What is an "inkwell?"

A cartridge without a printhead is essentially a plastic container containing ink .

It is equipped with a system of valves and transition chambers. Such cartridges are popularly called “ink tanks”.

They have a hole in the bottom, closed by a valve, through which ink flows into the head fitting.

There is a rubber sealing collar around the hole. When the ink tank is installed in the printer, the head fitting pushes back the valve and “drives” into the ink reservoir.

pressure equalization hole at the top of the cartridge As the ink is consumed, it is gradually replaced by air. The first cartridges had exactly this design. And this allowed cost-conscious printers to reuse them (and even repeatedly) by filling them with third-party ink.

How does a modern inkjet printer work?

Printers operate using microscopic drops of ink in multiple colors. The principle of operation of an inkjet printer is similar to matrix units, but here, instead of needles, nozzles are used, through which ink flows onto a sheet of paper in droplets. The size of each drop is several tenths of microns in diameter (which is significantly thinner than even an ordinary human hair). Only under a microscope can you see the many mini-dots that make up the image.

The droplets are applied to the paper by extrusion. And here, different manufacturers use different printing technologies.

- The thermal method was born in the 70s at Canon. Its essence lies in a microscopic element located in the nozzles - it can instantly heat up to enormous temperatures. This promotes the formation of gas bubbles that push the paint out. Today, Canon and HP brands use this method.

- The piezoelectric version is based on the fact that a piezoelectric crystal is located above the nozzle. When an electric current is applied to it, it begins to bend and pulls the diaphragm along with it. Increased pressure is created, which pushes the drop onto the material. This method formed the basis for the creation of Epson devices.

Each of these technologies has its own pros and cons.

- Thermotechnology involves high temperatures. This causes the formation of a carbon deposit and contributes to the failure of the print head.

- The piezoelectric element is the cheapest option and allows you to achieve high operating speeds.

All inkjet printing devices have their drawbacks. The most important of them are the slow process and the high cost of printing. Another point is to use photo paper with a special coating for printing photos. In addition, the cartridge is small in size, and therefore has a disadvantageous resource.

The last aspect indicates the significant high cost of servicing the device. Thus, with constant replacement of cartridges in inkjet machines, this will significantly affect the budget. However, a solution has been found – printing units with CISS.

The era of chips

Then Epson, in the fight against refillers, began to supply its cartridges with chips (miniature chips) that took into account ink consumption.

Now, even if users filled the cartridge with ink “to the very top,” the chip, with iron stubbornness, informed the printer that “the ink has run out.” And the printer required changing the cartridge.

Cunning users hacked the protocol for writing to the chip and learned to “persuad” it with the help of special devices - programmers . In response, the company first changed the recording protocol, and then built new chips with a larger number of contacts and a new protocol.

But this mystery was also solved; chips from third-party manufacturers appeared, which began to be used especially widely in CISS (continuous ink supply systems). In general, the well-known competition between “armor and projectile” continues. Note that the scope of application of chips has expanded greatly in recent years. They are also used in cartridges for laser printers .

Printhead cartridges

Printhead cartridges come in two varieties. One of them contains a print head (at the bottom) and an ink reservoir (or reservoirs, if the cartridge is color) in one housing.

The reservoir is usually filled with absorbent material (a type of foam) that is placed directly against the print unit.

In front of it there is a filter with very fine mesh that prevents ink clumps and particulates from entering. Otherwise, these particles and clots would get into the nozzles and clog them. And printing would become impossible.

Cartridges with a print head are designed for single use (as indicated by the inscription on the packaging - “for single use only”).

Thrifty users have learned to fill ink there, fortunately that the head life in them has some reserve. This cartridge has ventilation holes (under the sticker) to equalize pressure, through which it can be refilled.

Over time, foam rubber loses its properties and can hold less and less liquid. In this case, a problem arises due to the printer driver incorrectly displaying the ink level in the cartridge.

In most cases, HP cartridges with a print head do not have a chip that takes into account ink consumption. The consumption is calculated programmatically by the driver, which periodically reports it to the printer. If the cartridge is new, then the consumption is calculated correctly.

