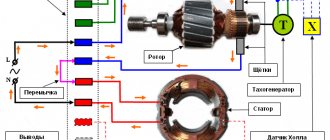

A belt drive is used to transmit torque from the electric motor shaft to the drum. When replacing? rotor ball bearings or damage to the drive wheel, it becomes necessary to remove the pulley from the washing machine motor. The impeller is fitted with an interference fit and secured against turning by a key or screw.

Reasons for pulley failure

The pulley is a ring with a groove corresponding to the profile of the belt used. The outer part is connected to the hub using spokes reinforced with stiffeners. The part is cast from reinforced plastic or aluminum alloy, and then goes through a dynamic balancing stage (to reduce vibration of the equipment during operation). Old-style machines used a belt with a trapezoidal profile; Indesit, LG or Bosch front-loading equipment uses a poly V-belt with increased strength.

Common causes of failure of a part installed on the motor:

- destruction of the spokes or bead as a result of material fatigue;

- the appearance of material peeling on the treadmill due to manufacturing defects, which damage the belt during operation;

- Damage to the mounting hole due to installation of the pulley with a misalignment or insufficient fixation.

What are the options for mounting the unit?

To remove the pulley from the electric motor that drives the tank using a belt, you must first determine the type of its fit.

Mounting methods differ in appearance and are defined as:

- spline connection (has a serrated edge of the shaft end);

- “hot” landing (the end of the engine axis is visually smooth and completely round);

- keyed fit (a groove is visible at the end);

- fit on a cone with a lock nut (the presence of fasteners is visually noticeable).

Self-diagnosis

Before removing or checking the condition of the drives, you must:

- Turn off power to the equipment, and then disconnect the water supply and drain lines.

- Remove the side covers and rear wall to gain access to the belt drive. On some machines, the belt drive is covered with an oval-shaped shield, which is attached to the body with Phillips-head screws.

- Place the machine on the side surface of the body.

- Remove the belt from the pulleys, loosen the motor mount to reduce tension, or remove the belt manually (by holding the rubber element with your hand while simultaneously rotating the impeller on the drum).

Self-diagnosis consists of inspecting the impellers and drive belt.

It is recommended to manually rotate the motor and drum shafts, which will allow you to determine the axial runout of the drive elements.

The supports are checked by rocking the shaft by the outer edge of the pulley manually or using a mounting blade. If damage, distortions or rolling bearings with increased play are detected, it is necessary to remove the pulleys to repair the washing machine.

Remove the washing machine drum if there is a disposable tank

If you need to twist a disposable tank, then after repairing the machine you will need to replace it with another one, it is best if it is no longer disposable.

We will look at the method of disassembling the drum in more detail below. The need for this arises when you need to separate the cross from the drum. The crosspiece needs to be replaced if the bronze bushing wears out. Finally, a few tips on how to properly care for your laundry assistant so that it lasts longer and you no longer need repair recommendations.

- Wipe the exterior and interior of your machine regularly to remove water stains. You can use a solution of dishwashing detergent on the outside; just wipe the inside of the drum with a damp cloth.

- After each wash, leave the hatch door open for a while to allow any remaining water from inside to evaporate.

- Periodically wash the conditioner container without using household chemicals.

- If the quality of the wash has deteriorated, and an unpleasant odor appears in the machine, then deep cleaning is necessary. To do this, you can purchase a special product in the store, or prepare it yourself. Simply mix 1 tablespoon of powder with ¾ cup of bleach. The resulting mixture must be poured into the machine and run a pre-soaking cycle, and then turn it on for rinsing. After completing the process, make sure that all the solution is removed from the drum.

- If you use the top surface of the machine as a shelf, cover it so that it does not get scratched or dirty. Do not place sharp objects on it and avoid contact with corrosive substances.

- It is advisable to change the connecting hoses for draining and collecting water every 5 years and regularly inspect them for wear and cracks.

We suggest you familiarize yourself with Harvesting and storing grapes

By following these simple rules, you will be able to keep your machine in working condition for a long time.

Withdrawal procedure

To remove the pulley from the washing machine drum yourself, you will need a screw puller for rolling bearings. The central nut is first unscrewed (not available on all installations), which can be kept from unscrewing spontaneously by a metal washer. Then the legs of the device are inserted between the spokes and rest against the rear part of the hub, the screw is located in the centering hole on the axle. When the handle rotates, the part is smoothly pulled off the shaft without damaging the mating surfaces.

When removing the drum wheel, sometimes there is a problem with unscrewing the central bolt or nut. To reduce the effort, it is necessary to heat the element with the flame of a portable gas torch or blowtorch. Then you need to try to unscrew the threaded element with a wrench. An alternative technique is based on the use of fluids such as WD40, which is poured into the gap between the bolt and the impeller. The solution penetrates the threads and reduces the force required to unscrew.

Removing the pulley from the electric motor

The electric motor rotor has a small pulley that cannot be removed without a puller. The motor is removed from the washing machine and cleaned of dust and dirt, and then placed on a table or clamped in a vice through wooden spacers. The puller's paws rest against the rear end of the part, and the bolt is installed in the centering hole. To reduce the force, the surface of the pulley is heated to 125-150°C using a torch or blowtorch. The elevated temperature removes the adhesive that is used at the factory to hold the part in place.

When warming up, it is necessary to protect the windings and ball bearings from heat. A damp rag is placed on the shaft and housing; excessive wetting of the material is not recommended due to the risk of water entering the internal cavities of the engine. The heated pulley is carefully pulled off the axle with a puller; the work is done wearing protective gloves to prevent hand burns. After dismantling the drive, the electric motor is disassembled and worn elements are replaced.

