A meat grinder is considered one of the most popular kitchen appliances; all modern food processors and blenders have not been able to supplant it from the kitchen. With the help of a meat grinder you can make not only minced meat and pates, it is used for making homemade sausages and sausages, squeezing juice, preparing vegetable puree, original cookies and pasta. All this will be available to any housewife, but to do this you need to know how to properly assemble a meat grinder so as not to call your husband into the kitchen when you urgently need to grind meat or squeeze out juice.

Mechanical meat grinder

Electric meat grinder

Design of a conventional meat grinder

Before assembling a meat grinder, you need to study its design. Since the times of the USSR, we were well aware of the old, but very reliable Soviet design - a manual version that still helps users in the kitchen today. Then its analogues began to appear, but only with an electric drive, but the main details remained the same.

- The one-piece body was made of cast iron, then they switched to various alloys based on light and durable aluminum. In the upper part of it there is the neck of the meat receiver, where processed products are placed.

- An auger is a specially shaped shaft that, when rotated, propels products toward the exit of the product.

- At its end, a knife is put on, which performs the grinding - it can be disk or with wings.

- The grid regulates the degree of grinding of products; instead, shaped devices are inserted into the meat grinder when working with dough.

- A round-shaped clamping device is used to securely fix all elements in the housing. There are special protrusions on it for easy fastening.

- A handle is attached to the rear of the shaft with a special wing screw to rotate the entire mechanism.

Important! The manual version of the product is installed on the edge of the table and secured using a special threaded device. Material must be placed under the metal base to prevent the product from moving on the table.

Equipment and consumables for making homemade sausage

Of course, the most important thing for a good sausage is quality meat. But in order to turn it into a flavorful sausage product, you will need special equipment and some consumables.

Let's start with the equipment.

Meat grinder

Sausage requires minced meat of a uniform and even texture, which a regular household meat grinder cannot produce in one go. You will have to twist the minced meat for the sausage filling three or four times, and then grind the mass with a blender. But even in this case, it may not be homogeneous enough, which will lead to excessive broth edema - the accumulation of liquid under the sausage casing.

If you want to make sausages regularly, it makes sense to buy a powerful, professional-grade meat grinder. The machines operate at high speeds and quickly grind the minced meat into a homogeneous mass. The cutter, a specialized equipment for chopping meat and other products, has proven itself to be excellent. It is useful not only for sausages, but also for pates, emulsions, and creams. It's not cheap, but it's worth the money.

The cutter makes the sausage mince uniform and smooth

Syringe

A sausage stuffer is needed to fill sausage casings with minced meat. The principle of its operation is simple.

- The metal cylinder is filled with prepared minced meat and placed in the housing.

- The sausage casing is placed on the tip.

- The syringe plunger is driven manually or using a motor.

- The piston pushes the minced meat through the tip of the syringe into the prepared casing.

Sausage stuffers can be horizontal or vertical. I prefer the vertical design as it works very smoothly and the sausage casing is tightly filled with minced meat, without any voids.

Syringes vary in barrel volume. It is measured in kilograms of minced meat that is placed inside. For home use, they take syringes with a volume of 1.5 kg, for small-scale production they use devices with a capacity of 5–10 kg, and if you are thinking about a small meat shop, then you can take a closer look at syringes that hold 12–15 kg of minced meat.

According to the control method, syringes can be electric, pneumatic, or manual. For home crafting, a manual sausage stuffer is sufficient.

Sausage stuffer ensures even and fast stuffing

The sausage casing can be filled with minced meat using a special tip that is placed on the meat grinder. The minced meat just needs to be turned through the meat grinder again, and it will end up in the casing. But I recommend using a sausage stuffer. It provides a much denser and more uniform packing.

Cords

Twine, cord, culinary thread - all this is necessary to secure the ends of the sausage casing. They are made from linen or cotton. In production, metal clips are used to tie sausages, but their installation requires special equipment - a clipper. It is not needed for home production. A good cord or twine is quite enough.

