One of the most important elements of the internal structure of a washing machine is the bearing. It is this that serves as a support for the shaft on which the drum is installed.

During operation of the washing machine, bearings withstand enormous loads.

As a result, after a certain time, the first calls to replace the bearings begin to appear - the Indesit washing machine begins to vibrate strongly during the washing process, and an unpleasant grinding sound is heard.

There is no point in delaying repairs. Ignoring the problem leads to complete destruction of the bearings and the drum wedge.

When does a part need to be replaced?

Provided that the washing machine is used correctly, the period of uninterrupted, high-quality operation of the bearings is calculated by the manufacturer for 6-10 years. However, exceeding the norm for loading laundry and improper installation of the washing machine significantly reduce the service life of the metal rings.

A signal that a bearing requires replacement is:

- Rumble and vibration during washing (most pronounced during the spin phase).

- Water leakage (leaks through a loose bearing and a worn oil seal and flows down the back wall of the drum).

The latest generation Indesit washing machines are equipped with a self-diagnosis system. Understanding the error code (the decoding is most often indicated by the manufacturer in the instruction manual), it is not difficult to determine the cause of the malfunction and decide on how to eliminate it.

Features of breakdown

If you follow the operating rules, you will need to replace the bearing no earlier than after 6 years of using the machine. It is after this time that the part is subject to natural wear and tear. Failure before the specified period indicates the influence of the following factors:

- Constantly overloading the drum. Imbalance of linen leads to increased load on the supporting part and accelerated wear of the part;

- deformation of the oil seal - a rubber sealing element that protects the bearing from moisture. If the seal is damaged, water washes away the protective layer and seeps into the bearing, causing corrosion and failure.

Constant overload of the drum can lead to rapid wear of the bearings

The main external sign of a bearing failure is increased hum, noise and vibration of the washing machine, and sometimes an unpleasant grinding noise during the spin cycle. You may also notice moisture appearing under the machine. If, when turning the drum manually, uneven rotation is felt, this indicates the formation of backlash - a gap between the drum and the tank. All of these signs indicate the need to replace the bearing on the Indesit washing machine.

How to replace it yourself?

Despite the fact that the work of replacing bearings requires a lot of time and some experience, it is possible to repair the washing machine yourself . The main thing is to carefully study the step-by-step algorithm of this process in advance.

Preparation

In order for the bearing replacement work to proceed as quickly as possible, it is necessary to carefully prepare.

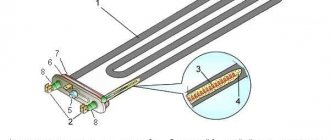

The first thing is to purchase a set of replacement bearings. The classic repair kit consists of two single-row ball bearings and an oil seal.

The second point is preparing the necessary tools. To avoid being distracted by searching for the right screwdriver or wrench during the repair process, you need to acquire in advance:

- hex keys;

- pliers;

- a set of horn wrench calls;

- hammer, files, knife;

- sandpaper, rags and wooden blocks.

A special liquid, WD-40, will help you quickly and easily remove stuck fasteners. It is applied to the soured element, wait one or two minutes, after which the desired fastener is unscrewed without much effort.

Disassembling the Indesit washing machine

Before you start disassembling the washing machine, you need to turn it off from the network, disconnect the drain and water supply hoses (the valve on the cold water pipe is already closed).

The washing machine is moved away from the wall and placed on a flat, stable surface. Nothing should prevent free access to any side of the household appliance.

You can get to the bearings only by completely disassembling the washing machine body.

This work is carried out in several stages:

- Removing the top cover. To do this, unscrew the two bolts securing the rear side cover. The panel is pushed back slightly and lifted up.

- Removing the dashboard. To do this, gently pressing the latch (plastic tab in the center) pulls out the powder receptacle. In the resulting niche, unscrew the bolts securing the dashboard. Having carefully disconnected the wires, the panel is removed from the latches and put aside.

- Removing the rear panel. To do this, unscrew the six bolts on the rear wall. Additionally, remove the belt connecting the pulley to the engine, the counterweight, the pipe connecting the powder compartment to the tank, the water intake valve, and the pressure switch.

- Removing the front panel. To do this, unscrew the drain filter (located at the bottom of the front panel), remove the hatch door and the rubber seal. The cuffs are carefully bent with a slotted screwdriver. In order to remove the door, you need to unscrew the bolts securing the hinge. The front panel moves away from the body without much effort as soon as the fixing bolts are unscrewed.

- In the lower part, dismantle the electric motor, disconnect the wiring of the heating element, remove the drain pipe and shock absorbers (to get to them, you need to put the washing machine on its side).

