What can an engine from an old washing machine look like?

If you are planning to make homemade products from a used engine, you need to figure out what it is and what it is capable of. In washing machines you can find three types of motors: asynchronous, brushless and commutated. Let's take a closer look at them:

- Asynchronous - can be two-phase or three-phase. Two-phase engines are found in older Soviet-made models. More modern machines are equipped with three-phase. The design of such an engine is extremely simple; it can reach speeds of up to 2800 rpm. The working engine removed from the machine just needs to be lubricated - and it is ready for new exploits.

Such motors are characterized by quiet operation. Their only drawback is their impressive dimensions.

- Commutator – you will find this type of motor in the design of most household appliances. Such devices can operate from direct and alternating current, have compact dimensions and a controlled speed. The only drawback of such an engine is the brushes that wear out, but these parts can be replaced if necessary.

It must be admitted that, in comparison with an asynchronous motor, such a motor is noisier. In addition, it often overheats and even sparks

- Brushless direct drive is the most modern motor from the Korean manufacturer. You will find it in modern washing machines from LG and Samsung.

Such models are the most compact. They are characterized by wear resistance, simplicity of design and high efficiency.

Now that you can determine the type of motor, all that remains is to decide where you can use the motor from the washing machine.

Capacitor for electric motor

For small motors (<1 kW), the value of the starting capacitor can be determined from the relationship:

C [uF] = (1800 x Pn) / U2

where Pn [W] is the rated power of the motor, U [V] is the supply voltage.

This formula is also suitable for calculating the starting capacitor value for single-phase start-phase motors.

For larger motors (>1kW) a capacitance of around 70uF/1kW is suggested. It is necessary to use starting capacitors with operating voltages of 400..630 V AC.

You can omit the calculations and simply connect a standard motor from the washing machine to 1 phase 220 V through a 7 microfarad capacitor connected between the required terminals. Connect the first power wire to the middle, and the second, depending on the direction of rotation, to one of the capacitor wires. The power drop will be 30% - this is in theory.

The issue of choosing a capacitor is easily resolved. Here are examples of capacitance values for different engine powers.

Pn [W] 90 120 180 250 370 550 750 1100 S [µF] 4 5 6 8 12 16 20 30

Useful: Connection diagram for generator in VAZ cars

The rotation power in the washing machine is the same in both directions. These are motors with a typical connection for a single-phase motor. The main winding is connected directly to 220 V and a phase winding is connected in parallel with it along with a series-connected capacitor. If you reverse the phase winding wires, the motor will rotate in the other direction, but the power will be slightly less. This circuit works during the spin cycle. The same for slow and fast rotations - the capacitance switches inside the washer from 7 µF to 16 µF. Read more about the capacitor here

We properly disassemble and decide what can be made from parts of an old washing machine

Disassembling a washing machine is a leisurely task. After working with water, a salt build-up may remain on the parts; it must be carefully removed so as not to damage the parts during removal. What can be made from an old washing machine? A motor will be useful for homemade projects - it will become the basis for many devices. The drum will also come into play. It is usually made of stainless steel. All pipes must be disconnected from the drum. A loading hatch may also be useful. In addition to these parts, do not rush to throw away springs, counterweights and body parts.

For those who are versed in electronics, you may need a circuit board - it can easily be used to find spare parts for repair work if necessary.

Scheme for connecting the motor to the network

Modern washing machine

When connecting the motor of a modern washing device to a 220V network, it is necessary to take into account its main features:

- it works without a starting winding;

- The motor does not need a starting capacitor to start.

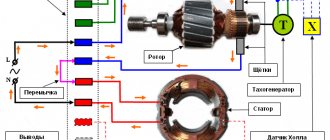

To start the engine, the wires coming from it must be connected to the network in a certain way. Below are diagrams for connecting brushed and brushless electric motors.

