Why is the write-off procedure necessary?

Some simply throw the faulty device in the trash, and some carry out a special write-off procedure. It is worth noting that according to current legislation, it is prohibited to throw equipment into a landfill.

This is punishable by an administrative penalty of up to 5 thousand rubles from individuals, and up to 200 thousand from legal entities. There are also documented difficulties that make it impossible to simply take a failed device to a landfill. In this case, the easiest way is to resort to the write-off procedure, which can be done either independently or with the help of specialists. Additionally, we will analyze what breakdowns must occur for the printer to be written off.

Typical malfunctions of inkjet models

Statistics show that of all printer models, inkjet devices break down most often. Usually the breakdown is related to the print head or switching mechanism (typical for HP deskjet 2050).

Paper jam

In inkjet printers, sometimes after printing the first sheet, the second sheet gets stuck (for example, in a model like the Epson l222 MFP). There may be several reasons for the breakdown:

- The paper pickup roller is not installed correctly;

- uneven wear.

On a note! Often the second sheet gets stuck if the flag on the sensor is broken. Typically, this situation occurs as a result of incorrect actions by the user who tried to forcefully remove a jammed sheet from the printer.

With increased wear on the brake pad, the printer begins to pick up several sheets at once. After replacing the pad, the device works normally. In addition, page jams in inkjet printers are often associated with the use of low-quality paper that has low density and insufficient thickness. In particular, this has an acute effect on the Canon mg 2440 model.

Printer brake pad

Incompatible cartridges

Sometimes manufacturers set regionalization on their models, so cartridges from another continent are not suitable for them . It is impossible to change the region at home - you need to contact a repair shop.

Using consumables from another manufacturer can lead not only to incompatibility with the printer and, as a result, to a lack of printing, but also to damage to the device. If it is not possible to purchase original cartridges, compatible containers are offered for sale, but you should only buy them in trusted brand stores so as not to run into a counterfeit or low-quality product.

Paper feeding problems

When printing on an inkjet device, the carriage sometimes jams. At the same time, a characteristic cracking sound is heard, the mechanism stops, and the display shows an error. Failed components must be replaced.

Print head failure

Perhaps the most common problem is when the printer stops printing due to a dry head. If the cartridge and head form one unit, the problem is solved by replacing the entire container.

Advice! Separately, the head can be cleaned with flushing liquid, and clogged nozzles can be cleaned using the programs of the printer itself. The operation must be repeated several times until the required quality is obtained.

The device does not print

In this situation, you need to check the reliability of the connection of the device to the outlet, as well as the wire connecting it to the computer. If there are no connection problems, there may be a breakdown in the high-voltage power supply. Also, the printer will not respond to commands if there are no drivers. They are installed from the disk included with the device.

The PC does not see the device

In some cases, after connecting the printer, the message “Unknown device” is displayed on the computer. One of the reasons for this may be a poor connection of the device to the electrical network, and if everything is in order with the electricity, you need to install drivers .

Other faults

When the cartridge runs out of ink, the print results in light colors. The problem is solved by installing a new cartridge. The instruction manual provides detailed guidance for this process.

If the print head nozzles are clogged, light streaks may appear on the document. To eliminate the problem, the head is removed and immersed in an alcohol solution for several hours.

On a note! Inkjet printers often “chew” sheets due to dirt getting on the pressure rollers. They are cleaned with a soft cloth soaked in an alcohol solution.

Why can't faulty equipment be thrown into a landfill?

Almost every electronic device that is not properly disposed of poses a threat to both the environment and human health. This happens due to the presence of hazardous substances and materials used in the construction of the equipment. For example, cartridges for most office printing devices, such as printers, copiers or MFPs, contain aluminum and iron oxides. Therefore, writing off these consumables must be taken with the utmost seriousness.

Laser printer toner contains a dangerous substance - cyanide. Inhalation of its particles can lead to various respiratory diseases, allergies, and in some cases, death. The filling of the devices contains dangerous compounds and metals, which, when exposed to the environment, release toxic substances hazardous to health.

The housings are made of plastic containing polystyrene. When exposed to temperatures, it releases styrene, which negatively affects the circulatory and nervous systems.