If it is refilled, the printer, identifying that the cartridge is the same, considers it empty. And a message periodically appears on the computer monitor screen demanding its replacement.

This is a known inconvenience, since it is not clear whether the printer is “streaking” because there is no ink in the cartridge, or because the nozzles are clogged?

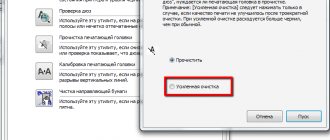

But we have learned to deal with this too - although not in all cases. To deceive the printer and think its cartridge is new, cover part of the contact pads of the cartridge with tape and insert it into the printer. After this, it is removed, the other pads are sealed and it is reinserted. After several such manipulations, the printer allows itself to be “persuaded.” Now you can work!

There are many types of cartridges, so it is not possible to give any universal recommendations on sealing contacts within the framework of this article. There is another way that sometimes works.

The printer only remembers data about the last few cartridges. By replacing several of them, you can fill this area of the printer’s memory, and the next (refilled) cartridge will be considered new.

But even after this, work is not always comfortable. Branded cartridges are refilled through the nozzle area (bottom) and in a vacuum . The user refills them from above (through the ventilation holes) and without any vacuum. Therefore, the ink fills the cavity unevenly , leaving air bubbles.

As a result, the cartridge has to be refilled more often than usual, adding 1-3 ml of ink. This applies more to color cartridges that have containers for 3 colors in one housing.

Ink cartridge. What is inside?

An inkjet cartridge is the main replaceable unit of an inkjet printer, filled with ink and equipped with special mechanisms and devices for transferring ink to paper.

In its most general form, an inkjet cartridge consists of an ink reservoir (ink section, ink tank), a cover, a print head and a plate with contacts for reading the ink counter and controlling the nozzles of the cartridge head.

In the picture, the ink reservoir is colored blue. In reality, it can be made of either colored or transparent plastic.

Cartridge cover

The cartridge cover is also made of plastic and is traditionally painted in the color of the ink with which it is refilled. On the cartridge cover you can see holes for refilling, prudently left by the manufacturer.

In addition to the refilling holes, the lid has holes for air to escape and maintain optimal pressure inside the cartridge.

Ink reservoirs

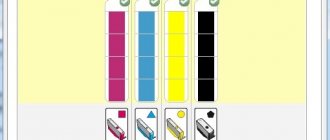

Inside the ink cartridge there are ink reservoirs: the black cartridge has only one reservoir, the color cartridge has three ink reservoirs for yellow, magenta and cyan. This device is typical for budget models of inkjet printers.

Single and three-section ink cartridges

More expensive inkjet printers designed for photo printing have from 4 to 8 ink cartridges of different colors.

An absorbent material is placed inside the ink cartridge reservoir to hold and distribute ink evenly. Most often, the microporous sponge shown in the figure acts as such a material.

Some HP ink cartridges have automatic valves and spring-loaded elastic air bags instead of an absorbent sponge.

When a print command is received, ink from the cartridge flows into the print head nozzles.

Printhead

The print head is the most important mechanism of an inkjet printer. The quality of the prints directly depends on it.

In some inkjet printer models, the print head is located not in the cartridge, but in the printer itself. A comparison of cartridges with and without a print head is presented below.

On the right side of the picture on the cartridge you can see three holes through which ink enters the print head located in the printer.

On the left side of the picture, the print head is not located in the printer, but on the ink tank. It is a narrow metal plate on the bottom of the cartridge, consisting of many microscopic holes. Under the holes there is a huge number of miniature cavities (nozzles, nozzles), into which ink comes from the cartridge reservoir. One of the latest print heads manufactured by Canon has 3072 nozzles (512 nozzles for each of 6 colors).

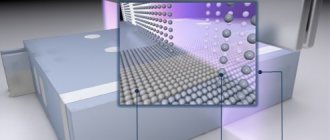

Magnified view of one nozzle of an inkjet cartridge print head

Print head nozzles The diameter of the print head nozzle of an inkjet cartridge is significantly narrower than the cutting diameter of a human hair. Due to the microscopic nature of the nozzles, ink cannot flow out on its own. The smaller the print head nozzle, the smaller the size of the droplet emitted from it. In turn, the smaller the ink drop, the less grainy the image and the higher its clarity, accuracy, and resolution.

