How do twin needles work?

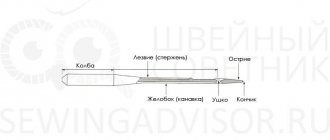

Structurally, a double needle consists of the following elements:

- Two standard sewing needles designed for stitching on a household machine.

- Holder housing. Most often it is made of plastic. This element holds the double needles together into a single structure.

- Flask. Designed for installing double needles into the needle holder of a sewing machine.

The double needle can be used in any sewing machine with a zigzag function. In their foot and needle plate there is an oblong slot necessary for the free movement of two needles.

How to install double needle?

Be sure to read the instructions for your machine to take into account all the installation details.

The double needle is installed in the sewing machine in the same way as a regular needle (with a flat cut back). Depending on the design of the machine, the second reel seat is installed or raised. Each needle is threaded separately, passing them along the same path. If the machine has only one thread guide, the second thread is not threaded through it, but is left free.

For double stitching, use a universal zigzag foot; open feet are also suitable for satin stitches or appliqués.

In some modern machines, it is necessary to set the appropriate mode before operation. The stitch switch on mechanical machines must be on a straight stitch.

When installing a double needle, do not use a needle threader! The filling process takes place only manually.

Types of double needles

There are several types of needles:

- Universal. Used to work with natural and artificial threads. They are suitable for most types of fabrics. Often, universal double needles of this type are called embroidery needles, since they give a beautiful and even zigzag stitch.

- For knitted fabrics. These needles are marked Stretch. They can also be used for working with elastic and stretchy fabrics.

- Metallic. These twin needles are used for stitching with metallic threads.

- Jeans These needles are used for stitching denim fabrics. As a rule, these are thick needles that are intended for working with high-density fabrics.

Double needle stitching of different widths is possible. The thinnest needles have a thickness of 1.6 mm. The maximum value is 4 mm.

The largest number of sizes are represented by universal double needles. The thinnest are considered to be products for stitching on elastic fabrics (number 75). Denim options include sizes from 100 and more.

The double needle is marked with two numbers. It is deciphered as follows:

- The first number indicates the distance between the needles.

- The second talks about the size of the needles (they must be of the same section).

Inserting the needle into the sewing machine

To install a twin needle in a sewing machine, you must follow these steps:

- Using the flywheel, set the needle holder to its highest position.

- Lower the machine foot.

- Loosen the fixing screw. In this case, you need to hold the installed needle. Now carefully loosen the fixing screw. Next, remove the needle from the holder.

- We install the double needle in the holder so that the flat part of the flask faces backwards. We deepen the needle until the edge of the flask touches the stop.

- While holding the twin needle in position, tighten the fixing screw. All that remains is to thread the thread, and you can give a test stitch.

We have prepared for you a detailed video course “Sewing Basics”

Get it now for free!

get a course

Threading the machine

To double stitch, you need to thread two threads into both needles. Accordingly, you will need a couple of coils. To obtain a neat seam, it is necessary to thread threads of identical thickness and quality into a double needle. You can choose any color, it all depends on your design ideas (this will not affect the quality of the stitching).

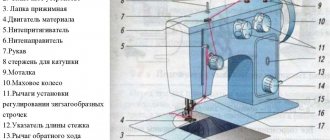

Threads into a double needle are threaded according to standard rules. The specifics of the procedure depend on the design of the specific machine. But all models are equipped with the following elements:

- thread tensioners;

- guides;

- thread guides, etc.

Therefore, to thread a double needle, you should use the instructions supplied with your specific sewing machine. Both threads are carried along the tensioners together, separating only at the very end, at the stage of threading through the eye of the needle. Threading the shuttle remains unchanged.

After completing the work, you will need to give a test line. It will help you make sure that everything was done correctly, and then you can sew with a double needle.

What should I do if my twin needle skips stitches when sewing?

It is not always possible to get a high-quality seam with a double needle the first time. If skipping stitches are noticed while sewing, do the following:

- We wind the upper threads onto spools of equal size. This approach will allow you to achieve uniform tension on each thread when sewing with double needles. The coils are arranged on one spool pin.

- Try increasing the upper thread tension. This should also be done if the stitches were uneven and the thread looped. Make sure both threads have the same tension and are threaded correctly into the needles. The bobbin thread tension should be standard.

- Check that the threads are threaded correctly when sewing with a twin needle.

How to thread a twin needle in a sewing machine

It is necessary to work only with original tools, as using a fake tool may cause the machine to break. Do not use deformed needles. They can break quickly and cause damage. These needles do not require a threader.

Step by step steps:

- Insert a double needle;

- Install the top thread for the left needle;

- Manually insert the top thread into the eye of the left needle;

- The thread must be threaded from the front;

- Insert the second spool pin onto the bobbin shaft;

- Place the spool and insert the top thread;

- Start sewing the product.

