household chainsaw, then you need to turn off the engine and let it cool for 20-30 minutes. For professional and semi-professional units, a break is performed in the form of stopping the engine for 5 minutes.

With each subsequent tank, it is necessary to increase the operating time of the engine. However, this applies only to professional and semi-professional units. Domestic chainsaws must be run in with extreme caution and should not be allowed to overheat. It is better to start the engine more often, but at the same time let it run in short-term modes, than vice versa.

How to extend the life of a new headset?

Experienced sawyers practice keeping a new saw set in a container with hot chain oil at a temperature of no more than 60°C for a day.

This procedure, known as stabilizing the internal structure of the metal, has a positive effect on its resistance to external loads and temperatures. Identical technology is recommended for processing saw sets used as replacement equipment.

During the break-in process, it is necessary to periodically monitor the chain tension, the presence of chain oil in the tank and its supply to the cutting working area. It is better to postpone checking the emergency stop mechanism of the chain until you have developed certain working skills.

Instructions for running in chainsaws

There are two types of break-in procedures, which are carried out on a new tool, and on a chainsaw after a major overhaul of the engine. A new chainsaw needs to be run in with an average load, since idling the engine helps reduce the engine's life. In order not to harm the tool, and at the same time carry out the procedure for grinding in rubbing parts correctly, you should ensure a gentle load on the chainsaw.

Running in the engine of a gas powered tool is carried out in the following way:

1. Setting the supply of the fuel-air mixture in an enriched form. To do this, you will need to adjust the carburetor. The process of starting the unit is described in detail here 2. The carburetor is adjusted by moving the adjusting screws L, H and T 3. Initially, the maximum engine speed is reduced by 600-700 rpm from the maximum value. To reduce the speed, you need to loosen screw H 4 with a slotted screwdriver. To determine the number of revolutions at idle, you need to use a tachometer. How to check the speed of a chainsaw with a tachometer is described here 5. If it is not possible to check the speed with a tachometer, then the adjustment should be carried out according to the instructions. Sawing operators need to purchase a tachometer to measure the speed, since the carburetor will regularly need to be adjusted for normal operation of the unit 6. Without a tachometer, adjustment is made by moving screw H a quarter turn in the rich direction. You can determine the increase in fuel supply by the sound of the engine 7. After completing the break-in stage, you will need to fine-tune the carburetor using a tachometer

During the running-in process, you need to let the unit run for 3-5 minutes at idle, and then start cutting wood with a small diameter of up to 10 cm. Heavy loads on the motor should be avoided, and the sawing process should be accompanied by pauses - 1 minute of work and a 20-second break for XX.

Analysis of controversial warranty situations

At the break-in stage, hidden defects often appear, which service and repair services must eliminate free of charge during the warranty period. Attempts to independently eliminate serious faults may become grounds for refusal of warranty repairs by service specialists.

Identified manufacturing defects, serious failures and malfunctions are eliminated at service centers free of charge, provided that the faulty component or unit does not have clearly identified signs of self-repair.

Incomplete depletion of the life of the saw set is not included in the list of manufacturing defects; replacement of tires and chains is carried out for a fee. Warranty repairs may be denied if the service department proves the use of surrogate consumable fuels and lubricants.