Write-off

If the useful life of an MFP or printer (see the link for exact data for various types of equipment) has expired and there is nothing more to help it, then such equipment should be written off.

General information about write-offs

If your printer is scrapped, you can't just throw it in the trash. This procedure is performed according to certain rules. In addition, for such an action, a fine is established at the legislative level - 5 thousand rubles for an individual, and 200 thousand rubles for organizations.

Stages of the procedure

The write-off of office equipment is carried out as follows:

- A separate commission is formed, which must draw up a document explaining the reasons for the write-off. They must be accompanied by additional documents, such as a technical passport, data from the registry, and accident reports.

- The device is being dismantled to remove parts containing precious metals.

- Next, a decommissioning act for the device is drawn up. All accompanying documents are attached to it, including evidence of its dismantling.

Faults for write-off

Several examples of the most common breakdowns that lead to the write-off of office equipment.

Inkjet models

The equipment can be written off:

- after incorrect operation of the paper path, which most often occurs due to wear of parts;

- breakdown of the print head cleaning unit;

- those breakdowns that were caused by contamination of any parts, which is why they were in a neglected state.

Laser devices

The most common reasons for write-offs:

- laser unit malfunction or cartridge wear;

- problems with the paper path;

- breakdown of the image transfer or fixing unit;

- board burning;

- parts are clogged with paper dust and paint.

Why you need to recycle: the harm of office equipment

Office equipment cannot simply be thrown away, as it contains elements that can harm the environment.

- Iron and aluminum oxides are contained in the cartridges, so they also need to be scrapped and disposed of in a certain way.

- Residues of printer ink (toner), which is used in laser printers, contain cyanide particles, which have a detrimental effect on human health.

- Electronic spare parts for devices also contain certain metal compounds, which, if exposed to air for a long time, will oxidize and produce hazardous substances.

- The printer bodies themselves are made of plastic, which, when heated by sunlight, releases compounds harmful to humans.

Write-off process

The process of writing off office equipment itself takes place in several stages. It begins with the creation of a commission, which draws up a report on why the device failed, for example, why the printer does not print after refilling the cartridge, if the problem is in the main board and repair is impractical. Subsequently, this act will need to be supplemented with a set of documents, such as a device passport, copies or originals of service certificates, etc.

Next, the decommissioned device is disassembled to extract precious metals from its components. You can handle this process either independently or entrust it to specialists.

The parts of the device that remain after the first stage of dismantling are sent to specialized organizations involved in recycling equipment. At the final stage, a write-off act is drawn up, to which relevant documents must be attached confirming the extraction of precious metals from the device, their registration with the state and the disposal of the remaining parts that can cause damage to the environment and human health.

At the end of the entire procedure, the commission is obliged to draw up a report on the initial diagnosis of the device and recognizing it as inoperable by the service center specialists.

How to make sure that a write-off is necessary?

During operation of any device, malfunctions, breakdowns and failure of individual parts may occur. Most often this happens due to inattentive use of the device, infrequent or poor-quality maintenance, or incorrect selection of consumables.

There may also be simple inattention. For example, if the printer does not scan a document, it is worth checking what mode is set on it. To begin with, you should contact a service center, where the technicians will be able to diagnose the problem, repair the device, if possible, or draw up a report of inoperability and the need for write-off.

Major printer failures

Despite the advent of laser technology, matrix and inkjet lasers have not gone out of use; they are still used today. They are easy to use and inexpensive to maintain. But laser printers have already proven their reliability and are used everywhere.

- Breakdowns of dot matrix printers

- The printer does not turn on

- The device turns on, but does not print

- The machine pulls a lot of paper

- A grinding noise is heard when the device is initializing

- The machine does not pull paper

- The machine crumples paper

- Software errors

- The print head moves to the side

- Light print

- Prints strange characters

- Fuzzy printing

- Streaks appear when printing

- Inkjet printer problems

- The device does not turn on

- The device crumples paper

- The ink carriage does not move

- Light print

- Text doubles

- Streaks on the print

- Typical laser printer failures

- The unit does not turn on

- The machine does not print

- The paper is wrinkled

- The image is not pinned

- Vertical black stripe

- Vertical white stripe

- Dark prints

- Grinding and squeaking noises during unit operation

- Paper stop

- Gray blurry stripe

- The paper does not tighten

- Faded prints

Breakdowns of dot matrix printers

Major breakdowns:

- The print head broke due to wear of the moving parts;

- The head cable was deformed due to its long service life;

- Sheets get stuck and deformed due to foreign objects or low-quality paper.