In order to remove the electric motor without problems, it is necessary, first of all, to dismantle the drive belt. Afterwards, gently rocking, the pulley is removed from the shaft.

In order not to disrupt the arrangement of all parts and connection of contacts, the elements must be photographed before dismantling .

Removing the Drum

Separately, it is worth considering such an important stage of disassembling a washing machine as removing the drum.

First, take out the tank . It's simple: just lift it with one hand, and with the other hand unhook it from the retaining springs and remove it from the car.

In order for further disassembly to proceed as quickly as possible, the tank is placed on a strong, flat surface (table) with the pulley facing up.

Modern models of Indesit washing machines are equipped with collapsible tanks. The two parts are fastened with special latches or bolts . All you need to do is remove the fixing elements and separate the tank into two halves.

Once the top of the tank is removed, the pulley must be removed. Its rotation is blocked with a wooden block, after which the pulley is unscrewed with a hexagonal star key.

How to knock out and remove a bearing?

Removing the old bearing proceeds according to the following algorithm:

- The old oil seal is removed from the socket (the rubber seal is pryed off with a slotted screwdriver).

- Using a chisel, the bearings are knocked out. Start with the outer element, larger in size. The drum is placed on a flat surface with the hatch opening down, a chisel is placed on the outer rim of the bearing, after which the metal ring is knocked out with several precise, fairly strong blows on the chisel with a hammer. The internal bearings are removed in the same way.

Strikes must be as accurate as possible. Otherwise, if the chisel comes off, it may damage the drum body.

Installing a new

After the seat, cleared of old bearings, has been treated with dirt and rust removers and lubricant, new parts are installed into it.

To do this, hitting the bearing on the outer edge, drive it into place . The bearing must fit into the seat until it stops. A new oil seal is inserted into the inside of the tank (the place of the insert is first treated with lubricant).

Assembly and testing

One of the key points in reassembling a washing machine after replacing the bearings is connecting the two halves of a non-separable tank.

In order for the two parts to fit as tightly as possible to each other, the seams are carefully sanded with sandpaper, degreased, and treated with sealant .

The prepared parts are connected and tightened with bolts and nuts (at least twenty pieces). The fastening locations are chosen in such a way that nothing interferes with the work during the process of tightening the nuts.

The assembled tank is connected to the pipe (the attachment point is additionally coated with sealant), a cuff, Tenami and a temperature sensor, after which it is returned to its original place inside the body, hooked onto damper springs, fixed to the lower shock absorbers, and connected to the hatch through the cuff.

At the top, the counterweight is returned to its original place .

The motor is mounted on the tank body: a pulley is put on the drum shaft, secured with a bolt and connected with a transmission belt to the motor pulley. As soon as the tank is fixed in its original place, you need to rotate the drum. The absence of play and any unpleasant sounds indicates that the bearings have been replaced correctly.

Lastly, the control panel is installed (during this process, you must check the marks on the location of electrical connections), the detergent dispenser housing, working water hoses, the inlet valve filter and the drain pump filter (if necessary, clean or replace with new ones).

Replacing bearings in an Indesit washing machine, video instructions:

Common replacement mistakes

Before you start replacing the bearing in an Indesit washing machine, let us draw your attention to the mistakes that non-experts make.

These violations when disassembling an Indesit washing machine can either simply slow down and complicate the process, or lead to new breakdowns, which will be much more difficult and expensive to fix:

- Do not use brute force when removing the pulley from the drum axle. They do this by rocking it from side to side, while gently pulling;

- Excessive force may cause the bolt heads to break off. Fixing this breakdown is possible, but quite troublesome;

- Haste and carelessness with the tank cap can damage the temperature sensor and break its wire. Then you will have to replace it too;

- Breakage of the moving unit;

- Do not forget to replace the gasket of the moving unit so that you do not have to repair it again;

- Also, so that you don’t have to disassemble everything again, before assembling the front and rear parts, carefully check all the wiring, especially at the connection points, sensor connections, etc.;

- How to change the bearings on a washing machine of other models, you can watch the video and make sure that there will be no fundamental differences for different Indesit models.

How to lubricate a part?

Periodic lubrication of bearings extends the life of uninterrupted, high-quality operation of the washing machine.

Creaks and other unpleasant sounds that appear during the washing process are a signal that the bearing needs to be lubricated (if damaged, replaced).

It is possible to carry out such work with your own hands, the main thing is to adhere to a clear algorithm of actions:

- Selecting the right lubricant. It is important that the selected lubricant has a high level of moisture resistance and does not contain aggressive chemical elements that can destroy the oil seal and metal shaft. The lubricant must be resistant to sudden temperature changes and have a certain degree of thickness and viscosity. You can buy lubricant in household appliance stores or specialized websites on the Internet.