First of all, determine the “work front” by excluding contacts that come from the tachogenerator and are not involved in the connection. They are recognized by a tester operating in ohmmeter mode. Having fixed the tool on one of the contacts, use another probe to find the paired pin. The resistance value of the tachogenerator wires is about 70 Ohms. To find pairs for the remaining contacts, call them in the same way.

Now we move on to the most important stage of work. Connect the 220V wire to one of the winding outputs. Its second output needs to be connected to the first brush. The second brush is connected to the remaining 220-volt wire. Plug in the motor to check its operation*. If you have not made any mistakes, the rotor will begin to rotate. Keep in mind that when connected like this, it will only move in one direction. If the test run went without any pads, the device is ready for use.

To change the direction of movement of the motor to the opposite, the connections of the brushes should be swapped: now the first will be connected to the network, and the second will be connected to the winding output. Check the readiness of the motor for operation as described above.

You can clearly see the connection process in the following video.

Old model washing machine

When connecting the engine in old-style cars, the situation is more complicated.

First, identify two matching pairs of pins. To do this, use a tester (also known as a multimeter). Having fixed the tool on one of the winding terminals, use another probe to find the terminal paired with it. The remaining contacts automatically form a second pair.

How to make a sharpener or grinding device from a washing machine engine

A sharpener is one of the most popular tools for the home. It can be used to sharpen garden tools, household knives and scissors. If you don’t already have one, buy it at any tool store or make a sharpening machine from a washing machine. The most difficult part is how to attach the sanding wheel to the motor. The easiest way is to buy a ready-made flange. It looks something like this.

Flange for motor

You can machine a flange from a metal pipe of a suitable diameter; most often, a tube with a cross-section of 32 mm is suitable. You need to cut a piece 15 centimeters long from it, this is quite enough to fix the emery. The flange is secured to the motor shaft by welding or a through bolt. The video describes in detail how a homemade washing machine sharpener works:

How to turn on a commutator type engine

The appearance of motors of different models may differ, but the design and operating principle are almost identical. The device consists of:

- housings;

- stator;

- stator coils (shoes) with two, three terminals;

- anchors;

- shtiva;

- two brushes;

- collector;

- tachometer (with two, three wires);

- terminal block.

To connect the motor, you need to know the outputs of the armature, stator, and tachometer windings. The tester will help you avoid getting tangled among the wires.

How to connect an electric motor

Set the tester to the mode of least resistance, call the windings of the tachometer, coils, and armature. Make connections through the terminals that connect to each other to find a pair. If you have a design with 4 wires, then red-brown are the stator, gray-green are the rotor. The colors of the wires of different SMA models may differ. Therefore, use a multimeter. Did you get a device with 6 wires? Those on the left regulate the speed of the machine with a tachometer. Their resistance is about 70 ohms. A correctly connected device picks up speed smoothly, does not crackle, does not spark. You can check how many revolutions the motor makes using a speed sensor.

You can see how to start the engine from the washing machine here:

Rotation adjustment

There are many ways to control speed:

- laboratory autotransformer;

- adjustment board for household appliances;

- screwdriver buttons, grinders;

- lighting regulators (switches, toggle switches).

The adjustment scheme is simple, you can do it yourself.

This is a satisfactory option for a pump or fan. More powerful mechanisms (for example, machine tools) will require a different regulator circuit.

The essence of the issue is to reduce the speed while maintaining performance. The connection is made through a tachogenerator, which transmits the number of turns to the speed controller microcircuit, which coordinates the cycle with a thyristor.