Some problems can be fixed at home with your own hands, others only in a workshop.

Inspect the cable and replace if necessary. Check the network voltage with a multimeter, connect to another outlet.

If the printer still does not turn on, inspect the cord connector, which is located under the top cover. The fuses may have blown.

Printer won't turn on? Check the switch. If you have the skills, change it or remove it from the circuit and connect the cord directly.

Start by checking your settings. Go to the “Printers and Faxes” menu and remove the printing ban. If there are tasks that have not yet been completed, delete them all.

Major breakdowns associated with mechanical damage:

If you have already opened the printer, inspect all components and microcircuits. Check the drivers, they may have failed or a complete reinstallation of the printer on the PC is required.

This type of printer malfunction in 99% of cases is due to a software glitch. Often the problem occurs when using roll paper, which is also typical for faxing.

IMPORTANT! Check the drivers on your PC, the program through which printing is carried out, and reinstall everything if necessary.

Wrong paper size is another common reason, so check this setting too and change it to the correct one.

The main breakdowns associated with grinding occur for the following reasons:

- Stepper motor is broken;

- The gears are worn out;

- The guide bar is deformed.

You can get rid of problems only by replacing worn parts.

Printer faults for disposal are often related to the fact that the machine does not feed the paper.

There are two main problems:

- Engine failure.

- Failure of the broaching mechanism.

During the broaching process, the sheets become wrinkled - this is due to a damaged broaching mechanism. Check the rubber rollers on the mechanism, they may be dirty.

The second common reason is poor paper quality and incorrectly selected density.

Errors in the software are not a reason to write off the printer, as they can be easily fixed. They appear during a forced interruption of the printing process. To fix the problem, you just need to reinstall the drivers.

The problem occurs due to a power failure; a simple reboot will help.

The printer is rarely written off for this reason, but it is very sad when, after changing the cartridge, the characters become paler and paler. After installing a new cartridge, history repeats itself.

This is due to improper installation of the ink ribbon, which wears out prematurely. The scroll mechanism can also cause light print.

The problem occurs due to a faulty controller. How to fix it? Turn off the printer power immediately.

Obvious character defects that are noticeable when comparing letters appear due to wear on the print head or needles.

Major breakdowns associated with wear of horizontal and/or vertical needles. Less often, the provoking factor is the electromagnet that controls them.

Inkjet printer problems

These devices are very popular due to their high print quality at a relatively low cost. However, they often break down, and it is quite difficult to eliminate the causes, so the printer is written off. But there are still some problems that can be easily fixed at home.

First of all, you need to check the quality of the port connection to the PC and to the electrical outlet. If no problems are found, then you should check the power supply (it may also be located inside the device). On such devices there is always a power indicator.

A multimeter will allow you to check all circuits, fuses and find the real reason.

If the paper tears or becomes deformed after entering the printer, then the printer failure is associated with a failure of the gear on the shaft that feeds it. Another reason is carriage jamming. This becomes clear while it is moving, an uncharacteristic sound appears, and when it stops, a crackling sound appears.

If the printer breaks down and the carriage stops working normally, check to see if there is a small piece of paper stuck in the mechanism. Inspect the shaft itself for rust.

ATTENTION! When the printer cover is open, the carriage will not move.

The sensor responsible for the open and closed position of the lid sometimes breaks. Check the voltage in the network; perhaps there is not enough voltage in one of the sockets for normal operation of the carriage.

Printer failures in terms of poor printing occur for the following reasons:

- Poor quality cartridge;

- Drying of the print head;

- Failure of the pump responsible for cleaning the head;

- The paint is running out.

Less common are problems with the control board or electrical part.