On the other hand, the smaller the print head nozzle, the greater the likelihood of ink drying out in it and the cartridge failing. Consequently, the smaller the print head nozzles, the more capricious the inkjet cartridge.

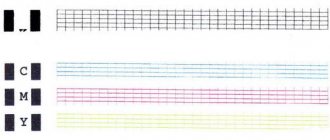

The size and shape of nozzles in inkjet printers varies depending on the printer model and inkjet printing technology. The figure below shows three printhead nozzles for inkjet printers using different printing technologies. drop 4 pl

drop 3 pl

drop 5 pl

Print head nozzles for inkjet printers using various inkjet printing technologies

The nozzle of a micro-piezo inkjet cartridge is significantly larger than that of a thermal inkjet cartridge. But thanks to meniscus control technology, droplets flying out of a micropiezo nozzle can be smaller than droplets flying out of narrow nozzles. The use of micropiezo technology makes it possible to obtain ink droplets measuring 3 pl with a nozzle diameter of 25 microns. In thermal inkjet printing, the smallest drops are 4-5 pl in size.

Print Head Nozzles Different printers have different nozzle placement on the print head.

Some manufacturers equip their cartridges with nozzles of the same size, others alternate small and larger nozzles, staggering them.

Ink

The next integral element of an inkjet cartridge is ink. Ink can be of different types: pigment, sublimation, water-soluble, solid, solvent and others. The choice of ink type depends on the inkjet printing technology.

You should only print with inks that are fully suitable for your inkjet printer. The quality of the print and the uninterrupted operation life of the inkjet printer depend on the quality of the ink used.

An indispensable requirement for ink for inkjet printers is a fine spectral composition, the presence of which ensures freshness and purity of shades. In order to create new interesting shades when printing using primary ink colors, it is necessary that the ink remains transparent when dried and does not change its color. The ink must be non-toxic, environmentally friendly and fade-resistant.

Special elements

Cartridges designed for piezoelectric printing are equipped with a piezoelectric plate that can bend under the influence of electric current. By bending, the plate reduces the volume of the ink reservoir, and the ink is squeezed out of the nozzles onto the paper.

Inkjet cartridges designed for bubble jet and thermoelectric printing are equipped with heating elements that heat the ink to boiling point and form steam. The ink heats up and forms bubbles, which push ink drops out of the nozzles and onto the paper.

Chips Recently, almost all manufacturers are equipping their inkjet printers with security chips, which make refilling cartridges more expensive and difficult, and in some cases completely impossible.

Ink cartridge chip

The memory of the inkjet cartridge chip stores information about the type of cartridge, its manufacturer, date and time of manufacture, activation date, effective period of use, the number of installations of the cartridge in the printer and the amount of ink consumed. Calculating the amount of ink consumed is very arbitrary, and in fact, a supposedly “empty” ink cartridge may turn out to be 30-50% filled with ink.

Cartridge of all times and peoples HP No. 45

There is another type of cartridge with a print head.

A typical representative is HP51645 (No. 45) for an HP printer.

It contains a sealed container with flexible walls and an elastic spring inside and a print head.

In front of the print head there is also a filter with very small cells that does not allow clots and other “garbage” to pass through.

An elastic spring from the inside expands the flexible walls and maintains a certain vacuum .

The force of gravity is balanced by the reduced pressure, and the ink does not flow out when there is no printing.

Cartridge No. 45 is a very successful development by HP and is still in use today.

It's a pity that printers for working with such cartridges are no longer produced. This record holder has a fairly large capacity - 42 ml and a long print head resource. It lends itself well to refilling.

If you handle it carefully, it can withstand dozens of refills . It is refilled through a hole in the bottom, which is closed with a steel ball and sealed with a round paper sticker.

When reusing this cartridge, the problem with the ink levels not displaying correctly remains. It can be solved in the same way - by manipulating the sealing of individual contacts.

Another advantage of this cartridge is that it has a sealed ink container. Thus, the nozzles do not dry out from the inside , only from the outside. Therefore, it is possible to resuscitate even such copies that, being empty, were removed and lay for several months separately from the printer.