This board allows you to increase or decrease speed, but requires constant, intense cooling due to overheating. A detailed video about adjusting speed, stroke force, and connecting the microcircuit can be viewed here:

Making a wood lathe from a washing machine

What else can you do with the washing machine motor? One popular idea is a wood lathe. Let's look at the step-by-step process.

| Illustration | Description of action |

| To firmly fix the engine on the workbench, make fasteners from a metal angle. To do this, drill holes for fixing to the motor legs and table. | |

| To fasten a wooden part, you will need a flange fixed to the motor shaft, and these are the studs made from ordinary bolts with cut off heads. Screw these pins into the base. You will need 3 studs. | |

| The motor is fixed to the table with self-tapping screws and to the metal part with bolts. | |

| The opposite end of the wooden part is attached with such a device. It consists of a screw with a loop, two wooden stands perpendicularly fixed to the corners. | |

| This wooden part must be movable so that different workpieces can be used. For mobility, it is mounted on a threaded stud with bolts. | |

| To control the motor you will need a power supply. You can use one of the computer units. You will need to install switches to adjust the rotation speed. | |

| How to connect a motor to a power supply in animation. | |

| To guide your tools, make a tool rest. It consists of two wooden parts and a metal corner. All parts are movable due to fastening with one bolt. | |

| The lower part of the tool rest is rigidly fixed on the workbench using self-tapping screws and corners. | |

| The workpiece is fixed on the machine on both sides: on the left - on studs, on the right - on a bolt with a handle. To fix it in the workpiece, you need to drill the corresponding holes. | |

| To work, you will need sharpened tools - cutters. | |

| Final sanding of the workpiece is done using a strip of sandpaper. |

A simple wood lathe from a washing machine motor

Greetings to all tinkerers, today we will look at how to make a small lathe from an old washing machine motor. The design of the machine has been simplified to the simplest, the homemade product is capable of turning bars into handles for tools, you can also sharpen sticks, and so on. The machine clamp is designed for wood processing, but you can try making a clamp for steel. If the project interests you, I suggest you study it in more detail!

Materials and tools used by the author:

List of materials:

— engine from an old washing machine;

- board for the base; - screws and nuts; - corner; — bolts, nuts, bearing (for the tailstock); - steel rods, plates, etc. List of tools:

- drill; - welding machine; - Bulgarian; - marker, ruler, tape measure. Lathe manufacturing process:

Step one. Headstock

First of all, we will make the headstock; an aluminum pulley has already been made on the motor, which will have to be redone. We mark everything and drill three holes in the pulley at the same distance from each other. After this, we drill holes at right angles for the screws. The author sharpened the ends of the screws, and then we installed the screws with nuts and groovers. As a result, we got spikes with which the headstock will cling to the block.

As for the power of the motor, this question remains unknown, but judging by the size, the motor has a power of at least 200-250 watts.

Step two. Installing the motor on the bed

Next, we install the motor on the frame, using a piece of thick board as a base. We need to raise the engine above the base, to do this we cut bars. The author uses steel corners as brackets, we screw them to the base with self-tapping screws, and then we attach the engine to the corners using bolts and nuts.

Step three. Tailstock

The tailstock base consists of a piece of rod and a steel plate that is screwed to the base. We weld a nut to the end of the rod into which the threaded shaft of the headstock is screwed. At the end of the shaft there is a stop in the form of a cone into which a bearing is inserted.

Step four. Tests

The machine lacks a stop; the author welded it from scrap metal; the stop can be left unscrewed and held with one hand. Now the machine can be tested; the author can easily make an excellent handle for a file from a block. The machine copes with the task, which means it makes sense to make it more convenient, reliable and of high quality, everything is in your hands. This is the end of the project, I hope you liked the homemade product and found useful thoughts for yourself. Good luck and creative inspiration if you decide to do this again. Don't forget to share your ideas and crafts with us!

Become the author of the site, publish your own articles, descriptions of homemade products and pay for the text. Read more here.

How to make a simple feather removal machine for home use from a washing machine with your own hands

The time of slaughtering a bird is a troublesome stage. This is usually done in the fall, when the ducks and broilers have reached the desired weight, and it is no longer profitable to keep them in the winter. You need to pluck several dozen or even hundreds of carcasses very quickly. You can get rid of hard labor with the help of a feather removal machine, and it’s easy to do everything from the same parts of the washing machine.