Major breakdowns leading to double images on paper can occur for the following reasons:

- The ink trail is not laid correctly;

- Incorrectly selected cable;

- The encoder strip is dirty.

Check to see if there is a foreign object inside the device.

A common reason is that the ink in the cartridges is running out. If air gets into the print head or the nozzles are clogged, this can also cause streaking on the paper. Less often than not, users encounter failures in the electrical or mechanical parts of the device.

Typical laser printer failures

These are the most complex devices. It is difficult to write off a laser printer, since it has a long service life and almost all breakdowns can be repaired at low cost.

The power supply or control unit may cause the equipment to become inoperative. Be sure to check the electrical voltage.

Often, no matter how funny it may sound, people forget to turn on the printer or accidentally press it down or break the power cable.

Other reasons include:

- Incorrect installation of drivers and software;

- Wrong choice of printing machine;

- Windows hangs;

- Paper jam;

- Foreign objects inside.

Mechanical failures are less common, but the board responsible for transferring the image to paper may also break.

This happens due to document residues, foreign objects, or the paper feed unit is worn out.

If prints on paper smudge easily, then the fuser or its guides are worn out.

This sign indicates wear on the photodrum. After replacing it, you can continue to use the cartridge.

If a foreign object or piece of paper gets under the dispenser blade, it is possible that a streak will appear on the sheet. But most often, a white stripe indicates that the toner is running low.

Cartridge defects such as wear of the squeegee and drum cause dark spots to appear on the sheet.

There are several provoking factors:

- rotating parts are dry and require lubrication;

- dirty rollers responsible for feeding sheets.

Due to clogging of the sensor responsible for paper output, sheets will remain inside the equipment.

If the magnetic roller is faulty or the cleaning agent is worn out, causing the toner to spill and a gray stripe to appear.

The problem appears due to wear of the clutch or sheet feed roller. If the paper tray is broken, it will also not tighten properly.

There are many laser cartridges on sale, as well as powders. Savings in this matter are unacceptable.

Other reasons:

- end of life of the photodrum;

- toner runs out;

- the dispenser blade is broken;

- high indoor humidity.

IMPORTANT! Check your print settings, there may be an economy print mode set there.

For all types of printing devices, there are three main causes of failure: contamination of components, spillage of ink, and malfunction of the scanner in the MFP.

Source: https://tehnofaq.ru/osnovnye-polomki-printerov/

Defects of inkjet MFPs

What is the reason for decommissioning the printer? Most often, devices of this type are written off for several reasons:

- There is a problem with the paper feeder. They can be caused by unsuitable or low-quality paper, or contamination in the path. The malfunction may also be caused by wear and tear of parts if the device was used regularly and in large quantities.

- Printer head failure. The reason for the write-off is low-quality toner. Also, the cartridge was cleaned or refilled incorrectly.

- Errors in automatic head cleaning are another reason for printer write-off. Too frequent cleaning, changing cartridges and printing documents in large quantities often provoke the appearance of an accumulation of dried ink on the print head, which leads to this malfunction.

Summarizing, we can conclude that the most common reasons for printing equipment failure are associated with severe contamination of components and insufficient or incompetent maintenance.

Printer faults for write-off

Malfunctions that lead to the printer being written off

There are several types of printing devices: matrix, laser and inkjet. Each of them has its own malfunctions, which lead to complete failure of the product and its further write-off.

The main malfunctions of a matrix type printing device include:

- Difficult process of passing paper sheets. Such a malfunction is caused by: the use of paper that is not intended for this particular model of printing device, failure of mechanical parts, and the ingress of foreign objects.

- Failure of the head responsible for printing. The most common cause of this malfunction is a breakdown of the mechanical elements that drive the head. Such damage occurs when the device is used for a long time.

- There is a problem with the integrity or flexibility of the print head cable. Long-term mechanical impact leads to the occurrence of these types of malfunctions.

- Failure of the unit responsible for cleaning the print head. With active use of the printer, frequent replacement of cartridges, as well as intensive cleaning of the heads, the coloring pigment begins to accumulate on the head of the device, which causes its breakdown.