The threading process is the same as with other types of needles. If the seamstress is a beginner and does not really understand this process, you should first watch several master classes, read manuals, and then start using the machine.

You might be interested in this: Instructions for sewing sofa covers yourself

The nuances of working with a double needle

To obtain an even and high-quality seam, the correct selection is necessary:

- threads;

- fabrics;

- needle

We are talking about the thickness of the needle and thread, as well as the type of material. It is very important to correctly select these parameters relative to each other. To achieve a beautiful and even stitch, working with a double needle is carried out at a reduced speed of the sewing machine.

Double needles can be used to stitch, embroider, quilt, etc. Such stitches are often used as decorative finishing on the bottom and side cuts and seams of products. They are especially popular when working with denim. It turns out to be almost impossible to make such a seam with only one needle, since it is difficult to maintain not only the same distance between the lines, but also the symmetry of the stitches.

As a rule, such stitches are performed as follows: we place the first needle at a distance of 1 mm from the edge of the product. These seams are not only reliable, but also have high decorative properties. If desired, you can use threads of different colors when working with double needles.

How to sew with a twin needle

Once the needle is installed, work can begin. There are a number of rules for this.

Sewing thick fabric

Attention! The flywheel should only be turned towards you.

The thickness of the needles is selected according to the material. It is necessary to check the degree of tension of the upper thread, stitch width, and stitch shape. If you do not have experience in threading, it is advisable to refer to the user manual. During operation, the product should be on the left side. It is advisable to put cardboard under the foot, make a hole and put the foot, pull the thread down about 7 cm. After finishing sewing, you need to lift the needle and foot, remove the cardboard, pull out the thread and cut it.

Flywheel

After completing the sewing process, you need to place a piece of fabric under the foot and turn on the machine. These are the main requirements when working on every sewing machine, at home or in a factory. Using a double needle, you can make a variety of stitches and operations.

We also need to tell you in more detail how to sew with a double needle on a Janome sewing machine.

For a machine from such a company there are the following types of needles:

- General, suitable for all materials (synthetics);

- Only for dense fabrics (felt, jeans);

- For working with thin materials (linen, pastels, knitwear).

When deciding to purchase a double needle, it is advisable to adhere to some rules, for example, it is recommended to pay attention to the space between the needles and the size of the eye. Threading is the same as with regular yarn, only with two spools.

Double stitching from the wrong side

The advantages of using a double needle are obvious - decorating products is much faster, and you get a beautiful and neat seam.

Janome brand sewing machines are excellent for sewing with double needles; in some situations you can use triple needles, this greatly expands the possibilities of work. Any machine from this company is distinguished by a large number of operations, power, quick settings, easy assembly and a long service life. It is used not only at home, but also in various enterprises. The price of such a machine is relatively low, but it has many useful functions.

You might be interested in this Simple patterns for wrap dresses: sew them yourself

Decorative designs and finishing

Using a double needle, finishing seams and amazing stitches for decoration are often made.

Needle sizes

The product looks quite original if different shades of threads are used. These tools are also popular for embroidery and can be used to create different designs and designs.

Sewing on braid

Using a double needle you can easily sew on a ribbon. In this case, the product will look more elegant. You need to insert a thread and a needle into the machine, and then sew the braid in the required place on the fabric. It is advisable to sew using a double seam.

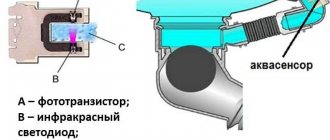

Ruffles with elastic

Using a double needle you can do other work. Assembling the product becomes more convenient if you use an elastic seam. The spool of the machine is wrapped with a medium-sized elastic band; it is advisable to take the yarn to match the product. After winding, you need to start sewing. It is recommended to make an indent of 2 mm while working. Due to the fact that the elastic band is located in the shuttle mechanism, the original assembly of the product comes out.

Sewing machine Janome

Raised tucks

All drawings are made using tucks. You need a professional presser to get them. Unlike the classic one, it has small indentations so that the fabric rises during operation.

In the process of working on a stitch, the pattern is influenced by the reliefs on the foot and their deepening. The more massive it is, the more relief there will be on the product. The tension level regulator is set to maximum. It must be remembered that fabric consumption will increase.

Reliefs with cord

To do this, you need a foot that is used for this type of tuck or decoration with beads. In the place where the cord will be located, you need to mark a line with soap. It must be sewn on the inside.

The process of working with an elastic band

Next, the product is placed carefully under the foot so that the cord is between the needles. When everything is ready, you can begin the sewing process. The result is original relief seams.

You may be interested in this Instructions and patterns for sewing leotards for rhythmic gymnastics

Decorative hem

Attention! A double needle can be used mainly on modern machines.

It is suitable for sewing thin fabrics. While working, you need to take a foot for a zigzag seam. The lines need to be sewn from the outside, but small indentations must be made.