The only thing that can cause difficulties is the search for rubber fingers with threads - beaters. You will have to order them, so keep in mind that you need to think about making the machine long before slaughter

The device does not require disassembling the washing machine. It is especially convenient to use machines with vertical loading. You just need to fix the beats in the drum so that they point inward. Before plucking, the chicken carcass must be scalded with boiling water and then simply thrown into a rotating drum. Here's what happens:

Important! To prevent water from getting on the engine of the feather removal machine, you need to protect it with a plastic casing.

And the last point - the feather removal device must be firmly fixed, since the vibration when loading the carcass will be very strong.

Lawnmower from a used motor

We continue to look for the answer to the question of where we can use the motor from an automatic washing machine. Another original idea is making a lawn mower. For a small area, an electric model connected to a power source with a cord is quite sufficient. The design of such a unit is very simple. You will need to make a platform on four wheels with a small diameter.

The platform can be made of metal or OSB board, plywood and even the body of the same washing machine

The engine is fixed on top of the platform, the shaft is threaded into the hole below, and the knife is attached to it. All that remains is to attach handles and a lever to the cart to turn the power on and off. If you have an asynchronous motor lying around, you will be surprised at how quiet the unit will be, even compared to factory models.

Advice! To prevent grass from wrapping around the knives, you need to slightly bend their cutting edges down.

Video: how to make a lawn mower

How to build a generator from an old washing machine

We continue to look at homemade products from a washing machine motor, and the turn has come to the generator. You won't be able to assemble a powerful device, but in the event of an emergency shutdown, you can be well prepared. To turn the engine into a generator, you will have to disassemble it and partially cut off the core. In the remaining part of the core you need to make grooves for neodymium magnets.

The magnets must be placed in two rows with the same spacing

The gaps between the magnets are filled by cold welding. To operate the device, the kit must include a motorcycle battery, a rectifier and a charge controller. Details of the work in the video:

Connection to washing machine

How to connect the motor to the washing machine? Features that must be taken into account in order to connect the electric motor from the washing machine to a 220 V network:

- the connection model shows that the motor operates without a starting winding;

- There is also no starting capacitor in the connection diagram - it is not required for starting. But the wires to the network must be connected strictly in accordance with the diagram.

Each of these motors is designed for 2 mains voltages. There are 2 connection diagrams for it.

You can connect the electric motor from the washing machine:

- "triangle" (220 V);

- "star" (380 V).

By switching the windings, they achieve a change in nominal voltage from 1 to 2. With existing jumpers on the electric motor and a block with 6 terminals, it is necessary to change the position of the jumpers.

For any connection scheme, the direction of the windings must correspond to the direction of the windings. The zero point for the “star” can be either the base of the winding or the end, in contrast to the “triangle”, where they are combined only alternately. In other words, the end of the previous one with the beginning of the next one.

The motor can also operate in a single-phase network, but not with absolute efficiency. For this purpose, non-polar capacitors are used. With capacitors connected to the network, the maximum power will not exceed 70%.

Homemade concrete mixer

If you have started a small renovation that requires, for example, plastering the walls, a concrete mixer will come in handy. Once again, washing machine parts will come in handy.

As a result, you will receive a compact device with low power, which you won’t mind throwing away after the repair work is completed.

As a container for concrete, you can use the same drum with pre-sealed holes for draining water. It is best to use parts from a front-loading machine; there will be almost nothing to redo. To strengthen the body, use a metal corner, and for convenient movement of the concrete mixer, equip it with wheels. The main difficulty in the design is the manufacture of a “swing” for the correct tilt and subsequent pouring of concrete. How to do it correctly in the video:

Homemade products from a washing machine engine: circular saw

You will be surprised, but a circular machine can also be built based on the motor from a washing machine. An important point in this matter is the additional equipment of the motor with a device that regulates speed. Without this additional module, the circular machine will work unevenly and simply will not cope with the task. Device assembly diagram:

Circular saw diagram

The principle of operation of the device is simple: the engine drives a shaft on which a small pulley is mounted. From the small pulley there is a drive belt to a large pulley with a circular saw.