- After the bearing has been removed from the drum (the process is described above in the text), the protective cover is removed from it, grease is placed inside, and the cover is fixed in its original place.

Do not use folk remedies to lubricate bearings.

Signs of bearing failure

Disassembling and assembling an Indesit washing machine is still a rather labor-intensive process that requires time. Therefore, without urgent need, no one will do such work with their own hands. How can you be sure that it’s really time to replace a machine’s bearing without climbing into its body? In this case, blind diagnostic techniques will help us. What should be done?

- First, we need to achieve rotation of the drum at maximum speed. To do this, set the appropriate spin mode (for example, 1000 rpm) and listen carefully to the sounds made by the machine - the bearing will give itself away.

- Next, you need to make sure that this is really a bearing; to do this, unplug the machine, remove things from the drum and try to twist it with your finger, now in one direction, then in the other. Hear a knock or metallic grinding sound - another indirect evidence in favor of bearing failure.

- Regularly check the space under the bottom of your Indesit washing machine for moisture. If puddles regularly appear there, it is possible that the problem is in the moving element of the drum.

In conclusion, we note that anyone who is familiar with working with equipment can replace the bearing in a “washing machine” from Indesit. The main thing in this matter is to do without amateur activities and act strictly according to the instructions, then everything will probably work out. If some stage of the work remains unclear to you, you can watch a video on this topic, where bearing replacement is illustrated in more detail.

Where to buy, at what price?

Each Indesit washing machine model has its own original repair kit (two bearings and an oil seal).

The serial number stamped on the metal bearing ring will help you determine which set you need to purchase .

If the part is worn out to such an extent that the serial number cannot be discerned, on the websites of sellers of spare parts for household appliances you can find out what bearings are available and which option is suitable for a particular model of washing machine.

Both bearings and the seal need to be replaced . Otherwise, there is no point in repairing the washing machine.

The manufacturer offers both metal bearings and rings made of heavy-duty plastic. Modern plastic bearings are especially popular among craftsmen, since their service life is several times longer than the service life of metal rings.

The cost of an original bearing for an Indesit washing machine varies from 330 to 1400 rubles.

What bearings are in Indesit machines?

For each model, spare parts are selected in accordance with the design features. You can find out which bearing specifically is in a particular washing machine from the Operating Instructions, or by removing old spare parts from a disassembled machine. When replacing parts, you must strictly follow the original size and choose identical parts.

The following bearings are usually installed in Indesit washing machines:

- 203,

- 204,

- 205,

- VA2V 633667.

Possible difficulties

If the model of the Indesit washing machine is outdated, then during the repair process a problem may arise in the form of a non-removable tank .

To remove the drum from it, the walls must be cut with a hacksaw. The tool is set level (cutting at an angle ensures that the tank will leak in the future), after which the cutting begins.

First, the locations of future fastenings are marked on the surface of the tank so that upon completion of the repair, the two halves can be bolted together.

Where can I find a repairman, how much does a repair cost?

Replacing a bearing is a rather lengthy and labor-intensive process that requires special care, accuracy and experience. The cost of such work starts from 3,300 rubles (for a washing machine with a collapsible tank), from 5,500 (for models with a non-dismountable tank).

The estimate includes not only the cost of the technician’s work, but also the price of the necessary set of consumables (bearing, oil seal, lubricant).

The technician will be able to announce the final amount to be paid only after the initial diagnosis of the washing machine.

You can invite a specialist to repair your washing machine from the service center (it is preferable to contact specialized service points for Indesit household appliances). Word of mouth works well - positive reviews about the master from friends and acquaintances.

The main thing to remember is that the master never takes the full amount to pay in advance; after the work is completed, the specialist issues a Certificate of Repair with a detailed breakdown of all expenses.

A lot of important and useful information about repairing Indesit washing machines is presented in this section.

How to change bearings on a washing machine. Preparing for replacement

So, you are convinced that your washing machine needs to replace the bearing, and you are sure that you can do this work yourself without involving a specialist. Where to begin?

Before you begin the repair, you must purchase a new set of bearings, including an oil seal. It is best to choose original spare parts from the manufacturer that match your model, even if they cost more than their analogues.

A new bearing set should include a rubber seal

Also required for repairs:

- flat and Phillips screwdrivers;

- chisel or impact screwdriver;

- hammer;

- pliers;

- wire cutters;

- socket wrenches;

- WD-40 product;

- glue;

- sealant.

Before disassembling the body of the washing machine, you need to make enough space both for work and for storing parts. Disconnect the washing machine from the power supply, disconnect the hoses, move the equipment away from the wall so that it is accessible from all sides. If possible, move it to a utility room (pantry, garage) in case the repair takes longer.