- Cartridge wear. Their failure is often caused by the fact that the printing ink used is not suitable for the given product model. Possible reasons may also be: a long break in operation or an incorrect procedure for cleaning cartridges.

Inkjet printer malfunctions leading to write-off:

- Cartridge failure. The reasons may be: the use of unsuitable or low-quality ink pigment, a long break in operation, incorrect operation of the carriage, or incorrect cleaning or refilling of the print head.

- There is a problem with the paper path. The reasons are the same as in the case of the matrix option.

- The print head cleaning unit is broken. The problem occurs for the same reasons as when using a dot matrix printer.

The laser printer must be written off for the following types of failures:

- Failure of the node responsible for securing text or images. The reasons may be: damage or rupture of thermal paper, malfunction of the heating mechanism or control unit.

- Problems with the node that is responsible for transferring text to paper. Mechanical damage to the print or laser head leads to failure.

REFERENCE! All models have common faults that appear as a result of severe contamination with coloring pigment and dust. To avoid their occurrence, periodic cleaning of mechanical parts is required.

Why you shouldn't throw faulty equipment into a landfill

All electrical products that are damaged must be properly disposed of. If this is not done, then significant damage will be caused to the environment, as well as human health. This is due to the following reasons:

- The cartridges used for printing contain aluminum and iron oxide. These substances have a negative impact on the environment.

- The coloring pigment contains cyanide in small quantities. This chemical, when exposed to the human body, leads to various diseases of the upper respiratory tract.

- All electronic elements of the device contain various chemical compounds and metal alloys. Over time, they begin to release toxic substances.

- The printer body is made with the addition of polystyrene. When heated, it begins to release an extremely dangerous substance - styrene. Styrene has a negative effect on the circulatory and central nervous system of a living organism.

How to write off a printer: description of the process

Despite the fact that there may be several reasons for writing off a faulty printing device, the write-off procedure itself will be the same in any case. It is performed as follows:

Even if you use the printer correctly, take care of it and carry out the necessary repairs on time, office equipment will someday fail because it has its own service life. The subsequent write-off and disposal procedure must be approached extremely responsibly. To do everything right, it is advisable to contact specialized companies. They guarantee high-quality work and also provide all the necessary documents.

Source: https://setafi.com/elektronika/printer/neispravnosti-printera-dlya-spisaniya/

Critical problems with laser printers

Printers in this category are subject to write-off due to:

- There is a problem with the component that transfers the image to the paper. The cause may be a malfunctioning laser unit or a worn-out cartridge, in which the photodrum is the first to fail.

- Problems with paper passing through the cycle.

- A malfunction of the component responsible for fixing the image, which occurs due to a malfunction of the heater or thermal film.

- Burnt out board. This can happen due to a short circuit. This can be understood by the fact that in addition to the impossibility of printing, the printer does not scan documents or makes low-quality copies of these documents.

Generally speaking, all laser printers fail due to contamination of internal components. To avoid this, it is worth cleaning the device regularly.

Typical malfunctions of laser models

Among the many types of printers, laser models, such as HPLaserjet 1100, 1020 and others, often have the same faults . Some of them can be fixed on your own, while some can only be repaired by a service department.

Damage to the photo cylinder

If, when printing text, a thin solid line appears along the sheet, which sometimes may appear intermittent, then this malfunction is associated with a scratched photo cylinder. This problem is typical, for example, for the Brother hi - 2300dr model.

When black dots appear on the sheet with a pitch of 76-94 mm, this is also due to a malfunction of the photodrum. This symptom is often found on Samsung scx-4200 models.

Sometimes printer users see large gray spots on the printed sheet. This failure is associated with damage to the surface of the photocylinder.

Drum coating wear.

If a gray background appears on the sheet, it means that the electrical contact has disappeared, as a result of which the cylinder has stopped functioning.

Important! With all of the above symptoms caused by a photodrum failure, the help of specialists is needed to replace the part, since this unit cannot be repaired.

Squeegee malfunctions

The photo cylinder in all laser MFPs and printers is always in contact with the toner. A squeegee is used to remove powder residue from the surface of the assembly. Its failure often appears as an uneven gray line along the page. The malfunction of this element may be due to several factors:

- wear;

- severe clogging;

- bad paper;

- garbage.