Twine is needed for tying sausages

Spices and additives

Good spices are required to prepare good minced sausage; they add sharpness, piquancy, and brightness to the taste of the future sausage. You can create an aromatic composition yourself, or you can buy ready-made spice mixes. If you want to achieve a real “factory” texture, taste and aroma, then you cannot do without specially selected flavoring additives. You can buy, for example, a ready-made kit for preparing hunting sausages or milk sausages.

Spices give the sausage a rich taste

How to choose equipment to suit your needs

There is a minimum set of equipment that you cannot do without.

- Meat grinder.

- Sausage stuffer.

- Nozzles for minced meat through which casings are stuffed.

- Control and measuring group: scales, thermometer.

The hardware options will depend on how serious you are. For your first experiments, a regular manual meat grinder with attachments may be enough for you. Well, with practice, an understanding will come in which direction your technological progress should move.

As I already said, it’s difficult to get good minced meat without a powerful meat grinder, and if you want to make truly high-quality sausage - smooth, dense, with good texture - then a syringe is a must.

Using a sausage stuffer ensures fast, dense and even stuffing of sausages.

Sausage casing – natural and synthetic

To make homemade sausage or frankfurters, you need a casing, which you will fill with minced meat using a sausage syringe. Sausage casings can be natural or artificial.

- Natural shells have high elasticity, permeability, and natural origin. They are suitable for the production of products of various densities, as they stretch well. They are produced in different diameters and lengths. About 550–570 g of minced meat can be placed in 1 meter of shell with a diameter of 34–36 mm. All of them are pre-processed and are a biologically safe product. Natural shells can be eaten. This type of casing requires preparation before use.

- Artificial shells have a uniform structure, are easy to fill and are durable. They are made from various raw materials: collagen, polyamide, fibrous paper. They cannot be eaten. Artificial shells can be of large diameter and capacity. About 2.4 kg of minced meat is placed in 1 m of collagen shell with a diameter of 45 mm.

For homemade sausages, you can purchase the type that seems most convenient for you to use. Authentic sausage, of course, must be made in a natural casing that is edible and harmless. Artificial casings work well for cooked sausages and allow for a wide variety of recipes.

Sausage in natural and collagen casing

Step-by-step assembly algorithm

How to assemble a mechanical meat grinder? To do everything correctly, you need to follow the operating instructions that come with each product. If it is missing, then we will tell you a step-by-step assembly method.

- The main shaft or auger must be inserted into the housing, with the handle attachment point coming out from the opposite side, and the remaining parts are installed at the thinner end.

- Installing the knife is the most important task; one side of it is flat and polished to a shine, so this part must face the grate in order to slide along it while working. Many users are confused about which side the cutting tool should be placed on - as a result, the device is assembled incorrectly.

- When installing the disk version, the cutting edge also always faces the grille. It is this moment that is of great importance - it all depends on how to install the knife correctly so that the meat grinder chops the food and does not crush it.

- Now it’s time to install the grille correctly - it has a special groove that must be inserted into the protrusion on the main body. The grid should fit snugly against the cutting tool.

- The final step is to tighten the clamping device, which securely fixes all the parts inside the case.

- Now you can install and secure the handle to rotate the mechanism. The meat grinder is assembled - you can attach it to the edge of the table and prepare minced meat.

We described in detail how to correctly assemble a manual meat grinder yourself; the main task is to correctly install the knife and grid, otherwise the product will not work. How to properly position the product for work is shown in the photo below.

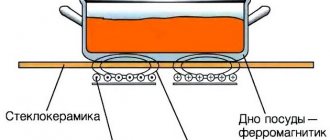

Electric meat grinder design

The body of electric meat grinders is most often made of plastic, in contrast to manual devices, which consist entirely of metal parts. In electrical appliances, only those parts that directly grind products (knives, grates) are made of metal, as well as other loaded elements that work to transmit force (auger, fixing and connecting elements). The main working part of the meat grinder is the engine built into the main body. When turned on, it rotates the auger, pushes the food towards the knives, and rotates the knife. In general, it does all the work.