To dismantle the drive, you can use a homemade puller made from a steel plate 10-15 mm thick. It is not recommended to use welded structures, since the force of tightening the pulley will destroy the seams. In a homemade device, symmetrical holes are drilled to install a threaded bushing for the lead screw. The configuration of the jaws matches the contour of the pulley. When removing, it is necessary to heat the pulley with a torch and use WD40 fluid.

How to remove the drive from the drum

To remove the pulley from the drum of the washing machine, you need to stop it using a wooden block (hammer handle, etc.) inserted between the spokes of the wheel, and at the same time unscrew the locking screw (or nut, depending on the model) located at the end of the drum shaft .

If the nut on the washer drum does not respond to force by hand, it should be treated with WD40 liquid or slightly heated using a hand torch. You can remove a “stuck” fastening from its place by sharply hitting the handle of a wrench placed on the nut or the end of a powerful screwdriver inserted into the groove of the screw.

Pulley installation

Installing a keyed wheel consists of the following steps:

- Insert the segment or rectangular key into the groove provided on the motor shaft.

- Heat the new pulley to a temperature of 125-150°C, and then put the part on the axle.

- Install the drive element using a mandrel and a hammer until it stops.

- After the parts have cooled, the engine is installed in its original place, and then the belt is put on.

- Check the operation of the drive, replace the removed covers of the washing machine body.

When installing the drive on a spline shaft, it is necessary to apply thread locking agent to the surface of the axle. The pulley for the poly V-belt is placed on the shaft using a screw press or a vice; warping of the parts is not allowed. The element is installed on the shaft to its original state (the location of the end edge of the pulley must be marked on the shaft before removing the part). The applied sealant crystallizes within 12-24 hours (depending on the manufacturer); engine operation is allowed after the fixative has hardened.

The drum pulley is put on the shaft in a heated state; sealants are not used in the connection. The part is pressed onto the shaft until it stops by striking a wooden spacer with a hammer. Excessive force poses a risk of structural failure. Then the central bolt or nut is tightened, which is kept from spontaneous unscrewing by a thread lock or the bent edges of a steel washer (depending on the manufacturer of the washing machine).

How to get to the details

The process of disassembling washing machines of all brands must begin by de-energizing the device, draining the water and disconnecting from communications. An important condition is to ensure free access to all parts of the device, so it must be moved to an empty, well-lit place.

On an Indesit washing machine, the unit is dismantled together with the electric motor. To get to it, you must partially disassemble the device.

To work you need to prepare the tools:

- screwdrivers (flat, Phillips or star);

Slotted screwdriver

- pliers;

- a set of keys or heads (mainly two sizes are needed: 10 or 12 and 17 or 19, depending on the model);

- bearing puller (universal with three “claws”);

Bearing puller

- hand-held gas burner or hair dryer (optional);

- rags, liquid for treating soured compounds (in difficult cases).

The sequence of actions when extracting an engine from a washing machine using an Indesit brand device as an example:

- Remove the top cover of the device by unscrewing the two screws on the back wall.

- After removing the fasteners along the edges of the back wall, set it aside, at the same time inspecting the surface of the drum for abrasions or tracks from water leaks. Wipe off any graphite dust from the brushes.

- Remove the belt: pry it up with your hand or a screwdriver, slowly turning the larger wheel.

- Unscrew the two bolts securing the electric motor and pull it out.

The removed engine must be cleaned of dirt and fixed on a workbench or table. Next, tighten the puller onto the part and heat it locally using a burner or hair dryer to a temperature of 100-150°C. This will destroy the epoxy compound that coats the splines at the factory. The part of the shaft entering the bearing and the adjacent part of the motor must be insulated from high temperatures. The easiest way to do this is with a wet rag, after making sure that excess moisture does not get inside, onto the windings.

Without a puller (purchased or homemade), it is impossible to pull the part off the shaft without ruining the entire assembly.

The video will help you understand how to remove the pulley from the motor of the Indesit washing machine.

Unscrewing the pulley bolt

The drum needs to be dismantled not only if a foreign object gets in, but also to replace the bearings. Different car models may have different tanks, but the algorithm for disassembling is approximately the same. First you will need to remove the pulley.

The pulley is attached to the drum shaft with a special bolt or nut right in the middle. The pulley twists in a counterclockwise motion, and it is better to place some object, for example, a block of wood, to avoid twisting.

Unscrewing the washing machine pulley bolt

Unscrewing a bolt is a rather difficult task, because it is reinforced with a compound specially poured into the hole that prevents it from unwinding during vibration. What to do if you can’t unscrew the bolt the first time? You can use a gas burner to heat it up. The metal will heat up, move, and require less effort to remove. Before using a gas burner, be sure to read the safety instructions, because working with it requires certain skills.

Washing machine pulley repair

So, repairing a washing machine pulley

has the following stages:

• Disconnect the car from all communications;

• Drag it to free space for convenient work;

• Unscrew the screws with a Phillips screwdriver;

• Remove the back wall;

• Remove the drive belt from both the engine and the pulley;

• We examine the pulley for the presence of certain defects;

• Using a wooden block, we clamp the pulley with the crosspiece, and the washing machine drive pulley is aligned

. This is necessary so that the shaft and pulley do not rotate and interfere with unscrewing the bolt;

• Then take a soldering iron to slightly heat the bolt. Immediately spray it with WD-40 or similar;

• We wait for the grease to interact with the remaining sealant, then unscrew the bolt with a wrench.

However, problems can also arise from the engine pulley. Washing machine pulley repair here

more difficult, because you may need to replace the brushes.

1. Unscrew and then remove the motor from the washing machine, disconnecting the wiring;

2. Then we look for a puller designed for pulleys;