Repairing a squeegee involves physically cleaning it from toner residues. If this does not lead to a positive result, the part must be replaced.

On a note! On Samsung ML-1210 printers and other models in this series, local spots sometimes appear during printing. The reason for this is an overfilled bunker. Repair work consists of cleaning the container from waste toner.

Precharge roller failure

If, when printing, the text doubles, the full image is not printed, a gray background appears, large spots appear, it means the pre-charge roller is broken . The cause of the breakdown may be:

- coating wear;

- pollution;

- poor quality cleaning.

The way out of the situation is to clean the damaged surface again. And if there is a lot of wear, a new roller is installed.

Problems with the operation of the magnetic shaft

The task of the magnetic roller is to attract charged toner for its further distribution throughout the photodrum. The main reasons for element malfunction are considered to be the following:

- the sound-conducting coating is completely worn out - the problem is solved by replacing the shaft;

- Foreign objects have fallen onto the surface of the roller - it is impossible to repair the part, and replacement is also necessary.

On color laser printers, incomplete printing (with gaps) is sometimes encountered. The cause of the breakdown may be: weak electrical contact, excessive wear, broken ring or failure of the contact spring. The malfunction can be easily eliminated by reassembling the magnetic shaft. However, if there is significant wear, the slip ring will have to be replaced.

On a note! The appearance of stripes crossing the sheet (typical of the Canon lbp 2900) indicates a curvature of the shaft. In this situation, installation of a new part is required.

Damage to the printer

Quite often, Samsung ML-1210 and other laser devices experience such characteristic malfunctions.

- Paper does not get caught or gets jammed. To fix the problem, you need to clean the paper pickup mechanism with a special liquid.

- The leaf is chewed at the exit. This means that the output roller is dirty. This requires prevention.

- The paper is jammed in the middle. In this case, the sheet exit sensor does not work. To fix the problem, it is necessary to replace the sensor, which is located under the curtain.

- A paper jam occurs after turning on the printer. The reason is that the sheet registration sensor has failed. This means that you need to check the operation of the sensor (in case of a malfunction, replace it), and also carry out preventative maintenance on the curtain.

Of course, there is much more damage in laser printing devices. The breakdowns that users encounter most often were described above.

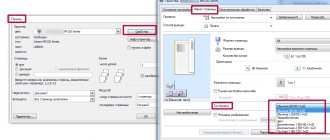

The computer does not see the device

To debug the collaboration between your computer and the printer, you need to follow several steps.

- Check the printer connection. To do this, you need to disconnect the cable from the computer and printer, and then plug it back in. The printer is connected via USB0.

- Check if the necessary drivers are present on your computer. Owners of rare printer models, for example, Kyocera fs-1040 gx, often face a lack of necessary software. Typically, the software is installed from the disk included with the device. But in order to download the most current drivers, or in the absence of an installation CD, you can download updates from the official resource of the equipment manufacturer.

- Find out if automatic printing is enabled. To do this, you need to go to the “Administration” section of the system. In Services, open Print Manager. Set the startup type to “Automatic” and the state to “running”.

Sometimes the computer does not see the printer due to the operating system, to check this, the device needs to be connected to another PC, and if everything works, it means that the OS needs to be debugged.

Other faults

Sometimes when printing text on a laser printer (for example, on an HP M1132 mfp), a black line appears along the sheet. This malfunction is associated with damage to the thermal film. After replacing the element, printing becomes normal.

In some cases, the image is not completely printed. This indicates that the thermistor of the heating mechanism has failed. The solution to the problem is to replace the thermal unit.

Another symptom is that in some places the print looks very pale. This means you need to clear the transfer roller. And if there is a lot of wear, a new part is installed.

If you hear a characteristic loud knock during operation, and paper jamming occurs at the output, then the problem is in the fastening unit. It needs to be completely replaced.

When a vertical white stripe appears on the printed sheet (typical for Xerox phazer 3117,3010), it means that the main mirror installed in the laser scanning mechanism has become dirty. To eliminate the problem, the block must be purged and cleaned with a special compound.