The electric meat grinder does not have a handle through which the user drives the auger; it is not necessary. But the devices often have a removable tray for serving food, which can be removed when not in use to save space.

The electric meat grinder always comes with a food pusher. You should definitely use it to move the meat towards the auger, this will avoid injury. The auger itself ends in a plastic fastening element, thanks to which the rotating element is fixed inside the housing. In new models of electric meat grinders, the knife has a complex relief, thanks to which the minced meat is of higher quality.

Read more about the design of a meat grinder in this article.

Operating principle of a manual meat grinder

One of the main elements and functional parts of the meat grinder is the screw shaft; it moves pieces of meat to special knives, which are fixed at the end of the shaft on special attachments. Thus, slowly but surely the raw material reaches the grinding and forming mesh. It comes in different shapes and hole sizes so that you can choose the desired consistency of the future minced meat.

All elements of a manual meat grinder are standard; they may differ only in the set of additional accessories

For information! Unlike appliances with an electric motor, manual meat grinders make virtually no noise. Another benefit could be energy savings. After all, any electric meat grinder is equipped with a fairly powerful motor, so the energy consumption will not be small.

When purchasing a manual meat grinder, pay attention to the quality of the material from which the body and main parts are made.

Even in a plastic meat grinder, the knives and grids must be metal. Otherwise, such a meat grinder can simply be handed over to a toy store. Unlike older models, some modern variations are equipped with siphons for squeezing juices or are used instead of a grater. Most of these devices, of course, are produced for electric drive, but you can also find manual and mechanical models.

Important! When working with a meat grinder, carefully select the meat - do not allow bones to get into the minced meat. Firstly, it will harm your health and may have a detrimental effect on those who try such a dish. And secondly, by using unselected pieces of meat, you risk dulling the knives ahead of time, damaging the auger shaft and the housing itself.

How to properly assemble an electric meat grinder

Assembling an electric meat grinder is no more difficult than a manual one. Detailed instructions, often illustrated, are in the user manual for each specific device. In general, the order of assembling the device is as follows.

- First you need to insert the auger into the slot on the motor housing. Then fix it by turning it counterclockwise so that the part snaps into place. This guarantees proper operation of the mechanism and transmission of force.

- It is advisable to check whether the mounting hole coincides with the auger and whether it is well secured. Otherwise, the meat grinder will not work, at least the auger will rotate in the socket.

- A knife is put on the free end of the screw part, and a grille is screwed on top of it. It is important to ensure that the parts are marked and fit correctly on the holes and threads. This will allow you to assemble the knife blade and the grate with the correct side.

- The entire structure is fixed with a clamping nut. It needs to be secured well.

- Next, you need to mount the food supply tray on the device body. That's it, the meat grinder is ready to work.

Installing additional equipment on a meat grinder

Many appliances also come with attachments for preparing sausages, cookies, or grills of various sizes. They can also be purchased separately. Depending on what accessory is used, the assembly sequence of the meat grinder may differ from the standard one. This information is in the user manual for each specific device.

The attachment for forming sausages and shaped attachments for cookies are attached to the end of the auger instead of a knife and grid, and is also secured with a clamping nut.

Kebbe attachment for forming sausages from minced meat

Some models have juice making equipment. It usually comes assembled and is simply installed on the meat grinder body.

Nuances of assembling an electric meat grinder

Analyzing the assembly process of an electric meat grinder, it should be noted that there is no clamp on the body, which is equipped with a motor. The kit includes a funnel with a safety pusher that guides the meat into the receiving hole. The screw is fixed directly in the housing with a special nut.

The assembly of a complicated electrical model can be performed according to the following algorithm:

- an auger is placed in the housing;

- a ring with three or four slots is put on the auger;

- a double-sided knife is placed;

- a grille with medium-diameter holes is attached from the kit;

- a second knife is installed;

- then comes the grid, in which there are the smallest holes;

- the clamping ring is fixed.

The accepted orientation of the knives is maintained - their flat side is directed towards the grate.