Important! When working with a homemade circular saw, take care of your hands. All structural parts must be firmly fixed.

The resulting unit will not be very powerful, so it can only be used for cutting boards up to 5 cm thick. How this homemade circular saw works:

Types of electric motors

An electric motor is a machine operating on electricity that moves various elements using a drive. They produce asynchronous and synchronous units .

Synchronous motor

It has been established since school days that when magnets approach each other, they attract or repel. The first case appears at opposite magnetic poles, the second - at like ones. We are talking about stable magnets and the magnetic field they constantly organize.

In addition to those presented, there are unstable magnets. Everyone, without exception, remembers the example from the textbook: the picture shows a magnet in the shape of an ordinary horseshoe. Between its poles there is a frame made in the shape of a horseshoe with half rings. Current was supplied to the frame.

Since the magnet rejects the same poles and attracts different ones, an electromagnetic field appears around this frame, which turns it in a vertical position. As a result, it is acted upon by a current opposite to the main case in terms of the symbol. The modified polarity rotates the frame and again sends it to the horizontal area. The operation of a synchronous electric motor is based on this belief.

In this circuit, current is supplied to the rotor winding , represented by a frame. The source that creates the electromagnetic field is the windings. The stator performs the functions of a magnet. In addition, it is made of windings or a set of stable magnets.

The rotor speed of such an electric motor is the same as the current supplied to the winding terminals, i.e. they work simultaneously, which gives the electric motor its name.

Asynchronous device

To understand the principle of operation, let’s remember the picture: a frame (but without half rings) is located between the magnetic poles. The magnet is made in the shape of a horseshoe, the ends of which are united.

We begin to slowly rotate it around the frame, observing what is happening. Until a certain point, the frame does not move. Further, at a specific angle of rotation of the magnet, it begins to spin behind it at a speed less than the speed of the latter. They do not work simultaneously, which is why the motors are called asynchronous.

In a real electric motor, a magnet is an electrical winding placed in the slots of the stator into which electric current is supplied. The rotor is considered a frame. In its grooves there are short-connected plates . That's what they call it - short-circuited .

Differences between electric motors

Externally, the motors are difficult to recognize. Their main difference is the operating rule. They also differ in their scope of application: synchronous, more complex in design, are used to drive equipment such as pumps, compressors, etc., i.e., operating at constant speed.

In asynchronous ones, as the overload increases, the rotation frequency decreases. They are supplied with a huge number of devices.

What else can be made from a washing machine drum: original decor ideas

The drum with its correct perforation is a material for the manufacture of decorative objects. Here are some interesting ideas.

Ottoman with drum base. It’s easy to do – you just need to attach the wheeled legs and make a soft seat

Such a drum can also be turned into an original lamp. If you place a lamp inside, the perforated surface of the drum will cast glare on the walls. Such lamps will look good on the ceiling of the veranda or even on the floor

Bedside tables and tables. Drums with doors from top-loading machines can be used to hide small items.

This is how the drum turns into a cabinet or nightstand

Making a barbecue from a drum from a washing machine, photo examples

A metal grill is a temporary product. Sooner or later it burns out and requires replacement. You can buy a new one each time or use improvised material, for example, a drum from a washing machine. Making this craft from a washing machine drum takes a couple of minutes. The beauty is that oxygen easily enters the perforated container, which causes active combustion.

Kebab coals burn quickly, and the process of cooking meat is significantly accelerated

The metal of the drum can withstand a couple of seasons. Make a comfortable stand for it so you don’t have to bend over, and you’re done. Standard length skewers will fit comfortably on a small roasting pan. If necessary, you can lightly weld a couple of guides.